Professional Documents

Culture Documents

Pre - Commissioning Activities

Uploaded by

Sayan KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pre - Commissioning Activities

Uploaded by

Sayan KumarCopyright:

Available Formats

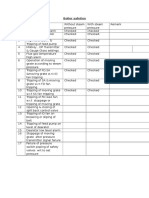

PRE-COMMISSIONING:Pre Commissioning activities A

GENERAL :

Checked level all the equipment and tightend their foundation bolts.

Checked all the motor wiring.

Checked and ensure that all the pipe lines and ducting are supported properly.

Checked all the strainer and valves for its operation.

Spiral agitators inserted in smoke tube

B BOILER :

Connection checked according to P&I digram.

Checked and tighten all the man holes and hand holes.

All flange joint bolts on boiler and steam line checked for mechanical fitness.

Checked and fixed the door ropes properly.

Checked all the mountings and fittings, they are fitted with proper gaskets at their

respective locations.

C.FEED WATER SYSTEM:

Done the Flushing of feed water pipelines.

Mobrey level switch is set the water level extra low, working satisfactory-OK

.Mobery level switches are set for ON, OFF operation of FW Pumps.

The strainers at pump suction are cleaned.

D. ELECTRICAL SYSTEM:

Loop testing of all the instruments and no load test of motor done.

Checked proper earth wires have been connected to all the motors and for

control panel.

Checked for the separate instrument earthing and power earthing connection to

control panel.

Checked the connection of PT, LT & TE (Flue gas).

Checked the voltage for 3 power supply.

Started the drives and checked for its correct rotation.

Set the OLR of all Motors as per their current ratting.

Checked the Trouble free operation of Mobrey (level controller).

E. FLUE GAS CIRCUIT :

Checked the chimney and duct connections and made sure that they are airtight.

Checked Economizer man holes nut bolts tightened

Checked refractory dimensions as per refractory drawing.

Checked the functioning of various dampers provided in the ducting.

All necessary bolts provided on ducting checked for mechanical

Fitness.

You might also like

- cOMMISSIONING 1 - WorksheetDocument60 pagescOMMISSIONING 1 - WorksheetPramod Dhir100% (1)

- Testing & Commissioning of Chilled Water PumpsDocument3 pagesTesting & Commissioning of Chilled Water Pumpsamg00733% (3)

- Pre Commissioning ChecksDocument25 pagesPre Commissioning Checkske72012No ratings yet

- Commissioning Procedure For A Boiler PDFDocument24 pagesCommissioning Procedure For A Boiler PDFpothan83% (6)

- Method of Statemnet For Testing Commissioning of Chilled Water PumpsDocument3 pagesMethod of Statemnet For Testing Commissioning of Chilled Water PumpsHasan V SNo ratings yet

- General Firefighting Wet Systems Method Statement For Testing & CommissioningDocument11 pagesGeneral Firefighting Wet Systems Method Statement For Testing & CommissioningAhmad Omar100% (3)

- Method Statement For Water Pump Testing and CommissioningDocument2 pagesMethod Statement For Water Pump Testing and CommissioningKamaruz Danial100% (12)

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhNo ratings yet

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocument2 pagesProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhNo ratings yet

- Method Statement For Installation of Firefighting Pump SetDocument13 pagesMethod Statement For Installation of Firefighting Pump SetRaj Kamal75% (4)

- Commissioning of HydroDocument59 pagesCommissioning of Hydropawannhpc100% (3)

- Method Statement of Sump PumpDocument3 pagesMethod Statement of Sump Pumpjames jatt Bond100% (2)

- Solar Hot Water PumpsDocument4 pagesSolar Hot Water PumpsJas JasminNo ratings yet

- Procedure For Testing & Commissioning of Water Booster Jockey PumpsDocument3 pagesProcedure For Testing & Commissioning of Water Booster Jockey Pumpsvin ssNo ratings yet

- Method Statement For Installation of Firefighting Pump Set PDFDocument13 pagesMethod Statement For Installation of Firefighting Pump Set PDFAhmed Issa100% (1)

- Commissioning ProcedureDocument24 pagesCommissioning ProcedureSumitskb100% (14)

- Testing and Commissioning Method Statement Procedure For Argonite SystemDocument2 pagesTesting and Commissioning Method Statement Procedure For Argonite SystemHumaid ShaikhNo ratings yet

- Water Balancing Procedures With Comments From Mechanical QCDocument22 pagesWater Balancing Procedures With Comments From Mechanical QCRaziKhan50% (2)

- V-Procedure Commissioning & Start Up Cooling TowerDocument9 pagesV-Procedure Commissioning & Start Up Cooling TowerGala Caesar AnugerahNo ratings yet

- Survey Works Rev 1Document12 pagesSurvey Works Rev 1Abraham JyothimonNo ratings yet

