Professional Documents

Culture Documents

The Contact Analisys For Barrel Coupling Based On Ansys

Uploaded by

Bruno SantosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Contact Analisys For Barrel Coupling Based On Ansys

Uploaded by

Bruno SantosCopyright:

Available Formats

www.ierjournal.

org

ISSN 2395-1621

International Engineering Research Journal (IERJ) Special Issue 2 Page 2171-2178, 2015, ISSN 2395-1621

The contact analysis for Barrel coupling

based on Ansys

#1

V.V.Vaidya , #2A.P.Tadmalle

1

2

vikrant.vaidya27@gmail.com

aptadmalle.scoe@sinhgad.edu

Sinhgad College of Engineering, 2Sinhgad College of Engineering

ABSTRACT

ARTICLE INFO

The Barrel coupling system is the method of choice in transferring torque between

rotating parts. The barrel coupling consists of a sleeve provided with semicircular

toothing around its internal diameter and a hub that is externally toothed A series of

cylindrical barrels, of hardened steel, are inserted in the holes formed by this toothing to

act power transmission element. The contact mechanism of barrel and sleeve and hub

behaves highly non linear and generates contact stresses. The contact stress is the key

parameter in barrel coupling design. This paper presents to determine maximum

contact stress occurring in barrel coupling. The results obtained from theoretical

Hertizan analytical method are compared with Finite element analysis values. In finite

element analysis different contact algorithm and contacts are employed to find best

possible FEA contact analysis technique. In this paper factors affecting on barrel

coupling size like the Nominal transmission torque and Radial load are discussed.

Barrel Coupling was modeled in Catia V5 CAD software and analysis of this was done

by using ANSYS work bench.

Article History

Received

2015

:18th

November

Received in revised form :

19th November 2015

Accepted : 21st November ,

2015

Published online :

22nd November 2015

Keywords

Barrel coupling, Radial load, contact Stresses, Transmission torque,

Contact algorithm

I. INTRODUCTION

Coupling is a mechanical device used to connect two shafts

together at their ends for the purpose of transmitting power.

Couplings do not allow disconnection of shafts during

operation, however if torque limit is exceeded beyond

designed value then coupling may get disconnected during

operation. Coupling can permit some degree of

misalignment among the connecting shafts. By careful

selection, installation and maintenance of coupling

substantial saving can be made in maintenance cost.

A Barrel coupling

The barrel coupling consists of a sleeve provided with

semicircular toothing around its internal diameter and a hub

that is externally toothed as shown in fig.1.7. A series of

cylindrical barrels, of hardened steel, are inserted in the

holes formed by this toothing to act as power transmission

element. Covers with their corresponding special seals serve

to assure the perfect-tightness of the inner zone, preventing

2015, IERJ All Rights Reserved

the penetration of dust and guaranteeing the continuity of

the necessary lubrication. Two double-lamina elastic rings

mounted on the hub, one on each side of the toothing, limit

the axial displacement of the barrels. Torque is transmitted

to the drums receiving flange, generally by two

diametrically opposed flat driving surfaces, located at the

periphery of the coupling flange, and also by means of bolts

which, at the same time, serve as connection with the drum.

An indicator located on the external cover which moves

relative to the marks on the hub as a function of wear,

permits control of internal wear of the toothing, without the

need to disassemble any part of the coupling. The same

indicator also serves to control the axial position of the

sleeve relative to the hub. The convex shape of the barrels

and the internal spaces of the toothing allows the oscillation

of the hub relative to the sleeve compensating angular

misalignments of 1 30 and an axial displacement that

varies between 3 mm and 8 mm.

Page 1

www.ierjournal.org

International Engineering Research Journal (IERJ) Special Issue 2 Page 2171-2178, 2015, ISSN 2395-1621

Fp=16315.79 N

2)Based on consumed power

Pc= 0.9 Kw

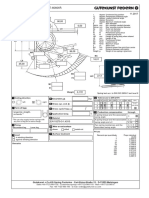

Fig.1 Barrel coupling

1.Hub

6.Allen screw

11.wear limit

grooves

16.grower

washer

2.sleeve

7.Indicator

12.grease

connection

17.barrel

guide ring

3.Inner

cover

8.seal

13.grease

overflow

18.seeger

ring

4.outer

cover

9.Allen screw

14.assembly

reference

5.Barrel

10.threaded

holes

for

disassembly

15.barrel

guide rings

Advantages

1. Barrel couplings have increased contact area, radial load

is better distributed hence life of coupling is increased.

