Professional Documents

Culture Documents

1 - 02 S - IOB Ammonia Casale - Switzerland

1 - 02 S - IOB Ammonia Casale - Switzerland

Uploaded by

Humaira NoorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 - 02 S - IOB Ammonia Casale - Switzerland

1 - 02 S - IOB Ammonia Casale - Switzerland

Uploaded by

Humaira NoorCopyright:

Available Formats

RAZI III A NEW AMMONIA PLANT DESIGNED BY CASALE

By G.L. Capetti, P. Talarico, E. Filippi

AMMONIA CASALE S.A.

Lugano, Switzerland

For presentation at 20th AFA International Annual Technical Conference Tunis, Tunisia, 19-21 June, 2007

Via G. Pocobelli 6 6900 Lugano Switzerland

Tel +41.91.960.72.00 Fax +41.91.960.72.91/2

www.casale.ch ammonia@casale.ch

Abstract AMMONIA CASALE has licensed its Ammonia Plant Technology; the Licensor is PIDEC, an Iranian Engineering Company, who is responsible for the detail engineering. PIDEMCO, an Iranian state-owned Company, is the Final User. The raw materials used include six recovered hydrogen streams (from nearby plants) in addition to natural gas. AMMONIA CASALE Technologies are used for ammonia plant debottlenecking in the process line and CASALE proprietary technologies are supplied. CASALE also supplied the assistance for the purchase of the critical equipment, the checks of the Vendors' drawings and critical piping and site assistance for plant commissioning and startup.

Introduction AMMONIA CASALE is mostly known for its activity in revamping existing plants as well as applying its high efficiency designs to critical items. Its activity in the field of new plant design and construction was mostly limited to supplying the design and proprietary equipment for synthesis loops to its Licensees. Recently AMMONIA CASALE has extended its range of operation, re-entering the market of entirely new plants by obtaining a contract for the supply of License, Basic Engineering and Proprietary Equipment of a new complete ammonia plant having a capacity of 2'050 MTD. The licensed AMMONIA CASALE process includes its proprietary and most advanced design for secondary reformers, shift converters, MU gas dehydration, synthesis converters and waste heat boilers, making the plant very efficient from all points of view, including that of energy consumption and capital cost. CASALE has also supplied to the main contractor its technical assistance for critical equipment purchasing, Vendors' drawings check, critical piping check and site assistance for plant commissioning and start-up. The plant has been built in Iran, in the RAZI PETROCHEMICAL COMPLEX, and is under commissioning.

Primary Reformer, Secondary Reformer Steam Drum & Waste Heat Boiler

Plant Raw Material The most common raw material for an ammonia plant in this area is natural gas (NG). In this case, in addition to NG, six hydrogen (H2) streams were available coming from the nearby petrochemical plants. These H2 streams were different in composition, pressure and temperature and their pressures were lower than the process pressure. The streams were combined, taking their composition and pressure into consideration, and injected into different points of the plant: the streams containing methane were compressed, preheated into the primary reformer and mixed with the NG stream at the desulphurizer outlet, whilst the other streams containing less than 1% vol. of methane and with traces of carbon oxides, were added to the process gas upstream to the methanator. The contribution of the H2 to the total ammonia production is about 40% of the plant capacity. In order to compensate possible fluctuation in the availability of hydrogen, the plant has been designed to maintain the nameplate capacity with 70% of H2 streams availability. Process Technology Taking the type of feed stocks and the plant capacity into consideration, the decision was made to design the plant according to the classical steam reforming process. The main process steps are: NG preheating and desulphurization with the addition of H2 rich stream at desulphurizer outlet, mixing with steam, primary reforming and secondary reforming with air. The secondary reformer is equipped with a CASALE burner. Shift conversion of carbon monoxide is performed in two steps, HTS and LTS. The two converters adopt CASALE axial-radial internals to reduce the pressure drop and catalyst volume. CO2 removal through aMDEA removal solution Methanation. CASALE M.U. gas dehydration by ammonia wash. Ammonia Synthesis with three beds, two interchangers and axial-radial CASALE internals Hydrogen recovery from loop purge through a membrane recovery unit.