- SECTION 22 14 29 Sump Pumps Part 1 - General 1.1 DescriptionDocument353 pagesSECTION 22 14 29 Sump Pumps Part 1 - General 1.1 DescriptionMi doremiNo ratings yet

- Testing and Commissioning of Motor Control Center Method StatementDocument3 pagesTesting and Commissioning of Motor Control Center Method StatementHumaid Shaikh75% (4)

- Testing & Commissioning of Split Air Conditioning AC UnitsDocument3 pagesTesting & Commissioning of Split Air Conditioning AC Unitsvin ssNo ratings yet

- Checklist For MEP Site WorksDocument5 pagesChecklist For MEP Site Works'AgusSp'No ratings yet

- Testing & Commissioning of Fan Coil Units FCU'sDocument2 pagesTesting & Commissioning of Fan Coil Units FCU'sDong VanraNo ratings yet

- Bypass Terminal Reheat Units Testing & Commissioning MethodDocument1 pageBypass Terminal Reheat Units Testing & Commissioning MethodDong VanraNo ratings yet

- Chemical Dosing System PRE Commissioning Check ListDocument1 pageChemical Dosing System PRE Commissioning Check ListBabu100% (2)

- Chiller Testing Procedure Rev 3Document11 pagesChiller Testing Procedure Rev 3Ali AimranNo ratings yet

- Method Statement LV Switchgear T&CDocument3 pagesMethod Statement LV Switchgear T&CphilipyongNo ratings yet

- Chemical Cleaning of Boiler Pressure Parts As TheDocument57 pagesChemical Cleaning of Boiler Pressure Parts As TheAnonymous 1OmAQ0u3No ratings yet

- Method Statement-IrrigationDocument5 pagesMethod Statement-Irrigationbhupsjangir100% (1)

- Instruction Operation For Packaged BoilerDocument37 pagesInstruction Operation For Packaged BoilerHasnul Hisyam Harun0% (1)

- Sample IOM-SchlumbergerDocument10 pagesSample IOM-Schlumbergerbmanojkumar16No ratings yet

- 2.0 Pre - Commissioning 2.1 Pre - Commissioning ActivitiesDocument6 pages2.0 Pre - Commissioning 2.1 Pre - Commissioning Activitiessamtom100% (1)

- Sat Procedure For MV SWGR Panels PDFDocument4 pagesSat Procedure For MV SWGR Panels PDFAmr ElkadyNo ratings yet

- Boiler Operation and MaintenanceDocument69 pagesBoiler Operation and MaintenanceGloria Hamilton100% (4)

- SAT PROCEDURE FOR MV SWGR PANELS - PdfToWordDocument4 pagesSAT PROCEDURE FOR MV SWGR PANELS - PdfToWordAmr ElkadyNo ratings yet

- Special Section - Know When To Look Outside The PID Tuning - IsADocument11 pagesSpecial Section - Know When To Look Outside The PID Tuning - IsAkumar_chemicalNo ratings yet

- MS - Fire ProtectionDocument7 pagesMS - Fire ProtectionBan DodoyNo ratings yet

- ChecklistDocument1 pageChecklistnaveentsipvtNo ratings yet

- Method Statement For Precommissioning & Commissioning of Close Control Units CCU'sDocument3 pagesMethod Statement For Precommissioning & Commissioning of Close Control Units CCU'svin ssNo ratings yet

- Testing & Commissioning of CCUDocument2 pagesTesting & Commissioning of CCUamg007100% (1)

- Procedure OperationalDocument2 pagesProcedure OperationalpernetiNo ratings yet

- Loop Test ProcedureDocument4 pagesLoop Test Procedureviddyadrian100% (2)

- Shameerpokkadan CVDocument5 pagesShameerpokkadan CVShameerNo ratings yet

- Sequence of Operation: For Fans& Blowers Start-UpDocument4 pagesSequence of Operation: For Fans& Blowers Start-UpMark CabralNo ratings yet

- Testing & Commissioning of Chilled Water Pressurization UnitsDocument3 pagesTesting & Commissioning of Chilled Water Pressurization Unitsvin ssNo ratings yet

- Mechanical CompletionDocument106 pagesMechanical Completionhorascanman100% (1)

- Pre-Functinal Checks FormatDocument15 pagesPre-Functinal Checks Formatchakravarthi kanugulaNo ratings yet

- Cooling Water Flushing Block C.Document4 pagesCooling Water Flushing Block C.Krishna VachaNo ratings yet

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong VanraNo ratings yet

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong VanraNo ratings yet

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong Vanra100% (1)

- Ishaq Instruction To Bidders - Rev0Document38 pagesIshaq Instruction To Bidders - Rev0ishaq ahmedNo ratings yet

- Testing and Commissioning For Pressurization UnitDocument3 pagesTesting and Commissioning For Pressurization UnitDong VanraNo ratings yet