2. Due to barrel and gear profile, for a given radial load 40

% stress reduction is obtained compared to other couplings.

T= 3870 Nm

B Calculation of radial load Fr

Fr=14377.4 N

C. Stribecks Equation

It is used for distribution of radial forces among barrels on

lower half part of coupling. It is based on the following

assumptions:

1) The rollers are rigid and they retain their circular shape.

2) The rollers are equally spaced.

3) The rollers in the upper half portion not support any load.

Figure 3.1.shows the forces acting on the inner race through

rolling elements,that supported maximum radial load Fr.

II. ANALYTICAL METHODOLOGY

Analytical methodology divides into two parts; first part

includes calculation of transmission torque and calculation

of radial load acted on barrels. Second part includes

calculation of contact stress induced due to application of

torque and radial load by using Hertzian theory.

A. Calculation of nominal transmission torque T (Nm)

\

1) Based on installed power

T=4300 Nm

The static pull in the drum is given by

Fig.2 Distribution of forces

2015, IERJ All Rights Reserved

Page 2

www.ierjournal.org

International Engineering Research Journal (IERJ) Special Issue 2 Page 2171-2178, 2015, ISSN 2395-1621

Stribecks equation is given by :

Contact area for 20 barrels=20 A

Contact stress=

Where Stribecks factor = 5.

P1 ,P2 ,P3 . are distributed forces

For this model of barrel coupling there are 20 barrels.

Total radial load 14500 N is converted into 9 forces

according to stribecks equation.

14500=1/5*20*P1

P1=3625 N (maximum radial load acted on barrel)

=3362.15 N

= 2637.18 N

= 1633.56 N

=622.7 N

D. Hertz contact stress theory

Contact between two continuous, non-conforming solids is

initially a point or line. Under the action of a load the solids

deform and contact area is formed According to the contact

area shape (under no external load), there are point contact

and line contact. It is obvious that after load applied line

contact will become rectangle contact and point contact will

be an ellipse contact area. Hertz contact stress theory allows

for the prediction of the resulting contact area, contact

pressure, compression of the bodies, and the induced stress

in the bodies.the maximum principal stresses occurring at

the surface of contact are given by Hertzian equation are

following

Total contact stress = [(contact stress due to radial load) 2 +

(contact stress due to torque)2]1/2

=[(650.8)2+ (5.655)2]1/2

Total contact stress=650.8 mpa

Above contact stress value is maximum contact stress

corresponding to maximum radial load P1 obtained from

stribecks equation.Now we obtained further contact stress

value to radial load P2,P3,P4 ,P5 obtained from stribecks

equation.

III. FINITE ELEMENT ANALYSIS OF BARREL

COUPLING

The Finite Element Method (FEM) is a numerical

approximation method. It is a method of investigating the

behaviour of complex structures by breaking them down

into smaller, simpler pieces. These smaller pieces of

structure are called elements. The elements are connected to

each other at nodes. The assembly of elements and nodes

are called a finite element model. Typical surface-surface

contacts analysis steps mainly include(1) Build 3D geometry model and mesh.

(2) Identify contact pairs.

(3) Name target surface and contact surface.

(4) Define target surface.

(5) Define contact surface.

(6) Set up element key options and real constants

(7) Define and control rigid goals movement.

(8) Apply the necessary boundary condition.

(9) Define solution options and load steps.

(10) Solve contact problems.

(11) Look over and analyze results.

A. Creation of Geometry of Barrel coupling

3D geometry model is built in CATIA software and

imported in ansys software.

Maximum principle stress is given by following

Where b is semi width of formed rectangular contact area is

given by

Fig.3 Creation of Geometry of barrel coupling

B.Material Selection

By putting values

Maximum contact stress,

E. Contact stress due to Torque:

Tangential load = ft =80357.14 N

Contact area is given by

2015, IERJ All Rights Reserved

For this application alloy steel have great advantages

than others. Alloy steels have higher strength and toughness.

