Professional Documents

Culture Documents

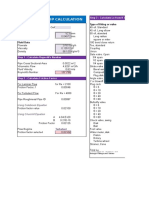

Calculations

Calculations

Uploaded by

SK NGCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculations

Calculations

Uploaded by

SK NGCopyright:

Available Formats

Calculations

OAR 690-014-0100(8): The maximum rate of use shall be determined by actual

measurement when possible. Water measurements may be made by weir, meter, rated

flume, reservoir capacity table or other method of measurement acceptable to the

Department. The report shall describe the method used in making the measurement, the

date made and a description of the location where the measurement was taken. It shall

contain sufficient information, including current meter notes, rating tables, and/or

calibration information to enable the Director to check the quantity of water measured in

each case. Computations for capacity of the system shall be submitted for all claims.

These computations may suffice to determine the maximum rate of application if the

system was not operating when the inspection was conducted.

The Department typically uses the following calculations to determine system capacities:

Flow rate for pumps:

(horsepower )( pump efficiency)

Q pump (cfs) =

(total head in feet )

NOTE: Pump efficiency factor for centrifugal pump (75%) = 6.61

Pump efficiency factor for turbine pump (80%) = 7.04

Total head is the sum of suction lift, pressure head, and discharge lift.

If the operating pressure is not measured, varying the assumed operational pressure in the

above formulas until the calculated outputs are equal, or nearly so, will generally give the

most correct theoretical capacity of the system.

Flow rate for sprinklers:

(number of heads)(rate per head in gpm)

Qsprinklers (cfs) =

449

NOTE: Use the maximum number heads operating at any one time.

448.831 gpm = 1 cfs; use 449

Rate per head in gpm comes from either manufacturer’s

specifications using orifice size and operating pressure or from

OWRD chart.

Calculations of flow in ditches, canals, and gravity flow pipes require a multiplication of

the velocity of flow by the area of the wetted perimeter’s cross-section. The following

two sections deal with the velocity portion of that calculation.

For ditches/canals:

Manning’s Formula:

1.486 2 / 3 1 / 2

v= r s

n

v = mean velocity of flow in feet per second

r = hydraulic radius in feet

s = slope of the energy gradient

n = coefficient of roughness

For gravity flow pipe systems:

Hazen-Williams Formula:

v = 1.31(c)(r 0.63 )( s 0.54 )

v = mean velocity of flow in feet per second

c = coefficient of roughness

r = hydraulic radius in feet

s = slope of energy gradient

For small reservoirs

(those not required to submit as-builts and rating curves):

v = (surface area in acres)(maximum depth)(0.4)

The Department has created a series of Excel spreadsheets to solve the equations for the

above systems. Those spreadsheets are available for download from the Department’s

website.

You might also like

- Pressure Safety Valve Sizing CalculationDocument4 pagesPressure Safety Valve Sizing CalculationAbelardo ContrerasNo ratings yet

- Java ResumeDocument4 pagesJava ResumeRekha Perumal VijayanNo ratings yet

- Understanding NPSHDocument34 pagesUnderstanding NPSHeliyanto budiartoNo ratings yet

- Hydraulic Calculation: Factor FDocument2 pagesHydraulic Calculation: Factor FKrishna PATELNo ratings yet

- Head Loss CalculationDocument7 pagesHead Loss CalculationCuong VuNo ratings yet

- Simulation of Distillation For ACETONE-BENZENE-CHLOROFORMDocument8 pagesSimulation of Distillation For ACETONE-BENZENE-CHLOROFORMfjcgNo ratings yet

- Orifice, Nozzle and Venturi Flow Rate Meters: Water & Air FlowmetersDocument4 pagesOrifice, Nozzle and Venturi Flow Rate Meters: Water & Air Flowmeterssiva_nagesh_2No ratings yet

- Calculating The PUMP SizesDocument1 pageCalculating The PUMP Sizesaman vermaNo ratings yet

- Line Single PhaseDocument2 pagesLine Single PhasehussamNo ratings yet

- Vacuum Pump SizingDocument1 pageVacuum Pump SizingMuhammad HassamNo ratings yet

- NSPHa CalculationDocument3 pagesNSPHa CalculationYakubuNo ratings yet

- Chapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeDocument6 pagesChapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeRicardo NapitupuluNo ratings yet

- TIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredDocument3 pagesTIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredAnonymous BJ9omONo ratings yet

- 00 BLANK Pipe Size Calc Sheet HWS - CWSDocument9 pages00 BLANK Pipe Size Calc Sheet HWS - CWSharoub_nasNo ratings yet

- Pressure Loss & Performance Fan Calculation: Input Data Edit Comp & Fitg View Graph View Chart & DRWGDocument11 pagesPressure Loss & Performance Fan Calculation: Input Data Edit Comp & Fitg View Graph View Chart & DRWGHerawan HeriNo ratings yet

- CIS7:2014Document66 pagesCIS7:2014Ken ChuahNo ratings yet

- How To Size A Control Valve For Liquid and Gas Applications Usi PDFDocument4 pagesHow To Size A Control Valve For Liquid and Gas Applications Usi PDFv noteNo ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- Series & Parallel PumpsDocument48 pagesSeries & Parallel PumpsMoh AmmNo ratings yet

