Professional Documents

Culture Documents

Avionics Ventilation System

Uploaded by

HtetMyetKoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Avionics Ventilation System

Uploaded by

HtetMyetKoCopyright:

Available Formats

21 - AIR CONDITIONING 21-26-00 AVIONICS VENTILATION SYSTEM DESCRIPTION/OPERATION

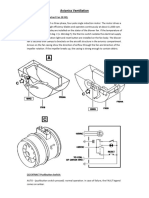

CONTENTS: General Open Circuit Configuration Closed Circuit Configuration Partially Open Circuit Configuration Self Examination GENERAL The system is automatically controlled by the Avionics Equipment Ventilation Computer and no crew action is required. The Avionics Equipment Ventilation Computer (AEVC) will change the system configuration depending on whether the aircraft is on ground or in flight and on aircraft skin temperature. Note that the BLOWER and EXTRACT pushbuttons must be in AUTO position. OPEN CIRCUIT CONFIGURATION In OPEN CIRCUIT CONFIGURATION, ambient air, drawn through the skin air inlet valve by the blower fan, is blown into the system. The air, after cooling avionics equipment, is drawn by the extract fan directly overboard. The OPEN CIRCUIT CONFIGURATION allows avionics equipment to be cooled with ambient air under certain conditions (on ground and skin temperature above 11C (51.8F) increasing, or above 4C (39.2F) decreasing). Note: the skin air inlet and outlet valves are fully open. CLOSED CIRCUIT CONFIGURATION In CLOSED CIRCUIT CONFIGURATION, the extracted avionics equipment air goes, through the skin exchanger isolation valve, into the skin heat exchanger to be cooled. then this air is blown into the avionics equipment again. When the AEVC detects airflow higher than the requested value, part of the hot air is bled under the cargo compartment floor by means of opening of the skin exchanger inlet ByPass Valve. the skin exchanger outlet ByPass Valve opens in order to decrease the noise level in the avionics bay. PARTIALLY OPEN CIRCUIT CONFIGURATION In PARTIALLY OPEN CIRCUIT CONFIGURATION, the system is almost like in closed configuration, part of the extracted air is expelled overboard. Note that the skin air outlet valve is an electrically operated single flap with a smaller flap built into it. This smaller flap is opened in flight (or on ground with take-off power selected) when the skin temperature is above 34C (93.2F). It returns to the closed position when the skin temperature decreases below 27C (80.6F). SELF EXAMINATION When does the skin exchanger inlet bypass valve open? A - In open circuit configuration. B - In partially open circuit configuration, or in closed circuit configuration with airflow higher than the requested value. C - When the ambient avionics bay temperature is above 34C (93.2F).

When does the skin heat exchanger operate on the ground? A - When the circuit operates in open circuit configuration. B - In closed circuit configuration when the skin temperature is below 11C (51.8F) (skin temperature increasing). C - In closed circuit configuration when the skin temperature is above 11C (51.8F) (skin temperature increasing).

21-26-00 AVIONICS VENTILATION SYSTEM INTERFACES

CONTENTS: Landing Gear Control Interface Unit (LGCIU) Engine Interface Unit (EIU) Centralized Fault Display Interface Unit (CFDIU) Skin Temperature Sensor Blowing Pressure Switches And Duct Temperature Sensor Extract Pressure Switch Skin Air Valves/SDAC Controller (AEVC)/SDAC Smoke Detector

