Professional Documents

Culture Documents

Construction, Design and Evaluation of Tailings Dams For New Mining Projects

Construction, Design and Evaluation of Tailings Dams For New Mining Projects

Uploaded by

Amine SammaaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction, Design and Evaluation of Tailings Dams For New Mining Projects

Construction, Design and Evaluation of Tailings Dams For New Mining Projects

Uploaded by

Amine SammaaCopyright:

Available Formats

CONSTRUCTION, DESIGN AND EVALUATION OF TAILINGS DAMS FOR

NEW MINING PROJECTS

Vlad COSMA Ph. D Student, University of Petrosani

Gheorghe LASC Ph. D Student, University of Petrosani

Oana BRIAC Ph. D Student, University of Petrosani

Susana IANCU Ph. D Student, University of Petrosani

ABSTRACT: This paper intends to discuss general features of tailings dams and embankments, the most significant

factors to be considered while designing and evaluating the construction and methods of analysing the

embankments stability.

KEY WORDS: construction, mining, tailing dams, stability

1. INTRODUCTION

Design depends on the quantity and the individual

characteristics of the tailings produced by the mining

operation, as well as the climatic, topographic, geologic,

hydro-geologic and geotechnical characteristics of the

disposal site, and on regulatory requirements related to

dam safety and to environmental performance.

It is essential that each specific dam has its own

design process and one important factor is the estimated

quantity of tailings to be disposed.

One significant aspect to be considered while design

and construction are done is to minimize adverse effects

to the environment.

The stability of the tailings impoundment is also

dependent on foundation characteristics, such as shear

strength, compressibility, and permeability. Depending

on soil characteristics, the layout can be adapted to

account for high permeability materials in the design

through the use of liners and/or adequate internal

drainage.

2. THE NEW MINING PROJECT IN ROMANIA

The Metaliferi Mountains represent an anomaly of

the European gold metallogeny and constitute one of the

most productive gold areas in Europe and worldwide,

especially due to the number of ore deposits, mined and

discovered gold reserves vs. the surface of the

metallogenic province [11]. Along the perimeter of the

Golden Quadrilateral, Fig 1, are proposed three new

mining projects which will operate gold and silver

deposits: Rosia Montana, Rovina and Certej all of them

are companies established in Romania, with majority

private shareholders. Rosia Montana Gold Cororation,

RMGC obtains the concession license for exploitation

in 1999, for the exploitation of gold and silver ores in

the Roia Montan area.

The mining perimeter of RMGC has a surface of

21.45 square kilometers and it overlaps the area of

231

Valea Roia River and its junction with Abrud River.

[13]

The project covers 25% of the surface of Roia

Montan Commune, a traditional mining community,

located in Apuseni Mountains.

Roia Montan Mining Project includes the

following objectives: the processing plant, Corna Valley

Tailing Management Facility TMF, 4 open pits: Cetate,

Carnic, Jig and Orlea, the waste dams of Gura Roiei

and Valea Slitei. In addition to these main access

roads, service roads will be constructed to connect the

plant site, open pits (Cetate, Crnic, Jig and Orlea),

waste rock dumps (Cetate and Crnic) and the Corna

TMF Dam. [13]

The 4 pits will be mined in two stages: Cetate and

Carnic during the first 9 years, whereas the pits from

Orlea and Jig will be open after the 9th year, and the

mining in Cetate pit will continue. Ore mining in the

pits will be carried out until year 14. The closure of the

pits and stockpiles will take place gradually, with Cetate

stockpile as of year 5, the stockpile and pit of Carnic as

of year 9, and Orlea and Jig pits during years 12 14.

The tailings dams of Gura Roiei and Valea Slitei are

located in the Wstern part of the area, on the left bank of

Abrud River, the tailings dam of Gura Roiei, and,

respectively, the tailings dam of Valea Slitei in the

valley of Slite Creek. They have a surface exceeding

40 hectares and they store a total volume of waste of 3.4

mil. m3.

A series of investigations were carried out in view of

developing a detailed understanding of the TMF site

characteristics which provided information on the

geology, hydrogeology and geotechnical conditions of

the region and location of TMF dams.

3. BASIC DESIGN CONCEPTS

STABILITY ANALYSIS

OF

THE

In general, tailings impoundments (and the

embankments that confine them) are designed using

information on tailings characteristics, available

construction materials, site specific factors (such as

topography, geology, hydrology and seismicity) and

costs. [4]

One of the basic principles used in the design of

impoundments and their embankments is the

maintenance of the phreatic surface within the

embankment. The phreatic surface is the level of

saturation in the impoundment and embankment (the

surface along which pressure in the fluid equals

atmospheric pressure. The phreatic surface exerts a

large degree of control over the stability of the

embankment, under both static and seismic loading

conditions. The major design precept is that the phreatic

surface should not emerge from the embankment and

should be as low as possible near the embankment face.

