Professional Documents

Culture Documents

P&ID Documentation and Control System Records

Uploaded by

clark_k2ntOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P&ID Documentation and Control System Records

Uploaded by

clark_k2ntCopyright:

Available Formats

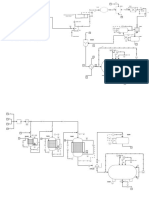

310 Documentation and P&ID

3-15 psi 4-20 mA

PY

19

NS

FV FF FT

16 16 16

Material A

LIC

11

FT

15

S PT

Material B

19

FV LT

11 11 PSV

14

TV TE

10 10

SS

SS

Material

Flow control

Figure 17.14 Illustration of a P&ID for a mixing station.

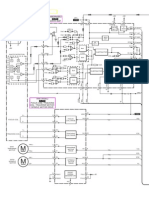

PLC documentation needs to be up-to-date, in order to have an accurate record

of the programming used in the control of the process. Updates and changes are vir-

tually impossible without accurate records.

The plumbing and signal lines in a process facility are shown in the P&ID. Stan-

dard symbols developed by the ISA for all of the various instruments, types of inter-

connections, actuator valves, and instrument functions are shown, together with an

example of a facility P&ID.

References

[1] Mulley, R. M., Control System Documentation, Research Triangle Park, NC: ISA, 1998.

[2] Battikha, N. E., The Condensed Handbook of Measurement and Control, 2nd ed., ISA,

2004, pp. 241–263.

[3] Jones, C. T., Programmable Logic Controllers, 1st ed., Patrick-Turner Publishing Co.,

1996, pp. 344–351.

You might also like

- Schematic Diagrams GuideDocument4 pagesSchematic Diagrams GuideHartono Prayitno86% (7)

- Cyl SDR NEW PLC Wiring Diagram Ver 2 PG 2Document1 pageCyl SDR NEW PLC Wiring Diagram Ver 2 PG 2Alexandre Werneck SilvaNo ratings yet

- Open B70 1DC Istruzioni IS117 Rev13-En PDFDocument56 pagesOpen B70 1DC Istruzioni IS117 Rev13-En PDFivoivan99No ratings yet

- Ensuring safe pressure testing of a food processing machineDocument2 pagesEnsuring safe pressure testing of a food processing machinemarceloNo ratings yet

- Servo Amp: B IC701 AN22004A-NFDocument1 pageServo Amp: B IC701 AN22004A-NFRoiser DelgadoNo ratings yet

- Pre Production P&ID COMPLETEDocument3 pagesPre Production P&ID COMPLETEOlamilekan Olamibode OwolabiNo ratings yet

- Chapter 7 - C F I D: Ontrol AND Ield Nstrumentation OcumentationDocument16 pagesChapter 7 - C F I D: Ontrol AND Ield Nstrumentation Ocumentationnmulyono100% (1)

- 220 Vac/24 VDC 220-24 VacDocument22 pages220 Vac/24 VDC 220-24 Vacfernandez123456No ratings yet

- Samsung K15aDocument4 pagesSamsung K15aLUIS CASTRONo ratings yet

- Chap 17Document15 pagesChap 17RajendraNo ratings yet

- Untitled Diagram - DrawioDocument3 pagesUntitled Diagram - DrawioVILLA KGAMADINo ratings yet

- Open Lamborghino 1 2Document1 pageOpen Lamborghino 1 2Victor Hugo MendezNo ratings yet

- SPK Data For Mass ChangeDocument4 pagesSPK Data For Mass ChangeRicardo Coutinho AmaralNo ratings yet

- Nama: Hilma Hermayasari NIM: M1B116002: Buatlah Flowsheet Dari Block Diagram Pulp?Document2 pagesNama: Hilma Hermayasari NIM: M1B116002: Buatlah Flowsheet Dari Block Diagram Pulp?I'amGuantenxNo ratings yet

- Mikromedia stm32 PinoutDocument2 pagesMikromedia stm32 PinoutjoseiutNo ratings yet

- Yr-Sss Point ListDocument4 pagesYr-Sss Point ListDewanjee AshrafNo ratings yet

- 03-FGLT-A Unit Data SheetDocument10 pages03-FGLT-A Unit Data Sheetcvbc47jvmxNo ratings yet

- LED backdrop and stage setup guideDocument1 pageLED backdrop and stage setup guideTina Reyes-BattadNo ratings yet

- VC216A-109-A-001 - 2 Dimensional DWG For 40B & BelowDocument16 pagesVC216A-109-A-001 - 2 Dimensional DWG For 40B & BelowLê Phước PhúNo ratings yet

- Presentation 1Document6 pagesPresentation 1Gilang Anugerah HernandaNo ratings yet