AVIONICS VENTILATION - SYSTEM INTERFACES

LANDING GEAR CONTROL INTERFACE UNIT (LGCIU) The Landing Gear Control Interface Unit 1 and 2 send a signal to the avionics controller for ventilation system control. Signal: Ground/flight, used for system control. ENGINE INTERFACE UNIT (EIU) The Engine Interface Unit 1 and 2 send the "take-off thrust on" signal to the avionics controller for ventilation system control. Signal: Thrust lever set to take off and N2 above idle, used for system control. CENTRALIZED FAULT DISPLAY INTERFACE UNIT (CFDIU) The avionics controller sends BITE data to the Centralized Fault Display Interface Unit via ARINC bus. Test of the system is performed by sending a test demand discrete signal to the controller. Signals: BITE data via ARINC bus and MCDU test demand via discrete, used for avionics equipment ventilation system monitoring. SKIN TEMPERATURE SENSOR The skin temperature sensor signals the skin temperature to the computer for configuration control. Signal: Skin temperature, used for configuration control. BLOWING PRESSURE SWITCHES AND DUCT TEMPERATURE SENSOR The blowing pressure switches and the duct temperature sensor signal a low flow and a high duct temperature to the controller, to both System Data Acquisition Concentrators and to the BLOWER pushbutton. On the ground, the ADIRU & AVNCS VENT light illuminates amber on the external power receptacle 108VU accompanied by the horn activation. Signal: Low pressure delta P = 0.025 psi (1,73 hPa) or high duct temperature temp = 62oC (144oF), used for fault and ventilation ground warnings located on external power receptacle 108VU. EXTRACT PRESSURE SWITCH The extract pressure switch signals a low flow to the controller, to both SDACs and to the EXTRACT pushbutton. On the ground, the ADIRU & AVNCS VENT light illuminates amber on the external power receptacle 108VU accompanied by the horn activation. Signal: Extract low pressure, used for fault and ventilation ground warnings located on external power receptacle 108VU.

SKIN AIR VALVES / SDAC The skin air valves position signals are sent to both SDACs for system display and for skin valve fault warning. Signal: Skin valve position feedback, used for system display and valve position disagree warning in flight (SKIN VALVE FAULT). CONTROLLER (AEVC) / SDAC The avionics controller monitors the skin air valves position, the conditioned air inlet valve and the exchanger inlet bypass valve position. In case of valve position disagree or loss of power supply of the controller, the controller sends an avionics system fault signal to both SDACs. Signal: Avionics system fault, used for valve position disagree warning on ground (except the skin exchanger outlet bypass valve) or loss of power supply of the Avionics Equipment Ventilation Computer. SMOKE DETECTOR The smoke detector signals smoke to the controller, to both SDACs, to both VENT pushbuttons and to GEN 1 LINE pushbutton. Signal: Smoke detected, used for smoke warning.

21-26-00 AVIONICS VENTILATION COMPONENTS

CONTENTS: Avionics Equipment Ventilation Computer (AEVC) Skin Air Inlet Valve Skin Air Outlet Valve Blower Fan Extract Fan Skin Exchanger Inlet Bypass Valve Skin Exchanger Isolation Valve Skin Exchanger Outlet Bypass Valve Conditioned Air Inlet Valve Filter Assembly Check Valves Pressure Switches Duct Temperature Sensor Skin Temperature Sensor Skin Heat Exchanger AVIONICS EQUIPMENT VENTILATION COMPUTER (AEVC) IDENTIFICATION FIN: 10HQ LOCATION ZONE: 128 COMPONENT DESCRIPTION The avionics computer controls the valves and fans in the avionics ventilation system. System condition information is sent to the avionics computer by pressure switches and temperature sensors in the system. SKIN AIR INLET VALVE IDENTIFICATION FIN: 15HQ LOCATION ZONE: 127 COMPONENT DESCRIPTION This valve is an electrically operated single flap valve which can be manually overridden. Before the valve is closed manually, it must first be isolated electrically with a toggle switch located inside the valve. TRAINING INFORMATION POINT After a maintenance action on this valve, check that the deactivation switch is put back to ON position in order to recover a normal operation of the system. SKIN AIR OUTLET VALVE IDENTIFICATION