This basically maintains a pore pressure at the face of

the embankment lower than atmospheric pressure plus

the weight of the embankment particles and maintains

the face of the dam. Thus any factors that might affect

the phreatic surface in the embankment may also affect

stability of the embankment. [8]

Fig. 1 Ore deposits and occurrences of mineralization in the Golden Quadrilateral, Apuseni Mountains [11]

3.1 Geological and geo-morphological factors

Even if they do not represent a direct cause of the

landslides, the geological factor is especially important

in their generation; this is why the diagram and

methods for forecasting the stability of the tailings

dams must be chosen depending on the geological

conditions.

3.2 Hydro-geological factor

It plays an important role for generating the slide

surface, and the presence of water in the rocks

influences the unit stress condition by the following

elements [4]:

the variation of the humidity in unsaturated soil;

hydrostatic pressure of the water in pores;

hydrodynamic pressure of the underground water.

When the water level decreases, a load increase

may be recorded, due to the cancellation of the waters

negative pressure effect, a phenomena manifesting

especially in the case of permeable rocks. The water in

the pores creates a pressure leading to the decrease of

the shearing strength of the rocks as a result of the

decrease of the actual pressure on the slide surface. All

these enforce the execution of drainage as effective as

possible of the base of the tailings dam in order to

232

completely remove the accumulated water to decrease

its hydrostatic level, a fact leading to the improvement

of this causes influence and the increase of the overall

stability of the rocks from the dam.

If the foundation base on which the dam shall be built

is not drained and the water stagnate in its vicinity, the

blocks rolling down on the embankment become

saturated with water and generates mud, which, soaking

the dams materials, discharges and generates

deformations. [3]

3.3 Geo-technical and geo-mechanical factors

Taking in consideration the geo-technical factor

always implies the determination of the strength

parameters and the weakest surfaces of the foundation

base, where the slide forces are concentrated. [1,2].

These surfaces may be considered stratification surfaces,

the fracture planes or the contact surfaces of the rocks

from the earthworks with the foundation base. In the

case of earthworks, it is considered that, during the

initial stage, the stored material lacks cohesion.

Nevertheless, due to the action of geological load, the

earthworks consolidate naturally and attain a certain

cohesion that must be taken into consideration in the

stability calculations. [5]

3.4 Anthropogenic (technogenic) factors

They refer to the changes of the stress and tensions

status in the earthworks due to the engineering action of

the human factor. Among these factors are mentioned the

overload of the earthworks in the upper part by the

technological machines placement and traffic or by

storing the rocks, respectively the excavation of the rocks

in the lower part of the earthworks. These factors change

the relation between the resistance forces and the forces

stressing the earthworks generating landslides.

In the same category may also be included the

earthworks geometric elements (gradient and elevation)

that are set out by geotechnical project and that influence

the stability level.

3.5 Hydro-meteorological and seismic factors

The rainfalls increase the humidity of the rocks

forming the earthworks and, implicitly, decrease the

stability reserves of even generate landslides. As a result

of the experimental research in the filed of earthworks

construction, it was found that the moistening of the

rocks of the foundation base may be detected at various

depths (2 3) m from the surface. The seismic factor it

is known that, during an earthquake, the seismic action

may go in any direction; due to this reason, it is considered

to be horizontal in the calculation, this being the worst case

condition as regards the effect on the earthworks stability.

[6]

4. EMBANKMENT CONSTRUCTION- LINERS

USAGE AND DRAINAGE SYSTEMS

Two research directions are followed in the tailings

dam stability study: dams stability and foundation

bases stability.[10]

Environmental considerations may create a need for

liners since tailings may have a potential to leach toxic

or undesirable constituents to underlying strata. Liners

may be composed of compacted native soils, compacted

tailings slimes. For economic reasons, compaction of

native soils or tailings slimes is the preferred methods of

reducing the permeability of impoundment bases.

The primary function of drainage systems is the

dissipation of pore pressure across the embankment.

[10]

5. MATHEMATIC METHODS IN ANALYZING

THE

STABILITY

OF

THE

MINING

CONSTRUCTION

The analysis of the dams stability is performed

based on the calculation of the stability factor FS , its

value indicating if the gradient shall slide or not.

The stability factor can be calculated depending on

the shearing strength parameters, in the simplest case of

non-cohesive soil, the stability factor being:

FS =

tg

tg

(1)

233

where, is the inside friction angle of the embankment

and earthworks material, corresponding to the shearing

strength, and is the gradient of the rewired slope.

