Professional Documents

Culture Documents

CP Pilot Manual

CP Pilot Manual

Uploaded by

enzomyboy0 ratings0% found this document useful (0 votes)

190 views7 pagesThe Chandler and Price Pilot Press is a hand operated press, designed to be mounted on a bench or cabinet. Little or no experience is required in its operation. A single disc, depressible grippers, one semi-steel chase, one wrench, two cast rollers, four roller trucks, upper feed board and deIii very hoard are standard equipment on this press.

Original Description:

Original Title

cp-pilot-manual

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Chandler and Price Pilot Press is a hand operated press, designed to be mounted on a bench or cabinet. Little or no experience is required in its operation. A single disc, depressible grippers, one semi-steel chase, one wrench, two cast rollers, four roller trucks, upper feed board and deIii very hoard are standard equipment on this press.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

190 views7 pagesCP Pilot Manual

CP Pilot Manual

Uploaded by

enzomyboyThe Chandler and Price Pilot Press is a hand operated press, designed to be mounted on a bench or cabinet. Little or no experience is required in its operation. A single disc, depressible grippers, one semi-steel chase, one wrench, two cast rollers, four roller trucks, upper feed board and deIii very hoard are standard equipment on this press.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

THE CHANDLER AND PRICE

PILOT PRESS

@Standard equipment on the

Chandler & Price Pilot Press ins

cludes a single dise, depressible grip-

pers, one semi-steel chase, one

wrench, two east rollers, four roller

trucks, upper feed board and de-

elhe total

boxed ready for sh

tof this press,

ent, is 210

pounds. Immediate delivery ean be

‘made from stock.

(Es tickets, programs, menus and other jobs to be run in

small quantities can be printed economically on this thor-

oughly efficient little press. It is a hand operated press, designed

to be mounted on a bench or cabinet. Little or no experienc

required in its operation. It is quickly made ready, easily handled

and the printing results secured are exceptionally fine for so

small a press. The Chandler & Price Company, Cleveland, Ohio.

CHANDLER & PRICE

PRINTING PRESSES AND PAPER CUTTERS

INSTRUCTIONS FOR ASSEMBLING AND OPERATING

‘THE CHANDLER & PRICE PILOT PRESS

Unpacking — after corefully unpacking, clean the dirt and grease from the Press. It is then ready to be set in posl-

tion.

The set screw tied fo the package on the press belongs to the hand lever,

The long hand lever is placed on the shaft which has @ key tied to it with twine, After placing on shaft, tighten

set screw securely. The lever can be placed on the opposite end of the shaft if more convenient for the operator. To

do this, remove the collar and change ends with the handl

Remove package tied to the press. This contains two (2) table brackets. The left hand bracket has a lug with a

hole in it, In assembling, the long part of the spring rod goes into the hole in the lug, and the bottom of the brack-

is placed on the shaft that has a nut to tighten the bracket against the frame. Place the right side bracket on the

right side of the shaft and tighten with the shaft nut.

Put the ink disc in the hole in the dise bracket, then place the form rollers in the saddles after putting roller trucks

on the ends of the rollers. Do not let form rollers rest on ink dise or form as rollers will become flat and ruined.

the feed table to the brackets, by operating the press to get the clearance of the moving parts, such as the hand

lever and platen. After the table is set in the correct position, screw the four wood screws through the brackets into

the feed table. Oil the press with a good grade of machine oll and the press is ready to operate.

\ The chase is the steel frame in which the type form is locked. It is placed on the two lugs, [ust below the bed of

the press, and held in place by the strong spring clamp at the top. When placing or removing the chase from the

press, care must be taken not fo injure the type or cuts in the form by striking them on the platen or grippers.

The platen is the metal surface on which is placed the sheet to be printed. It must be covered with a number of

sheets of poper, which are held at the top and bottom by the tympan beles. This packing in the printer's longvage

‘called the tympan. The top sheet it « heavy ciled shest of manila, and under it four (4) sheets of 50-pound S&SC

jook should be placed and clamped down tight by the tympan bales. Be sure these are tightly down, for if loose

they may ruin the type and injure the press. If the form to be printed Is a heavy one, it may be necessary to add a

press-board under the top sheet. This board should not go under the tympan bales. It is best to take the first im-

pression on the top sheet without @ press-board under the tympan.