FIN: 22HQ LOCATION ZONE: 126 COMPONENT DESCRIPTION This valve is an electrically operated single flap valve with a smaller flap built into it. Before the valve is closed manually, it must first be isolated electrically with a toggle switch inside the valve. TRAINING INFORMATION POINT After a maintenance action on this valve, check that the deactivation switch is put back to ON position in order to recover a normal operation of the system. BLOWER FAN IDENTIFICATION FIN: 20HQ LOCATION ZONE: 128 COMPONENT DESCRIPTION The blower fan is powered with: - a three phase, four pole single induction motor for high speed, - a three phase, six pole single induction motor for low speed. A thermo switch and relay are installed on the stator of the blower fan. If the temperature of the stator reaches +140 +6 -6 deg C (+284.00 +10.80 -10.80 deg.F), the thermo switch isolates the electrical supply to the fan. A fault indication light and reset button are installed on the fan body. EXTRACT FAN IDENTIFICATION FIN: 18HQ LOCATION ZONE: 128 COMPONENT DESCRIPTION The extraction fan is identical to the blower fan. SKIN EXCHANGER INLET BYPASS VALVE IDENTIFICATION FIN: 16HQ LOCATION ZONE: 126 COMPONENT DESCRIPTION This valve is of the butterfly type, with an actuator which moves the butterfly to the open or closed position. Two microswitches signal the valve position to the avionics computer 10HQ. A visual position indicator is located on the top of the actuator unit. SKIN EXCHANGER ISOLATION VALVE IDENTIFICATION FIN: 24HQ LOCATION ZONE: 126 COMPONENT DESCRIPTION The skin exchanger isolation valve 24HQ is installed upstream of the skin heat exchanger. This valve is identical to the skin exchanger inlet bypass valve 16HQ. SKIN EXCHANGER OUTLET BYPASS VALVE IDENTIFICATION FIN: 23HQ LOCATION ZONE: 125 COMPONENT DESCRIPTION The skin exchanger outlet bypass valve is installed downstream of the skin heat exchanger. This valve is identical to the skin exchanger inlet bypass valve 16HQ. CONDITIONED AIR INLET VALVE

IDENTIFICATION FIN: 21HQ LOCATION ZONE: 127 COMPONENT DESCRIPTION The conditioned air inlet valve is installed in a duct which is connected to the cockpit main supply duct. This valve is similar to the skin exchanger inlet bypass valve. FILTER ASSEMBLY IDENTIFICATION FIN: 2081HM, 2082HM, 2083HM LOCATION ZONE: 127 COMPONENT DESCRIPTION A two-stage filter assembly is installed upstream of the blower fan 20HQ. The first-stage is a cleanable plate type filter 2081HM which removes dust particles above 1000 microns and a multi-layer filter which removes water particles. The second stage is a cleanable, corrugated-cartridge-barrier filter 2082HM which removes any dust particles above 400 microns. The filter assembly is also equipped with pressure test ports for checking the clogging level of the demister and dust filter assembly (through a portable manometer). CHECK VALVES IDENTIFICATION FIN: 2140HM, 2150HM LOCATION ZONE: 128 COMPONENT DESCRIPTION A check valve 2140HM is installed downstream of the blower fan. The check valve is designed to be installed in line between the ducts. Two semicircle flaps are installed on a hinge-bar, a spring holds these semicircle flaps in the closed position. A check valve 2150HM is installed downstream the skin air inlet valve. The purpose of the check valve is to protect the system at the air inlet against possible adverse effects caused by cabin differential pressure. PRESSURE SWITCHES IDENTIFICATION FIN: 17HQ, 19HQ, 30HQ LOCATION ZONE: 121, 127, 127 COMPONENT DESCRIPTION Three pressure switches are installed in the avionics ventilation system, two in the blowing circuit and one in the extraction circuit. The switches are of the capsule/microswitch type with an electrical connector at the top. A low flow indication is given at a differential pressure of 1.7 mbar plus 1.3 or minus 0.5 mbar. DUCT TEMPERATURE SENSOR IDENTIFICATION FIN: 26HQ LOCATION ZONE: 128 COMPONENT DESCRIPTION It consists of a thermistor mounted in a stainless-steel tube, an electrical connector is mounted at the top. The set temperature values are: - increasing temperatures 62 deg.C +1 deg.C (143.6 deg.F +1.8 deg.F). - decreasing temperatures 60 deg.C +1 deg.C (140 deg.F +1.8 deg.F) SKIN TEMPERATURE SENSOR