It posses higher hardenability which has great significance

in heat treatment of components and also better corrosion

resistance compared to plain carbon steel. EN24 is a popular

grade of through-hardening alloy steel due to its excellent

machinability. EN24 is used in components such Axles,

connecting rods, high tensile bolts, studs,power transmission

slide gears, slide cams, differential shafts, pinion sleeves,

spindle gears and compensating washers. EN24 can be

Page 3

www.ierjournal.org

International Engineering Research Journal (IERJ) Special Issue 2 Page 2171-2178, 2015, ISSN 2395-1621

further surface hardened to create components with

enhanced wear resistance by induction or nitriding

processing.

C. Define contact properties

Once material properties are given to coupling in Ansys,

contact elements need to define. Contact properties are

given in four stages in ansys.In first stage contact class has

to be defined. Generally there are two contact classes: rigidflexible and flexible-flexible. In rigid-flexible contact, one

or more of the contacting surfaces are treated as rigid. The

other class flexible-flexible contact is the more common

type. In this case, all contacting bodies are deformable. In

second stage contact area has to be defined. , there are two

groups of contact: point-surface contact and surface-surface

contact. In ANSYS, the contact is generated by pair. For the

point-surface contact, the `point` is contact and the `surface`

is target. For surface-surface contact, both contact and target

are surfaces and they have to be specified which surface is

contact and which is target.

In third stage behaviour of contact surface has to be

specified. Contact surface has different types of behaviour

according to different characteristics of contact. Normally

there are frictional, no separation, bonded. In frictional

contact, the contact body can slide on the target surface in

the tangential direction. It can translate in the normal

direction. This behaviour can simulate the contact opens and

closes. Frictional contact is most reliable contact behaviour

in analysis of barrel coupling as barrels fits in cavities of

semicircular toothing of sleeve and hub where friction exists.

In bonded contact no relative movement between each other

in the rest of analysis is possible. They look like one body.In

this analysis we have used first frictional contact and after

that bonded and no separation contact is used for checking

best possible contact. In fourth stage contact algorithm has

to be specified in ansys.contact algorithms are used to solve

contact problems. Pure Lagrange multiplier,pure penalty

method and the Augmented Lagrangian are three contact

algorithm are used to solve contact problems.In this analysis

first the Augmented Lagrangian Method is used to solve

contact problems with friction and after that pure penalty

and langrange multiplier method is used for finding best

possible combination.

Fig.4.Meshing

E. Setting boundary conditions and applying loads

Total radial load 14500 N is applied on coupling and torque

of 4500 Nm acted on body. the total radial load is divided

according to stribecks equation and applied to barrels in

lower half portion of coupling.

Fig.5 Application of boundary and loads

F. Solution of contact stresses and deformation

With the help of simulation contact stress and deformation

obtained. Generally von misses stress can be found out and

helpful in analysis. Through simulation, result of the

maximal contact stress was 601.06 Mpa while the Hertzian

theory value was 650.08 MPa. The comparison revealed that

there was good consistency between the Hertzian theory

solution and finite element solution.

D.Meshing

In first stage of meshing element type is specified for

coupling. Different element type can be given to different

parts of coupling just like sleeve, hub and barrels. For

barrels,

hub and sleeve part solid 187 tetrahedral element type is

given. Barrel surface which comes in contact with sleeve

inner and hub outer surface represents contact and target

surface and separate contact and target element is given to

that contact faces.CONTA 174 as contact element and Targe

170 as target element is applied.

2015, IERJ All Rights Reserved

fig.6 contact stress on barrel coupling

Page 4

www.ierjournal.org

International Engineering Research Journal (IERJ) Special Issue 2 Page 2171-2178, 2015, ISSN 2395-1621

Fig.7 contact stress on barrels

The above Figures 6& 7 shows the analysis results of barrel

coupling. It clearly indicates that maximum stress is

occurred on barrel at the contacting region. From figure we

can also know that the contact area had an approximate

ellipse shape in contact area. The contact stress for

particular this analysis is varies 601.06 Mpa to 66.98

Mpa.In this analysis we have used frictional contact with

contact algorithm as augumented langrange.after that we

have changed contact algorithm pure penalty and langrane

multiplier with frictional contact and solution obtained.after

that we have changed types of contact such as bonded, no

separation with all three algorithm and solution obtained.