A more complete definition is given by comparing

the stresses on the slide surface plane, respectively:

FS =

(2)

where, f represents the shearing strength put into

action, and is the value of the shear stress generated in

the body of the construction.

This definition also involves the concept of action

level m, being

m=

l

=

f FS

(3)

All definitions show that, in order to assure the

dams stability, the FS must have values greater that one,

FS.> 1.

There are two main categories of stability analyses:

balance (static) methods, and, respectively, deformation

(hyperstatic) methods, which take into consideration the

ratio stress-deformation, as well as certain mixed

methods. [9]

The static methods are based on the analysis of the

landmarks from massive; they are presently the most

used. These methods admit the sliding of a portion of

the earth massive, by making up a well defined sliding

surface and study the balance of this portion under the

action of the external forces at the time of starting up of

the movement.

The methods of the ultimate balance use the

equations of the static balance for calculating the

average value of the tangential shearing effort and of

the normal effort , which satisfy the Coulomb criteria:

= tg + C

(4)

Most of the methods divide the free mass, outlined by

the sliding surface in n vertical strips.

In order that the balance is ensured, the following

conditions must be satisfied:

1. the forces acting on each strip should be in balance

(the polygon of forces should close up);

2. the vectorial amount of the resultants of the forces

that arise on the separation surfaces between each

pair

of

strips

must

be

X i = 0 );

null

Ei = 0 ,

3. the sum of the moments of all forces in relation to

any point of the plan, therefore in relation to the

rotation center 0, must be null.

These conditions are materialized through equations

of balance of the vertical forces (

horizontal forces (

X i ) and of the

Ei ). The methods of analysis of

the stability may be classified according to the way in

which they satisfy such equations.

The methods satisfying all the balance equations

take into consideration 3 equations on strip, therefore 3n

equations. The unknown are: n values of N (one on a

strip), (n-1) for X (one on the interface), (n-1) for E, (n-

1) for the position of E (noted hE) and another unknown

FS, totalizing (4n-2) unknown. Therefore there are

necessary (n - 2) additional equations resulted from

supplementary hypotheses.

Only the Janbu and Morganstern-Price methods

satisfy all balance conditions. In the analysis of the

stability of earthworks, the most used methods are,

Fellenius, Janbu and Bishop, for which there are presently

many calculation programs or dedicated software,

developed on these methods.

The recommended values for the safety coefficients

are, Fs > 1.5. The experience shows that:

- the earthwork remains stable if, Fs > 1, 5;

- the braking risk arises for , 1< Fs< 1,5

The methods of assessment of the stability may be

grouped as follows:

o assessment of the possibility that an earthwork may be

involved in a sliding phenomenon;

o the assessment of the stability of different types of

earthworks in different conditions (for instance, at the

completion of their building or after some time);

o the analysis of the stability of the sliding body, in order

to understand the mechanisms that determined the

breaking of the earthworks;

o economic assessment of the works of restoration over

the earthwork stability;

o the assessment of the effects of dynamic loading, such

as those induced by earthquakes ;

o understanding the evolution of the natural forms

emphasized by the morphological analyses.

Normally, one would rather choose the Janbu

methods, as it is a more precise method and allows more

ample analyses of the tailings dam stability.

5.1 Fellenius Method

In order to determine the coefficient of stability, the

sliding mass, determined by the sliding surface established

through the same method is divided into several strips,

Fig. 2.

Usually, the width of a strip is bi = 0.1R. If such a ratio

is taken into account, it results a too big number of strips

(or too small), and consequently it is adopted an average

width that should lead to a total number of strips between

5 and 10. In this case, the expression of the coefficient of

stability Fs is provided by the ratio between the sum of the

moments of the forces opposing Mr to the sliding and the

sum of the moments of the forces that converge to put in

movement the earthworks Ma.

Fs =

Mr

Ma

(5)

The rocks resistance coefficient, and C, are

taken as average values along the sliding surface L. The

authors of the Swedish method outlined that on the two

sides of the strip, considered on the sliding direction,

another two categories of forces: Xi forces that are vertical

shearing forces and the horizontal forces Ei .The Xi forces

being very similar as size, and of contrary direction, were

neglected in the general balance of the sliding mass. Later

on, Bishop took into consideration the Xi forced in the

234

analysis of the stability, and the difference between the

two resultants was only 1 %. As concerns the Ei,

horizontal forces Fellenius showed that, if they are not

taken into account, it is only produced an error of 5 %.

Fig. 2 Method of calculation of the stability coefficient

according to Fellenius

So that the earthwork would not slide, the calculated

safety coefficient must be improper, meaning s >1. For

less than a unit values, the massive losses the natural

balance and the sliding of the examined earthwork takes

place.