- TR 02Document1 pageTR 02fadli arsyadaNo ratings yet

- ESP32 LCD+SDCard+Sound+JoypadDocument1 pageESP32 LCD+SDCard+Sound+Joypadfabriciolima369No ratings yet

- Abcde FG I H J Klmno PQRST Uvwxy Z / Abcde FG I H J Klmno PQRST Uvwxy ZDocument2 pagesAbcde FG I H J Klmno PQRST Uvwxy Z / Abcde FG I H J Klmno PQRST Uvwxy ZMahendraNo ratings yet

- Ilovepdf MergedDocument2 pagesIlovepdf MergedTalia AuquillaNo ratings yet

- YR Chiller Point ListDocument4 pagesYR Chiller Point ListDewanjee AshrafNo ratings yet

- Steering Valve OrbitrollDocument4 pagesSteering Valve OrbitrollLU YONo ratings yet

- Optimizing video CD changer performanceDocument11 pagesOptimizing video CD changer performancekleber.rleite7355No ratings yet

- Hydraulic Diagram - MLT845S3E2Document7 pagesHydraulic Diagram - MLT845S3E2andraNo ratings yet

- Simplified P&ID - MergedDocument2 pagesSimplified P&ID - MergedTalia AuquillaNo ratings yet

- P&id BoilerDocument1 pageP&id BoilerBagus AryowibowoNo ratings yet

- ESPEC 1756 IF16 EAnaloga PDFDocument5 pagesESPEC 1756 IF16 EAnaloga PDFFelixWhiteNo ratings yet

- Global Service Way - Technical Information on Cigar Lighter, Power Socket and Auto Clock WiringDocument1 pageGlobal Service Way - Technical Information on Cigar Lighter, Power Socket and Auto Clock WiringHendra GunawanNo ratings yet

- Sensores CMP y CKPDocument3 pagesSensores CMP y CKPGggNo ratings yet

- Wiring Diagram DskiDocument3 pagesWiring Diagram DskiotwkayadanmampuNo ratings yet

- Hydraulic System: Main Menu Click The Volvo-Logo in The Lower Right Corner To Return To This MenuDocument4 pagesHydraulic System: Main Menu Click The Volvo-Logo in The Lower Right Corner To Return To This MenuCarlos Alberto BaptistaNo ratings yet

- Illustrated Parts Catalogue: Ed. 4 Rev. 3 - November, 2018Document2 pagesIllustrated Parts Catalogue: Ed. 4 Rev. 3 - November, 2018Andrii KlishchevskyiNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangerssaiminNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDavid Muñoz CastroNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersAdam AnugrahesaNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersTifano KhristiyantoNo ratings yet

- Rotational Equipment, Heaters & Valves GuideDocument1 pageRotational Equipment, Heaters & Valves GuideBülent KabadayiNo ratings yet

- Equipments SymbolDocument1 pageEquipments SymbolabdelillahNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and Exchangersprajakt_pieNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersAnonymous oVRvsdWzfBNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangerschianhhoNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersabdallahNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersgrabettyNo ratings yet

- Rotational Equipment, Heaters & Valves GuideDocument1 pageRotational Equipment, Heaters & Valves GuidevpjagannaathNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersSONWALYOGESHNo ratings yet

- YT OptiView (Rev J - 02)Document12 pagesYT OptiView (Rev J - 02)Mohd Shareen Ezzry Mohd SomNo ratings yet

- Equipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangersDocument1 pageEquipment and Vessels 2. Rotational Equipment 3. Heaters and ExchangerspsaayoNo ratings yet

- Forecast PA Week#52Document141 pagesForecast PA Week#52Indra PurnamaNo ratings yet

- PVG 32 Proportional Valve Group General Description: Technical InformationDocument1 pagePVG 32 Proportional Valve Group General Description: Technical InformationjonNo ratings yet

- 1756-If16, 1756-If16K: Controllogix Voltage/Current Analog Input ModuleDocument5 pages1756-If16, 1756-If16K: Controllogix Voltage/Current Analog Input ModuledurbanmejiasNo ratings yet

- Revised G0544, G5850Z & G5851Z Wiring Diagram: Rab-A35 Rab - A18Document1 pageRevised G0544, G5850Z & G5851Z Wiring Diagram: Rab-A35 Rab - A18JUAN RIVERA DUEÑASNo ratings yet

- Schematic Diagrams: 12-1 Scaler1 Signal Input, Lvds OutputDocument25 pagesSchematic Diagrams: 12-1 Scaler1 Signal Input, Lvds OutputssoeeksNo ratings yet

- PN RatingDocument24 pagesPN Ratingjp3863887No ratings yet

- Meteran Ning Panel Ono SkalaneDocument1 pageMeteran Ning Panel Ono Skalanewyne leonheartNo ratings yet

- Ep100 ManualDocument20 pagesEp100 Manualhang100% (1)