The main process parameters are the following: Steam to carbon ratio (referred to NG stream only): 3 to 1 CO slip from LTS: less than 0.2% vol. (dry base) CO2 slip from absorber: less than 200 ppm vol. CO2 removal is water balanced (no waste water) Ammonia Converter inlet pressure: 150 bar g Hydrogen recovery unit: recovery about 90% (vol.) of H2 fed to the unit. High pressure steam at 120 g and 505C (completely used within ammonia plant) Medium pressure steam is at 40 bar g and 376C (completely used within ammonia plant) Low pressure steam is at 3.5 bar g and 220C (completely used within ammonia plant). Total energy consumption (evaluated as feeds + fuel + steam import from package boiler) is 7.20 Gcal/MT of produced ammonia. Primary Reformer (top fired) Radiant Box The plant has a closed steam balance, for the start-up a 100 t/h package boiler has been furnished. During normal operation the package boiler is maintained at 30t/h in order to get the boiler ready in case of plant shut-down. As it can be seen from the above information, the plants main characteristics, differentiating it from the other designs, is the use of the AMMONIA CASALE proprietary equipment, making this plant design very effective in terms of capital cost and process efficiency. The main characteristics of this proprietary equipment are: CASALE secondary reformer burner: it has a low pressure drop on both air and process side and a short flame, together with a long duration of the tip, and a high uniformity of temperature and composition at catalyst inlet. CASALE axial-radial shift converters (high and low temperature): the axial-radial flow in the catalyst bed ensures a low and stable pressure drop throughout the entire catalyst life, thus providing a longer catalyst life, a better conversion, a slimmer and less expensive pressure vessel. CASALE M.U gas dehydrator by ammonia wash: it is very simple and it ensures a dry make up gas to the synthesis loop, and the mixing contact of ammonia with syngas is achieved by an injector, therefore obtaining a pressure recovery of the M.U. gas and a perfect contact of liquid and gas phases.

CASALE synthesis converter: it guarantees the highest conversion per pass, reducing the energy consumption and the size of the loop equipment.

All these CASALE technologies mentioned above are also very well proven and reliable, having already been used in many revamped plants and having already achieved a very long operating life. Environmental Impact of the Ammonia Plant The ammonia plant has been designed in such a way as to reduce the environmental impact as much as possible. In fact, the only liquid wastes are the boiler blow down and the air compressor interstage coolers condensate. The boiler blow down, about 4t/h, after flashing and cooling, is used as cooling water make-up for the cooling water loop. Shift Converters The same for the air compressor interstage condensate, about 2.5 t/h depending on the season, which is returned to the cooling water return header. The only gaseous waste is the flue gas from the primary reformer (about 400 t/h) that contains less than 1.5 ppm vol. SOx and about 110 mg/Nm3 of NOx. The guaranteed figure of NOx is less than the one required by the European Community for new plants (140 mg/NM3 calculated at 3% oxygen excess). A report has been prepared to demonstrate to the financing bank that, from an environmental point of view, the plant is designed according to the European Community Regulation.

The Contract The contract was awarded to AMMONIA CASALE and Pidec, through an official international public bid, where CASALE/Pidec succeeded over several international competitors.

Pidec is an Iranian engineering company located in Shiraz and it is the most experienced and well reputed engineering company in Iran with a broad experience in chemical and petrochemical plant detailed engineering, procurement and construction. The plant's Final User is Razi Petrochemical Complex, an affiliate of PIDEMCO, that is one of the Iranian state-owned companies well-known in the field of petrochemical production. AMMONIA CASALEs scope of work was: Full plant technology license. Plant Basic Engineering Package. Supply of proprietary items. Assistance to PIDEC for plant detail engineering, commissioning and start-up.

The contract was awarded at the beginning of the year 2002 and the effective starting date was at the beginning of August 2002. AMMONIA CASALE was responsible for the technology license for the entire ammonia plant and the preparation of the Basic Engineering Package (BEP) for the plant. To familiarize PIDEC's and PIDEMCO's personnel with the ammonia plant design, a task force was created that worked face-to-face with CASALE's task force in Switzerland. In this way, all the problems and questions arising about the process features of the plant and relevant equipment, machineries, instruments, specifications, equipment arrangements, etc. were solved as soon as they were evidenced and very few questions arose during the detailed engineering phase. The cooperation with the Engineering Company and the Final User was further continued in Shiraz where, from tim-to-time and upon request, CASALE specialists were sent to attend and to check the development and the good execution of the job. The Iranian task force had been present in CASALEs offices for about five months until the first issue of the BEP (issued before HAZOP). Some of them were also present at the HAZOP plant analysis. CO2 Removal HAZOP was performed one month after the BEP first issue. The final BEP issue, after HAZOP, was carried out by CASALE only, but all the discussions and decisions inherent to the plant final configuration had already been discussed before.