5.2 Janbu Method

Janbu Method is a simplified extrapolated version also for

the cases when the earthworks is made of many layers

with different physical and mechanical properties and is

based on the calculation of the shearing effort.

The sliding surface is divided into more strips, like in

case of the Fellenius methods.

There are calculated the vertical and horizontal

pushing forces for each strip and then the stability

coefficient. These are implicit equations and are solved

iteratively, making as much iteration as are necessary until

obtaining the right solution

5.3 Bishop method

This method is based on the hypothesis that the active

side forces for a single strip have null resultant after the

vertical direction.

At the Fellenius method, for determining the stability

coefficient, the sliding mass, determined by the sliding

surface established by this method is divided into more

strips.

Janbu method is an extrapolated version also for the

situations when the earthworks are made of many layers

with different physical and mechanical properties and are

based on the calculation of the shearing effort. The sliding

surface is divided into more strips, the calculation

principle being shown in the figure 2.

6. GEOMECHANICS TESTS IN STUDIED AREAS

All methods for analysing mining construction

stability are based on the rocks geomechanical study.

Therefore lab tests have been made in the Analysis and

Construction Tests Laboratory from Petrosani

University on rocks collected from the new mining

projects areas. [1, 2] The main physical and mechanical

characteristics which are particularly relevant to carry

out the stability study are presented next and have been

made available to development engineers.

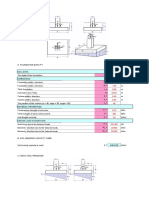

The results are presented in Table 1 and Table 2

which summarise the lab tests.

7. CONCLUSIONS AND REMARKS

The water from pores creates a pressure that leads to

reduction of the rocks shearing resistance as a result of

the diminution of the effective pressure on the sliding

surface.

Among the anthropogenic factors with influence over

the stability of earthworks, we mention the overloading

of the earthworks on the upper part by the setting and

running of the technological machines, the rocks storage,

respectively the excavation of rocks at the lower part of

earthworks. These factors modify the ratio between the

resistance forces and the forces that stresses over the

earthworks for sliding.

The stability degree is influenced also by the

geometric elements of the earthworks, the inclination

and the height that are established by geotechnical

projects. The calculation of the shearing effort is based

on physical and mechanical properties.

The seismic factor, the seismic action, may have any

direction, but the most dangerous is deemed the horizontal

one, as it is the most unfavorable concerning the effect

over the stability of earthworks.

The analysis of the stability of earthworks is made

though the models: Fellenius, Janbu and Bishop but the

Janbu method is preferred, as it is a more precise

method and allows more ample analyses of the stability

of the tailings dam.

The experience showed that the breaking risk arises

for 1< Fs< 1.5 and the earthworks remain stable if Fs >

1.5;

A review of the practice in tailings

dam/impoundment design and construction shows that

great technical progress has been made. Better

investigation and design tools are available.

New technologies in construction and geomembrane liners are commonly used where tailings may

present a risk of groundwater contamination, and design

and construction methods for lined impoundments have

been developed. Improvements have been made to the

traditional upstream construction method to reduce

stability risks.

Environmental

considerations

have

become

increasingly more important in tailings dam design and

permitting.

Sample no.

Table 1. Physical properties of rocks from mining areas of interest

Mining

The

The

Porosity

Limits of

Plasticity

area

comprebulk

n

plasticity

Index

[%]

ssibility density

IP

module

a

Upper Lower

M

[kN/m3]

Wc

Wf

[KPa]

1

7981

18.70

30.22

36.15 21.65 14.50

Certej-

Rosia

Montana

Rovina

Graininess/ degree of

uniformity,

Rock type, U

Screening

Fine sand

Neuniform

U=3.197

Dust,Very

uniform

-

Large sand

Irregularly

Fine sand

Irregularly

Fine sand

Irregularly

U=6.461

Dust, Uniform

U=11.205

Dust, Uniform

U=4.676

Dust,

Very

uniform

U=6.070

Dust, Uniform

U=3.556

Dust,

Very

uniform

U=2.526

Dust.

Very

uniform

U=5.749

Dust, Uniform

23.58

13.53

17,79

31,50

12352

17.24

35.36

5924

17.31

34.23

51.32

32.57

18.75

6103

17.26

35.31

5178

18.99

21.50

46.25

21.96

24.29

6306

20.76

18.36

Small gravel

Irregularly

4719

18.04

26.52

Large sand

Irregularly

235

Settling

Large sand

Irregularly

Fine sand

Irregularly

Certej

Rosia

Montana

Rovina

Sample no.