IV. RESULTS AND DISCUSSION

We have found contact stress in barrel coupling by Hertz

analytical method. These contact stresses also obtained from

finite element analysis. In finite element analysis different

methodologies are for finding contact stress analysis. There

are different types of contact such as frictional, bonded, no

separation and different contact algorithms for contact

detection such as pure penalty,augumented langrange,and

langrange multiplier. We have made all possible

combination of these types of contact along with contact

algorithm to find best possible method of contact analysis in

finite element analysis.

A Comparison between contact algorithms with frictional

contact

In this frictional contact as type of contact is selected and

three contact algorithm used one by in finite element

analysis. Results obtained are compared to Hertz analytical

method. Results are shown in Table I and figure 8

TABLE I

COMPARISON BETWEEN CONTACT ALGORITHMS

WITH FRICTIONAL CONTACT IN FEM

Radial

Load

in

N

Contact

stress(Mpa)

by

Augumented

Langrange

Contact

stress(Mpa)

by

Pure

penalty

Contact

stress(Mpa)

by

Langrange

Multiplier

Hertz

Anal

ytical

Meth

od

3625

601.06

601.06

531.04

3361.

8

2636.

9

1633

580.12

580.12

472.07

650.

8

627

502.79

502.79

413.1

425.46

425.46

354.12

621.9

9

270.8

270.8

236.18

2015, IERJ All Rights Reserved

555.

3

437

269.

8

Fig.8 Comparison between contact algorithms with frictional contact in

FEM

Results shown in table I revealed that contact stress obtained

from contact algorithm pure penalty and augumented

langrange is almost same within 5% to 7% to Hertz

analytical method contact stress values but langrange

multiplier method obtained results deviates more than

analytical method.frictional contact is with all contact

algorithms. In Frictional contact the contact body can slide

on the target surface in the tangential direction. The results

for the augumented langrange and pure penalty algorithms

are good for all problems provided they are used with

surface to surface contact elements. The results for the

langrange multiplier algorithms can be quite sensitive to

matching of the nodes on contact region so values deviate

more [10].frictional contact with pure penalty or augumented

langrange nearly gives reliable solution.

B Comparison between contact algorithms with bonded

contact

In this we have used bonded contact and contact algorithm

is changed one by one. Results are obtained are shown in

table II and fig.9 are compared to Hertz analytical

method.In Bonded contact as soon as the contact is detected,

then the nodes in contact are bonded in all directions and all

the degrees of freedom are constrained. Not any relative

movement between each other in the rest of analysis is

possible. They look like one body,irrespective of loading,

behaviour of other parts.

TABLE III

COMPARISON BETWEEN CONTACT ALGORITHMS

WITH BONDED CONTACT IN FEM

Radial

Load

in N

Contact

stress(Mpa)

by

Augumented

Langrange

Contact

stress(Mpa)

by

Pure

penalty

Contact

stress(Mpa)

by

Langrange

Multiplier

Hertz

Analytical

Method

3625

109.72

109.72

109.72

650.8

3361.8

97.533

97.533

97.533

627

2636.9

85.342

85.342

85.342

555.3

1633

73.351

73.351

73.351

437

621.99

60.96

60.96

60.96

269.8

Page 5

www.ierjournal.org

International Engineering Research Journal (IERJ) Special Issue 2 Page 2171-2178, 2015, ISSN 2395-1621

Fig.10 Comparison between contact algorithms with no seperation contact

Fig.9 Comparison between contact algorithms with bonded contact in FEM

Results in table II and Fig.9 reveals that bonded contact

gives the same result of all three contact algorithm as in

bonded contact there is no relative movement among parts.

Results are highly deviates more than 25% from Hertz

analytical method, so results are not reliable.

C. Comparison between contact algorithms with no

seperation contact

In this we have used no separation contact and contact

algorithm is changed one by one. Results are obtained are

shown in table no and graph are compared to Hertz

analytical method.