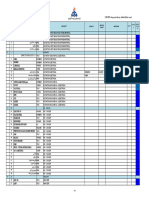

Follow-Up and Assistance during Detail Engineering The detail engineering was performed at PIDEC's offices in Shiraz. All the critical items highlighted during the basic engineering on the basis of CASALE's experience, were subject to CASALE's control and approval during all the phases from the beginning of the detailed engineering with the material requisition check and approval, to the conclusion with the selected Vendor final drawings check and approval. The critical items subject to CASALE's control and approval were: Ammonia plant compressors (air, syngas and ammonia). Heavy duty service pumps (BFW pumps, CO2 circulating solution pumps, liquid ammonia (-3C) pumps). All high pressure static equipment (working above 100 bar g). All reactors and catalyst vessels (secondary reformer, desulphurizer, HTS, LTS, etc.). Primary reformer for which AMMONIA CASALE prepared the process specification. This item has been designed and supplied by other. Start-up heater.

In addition to the above, critical pipe-lines, such as pipe routing and stress analysis, have been checked by CASALE. In particular, the following lines have been checked: All the hot lines working above 350C in the hot front end CO2 system process gas lines, CO2 lines and circulation solution lines. The synloop main process gas line, from compressor suction to synconverter to exchangers, back to the compressor.

The instrumentation controls have been performed for: All control valves of 3" and above. All critical instruments (i.e. in-line analyzer). DCS configuration inclusive of the implementation of advanced process control for plant load and primary reformer combustion optimization.

Synthesis Converter

ESD configuration for plant interlocks. In particular, all the interlocks signals from/to vendor packages alike, compressors and primary reformers were jointly agreed upon by Casale, Vendors, PIDEC and PIDEMCO.

Assistance during Plant Erection In order to assure the proper erection of the plant, CASALE specialists for welding inspections were sent to the site. The welding procedures for critical piping mentioned before were supplied by CASALE. CASALE prepared the procedure for plant commissioning, start-up and normal operation. Presently CASALE supervisors are at the site to supervise these activities. A training course for operators has been held by CASALE. The course was divided in two stages: one theoretical at CASALE's offices and one practical at one of our Client's plants. The plant is being commissioned and CASALE is performing the plant check-out, giving to the Client the process assistance for plant start-up.

Conclusion CASALE has the capability to license the technology for entire ammonia plants and to give support to the EPC contractor for the best success of the plant. This capability is proven by the construction of the Razi III ammonia plant, and by the recent acquisition of a second contract for another 2'050 MTD plant NG based. This technology is based on the use of all CASALE proprietary items, ensuring the most cost effective and efficient plant design.

Lugano, January 2007

Code: adirec/paper/conf/meetings/ammonia/Nitrogen 2007/Razi's third new 2050 MTD

10

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Performance Task 1 in General Chemistry 1: My Illustration of The "Steam Distillation"Document4 pagesPerformance Task 1 in General Chemistry 1: My Illustration of The "Steam Distillation"Jazelle DignoNo ratings yet

- Basics of Reforming, Shapes and Carbon WSVDocument28 pagesBasics of Reforming, Shapes and Carbon WSVMuhammad NaeemNo ratings yet

- 2002 Tech VarahaluDocument11 pages2002 Tech VarahaluMuhammad NaeemNo ratings yet

- Items Description Total Items No. Average Electricity Usage (Watts)Document2 pagesItems Description Total Items No. Average Electricity Usage (Watts)Muhammad NaeemNo ratings yet

- Cats 0e92 42f2 Bcba 43455143d4a1 OriginalDocument1 pageCats 0e92 42f2 Bcba 43455143d4a1 OriginalMuhammad NaeemNo ratings yet

- Saudi Arabia Expats FeesDocument5 pagesSaudi Arabia Expats FeesMuhammad NaeemNo ratings yet

- ERE N Levy FeesDocument1 pageERE N Levy FeesMuhammad NaeemNo ratings yet

- Saudi Arabia Expats FeesDocument5 pagesSaudi Arabia Expats FeesMuhammad NaeemNo ratings yet

- 10-022 Final ReportDocument83 pages10-022 Final ReportMuhammad NaeemNo ratings yet

- Draft Methodology For Calculating Furnace Fan Efficiency PDFDocument6 pagesDraft Methodology For Calculating Furnace Fan Efficiency PDFMuhammad NaeemNo ratings yet

- 1083ch7 0015 PDFDocument18 pages1083ch7 0015 PDFMuhammad NaeemNo ratings yet

- Residence Handbook - 16-17 - WebDocument62 pagesResidence Handbook - 16-17 - WebMuhammad NaeemNo ratings yet

- Nitrogen Power Banks PDFDocument2 pagesNitrogen Power Banks PDFMuhammad NaeemNo ratings yet