IDENTIFICATION FIN: 28HQ LOCATION ZONE: 126 COMPONENT DESCRIPTION It consists of a sensor element through which an electrical current passes to measure the potential difference proportional to the temperature. The set temperature values are as follows: - on ground, increasing values +7 deg.C (+44.60 deg.F), decreasing values +4deg.C (+39.20 degF). - after takeoff, increasing values +36 deg.C (+96.80 deg.F), decreasing values +31 deg.C (+87.80 deg.F). SKIN HEAT EXCHANGER COMPONENT DESCRIPTION A skin heat exchanger is located in the upper fuselage between frames 12 and 14 and, in normal flight operations, is used to cool the avionics ventilation air. A thermally insulated internal wall is bolted to the frames to form two rectangular ducts. This internal wall is easily removed for structural inspection. A drainage system is included to deal with any condensation when the heat exchanger is in operation.

21-43-00 FWD CARGO COMPARTMENT VENTILATION/HEATING SYSTEM PRESENTATION

CONTENTS General Pressure Regulating Valve (PRV) Trim Air Valve Inlet Isolation Valve Extraction Fan Outlet Isolation Valve Pressure Switch Ventilation Controller Heating Controller

You might also like

- Introduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsFrom EverandIntroduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsNo ratings yet

- Introduction to Fly-By-Wire Flight Control SystemsFrom EverandIntroduction to Fly-By-Wire Flight Control SystemsRating: 5 out of 5 stars5/5 (1)

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveFrom EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectiveRating: 5 out of 5 stars5/5 (2)

- Atr72 Hydraulic SystemDocument8 pagesAtr72 Hydraulic SystemBernhard DallnAirNo ratings yet

- A320 Avionics Level 1Document270 pagesA320 Avionics Level 1Tarik Benzineb100% (2)

- Airbus Flight Control Laws: The Reconfiguration LawsFrom EverandAirbus Flight Control Laws: The Reconfiguration LawsRating: 4.5 out of 5 stars4.5/5 (16)

- Operation of Tube MillsDocument26 pagesOperation of Tube Millsssk3712100% (2)

- A320 Fuel SystemDocument211 pagesA320 Fuel SystemSHAKTI ASHISH KAR100% (1)

- Ata 31 03 01Document564 pagesAta 31 03 01Wilson BenincoreNo ratings yet

- Differences b777 Vs - CargoDocument2 pagesDifferences b777 Vs - Cargoaerologik_347746151100% (1)

- Tips A320 ResetDocument82 pagesTips A320 Resetgarry pangkey100% (1)

- UNITED A319-A320 ATA-47 Fuel Tank Inerting System FunctionsDocument70 pagesUNITED A319-A320 ATA-47 Fuel Tank Inerting System FunctionsBELISARIONo ratings yet

- Pneumatics: Training Manual B767-3S2F Ata 36-00Document55 pagesPneumatics: Training Manual B767-3S2F Ata 36-00luisao9escobarNo ratings yet

- Airbus 320 APUDocument136 pagesAirbus 320 APUSelcuk GuncanNo ratings yet

- Reversers Use A320Document26 pagesReversers Use A320Maitreya Shah100% (1)

- Ibook FlightDeck - V5 - Web PDFDocument46 pagesIbook FlightDeck - V5 - Web PDFtansu özdemir100% (1)

- A319/ A320/ A321 Technical Training ManualDocument76 pagesA319/ A320/ A321 Technical Training ManualŞevval YalınNo ratings yet

- Minimum Requirements For Design and Engineering of BuildingsDocument70 pagesMinimum Requirements For Design and Engineering of BuildingsHugoNo ratings yet

- Boiler Risk AssessmentDocument12 pagesBoiler Risk AssessmentMustafa Adel83% (6)

- 787故障快速处理参考手册R2Document211 pages787故障快速处理参考手册R2Chen AndyNo ratings yet

- A319 A320 A321 21z Sistema Aire AcondicionadoDocument330 pagesA319 A320 A321 21z Sistema Aire Acondicionadomarcelojm7No ratings yet

- Standard 160 Moisture Control PDFDocument6 pagesStandard 160 Moisture Control PDFaruiloba99No ratings yet