TABLE IIIII

COMPARISON BETWEEN CONTACT ALGORITHMS

WITH NO SEPERATION CONTACT IN FEM

Radial Contact

Contact

Contac Hertz

Load

stress(Mpa) stress(Mpa t

Analytical

in N

by

)

stress( Method

Augumente by

Mpa)

d

Pure

by

Langrange

penalty

Langra

nge

Multip

lier

Results in table III and Fig.10 revealed that pure penalty and

augumented langrange gives same result for no separation

contact.Langrange multiplier gives more than 20%deviation

to Hertz analytical method than other two contact

algorithm.For 3D model pure penalty and augumented

langrange gives better than langrange multiplier.

D. Comparison between contacts with augumented

langrange algorithm

In this contact algorithm as augumented langrange is kept

constant and contact changed with frictional, bonded and no

separation. Results obtained are compared with Hertz

analytical method.

TABLE IV

COMPARISON BETWEEN CONTACTS WITH

AUGUMENTED LANGRANGE

Radial Contact

Contact

Contact

Hertz

Load

stress(Mpa) stress(Mpa) stress(Mpa) analytical

in N

With

With

With

no method

frictional

bonded

separation

contact

contact

contact

3625

601.06

109.72

490.8

650.8

3361.8

580.12

97.533

436.27

627

2636.9

502.79

85.342

381.74

555.3

3625

490.78

490.78

732.81

650.8

1633

425.46

73.351

327.2

437

3361.

8

2636.

9

1633

436.27

436.27

651.39

627

621.99

270.8

60.96

272.67

269.8

381.74

381.74

569.37

555.3

327.2

327.2

488.54

437

621.9

9

272.67

272.67

407.12

269.8

2015, IERJ All Rights Reserved

Page 6

www.ierjournal.org

International Engineering Research Journal (IERJ) Special Issue 2 Page 2171-2178, 2015, ISSN 2395-1621

Fig.11 Comparison between contacts with augumented langrange algorithm

Fig.12 Comparison between contacts with pure penalty algorithm

Results obtained in table IV and fig.11 revealed that

frictional contact gives nearly same within 5% to 7% to as

result to Hertz analytical method. Bonded contact and no

separation contact stress values deviate more than 20% .

Other contact failed to give proper results.

E. Comparison between contacts with pure penalty

algorithm

In this contact algorithm as pure penalty is kept constant and

contact changed with frictional, bonded and no separation.

Results obtained are compared with Hertz analytical method.

TABLE V

COMPARISON BETWEEN CONTACTS WITH PURE

PENALTY

Radial Contact

Contact

Contact

Hertz

Load

stress(Mpa stress(Mpa stress(M analyti

in N

)

)

pa)

cal

With

With

With no metho

frictional

bonded

separatio d

contact

contact

n contact

Results obtained in table V and fig .12 revealed that

frictional contact gives nearly same as result to Hertz

analytical method. Bonded contact and no separation

contact stress values deviate more. Other contact failed to

give proper results.

F. Comparison between contacts with Langrange Multiplier

In this contact algorithm as Langrange multiplier is kept

constant and contact changed with frictional, bonded and no

separation. Results obtained are compared with Hertz

analytical method.

TABLE VI

COMPARISON BETWEEN CONTACTS WITH

LANGRANGE MULTIPLIER

Radial Contact

Contact

Contact

Hertz

Load

stress(Mpa) stress(Mpa) stress(Mpa) analytical

in N

With

With

With

no method

frictional

bonded

separation

contact

contact

contact

3625

601.06

109.72

490.8

650.8

3361.

8

2636.