- UPVC Pipe SizeDocument2 pagesUPVC Pipe Sizeahmedomar_953724702No ratings yet

- Flow Through Packed BedDocument7 pagesFlow Through Packed BedHomo SapienNo ratings yet

- Pressure Drop Calculation: Type of Fitting or Valve Pipe DataDocument3 pagesPressure Drop Calculation: Type of Fitting or Valve Pipe DataRawlinson TolentinoNo ratings yet

- Line Sizing Single Phase Fluid Flow: Chemical Engineering CalculationsDocument2 pagesLine Sizing Single Phase Fluid Flow: Chemical Engineering CalculationsRawlinson TolentinoNo ratings yet

- Friction LossesDocument34 pagesFriction LossesTahaNo ratings yet

- Air CompressorDocument37 pagesAir Compressorsamal_biswaNo ratings yet

- E PipeAlator08Document9 pagesE PipeAlator08nguyentienphatNo ratings yet

- PSV-Tag No.: K K CFDocument3 pagesPSV-Tag No.: K K CFoas217No ratings yet

- Liquid Line SizingDocument8 pagesLiquid Line Sizingsamuad59No ratings yet

- Lecture 6 1Document24 pagesLecture 6 1Dany LoboNo ratings yet

- EQ-502 Curve Fitting - PolynomialDocument8 pagesEQ-502 Curve Fitting - PolynomialadpanfeqNo ratings yet

- Flow Meter Audit Typical MethodDocument21 pagesFlow Meter Audit Typical MethodAbhishek RathiNo ratings yet

- Sizing Two Phase Horizontal SeparatorDocument26 pagesSizing Two Phase Horizontal SeparatorRyan Goh Chuang HongNo ratings yet

- PRV-1 StepxStep PDFDocument8 pagesPRV-1 StepxStep PDFmiltonNo ratings yet

- Bubble Dew - Solver IPDocument33 pagesBubble Dew - Solver IPApsari Puspita AiniNo ratings yet

- Booster Pump Head Calculation - AaDocument5 pagesBooster Pump Head Calculation - AaAdnan AttishNo ratings yet

- Total Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Document41 pagesTotal Head, N.P.S.H. and Other Calculation Examples: Jacques Chaurette P. Eng., June 2003Anonymous 1fyKr9XSeGNo ratings yet

- Hot Water System Sizing CalculationDocument1 pageHot Water System Sizing CalculationPhyu Mar Thein KyawNo ratings yet

- Additional Refrigerant Charge Calculation ToolDocument73 pagesAdditional Refrigerant Charge Calculation ToolStefy CarrascoNo ratings yet

- Volum Water HydrotestDocument2 pagesVolum Water HydrotestFerinoviardi100% (1)

- Pump System CalculationsDocument31 pagesPump System CalculationsMandarNo ratings yet

- Pressure Drop in Air Piping SystemsDocument12 pagesPressure Drop in Air Piping SystemsDamith Buddhika Sri WimalarathnaNo ratings yet

- 06 - CompressorsDocument16 pages06 - CompressorsSrinivasa Rao Venkumahanthi100% (1)

- Design Calculation Sheet: 1-AbbreviationsDocument2 pagesDesign Calculation Sheet: 1-AbbreviationsOltun KAYANo ratings yet

- 300 Lit Water Tanks Stem Heating CalculationDocument8 pages300 Lit Water Tanks Stem Heating CalculationEngFaisal AlraiNo ratings yet

- Hydraulic Calculation For FFDocument2 pagesHydraulic Calculation For FFArshath FleminNo ratings yet

- Velocity Ranges (Metcalf & Eddy) Pressurized Pipe Non-Pressurized Pipe Through Gravity 1 - 3 M/s 0.5 - 1 M/s 0.1 - 0.6 M/sDocument4 pagesVelocity Ranges (Metcalf & Eddy) Pressurized Pipe Non-Pressurized Pipe Through Gravity 1 - 3 M/s 0.5 - 1 M/s 0.1 - 0.6 M/sFatima AnwarNo ratings yet

- Darcy - Weisbach - EquationDocument6 pagesDarcy - Weisbach - Equationachmadh_2010No ratings yet

- Stair Case Pressurization Calculation Class ADocument8 pagesStair Case Pressurization Calculation Class AfisplNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams EquationNur IzzaidahNo ratings yet

- Sgps Id01 CalcDocument48 pagesSgps Id01 Calcsaroat moongwattanaNo ratings yet

- Weil Pump Flow and Basin Sizing Calculator (EDocFind - Com)Document15 pagesWeil Pump Flow and Basin Sizing Calculator (EDocFind - Com)mohdnazirNo ratings yet

- Pump SizingDocument3 pagesPump SizingTagabo AliNo ratings yet

- Flow Meter Orifice CalculationDocument27 pagesFlow Meter Orifice CalculationLaksono BudiNo ratings yet

- Air Cooled HX Data SheetDocument1 pageAir Cooled HX Data SheetHoney TiwariNo ratings yet