‘After pulling the impression under the tympan, mark the margins on the sheet to be printed and then set the gauge

pins. Wesh the ink from the impression on the tympan sheet and then pull an impression on the sheet of stock to be

rinted. If any letter or part of form does not print clearly, it must be made ready by spotting the low spots with

fissve until all parts print evenly.

‘After printing each job, the form should be taken from the press and thoroughly cleaned. First dampen a cloth with

cleaning fluid and wipe the ink from the form. Then scrub the form with a benzine brush saturated with gasoline

cfier which the form should be wiped again with @ soft dry cloth.

‘A word of caution: Be sure there are no buttons or pins in the rags as they will nick the type ond scratch the cuts,

The press end rollers should have the ink washed from them every evening. When washing the rollers always use

kerosene as gasoline will cause the form rollers to crack.

CHANDLER & PRICE

NEW MODEL

PILOT PRESS

PARTS LIST

THE CHANDLER & PRICE CO., CLEVELAND 3, OHIO

20738

237

7

293 260 266

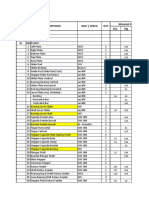

NEW MODEL PILOT PRESS PARTS.

Number Figure Name

201 1 Left Side Frame

202 2 Right Side Frame

203 1 Bed

2038 2 ~~ ‘Bed Screw

204 2 Platen

204N 1_—Impression Screw Nut

2048 1 ‘Top Impression Screw

2041S 1 Bottom Impression Screw

208 1 Rocker

206 2 Yoke

206C * +~— Yoke Spring Cotter

206E 2 Yoke Spring

206R 2 ~—-Yoke Spring Rod

206% 2 Yoke Shaft

206188 * Yoke Shaft Set Screw

207 1 Disc

208 1 Disc Bracket

2088 2 Disc Bracket Screw

217 2 Roller Arm

2178 2 ‘Roller Arm Screw

219 1 Left Feed Table Bracket

220 2 Right Feed Table Bracket

221 1 Left Roller Frame

221GP * Roller Saddle Guide Pin

221P * — Roller Frame Pin

222 2 Right Roller Frame

224 1 Lever

224K «1 Lever Key

2248S 1 Lever Set Screw

227 2 Ink Roller Truck

228 * Chase

230 1 Chase Hook

230E * Chase Hook Spring

230H = * — Chase Hook Spring Hanger

2308 * Chase Hook Screw

231 1 Gripper Bar

231E 1 Gripper Bar Spring

2318 2 Gripper Bar Screw

2318S * Gripper Bar Set Screw

234 * — Roller Mould Base

234% * Roller Mould Tube

235 * — Roller Mould Star

236 * Disc Lever Cam

* — Not shown on diagram,

Number Figure

236 S

237

2378

238

238 P

239

239 C

239E

239 P

239R

241

241N

241i

241148

245 P

247

247

255

2558

260

263

263 Cast

263 P

264

264R

267

2678

269

269 P

271

2741

274148

280

280T

283

283 S

284

2848

285

285T

286

286 P

NN ON EN FENN EE ERE NE HEN ENE NE EN EE ee ee ee

es

Name

Disc Lever Cam Screw

Disc Lever

Disc Lever Screw

Disc Lever Pawl

Disc Lever Pawl Pin

Saddle

Roller Saddle Cotter

Saddle Spring

Roller Saddle Pin

Saddle Rod

Front Brace Rod

Front Brace Rod Nut

Back Brace Rod

Back Brace Rod Screw

Saddle Key Pin

Left Side Arm

Right Side Arm

Side Arm Washer

Side Arm Washer Screw

Wrench

Roller Stock

Cast Rollers

Roller Retaining Pin

Tympan Bale

Tympan Bale Rivet

Gripper Spring Clamp

Gripper Spring Screw

Roller Shaft

Roller Shaft Pin

Roller Shaft Washer

Yoke Collar

Yoke Collar Screw

Gripper

Gripper Screw

Lower Feed Table

Lower Feed Table Screw

Upper Feed Table

Upper Feed Table Screw

Upper Feed Table Bracket

Upper Feed Table Bracket

Thumb Screw

Upper Feed Table Fork

Upper Feed Table Fork Stud

You might also like

- L900 BDocument42 pagesL900 BheartofdixieNo ratings yet

- 9js150ta-B QH50-G16576Document32 pages9js150ta-B QH50-G16576Stewart DuncanNo ratings yet