9

1633

580.12

97.533

436.27

627

621.9

9

502.79

85.342

381.74

555.3

425.46

73.351

327.2

437

270.8

60.96

272.67

269.8

2015, IERJ All Rights Reserved

3625

531.04

109.72

732.81

650.8

3361.8

472.07

97.533

651.39

627

2636.9

413.1

85.342

569.37

555.3

1633

354.12

73.351

488.54

437

621.99

236.18

60.96

407.12

269.8

Page 7

www.ierjournal.org

International Engineering Research Journal (IERJ) Special Issue 2 Page 2171-2178, 2015, ISSN 2395-1621

[3]A. Tjernberg, Load distribution in the axial direction in

a spline coupling,Engineering failure analysis 8(2001),557570

[4]Pandiyarajan. R, Starvin.M.S, Contact stress distribution

of large diameter ball bearing using Hertzian Elliptical

contact, Procedia Engineering 38 (2012) ,pp264 269

[5]Seok-chul Hwang,Jin-Hwan Lee, Contact stress analysis

for a pair of mating gears, Mathematical and computer

modelling 35 (2011), pp 123-134

[6]Sorin, 3d contact stress analysis for spur gears, Finite

Elements in Analysis and Design 62 (2000), pp 447-459

[7]Zhang Yongqi,Tan Qingchang, Analysis of Stress and

Strain of the Rolling Bearing by FEA method, Physics

Procedia 24 (2012),pp 19 24

[8]Vahid Monfared, Contact Stress Analysis in Rolling

Bodies by Finite Element Method (FEM) Statically, Journal

of Mechanical Engineering and Automation 2012, 2(2),pp

12-16

[9]Barrel couplings, by Juares technical Barrel coupling

catalogue.

[10]Pilkey, W. D, Contact Stresses, in Formulas for Stress,

Strain, and Structural Matrices, Second Edition, John

Wiley & Sons, Inc., Hoboken, NJ, USA pp 413-449

Fig.13 Comparison between contacts with Langrange Multiplier algorithm

Results obtained in table VI and Fig. 13 revealed that

frictional contact gives nearly same and realistic result to

Hertz analytical method. Bonded contact and no separation

contact stress values deviate more. Other contact failed to

give proper results.

V .CONCLUSION

1. Contact stresses are depend on contacting area between

hub and barrel & contacting area between barrel and sleeve.

2. Contact stresses of barrel coupling are depending on inner

diameter and outer diameter of barrel, material properties of

coupling.

3. Contact stresses of barrel coupling are most efficiently

calculated by Hertz contact theory.

4. The result of contact stress analysis of the barrel coupling

by FEM and Hertz analytical method is almost same within

5% to 7%

5. In finite element analysis result obtained by contact

algorithm pure penalty and augumented langrange with

frictional contact and Hertz analytical method is almost

same within 5% to 7%.

6. In finite element analysis result obtained with frictional

contact are more consistent to Hertz analytical method than

obtained with bonded contact and no separation contact.

7. In finite element element analysis result obtained with

bonded contact is remains same for all three contact

algorithm.

REFRENCES

[1]Tang Zhaoping, Sun Jianping,The Contact Analysis for

Deep Groove Ball Bearing Based on Ansys, Procedia

Engineering 23 (2011), pp 423 428.

[2]Vivek Karaveer, Ashish Mogrekar, Modelling and

Finite Element Analysis of Spur Gear, International

Journal of Current Engineering and Technology 3(2013),pp

2104-2107

2015, IERJ All Rights Reserved

Page 8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Computational Geomechanics With Special Reference To Earthquake EngineeringDocument395 pagesComputational Geomechanics With Special Reference To Earthquake EngineeringRomarioSebastian100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Application Basics Lifting TongsDocument9 pagesApplication Basics Lifting TongsBruno SantosNo ratings yet

- Visual Inspection I y IIDocument68 pagesVisual Inspection I y IISantos Junnior Hipolito SandovalNo ratings yet

- Rajan - Intermediate Structural Analysis and Design - PrintDocument484 pagesRajan - Intermediate Structural Analysis and Design - Printnarciszu50% (2)

- CRL101-Wheel Flange Lubrication W-126-A1004Document2 pagesCRL101-Wheel Flange Lubrication W-126-A1004Bruno SantosNo ratings yet

- p9 PDFDocument4 pagesp9 PDFGoran VišnjarićNo ratings yet

- Steel Mill Ladle Weigihing System - SchenckDocument22 pagesSteel Mill Ladle Weigihing System - SchenckBruno SantosNo ratings yet

- High Performance Hoisting Ropes: WiresolutionsDocument32 pagesHigh Performance Hoisting Ropes: WiresolutionsBruno SantosNo ratings yet