Table 2 Mechanical characteristics of rocks from mining area of interest

Mining

area

UCS

[kPa]

Compressive strength triaxial

TCS

[kPa]

Drained

Undrained

485.0

1047.9

1236.1

651.1

883.4

475.3

1055.3

1232.6

701.0

905.3

499.5

1095.2

1247.2

696.3

911.3

242.5

562.9

795.2

430.7

618.8

154.3

761.3

949.5

298.4

464.5

176.3

629.0

971.5

496.8

751.1

141.1

496.8

618.8

298.4

486.6

66.1

342.5

486.6

188.2

310.2

88.2

364.5

508.6

254.3

420.4

REFERENCES

[1]. Arad, V., Arad, S., 1995. The stability and

reliability analysis of development openings in the Jiu

Valley, Proceedings of the Fourth International

Symposium on Mine Planning and Equipment

Selection, Eds. Singhal, Mehrotra, Hadgigeorgiou,

Poulin, Balkema Publisher, pp. 825-827, 1117 pg.,

Calgary, Canada, ISBN 90 54 10 569 0

[2] Arad, V., Arad, S., Nita, A., Baciu, F., Nistor, C.,

Anca, D., 2011. Geomechanical characterization of

rocks from Sibiu County used in construction,

Proceedings Paper, International Multidisciplinary

Scientific Geo Conference, pp. 467-473, DOI:

10.5593/sgem2011, Sofia, Bulgaria ISSN 1314-2704,

2011

[3] Das, B.M., 1990. Principles of Geotechnical

Engineering, Second Edition. PWS-Kent Publishing

Corp., Boston, Massachusetts.

[4] Davies, M.P., T.E. Martin and P.C. Lighthall, 2000.

Tailings dam stability: essential ingredients for success.

Chapter 40, Slope Stability in Surface Mining, SME, pp.

365-377.

[5] Davies, M.P. and S. Rice, 2001. An alternative to

conventional tailings management dry stack filtered

tailings. . "Tailings and Mine Waste 2001," Fort Collins,

Colorado, pp. 411- 420.

[6] Dougherty, E.R., 1990. Probability and Statistics for

the Engineering, Computing, and Physical Sciences.

Prentice Hall: New Jersey, 800 pages.

236

Cohesion/

Friction angle

from TCS

C/

[kPa]/[]

Drain

Uned

drained

Shear strength

[kPa]

313.4/

17.8

312/20

137.4/

23.5

187/22

175

208.3

225

238.1

Cohesion

/

Friction

angle

from

Share

strength

[kPa]/[]

104.2/30

175

210.5

225

245.6

107.2/31

315.3/

21

108.5/

23.5

208.9/

17.8

77.4/

33.2

169.6/

5.7

82.6/

10,4

91.8/

10.4

191/23

175

212.5

225

243.7

110/30.5

88.4/

17.8

51.3/

14.4

76.0/

25.8

40.2/

17.8

29.9/

5,7

34.2/

14.4

175

160.7

225

178.6

98.2/19.7

175

125.0

225

142.9

62.5/19.7

175

166.7

225

208.3

20.8/39.8

175

101.2

225

131.0

23.8/25.5

175

65.5

225

89.3

35.7/13.4

175

89.3

225

107.1

26.8/19.7

[7] Doyle, F.M. (ed.)., 1990. "Mining and Mineral

Processing Wastes: Proceedings of the Western

Regional Symposium on Mining and Mineral

Processing Wastes, Berkeley, CA, May 30 - June 1,

1990." Society for Mining, Metallurgy, and Exploration,

Inc. Littleton, Colorado.

[8] Dunne, B. 1997. Managing design and construction

of tailings dams. Proceedings of the International

Workshop on Managing the Risks of Tailings Disposal.

ICME-UNEP, Stockholm, pp. 77-88.

[9] Michael P. Davies, Peter C. Lighthall, Steve Rice

and Todd E. Martin Canadian Dam Association (CDA)

1999. Dam Safety Guidelines.

[10] International Committee on Large Dams (ICOLD)

1994. Tailings Dams Design of Drainage Review

and Recommendations, Bulletin 97.

[11] Popescu Gh. C., 1986. Applied metallogeny and

geological prognosis (in Romanian), Part 1. Ed. Univ.

of Bucharest.