- SchematicDocument183 pagesSchematicJanne KiviahoNo ratings yet

- Description and Operating Instructions For The Duplex Filter 2.04.5 DN 25-50Document12 pagesDescription and Operating Instructions For The Duplex Filter 2.04.5 DN 25-50KaushalKishoreNo ratings yet

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Eagle Beaver 35-60gsl Cama BajaDocument55 pagesEagle Beaver 35-60gsl Cama BajaJorge CordobaNo ratings yet

- Low Boy Ganzo DollyDocument55 pagesLow Boy Ganzo DollyDaniel Vargas RibeiroNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- 6 Product List Tata Hitachi EX 200Document4 pages6 Product List Tata Hitachi EX 200ER Sudhir MishraNo ratings yet

- Suspension Hendrickson CamionesDocument10 pagesSuspension Hendrickson CamionesEstuars SalgueroNo ratings yet

- Komatsu WA180 PDFDocument282 pagesKomatsu WA180 PDFmiguel100% (3)

- 2.04.5 DN25-50 - KS - 4-36-2 - Marine - GBDocument13 pages2.04.5 DN25-50 - KS - 4-36-2 - Marine - GBJohn ZhongNo ratings yet

- Retsco Type B RrvalveDocument2 pagesRetsco Type B RrvalveGregory Stewart100% (1)

- Le BLONDDocument47 pagesLe BLONDjacksonholland8335100% (1)

- GIANT WheelSystem Service Info - V01 PDFDocument32 pagesGIANT WheelSystem Service Info - V01 PDFcsrpirataNo ratings yet

- Llave de Tuberia FosterDocument17 pagesLlave de Tuberia FosterjuansinopecNo ratings yet

- Mosin Nagant Rifle Exploded Views and DisassemblyDocument19 pagesMosin Nagant Rifle Exploded Views and DisassemblyKarlton Criswell100% (4)

- PilotSystem Gas15Gal 1BBL - V5Document21 pagesPilotSystem Gas15Gal 1BBL - V5antonio alberto gutierrez suarezNo ratings yet

- Putz Manual - Part7Document2 pagesPutz Manual - Part7Vijay BhureNo ratings yet

- Despiehooj&Compflesor/Compressorparts/Vue Eclatee Du Compre ' "" ' K"C,, - ' ' J " ':, 'Document3 pagesDespiehooj&Compflesor/Compressorparts/Vue Eclatee Du Compre ' "" ' K"C,, - ' ' J " ':, 'rpichoNo ratings yet

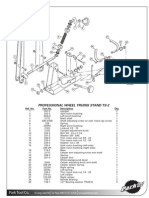

- Park Tool Co.: Professional Wheel Truing Stand Ts-2Document1 pagePark Tool Co.: Professional Wheel Truing Stand Ts-2Jackson WallNo ratings yet

- Hydraulic Tubing PunchDocument19 pagesHydraulic Tubing Punchu2006262918No ratings yet

- Harvester 9566755522Document2 pagesHarvester 9566755522Ram ParimalamNo ratings yet

- First Choice Parts - 2015Document12 pagesFirst Choice Parts - 2015Security Lock DistributorsNo ratings yet

- LIPBA - Lincoln Spare Parts List PDFDocument3 pagesLIPBA - Lincoln Spare Parts List PDFLaurentiu DafinaNo ratings yet

- Disassembly-P10-P12 .380Document5 pagesDisassembly-P10-P12 .380Karyn WathenNo ratings yet