- 16 SKP Bridon Crane Brochure 5th EditionDocument16 pages16 SKP Bridon Crane Brochure 5th EditionBruno Santos100% (1)

- Xtek Crane BrochureDocument8 pagesXtek Crane BrochureBeniamine SarmientoNo ratings yet

- Crane DesingDocument243 pagesCrane Desingjulianzl2110No ratings yet

- Moving Loads in Structural Dynamics of Cranes: Bridging The Gap Between Theoretical and Practical ResearchesDocument7 pagesMoving Loads in Structural Dynamics of Cranes: Bridging The Gap Between Theoretical and Practical Researchesdsn_sarmaNo ratings yet

- Weight Reduction of Reach Stacker (Konecrane)Document111 pagesWeight Reduction of Reach Stacker (Konecrane)Bruno SantosNo ratings yet

- Stress Analysis of Mast Structure For Water-Well Drilling MachineDocument8 pagesStress Analysis of Mast Structure For Water-Well Drilling MachineBruno Santos100% (1)

- 16 SKP Bridon Crane Brochure 5th EditionDocument16 pages16 SKP Bridon Crane Brochure 5th EditionBruno Santos100% (1)

- Design of Aluminium Boom and Arm For An Excavator PDFDocument7 pagesDesign of Aluminium Boom and Arm For An Excavator PDFBruno SantosNo ratings yet

- Datasheet Mola de Torção 16161RDocument1 pageDatasheet Mola de Torção 16161RBruno SantosNo ratings yet

- Back to Basics: Curvic Coupling DesignDocument13 pagesBack to Basics: Curvic Coupling DesignBruno SantosNo ratings yet

- Lecture 37PNEUMATICS ACTUATORSDocument43 pagesLecture 37PNEUMATICS ACTUATORSpratapy234No ratings yet

- TCB InglesDocument9 pagesTCB InglesBruno SantosNo ratings yet

- JAU124932-FOLLETO Acoplamientos INGLES BajaDocument32 pagesJAU124932-FOLLETO Acoplamientos INGLES BajaBruno SantosNo ratings yet

- Structural Analysis of Mast of Special Rotary Drilling Rig For Transmission LineDocument5 pagesStructural Analysis of Mast of Special Rotary Drilling Rig For Transmission LineBruno SantosNo ratings yet

- ds32 431Document6 pagesds32 431luthfibomentNo ratings yet

- TSCHAN Barrel-Coupling USADocument12 pagesTSCHAN Barrel-Coupling USABruno SantosNo ratings yet

- Barrel Couplings For Drums, Model: Mechanical Components For Lifting, Hoisting, Transport and Storage MachineryDocument7 pagesBarrel Couplings For Drums, Model: Mechanical Components For Lifting, Hoisting, Transport and Storage MachineryBruno SantosNo ratings yet

- Contact Stress Analysis of Barrel Coupling Using FEADocument8 pagesContact Stress Analysis of Barrel Coupling Using FEABruno SantosNo ratings yet

- Degradation Mechanisms of Wire Ropes Operating On Multi-Layer Crane and Mine Hoisting Drums PDFDocument19 pagesDegradation Mechanisms of Wire Ropes Operating On Multi-Layer Crane and Mine Hoisting Drums PDFBruno SantosNo ratings yet

- Plate Buckling Manual en PDFDocument54 pagesPlate Buckling Manual en PDFBruno SantosNo ratings yet

- Design and Analysis of Barrel CouplingDocument5 pagesDesign and Analysis of Barrel CouplingBruno SantosNo ratings yet

- Baja Sae Design ReportDocument14 pagesBaja Sae Design Reportlucky_agrawal45No ratings yet

- AutoPIPE TutorialDocument204 pagesAutoPIPE TutorialViche Carsa100% (1)

- Patran 2008 r1 Interface To Dytran Preference GuideDocument252 pagesPatran 2008 r1 Interface To Dytran Preference GuideKevinNo ratings yet

- Water Pipe Robot With Soft Inflatable ActuatorsDocument7 pagesWater Pipe Robot With Soft Inflatable ActuatorseyaoNo ratings yet