- A Project On Factory Act 1948: Guided By: - Prof. MADHURA TILLAK Dr. Jkpim-MbaDocument8 pagesA Project On Factory Act 1948: Guided By: - Prof. MADHURA TILLAK Dr. Jkpim-MbaNimesh TakvaniNo ratings yet

- A319 320 Fault Verification GuideDocument62 pagesA319 320 Fault Verification GuideAnonymous afPplXbcNo ratings yet

- Airbus A320 Fault Verification GuideDocument76 pagesAirbus A320 Fault Verification Guideprsnjt11100% (1)

- B737NG Air SystemsDocument10 pagesB737NG Air SystemsMohamood Salman SiddiquiNo ratings yet

- Training Manual B 737-300/400/500: ATA 24 Electrical PowerDocument138 pagesTraining Manual B 737-300/400/500: ATA 24 Electrical PowerINFO WORKLINKNo ratings yet

- 5 Aids ReportsDocument4 pages5 Aids ReportsRiccardo Mazzaia100% (1)

- Airbus A320 Brake Accu PNCDocument19 pagesAirbus A320 Brake Accu PNCPanagiotis Diakidis100% (1)

- A320 30 Rain and Ice ProtectionDocument72 pagesA320 30 Rain and Ice ProtectionBahador100% (2)

- Indian CourtyardDocument7 pagesIndian CourtyardPalak GadodiaNo ratings yet

- TTM Gen Fam 21Document146 pagesTTM Gen Fam 21aerologik100% (2)

- 09 TowingDocument10 pages09 TowingBianco YepNo ratings yet

- Commercial Aircraft Hydraulic Systems: Shanghai Jiao Tong University Press Aerospace SeriesFrom EverandCommercial Aircraft Hydraulic Systems: Shanghai Jiao Tong University Press Aerospace SeriesNo ratings yet

- Elac Sec Efcs Trouble Shooting Tips Booklet PDFDocument57 pagesElac Sec Efcs Trouble Shooting Tips Booklet PDFGenaro Rodriguez100% (1)

- CH21Document15 pagesCH21ranjit prasadNo ratings yet

- Airbus A320 Idg ServiceDocument22 pagesAirbus A320 Idg ServicePanagiotis Diakidis100% (5)

- Examen A340Document88 pagesExamen A340Alex E. Morales100% (2)

- Air Conditioning CH 21: Training Manual B767-3S2F Ata 21-00Document131 pagesAir Conditioning CH 21: Training Manual B767-3S2F Ata 21-00David OwenNo ratings yet

- Eicas Messages - Failures - B767 Passenger and Freighters Airplanes - (Only Reference)Document31 pagesEicas Messages - Failures - B767 Passenger and Freighters Airplanes - (Only Reference)Daniel Ospina100% (2)

- E175 CockpitDocument6 pagesE175 CockpitMyo Myint AungNo ratings yet

- As-Nz 1668.2-2012 PDFDocument10 pagesAs-Nz 1668.2-2012 PDFMay Tinh Bang100% (2)

- Breaker A330Document33 pagesBreaker A330Anh TuanNo ratings yet

- Vragen VACBI A330-200 ATA 29Document3 pagesVragen VACBI A330-200 ATA 29Arkadiy Chernov100% (1)

- Single Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) Information SystemsDocument40 pagesSingle Aisle Technical Training Manual T1+T2 (CFM 56) (LVL 2&3) Information Systemssan2inNo ratings yet

- Airbus320 FinDocument12 pagesAirbus320 Finvinay100% (1)

- ATA 21 Air ConditioningDocument188 pagesATA 21 Air ConditioningDiniswari Alrino100% (1)

- Iae V2500 Engine Questions: TH THDocument12 pagesIae V2500 Engine Questions: TH THRafael SantosNo ratings yet

- Standards For Shopping MallDocument42 pagesStandards For Shopping MallhalfbloodCHB79% (70)

- Airbus A320 ATA 31 EIS PresentationDocument101 pagesAirbus A320 ATA 31 EIS Presentationcacad999No ratings yet

