Professional Documents

Culture Documents

Plastic Processing Formula

Uploaded by

Mony ES0 ratings0% found this document useful (0 votes)

17 views1 pageCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pagePlastic Processing Formula

Uploaded by

Mony ESCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

CHILLER SIZING

INJECTION 30#/HR H.D.POLYETHYLENE…………………………... = 1 TON

MOLDING 35#/HR L.D.POLYETHYLENE/POLYPROPYLENE….... = 1 TON

40#/HR NYLON…………………………………………… = 1 TON

50#/HR POLYSTYRENE OR ABS……………………….. = 1 TON

65#/HR PVC OR POLYCARBONATE…………………… = 1 TON

70#/HR P.E.T……………………………………………..... = 1 TON

EXTRUSION 50#/HR POLYETHYLENE OR POLYPROPYLENE……. = 1 TON

75#/HR POLYSTYRENE………………………………….. = 1 TON

80#/HR PVC……………………………………………….. = 1 TON

BLOW 35#/HR POLYOLEFINS…………………………………... = 1 TON

MOLDING

AUXILLARY EQUIPMENT COOLING

AIR COMPRESSOR (NO AFTER COOLER)…………………........ = .16 TON/HP

AIR COMPRESSOR (WITH AFER COOLER)…………………….. = .2 TON/HP

VACUUM PUMP………………………………………………….... = .1 TON/HP

HYDRALIC COOLING…………………………………………….. = .1 TON/HP

HOT RUNNER MOLD……………………………………………… = .1 TON/10.5 KW

WATER PUMP IN CIRCUIT……………………………………….. = .2 TON/HP

FEED THROAT-400 TON MACHINE AND ABOVE…………….. = 1 TON

BELOW 400 TON…………………………………………………... = 1/2 TON

EXTRUTER COOLING

GEER BOX COOLING……………………………... = 1 TON/100HP

FEED THROAT 3” SCREW OR LESS…………….. = 1 TON

ABOVE 3” SCREW………………………………... = 2 TONS

BARREL OR SCREW COOLING…………………. = 1 TON/INCH OF SCREW DIA.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 5 Whys: Why 1 Why 2 Why 3 Why 4 Why 5 Why? Because Why? Because Why? Because Why? Because Why? BecauseDocument2 pages5 Whys: Why 1 Why 2 Why 3 Why 4 Why 5 Why? Because Why? Because Why? Because Why? Because Why? BecauseMony ESNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Title: Bahama Bistro Lunch Order Delays: Background: Proposed Countermeasure(s)Document2 pagesTitle: Bahama Bistro Lunch Order Delays: Background: Proposed Countermeasure(s)Mony ESNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Super Simple Lean Six Sigma Glossary - P300 9 - GoLeanSixSigma - ComDocument30 pagesSuper Simple Lean Six Sigma Glossary - P300 9 - GoLeanSixSigma - ComMony ESNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 8-Wastes-Check-Sheet v3.1 GoLeanSixSigma - ComDocument6 pages8-Wastes-Check-Sheet v3.1 GoLeanSixSigma - ComHector GNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Problem Solvers Toolkit - B100 2 - GoLeanSixSigma - ComDocument192 pagesThe Problem Solvers Toolkit - B100 2 - GoLeanSixSigma - ComMony ES100% (11)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Go Getters Guide To Coaching DMAIC P205 3 GoLeanSixSigma - Com v2Document19 pagesGo Getters Guide To Coaching DMAIC P205 3 GoLeanSixSigma - Com v2Mony ESNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Go-Getters Guide To Dmaic: An Easy To Use, Comprehensive Reference For Completing Successful Lean Six Sigma ProjectsDocument8 pagesGo-Getters Guide To Dmaic: An Easy To Use, Comprehensive Reference For Completing Successful Lean Six Sigma ProjectsMony ES100% (1)

- Lean Six Sigma Traingin RolloutDocument16 pagesLean Six Sigma Traingin RolloutMony ESNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Super Simple Lean Six Sigma Glossary - P300 9 - GoLeanSixSigma - ComDocument30 pagesSuper Simple Lean Six Sigma Glossary - P300 9 - GoLeanSixSigma - ComMony ESNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

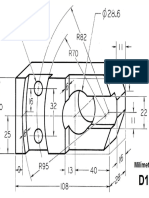

- Practice 3d Part 1Document1 pagePractice 3d Part 1Mony ESNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Lean Six Sigma Traingin RolloutDocument16 pagesLean Six Sigma Traingin RolloutMony ESNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Go Getters Guide To Coaching DMAIC P205 3 GoLeanSixSigma - Com v2Document19 pagesGo Getters Guide To Coaching DMAIC P205 3 GoLeanSixSigma - Com v2Mony ESNo ratings yet

- Probabilities For Compound EventsDocument9 pagesProbabilities For Compound EventsMony ESNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Larson 1 InstructorDocument66 pagesLarson 1 InstructorMony ESNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Practice 3d PartsDocument1 pagePractice 3d PartsMony ESNo ratings yet

- MIRL States North DakotaDocument38 pagesMIRL States North DakotaMony ESNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Creo3F000 Parametric ConfigoptionsDocument116 pagesCreo3F000 Parametric ConfigoptionskicklOpNo ratings yet

- Pro/ENGINEER Wildfire 3.0 Tips: Keyboard/mouse ShortcutsDocument6 pagesPro/ENGINEER Wildfire 3.0 Tips: Keyboard/mouse ShortcutsCADTDDNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)