- 2005 01 1221Document10 pages2005 01 1221api-3702571No ratings yet

- Akers - A Method of Structural Load Prediction For High-Speed Planing Craft (SNAME)Document24 pagesAkers - A Method of Structural Load Prediction For High-Speed Planing Craft (SNAME)Tomislav TomoNo ratings yet

- FE Analysis SyllabusDocument3 pagesFE Analysis SyllabusSushil MundelNo ratings yet

- Dynamic Analysis of Rectangular Isotropic Plates Using Weak-Form Variational PrincipleDocument13 pagesDynamic Analysis of Rectangular Isotropic Plates Using Weak-Form Variational PrincipleEnem Johnmartins IkemefunaNo ratings yet

- Tutorial 1 Introduction of FEA and ABAQUSDocument6 pagesTutorial 1 Introduction of FEA and ABAQUSThanigai VelNo ratings yet

- Lecture Rbobm BeamerDocument153 pagesLecture Rbobm BeamerLê QuỳnhNo ratings yet

- A Fatigue Analysis and Life Estimation of Crankshaft-A ReviewDocument7 pagesA Fatigue Analysis and Life Estimation of Crankshaft-A ReviewDiego AvendañoNo ratings yet

- Staad FEMfdn 5Document54 pagesStaad FEMfdn 5SidharthNo ratings yet

- Easwari Engineering College Question Bank: Finite Element AnalysisDocument12 pagesEaswari Engineering College Question Bank: Finite Element Analysisamsubra8874No ratings yet

- OptiStruct Optimization - v13 - Rev20140707 PDFDocument278 pagesOptiStruct Optimization - v13 - Rev20140707 PDFvovanpedenkoNo ratings yet

- News Letter For Expansion Bellow PDFDocument4 pagesNews Letter For Expansion Bellow PDFAsma KhanNo ratings yet

- Basic Concepts of FEMDocument23 pagesBasic Concepts of FEMDeion BonserNo ratings yet

- Ballistic Performance of Multi-Layered Metallic Plates ImpactDocument11 pagesBallistic Performance of Multi-Layered Metallic Plates ImpactKhaiNo ratings yet

- Broch Samcef Field AnDocument6 pagesBroch Samcef Field AnAnonymous KdnOsd9No ratings yet

- Movable PolyhouseprojectDocument17 pagesMovable PolyhouseprojectSHAW AcademyNo ratings yet

- Finite Element Modelling and Simulation of Gun Dynamics Using ANSYS'Document5 pagesFinite Element Modelling and Simulation of Gun Dynamics Using ANSYS'Yousaf SaidalaviNo ratings yet

- Advancing Analysis Capabilities in Ansys Through Solver TechnologyDocument16 pagesAdvancing Analysis Capabilities in Ansys Through Solver Technologynz578427No ratings yet

- Kamal - 2015 - Encased Beam With Variable Upper SteelDocument8 pagesKamal - 2015 - Encased Beam With Variable Upper SteelRene Rodrigues O. SilvaNo ratings yet

- Meshing Methods (ANSYS Meshing) - Everyone Is Number OneDocument14 pagesMeshing Methods (ANSYS Meshing) - Everyone Is Number Oneicemage1991No ratings yet

- Metals: An Analysis of Creep Phenomena in The Power Boiler SuperheatersDocument12 pagesMetals: An Analysis of Creep Phenomena in The Power Boiler Superheatersbastian orellanaNo ratings yet

- Global Analysis of Tall Buildings With Tubed Mega Frame StructuresDocument154 pagesGlobal Analysis of Tall Buildings With Tubed Mega Frame Structuresdxzaber100% (2)

- Surface Settlements from TunnellingDocument84 pagesSurface Settlements from Tunnellingyahyashak100% (3)

- Effect of Mesh Size of Floor SlabDocument6 pagesEffect of Mesh Size of Floor SlabKrishna Murari100% (1)

- COMSOL MultiphysicsDocument11 pagesCOMSOL MultiphysicsJagriti KalraNo ratings yet

- Application of Differential Equations To Calculations of Large Deformations of Structural MembersDocument7 pagesApplication of Differential Equations To Calculations of Large Deformations of Structural MembersMohammad YusufNo ratings yet