- CVDocument2 pagesCVRizki HidayatNo ratings yet

- DPP-02 Chemical KineticsDocument1 pageDPP-02 Chemical KineticsprathmfedNo ratings yet

- 1 WS - Intro To ThermochemistryDocument3 pages1 WS - Intro To ThermochemistryKeyur PatadiaNo ratings yet

- UOP PX-Plus ™ XPDocument2 pagesUOP PX-Plus ™ XPana_dcz7154No ratings yet

- Selective Oxidation of - Butane Maleic Anhydride. 3. Modeling StudiesDocument4 pagesSelective Oxidation of - Butane Maleic Anhydride. 3. Modeling StudiesJuan David Rangel PintoNo ratings yet

- The Indian Public School-Coimbatore Electricity and ChemistryDocument2 pagesThe Indian Public School-Coimbatore Electricity and ChemistryDhriti GuptaNo ratings yet

- United States Patent (19) : 51 Int. Cl. ...................... Conc29/86, Conc29/80, No!", Deutsche Texaco AGDocument7 pagesUnited States Patent (19) : 51 Int. Cl. ...................... Conc29/86, Conc29/80, No!", Deutsche Texaco AGArka Krisna PratamaNo ratings yet

- Combustion FundamentalsDocument5 pagesCombustion FundamentalsRam Krishna SinghNo ratings yet

- Engineering Design Guidelines Flare Systems Rev3.4webDocument25 pagesEngineering Design Guidelines Flare Systems Rev3.4webAntonioNo ratings yet

- Sle PDFDocument5 pagesSle PDFYasmin Kaye100% (1)

- Natural Gas Processing LectureDocument19 pagesNatural Gas Processing LectureManepalli Narasimha Murthy50% (2)

- Chemical Test FormedDocument57 pagesChemical Test FormedMD Ashraful MD AshrafulNo ratings yet

- Presentation1 3Document11 pagesPresentation1 3NerviRitaNo ratings yet

- Propylene Chlorination ReactorDocument7 pagesPropylene Chlorination ReactorJesús SilvaNo ratings yet

- Seperation TechniqueDocument6 pagesSeperation TechniquelindaoeghagharaNo ratings yet

- Lurgi's MPG Gasification Plus RectisolDocument12 pagesLurgi's MPG Gasification Plus Rectisolmourinho2No ratings yet

- Cbse Test Paper-01 Class - 12 Chemistry (Solutions) : Vapour Pressure of The SolutionDocument5 pagesCbse Test Paper-01 Class - 12 Chemistry (Solutions) : Vapour Pressure of The SolutionTr Mazhar PunjabiNo ratings yet

- 1A States of Matter - Edexcel IGCSE Chemistry Unit 1 NotesDocument32 pages1A States of Matter - Edexcel IGCSE Chemistry Unit 1 NotesZoonieFR0% (1)

- Well Head Chistmas TreeDocument9 pagesWell Head Chistmas TreeSatria 'igin' Girindra Nugraha100% (1)

- Chemical KineticsDocument11 pagesChemical KineticsNishant Raj KhuraNo ratings yet

- Crude-Oil-Analyzer-PAC ASTM D7169 PDFDocument4 pagesCrude-Oil-Analyzer-PAC ASTM D7169 PDFJesus David Badillo AcevedoNo ratings yet

- "Kinetics Explanation": Nadia Hazira Radzuan Boah Nabilla ShupuDocument6 pages"Kinetics Explanation": Nadia Hazira Radzuan Boah Nabilla ShupuNurul SabriNo ratings yet

- Chapter - 13 - Chemical - Kinetics (Compatibility Mode) PDFDocument40 pagesChapter - 13 - Chemical - Kinetics (Compatibility Mode) PDFLel Lailiy100% (1)

- List of Vendor 17.12.93Document75 pagesList of Vendor 17.12.93IRANIAN 23No ratings yet

- The Mechanism of The Reaction Between Ketenes and The Grignard ReagentDocument3 pagesThe Mechanism of The Reaction Between Ketenes and The Grignard ReagentAnonymous tI3GfXjR70% (1)

- SOP Compressed GasesDocument13 pagesSOP Compressed GasesShamsol AriffinNo ratings yet

- 337TO 003 World's Largest FLNG PreludeDocument9 pages337TO 003 World's Largest FLNG PreludeRamNo ratings yet

- Carbohydrazide A Hydrazine Replacement PDFDocument6 pagesCarbohydrazide A Hydrazine Replacement PDFTaufiqTaufiqNo ratings yet

- Batch Processing & Scheduling EDITED 19-3-2019Document47 pagesBatch Processing & Scheduling EDITED 19-3-2019Engr Muhammad IrfanNo ratings yet