- ABB 3332650 CatalogDocument40 pagesABB 3332650 CatalogOMARNo ratings yet

- DESVASTADORA YH-801 零件本 操作手冊 PDFDocument15 pagesDESVASTADORA YH-801 零件本 操作手冊 PDFSandra Liliana Rodriguez NietoNo ratings yet

- Eaton Fuller FS 5205A Transmission Parts ManualDocument22 pagesEaton Fuller FS 5205A Transmission Parts ManualJesus Antonio Ramos EscalanteNo ratings yet

- Eaton Fuller FS 5205B Transmission Parts ManualDocument22 pagesEaton Fuller FS 5205B Transmission Parts ManualSmaily Lopez TobarNo ratings yet

- Backhoe Swing Tower and BoomDocument4 pagesBackhoe Swing Tower and BoomGerardo BalboaNo ratings yet

- Transmision FABCO TC-142Document22 pagesTransmision FABCO TC-142Maya OlmecaNo ratings yet

- HPS STGDocument33 pagesHPS STGDJGGNo ratings yet

- SHIPBOARD PALLET TRUCK - ManualDocument18 pagesSHIPBOARD PALLET TRUCK - Manualreka1950No ratings yet

- 621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Document3 pages621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1JESUSNo ratings yet

- Disassembly Manual TransmissionDocument12 pagesDisassembly Manual TransmissionRyan Jay Atilano LontocNo ratings yet

- Actobotics Assortment Pack IncludesDocument8 pagesActobotics Assortment Pack Includesanon_937334650No ratings yet

- 1959 Locke Mower Parts ManualDocument60 pages1959 Locke Mower Parts ManualJoseph T. Buscaglia100% (1)

- Prusa I3 Build Document by 3D Printer Czar PDFDocument29 pagesPrusa I3 Build Document by 3D Printer Czar PDFlasersmartNo ratings yet

- Hilti Dx35 Parts ListDocument1 pageHilti Dx35 Parts Listsajjad_naghdi241No ratings yet

- LG400 Schaft CompetitionDocument3 pagesLG400 Schaft Competitionsjdarkman1930No ratings yet

- Goodman CPLT Parts ManualDocument11 pagesGoodman CPLT Parts ManualPeter ManNo ratings yet

- WB-LS 11Document16 pagesWB-LS 11Rob ThoenNo ratings yet

- Ornamental ManualDocument26 pagesOrnamental ManualКонстантин ГусевNo ratings yet

- BOM Mesin Band Sealing Capsule2-31-01-18Document37 pagesBOM Mesin Band Sealing Capsule2-31-01-18admin sasatek123No ratings yet

- Partes de Horquilla GSForkPartsDocument2 pagesPartes de Horquilla GSForkPartsJavier ArrarásNo ratings yet

- 069Document2 pages069aliasghar yadegariNo ratings yet

- MK18-20 SparelistDocument26 pagesMK18-20 SparelistaritmeticsNo ratings yet

- LT 135 PartsCatalogDocument24 pagesLT 135 PartsCatalogalxsscabalNo ratings yet

- g2 Mounting Instructions T 420 Nissan 2004 PresentDocument10 pagesg2 Mounting Instructions T 420 Nissan 2004 PresentLisette HowardNo ratings yet

- Total Materials ListDocument18 pagesTotal Materials ListKushal SrivastavaNo ratings yet

- GML Repair ManualDocument17 pagesGML Repair ManualAndy DowdNo ratings yet

- DF 2010Document24 pagesDF 2010visual619No ratings yet

- Morin Actuator-79S 79B 79C HPDocument8 pagesMorin Actuator-79S 79B 79C HPInamex-fpVeracruzNo ratings yet

- CAPRA CF Exploded DrawingDocument1 pageCAPRA CF Exploded DrawingBen DechoNo ratings yet

- Transmission Tower RestorationDocument21 pagesTransmission Tower Restorationjorge Angel LopeNo ratings yet

- First Rear Axle HousingDocument24 pagesFirst Rear Axle HousingMantenimiento Mecanico BiddleNo ratings yet

- Tecumseh Parts List OHV 135Document5 pagesTecumseh Parts List OHV 135M MNo ratings yet

- Powertec wb-ft11Document12 pagesPowertec wb-ft11carlosNo ratings yet