[12] Popescu Gh. C., Neacsu, A., 2012. Modeling of

epithermal gold and porphyry copper deposits from

metaliferi mountains (Romania), Romanian journal of

mineral deposits, Geological Institute of Romania

Society of Economic Geology of Romania, ISSN 12205648, vol 85 issue 1, Bucharest, 2012

[13] RMGC project, http://www.rmgc.ro/

[14] U.S. Environmental Protection Agency Office of

Solid Waste Special Waste Branch, Design of Tailings

Dams and Impoundments

You might also like

- Cohesive Sediments in Open Channels: Erosion, Transport and DepositionFrom EverandCohesive Sediments in Open Channels: Erosion, Transport and DepositionNo ratings yet

- A Review of Catastrophic Flow Failures of Deposits of Mine WateDocument17 pagesA Review of Catastrophic Flow Failures of Deposits of Mine WateAbraham FIgueroa ARevaloNo ratings yet

- UniPile5 Examples Manual PDFDocument54 pagesUniPile5 Examples Manual PDFkabasy2015No ratings yet

- Olson 2001 PDFDocument564 pagesOlson 2001 PDFDaiane SouzaNo ratings yet

- Design of Small Diameter Frictional Piles and Cases StudyDocument71 pagesDesign of Small Diameter Frictional Piles and Cases StudyLeung Liang50% (2)

- Hydraulic Design AssignmentDocument6 pagesHydraulic Design AssignmentTapiwanaisheNo ratings yet

- EnergiesDocument26 pagesEnergiesOscar Javier ArevaloNo ratings yet

- File 0147 Jeoteknik Ve Enjeksiyon-KKARAKUS-AKOCBAYDocument7 pagesFile 0147 Jeoteknik Ve Enjeksiyon-KKARAKUS-AKOCBAYMuhammadImranShahzadNo ratings yet

- Seismic Deformation Analysis of A Rockfill Dam With A Bituminous Concrete CoreDocument10 pagesSeismic Deformation Analysis of A Rockfill Dam With A Bituminous Concrete CoreFioz AriyandiNo ratings yet

- Rock MechanicsDocument139 pagesRock MechanicsAastha Soni100% (1)

- Problem Analysis of Geotechnical Well Drilling in Complex EnvironmentDocument7 pagesProblem Analysis of Geotechnical Well Drilling in Complex EnvironmentElgi Zacky ZachryNo ratings yet

- Stability Conditions in Lignite Open Pits From RomDocument22 pagesStability Conditions in Lignite Open Pits From RomJorge SalasNo ratings yet

- Imwa2000 16Document15 pagesImwa2000 16MezamMohammedCherifNo ratings yet

- Design of Diversion Dam in Tarbela Dam Pakistan: Graduate School of Water ResourcesDocument27 pagesDesign of Diversion Dam in Tarbela Dam Pakistan: Graduate School of Water Resourceskadek purnNo ratings yet

- Engineering Geology NotesDocument8 pagesEngineering Geology NotesRudra SinghNo ratings yet

- Bundu Tuhan Landslide 2011Document12 pagesBundu Tuhan Landslide 2011Zeric TengNo ratings yet

- Geomechanical Evaluation of An Onshore Oil Field in The Niger Delta, NigeriaDocument13 pagesGeomechanical Evaluation of An Onshore Oil Field in The Niger Delta, NigeriaJairo CortesNo ratings yet

- Bukowski-bromek-Augustyniak-2006-Using The Drastic System To Assess The Vulnerability of Ground Water To Pollution in Mined Area of The Upper Silesian Coal BasinDocument8 pagesBukowski-bromek-Augustyniak-2006-Using The Drastic System To Assess The Vulnerability of Ground Water To Pollution in Mined Area of The Upper Silesian Coal BasinraulxNo ratings yet

- Research Critique Part 2Document8 pagesResearch Critique Part 2azziraem jaranillaNo ratings yet

- Ii 2017Document5 pagesIi 2017Anonymous iWaBM6P9V6No ratings yet

- Design Criteria For DamDocument42 pagesDesign Criteria For Damjnf75% (4)

- Mining Geomechanics - AWestern. AustraliaDocument6 pagesMining Geomechanics - AWestern. AustraliaAlonso ValerianoNo ratings yet

- Elements of Dam EngineeringDocument11 pagesElements of Dam Engineeringreem.ranoom.moon100% (4)

- Drainage For DamsDocument10 pagesDrainage For Damschutton681No ratings yet

- Slope Movement Types and Processes - 2nd WeekDocument38 pagesSlope Movement Types and Processes - 2nd Weekanilmizrak2199No ratings yet

- Sustainability 12 06667 v2Document30 pagesSustainability 12 06667 v2yehunzer yeneshNo ratings yet

- Hudson, J. A. and Harrison, J. R. - Rock Mechanics (Part1) - 40Document1 pageHudson, J. A. and Harrison, J. R. - Rock Mechanics (Part1) - 40Khatri NiwasNo ratings yet

- Reservoir Rim Slope Stability Due To Rainfall and Operation of Susu DamDocument6 pagesReservoir Rim Slope Stability Due To Rainfall and Operation of Susu DamShah FaisalNo ratings yet