- Relief Valve SizingDocument3 pagesRelief Valve SizingcutefrenzyNo ratings yet

- 4.4 Heat Ex ChangersDocument7 pages4.4 Heat Ex Changersmukesh kaushikNo ratings yet

- Pumps & Pumping SystemDocument4 pagesPumps & Pumping SystemAjay kunwar singhNo ratings yet

- News Vol3 I7 JulDocument4 pagesNews Vol3 I7 JulSonal GuptaNo ratings yet

- Fluid Mechanics II (Chapter4)Document15 pagesFluid Mechanics II (Chapter4)حيدر محمدNo ratings yet

- 4.2 Water PumpDocument8 pages4.2 Water PumpPRATIKNo ratings yet

- Unigraphics NX8 - SweepDocument29 pagesUnigraphics NX8 - SweepGary Bam100% (3)

- TMTransmissionTE27 32FF.01enDocument96 pagesTMTransmissionTE27 32FF.01ensandeep palNo ratings yet

- Anionic GapDocument8 pagesAnionic GapMaria-Larisa HohanNo ratings yet

- Aerial Drone Solutions - Asset Inspections V2Document8 pagesAerial Drone Solutions - Asset Inspections V2Roy MoserNo ratings yet

- Bidding Document Banking Reconciliation System - 0Document9 pagesBidding Document Banking Reconciliation System - 0Usman AmjadNo ratings yet

- To Study On Marketing Strategies of SamsungDocument64 pagesTo Study On Marketing Strategies of SamsungVaibhav Shah MangalamjobsNo ratings yet

- Ecn 405 3Document84 pagesEcn 405 3Yatharth KhannaNo ratings yet

- Final Lab Report 1Document4 pagesFinal Lab Report 1haynsaNo ratings yet

- Ef Ei04 01Document7 pagesEf Ei04 01TAHER AMMARNo ratings yet

- A&P by John UpdikeDocument4 pagesA&P by John Updikenazish aliNo ratings yet

- Operating Instruction and Documentation: Automotive Lift Date: 10-2000 Manual Date: 06.10.2000 Version: ElectronicDocument45 pagesOperating Instruction and Documentation: Automotive Lift Date: 10-2000 Manual Date: 06.10.2000 Version: Electronicmordidomi100% (1)

- IMO RequirementsDocument5 pagesIMO RequirementsKiên TạNo ratings yet

- QuestionnairesDocument5 pagesQuestionnairesKrisk TadeoNo ratings yet

- Contractual Teachers Advertisment 2022-23Document5 pagesContractual Teachers Advertisment 2022-23Gunaganti MaheshNo ratings yet

- Standard 9 Number SystemsDocument7 pagesStandard 9 Number SystemspandaNo ratings yet

- Comparison of BS and BSEN For Steel Simplified VersionDocument19 pagesComparison of BS and BSEN For Steel Simplified VersionSadashiva sahooNo ratings yet

- A Ls Tom Training CatalogDocument98 pagesA Ls Tom Training CataloglosamigosfcNo ratings yet

- Engine Equipment TableDocument2 pagesEngine Equipment TableFandy MaulanNo ratings yet

- Water Balance - Mar23pdfDocument1 pageWater Balance - Mar23pdfSetiawan HatmajiNo ratings yet

- 679 02 Fenner Chain DrivesDocument32 pages679 02 Fenner Chain Drivesparag76760% (1)

- Lesson Number/ Title/Focus Key Understanding (KU) and Key Questions (KQ) Activities/ Teaching StrategiesDocument5 pagesLesson Number/ Title/Focus Key Understanding (KU) and Key Questions (KQ) Activities/ Teaching StrategiesCeline Grace Monterero50% (2)

- Internship Report On Customer Service and Satisfaction of Prime Bank LimitedDocument49 pagesInternship Report On Customer Service and Satisfaction of Prime Bank LimitedNaman KandpalNo ratings yet

- Trip Distribution TechniquesDocument1 pageTrip Distribution TechniquesChristopher PantojaNo ratings yet

- Operasi Teknik Kimia Iii Rizka Amalia, S.T., M.TDocument60 pagesOperasi Teknik Kimia Iii Rizka Amalia, S.T., M.TEnricoNo ratings yet

- Radiology Fellowships - Austin HealthDocument4 pagesRadiology Fellowships - Austin Healthsage masonNo ratings yet

- Activity 2.1: I. Write The Pronoun That Can Take The Place of Each NounDocument2 pagesActivity 2.1: I. Write The Pronoun That Can Take The Place of Each NounMark Alvin Jay CarpioNo ratings yet

- Memo Schools Division Guidelines On The Issuance and Accountability of Parentguardian For The Borrowed Ict Devices and Other Related MattersDocument11 pagesMemo Schools Division Guidelines On The Issuance and Accountability of Parentguardian For The Borrowed Ict Devices and Other Related Mattersvictorli cionNo ratings yet

- Jsce PDFDocument530 pagesJsce PDFKhin Sandi KoNo ratings yet

- 2WAB0 BBK Week 1-2 AnnotatedDocument45 pages2WAB0 BBK Week 1-2 Annotatedxenia sastropawiroNo ratings yet