- Generator Operation PMIDocument30 pagesGenerator Operation PMIrohit_0123100% (2)

- Testing and Commissioning Method Statement For Fire Fighting PumpsDocument2 pagesTesting and Commissioning Method Statement For Fire Fighting PumpsHumaid Shaikh100% (1)

- Method of Statement For Testing Commissioning of Ventilation General Exhaust FansDocument2 pagesMethod of Statement For Testing Commissioning of Ventilation General Exhaust Fanslesystemsb systemNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Panth Prakash by Rattan Singh Bhangoo (English Translation)Document574 pagesPanth Prakash by Rattan Singh Bhangoo (English Translation)SikhSangat Books80% (5)

- Numerical Modeling of Darcy-Weisbach Friction Factor and Branching Pipes ProblemDocument7 pagesNumerical Modeling of Darcy-Weisbach Friction Factor and Branching Pipes ProblemSayan KumarNo ratings yet

- Bachitar Natak An Analysis - DR - Devinder SinghDocument22 pagesBachitar Natak An Analysis - DR - Devinder SinghManinder SinghNo ratings yet

- Friction Factor ArticleDocument10 pagesFriction Factor ArticleLim BrandonNo ratings yet

- Kirpal Singh - Sikhs and AfghansDocument21 pagesKirpal Singh - Sikhs and AfghansSayan KumarNo ratings yet

- Sikh Socio Cultural ThesisDocument304 pagesSikh Socio Cultural ThesisSayan KumarNo ratings yet

- The Sikhs in History by Dr. Sangat SinghDocument453 pagesThe Sikhs in History by Dr. Sangat SinghSikh Texts100% (2)

- Ganjnama by Bhai Nand Lal Ji (Gurmukhi, Persian, English Meanings)Document24 pagesGanjnama by Bhai Nand Lal Ji (Gurmukhi, Persian, English Meanings)nss1234567890100% (1)

- Evaluation of Vertical Kaplan Turbine Using CFD: Conference PaperDocument11 pagesEvaluation of Vertical Kaplan Turbine Using CFD: Conference PaperSayan KumarNo ratings yet

- The Generation of Arbitrary Order Curved Meshes For 3D Finite Element AnalysisDocument29 pagesThe Generation of Arbitrary Order Curved Meshes For 3D Finite Element AnalysisSayan KumarNo ratings yet

- English Translation of Chritropakhyaan From Dasam Granth Vol-1Document399 pagesEnglish Translation of Chritropakhyaan From Dasam Granth Vol-1hardeep67% (3)

- 3D CFD Simulation of The Runaway Process of A Pelton TurbineDocument12 pages3D CFD Simulation of The Runaway Process of A Pelton TurbineSayan KumarNo ratings yet

- Transient CFD and Experimental Analysis For Improved Pelton Turbine Casing DesignsDocument12 pagesTransient CFD and Experimental Analysis For Improved Pelton Turbine Casing DesignsSayan KumarNo ratings yet

- Edit It UrselfDocument1 pageEdit It UrselfSayan KumarNo ratings yet

- 2 The (Galerkin) Finite Element Method: 2.1 Approximate Solution and Nodal ValuesDocument50 pages2 The (Galerkin) Finite Element Method: 2.1 Approximate Solution and Nodal ValuesSayan KumarNo ratings yet

- Design Analysis of Parts of Francis Turbine: Provision of Features To Blend Some Reaction Into ImpulseDocument35 pagesDesign Analysis of Parts of Francis Turbine: Provision of Features To Blend Some Reaction Into ImpulseMarcelo DelgadoNo ratings yet

- I Hate LyricsDocument1 pageI Hate LyricsSayan KumarNo ratings yet

- Blah Blah BlahDocument1 pageBlah Blah BlahSayan KumarNo ratings yet

- Fifteen Upanishads 07 AitareyaDocument5 pagesFifteen Upanishads 07 AitareyarahuleyesNo ratings yet

- Lyrics of A SongDocument1 pageLyrics of A SongSayan KumarNo ratings yet

- Fea6 PDFDocument16 pagesFea6 PDFZhiqiang GuNo ratings yet

- Finite Elements BasisfunctionsDocument20 pagesFinite Elements BasisfunctionsShoheh RahmanNo ratings yet

- BHELSMPTESTDocument4 pagesBHELSMPTESTSayan KumarNo ratings yet

- AssignmentDocument1 pageAssignmentSayan KumarNo ratings yet

- Boiler SafetiesDocument1 pageBoiler SafetiesSayan KumarNo ratings yet

- Autodesk Mechanical Installation ProcessDocument19 pagesAutodesk Mechanical Installation ProcessSayan KumarNo ratings yet

- Material ScienceDocument1 pageMaterial ScienceSayan KumarNo ratings yet

- RRB 2014veerDocument1 pageRRB 2014veerSayan KumarNo ratings yet