- Water 14 02486Document17 pagesWater 14 02486Janmarc PadilskiNo ratings yet

- 1 PBDocument9 pages1 PBpipit musdhalifaNo ratings yet

- Sensors 18 04373Document13 pagesSensors 18 04373etsimoNo ratings yet

- Esrael Hungwe Assignment 1Document5 pagesEsrael Hungwe Assignment 1ESRAEL HUNGWENo ratings yet

- Chapter 1 IntroductionDocument11 pagesChapter 1 IntroductionLondeka MnguniNo ratings yet

- SPE 142713 - Tight Gas Reservoirs - Geological EvaluationDocument9 pagesSPE 142713 - Tight Gas Reservoirs - Geological EvaluationPedroNo ratings yet

- TMW 2022 - Application of 3D Limit Equilibrium Method in Tailings Dam Breach AnalysisDocument12 pagesTMW 2022 - Application of 3D Limit Equilibrium Method in Tailings Dam Breach AnalysisTeklweini A MehariNo ratings yet

- Forests 14 00808 v3Document20 pagesForests 14 00808 v318-1-01533No ratings yet

- Jigjiga University: Dep:-Hydraulic EngineeringDocument17 pagesJigjiga University: Dep:-Hydraulic Engineeringshucayb cabdiNo ratings yet

- Design Considerations of A High Rockfill Dam Nam Ngum 2 0709 PDFDocument12 pagesDesign Considerations of A High Rockfill Dam Nam Ngum 2 0709 PDFnavin263No ratings yet

- 1 Ch1 and 2 Introduction and Relationship Between Eng Geology and Structures 2022 2023Document19 pages1 Ch1 and 2 Introduction and Relationship Between Eng Geology and Structures 2022 2023Yousif MawloodNo ratings yet

- Engineering Geology 1Document203 pagesEngineering Geology 1B Divya jyothiNo ratings yet

- Instability Mechanism Pressure Relief and Long AncDocument21 pagesInstability Mechanism Pressure Relief and Long Ancbisk0tNo ratings yet

- Geotechnical Investigations For Tunnelling byDocument47 pagesGeotechnical Investigations For Tunnelling byfarman aliNo ratings yet

- Finall Assessment Report (Confirm)Document24 pagesFinall Assessment Report (Confirm)nulhassan442No ratings yet

- Kostic Et Al - 2016Document10 pagesKostic Et Al - 2016SrdjanNo ratings yet

- Embankment Slope Stability Analysis of Dwight Mission Mine Site RDocument10 pagesEmbankment Slope Stability Analysis of Dwight Mission Mine Site REric ChanNo ratings yet

- INTRODUCTION: (Importance To A Civil Engineer) :: Engineering Geology Unit - IDocument13 pagesINTRODUCTION: (Importance To A Civil Engineer) :: Engineering Geology Unit - IsivabharathamurthyNo ratings yet

- Engineering Geology UNIT-I Part-IDocument14 pagesEngineering Geology UNIT-I Part-IsivabharathamurthyNo ratings yet

- Liquefaction Remediation: February 2012Document31 pagesLiquefaction Remediation: February 2012shakir shahNo ratings yet

- Some Critical Aspects of Subaqueous TunnellingDocument20 pagesSome Critical Aspects of Subaqueous TunnellingmetropodikasNo ratings yet

- An Open-Pit Coalmine Surcharged by Artesian Water PressureDocument22 pagesAn Open-Pit Coalmine Surcharged by Artesian Water PressurebrowncasNo ratings yet

- Fiver 33Document23 pagesFiver 33Hassan Raza GilalNo ratings yet

- Influence of DiscontinutyDocument11 pagesInfluence of Discontinutygia26No ratings yet

- Soil Mechanics Unit 1 NotesDocument31 pagesSoil Mechanics Unit 1 NotesBalaChandran92% (13)

- 14 - Liquefaction, PHD ProposalDocument8 pages14 - Liquefaction, PHD ProposalNaghizadehrokni100% (1)

- Notes 1Document59 pagesNotes 1Burkan YayçıNo ratings yet

- CFRD 17 - Roy Ruiz VásquezDocument18 pagesCFRD 17 - Roy Ruiz VásquezjnfNo ratings yet

- Pipeline Geotechnical EngineeringDocument12 pagesPipeline Geotechnical Engineeringlyonhearted0% (1)

- Chapter 1-INTRODUCTIONDocument11 pagesChapter 1-INTRODUCTIONLondeka MnguniNo ratings yet

- Case Studies of Dam FailuresDocument9 pagesCase Studies of Dam Failuresሚካኤል መሓሪ Michael Moges83% (6)

- Unit - 5 Geological Investigation in Civil Engineering: Geological Conditions Necessry For Construction of DamsDocument10 pagesUnit - 5 Geological Investigation in Civil Engineering: Geological Conditions Necessry For Construction of DamsYuvaraj DNo ratings yet

- Review EmbankmentDocument4 pagesReview EmbankmentHa NaNo ratings yet

- Fundamentals of the Petrophysics of Oil and Gas ReservoirsFrom EverandFundamentals of the Petrophysics of Oil and Gas ReservoirsNo ratings yet

- Reservoir Characterization of Tight Gas Sandstones: Exploration and DevelopmentFrom EverandReservoir Characterization of Tight Gas Sandstones: Exploration and DevelopmentNo ratings yet

- Pondasi Tapak P1Document6 pagesPondasi Tapak P1abduh81No ratings yet

- Plaxis Bulletin 31Document20 pagesPlaxis Bulletin 31sb1966No ratings yet

- Prokon Product ROCK STABILITY ANALYSIS v1.0Document3 pagesProkon Product ROCK STABILITY ANALYSIS v1.0rodain najjarNo ratings yet

- Newmark Deformation AnalysisDocument5 pagesNewmark Deformation AnalysisJhinNo ratings yet

- Cavity Expansion in SandsDocument21 pagesCavity Expansion in SandsszilvagyizsoltNo ratings yet

- Ubstructure Esign: Bridge Design Manual - 2002 Substructure DesignDocument14 pagesUbstructure Esign: Bridge Design Manual - 2002 Substructure DesignHundeejireenyaNo ratings yet

- Heap Slope DesignDocument14 pagesHeap Slope DesignNoon Abdallah AbdalroufNo ratings yet

- A Comparison Between Limit Equilibrium and Finite Element Methods For Slope Stability AnalysisDocument18 pagesA Comparison Between Limit Equilibrium and Finite Element Methods For Slope Stability AnalysisGabriel ArirupaNo ratings yet

- Grouting On Sandy SoilDocument48 pagesGrouting On Sandy SoilSabari PrasanthNo ratings yet

- 1 19446 WP Landfill KLAVDocument6 pages1 19446 WP Landfill KLAVbrowncasNo ratings yet

- PLAXIS - 3D - CEV21 - Tutorial - 07 - Rapid Drawdown Analysis (ULT)Document15 pagesPLAXIS - 3D - CEV21 - Tutorial - 07 - Rapid Drawdown Analysis (ULT)Tirawat SimlemkimNo ratings yet

- Lateral Load Capacity of PilesDocument9 pagesLateral Load Capacity of Pileschutton681No ratings yet

- Análisis Dinámico Con FLACDocument294 pagesAnálisis Dinámico Con FLACHennry VargasNo ratings yet

- Multi-Stage Rapid DrawdownDocument9 pagesMulti-Stage Rapid DrawdownlucaggNo ratings yet

- Practical Approaches To Sand Management, Andrew Acock, 2004Document18 pagesPractical Approaches To Sand Management, Andrew Acock, 2004Anonymous Xy309m9Sm9No ratings yet

- Hanna TibebuDocument119 pagesHanna Tibebuambachew64No ratings yet

- Predictions in Soil EngineeringDocument52 pagesPredictions in Soil Engineeringxieyn100% (1)

- CEN 512 Shear Strength of SoilsDocument5 pagesCEN 512 Shear Strength of SoilsRustom RemorozaNo ratings yet

- ICGE 15 KN 04 Endicott PDFDocument10 pagesICGE 15 KN 04 Endicott PDFDiego SerónNo ratings yet

- Registro C22-S3-PPDocument13 pagesRegistro C22-S3-PPAndres ViasusNo ratings yet

- Allowable Load On Single PileDocument16 pagesAllowable Load On Single PileSugiarto SaptomoNo ratings yet

- Fig. 3.5: Adhesive Wear. All Theories Which Predict Wear Rates Start From The Concept of TrueDocument42 pagesFig. 3.5: Adhesive Wear. All Theories Which Predict Wear Rates Start From The Concept of TruevishiwizardNo ratings yet

- Geotechnical Engineering-Ii: BSC Civil Engineering - 5 SemesterDocument19 pagesGeotechnical Engineering-Ii: BSC Civil Engineering - 5 SemesterSaid-Mansour MohamedNo ratings yet

- Littlejohn 1970Document12 pagesLittlejohn 1970George HaileNo ratings yet

- Engineering 473Document593 pagesEngineering 473khudhayer1970100% (1)

- Theory Manual ENGLISH PDFDocument111 pagesTheory Manual ENGLISH PDFpoojaNo ratings yet