- Flight Control LawsDocument9 pagesFlight Control LawsSreeja SunderNo ratings yet

- AN0080 A2 Ventilation of Battery Rooms or EnclosuresDocument2 pagesAN0080 A2 Ventilation of Battery Rooms or EnclosuresIsmet KoracNo ratings yet

- ATA 76 PW1100 - Rev. 0 (16-12-19)Document38 pagesATA 76 PW1100 - Rev. 0 (16-12-19)JOSE SANDOVALNo ratings yet

- ASTRA13011e (2009V1.05)Document26 pagesASTRA13011e (2009V1.05)cumicaNo ratings yet

- 021 Heating-Ventilation-Air Conditioning-UP CE ING MEP 060 0Document66 pages021 Heating-Ventilation-Air Conditioning-UP CE ING MEP 060 0Vũ Văn HảiNo ratings yet

- CB RESET A320 and ProcedureDocument74 pagesCB RESET A320 and ProcedureHasry RitongaNo ratings yet

- 737 300 Electrical PowerDocument90 pages737 300 Electrical PowerMeda50% (2)

- Principles of IVF Laboratory Practice PDFDocument326 pagesPrinciples of IVF Laboratory Practice PDFSudeep Sambharam60% (5)

- A320 32 L1 (Jan2004 CMP)Document40 pagesA320 32 L1 (Jan2004 CMP)HENIGUEDRI100% (1)

- Air Bus 330Document28 pagesAir Bus 330Putu RobedNo ratings yet

- ATA 23 - CommunicationsDocument70 pagesATA 23 - CommunicationsQuoc Tan HuynhNo ratings yet

- High Tech For Highest Pressures: The BOGE SRHV 470-10 Booster.Document2 pagesHigh Tech For Highest Pressures: The BOGE SRHV 470-10 Booster.Air Repair, LLCNo ratings yet

- Self Examination: 36 - PneumaticDocument2 pagesSelf Examination: 36 - PneumaticAhmed Abdoul ZaherNo ratings yet

- Manufacturing of AcetyleneDocument45 pagesManufacturing of Acetylenebecpavan100% (1)

- ECS Report 19Document11 pagesECS Report 19Suman BajracharyaNo ratings yet

- FinDocument5 pagesFinJulian Esteban CardenasNo ratings yet

- B 757Document172 pagesB 757Jorge Villagomez0% (1)

- Airbus NotesDocument128 pagesAirbus NotesmartinbutlerNo ratings yet

- Airbus AC A320 Jan16Document390 pagesAirbus AC A320 Jan16simon100% (1)

- Brake Alternate Servovalve Fault - WISEDocument2 pagesBrake Alternate Servovalve Fault - WISERizwan100% (1)

- Avionics VentilationDocument4 pagesAvionics Ventilationsa eedNo ratings yet

- Ata 21 Air ConditioningDocument9 pagesAta 21 Air Conditioninggreatest everNo ratings yet

- (C025) Primer 1757b1c-Y-Gl2Document15 pages(C025) Primer 1757b1c-Y-Gl2Артем РожновNo ratings yet

- ABS Fire and Safety Features For MODU - Part5Document40 pagesABS Fire and Safety Features For MODU - Part5Eyoma Etim100% (1)

- Civil Suit Against Establishment of Slaughter House at Pali in Faridabad Withot Approval of State Committee - Abhishek KadyanDocument29 pagesCivil Suit Against Establishment of Slaughter House at Pali in Faridabad Withot Approval of State Committee - Abhishek KadyanNaresh KadyanNo ratings yet

- 10.3 Ventilation Surveys - Air Quality and Quantity SurveysDocument11 pages10.3 Ventilation Surveys - Air Quality and Quantity SurveysDeepakKattimaniNo ratings yet

- Arina Bintan Kamila - Analisa Pati PDFDocument45 pagesArina Bintan Kamila - Analisa Pati PDFArina Bintan KamilaNo ratings yet

- Orca Pico 50 Eng-2016Document4 pagesOrca Pico 50 Eng-2016Netzone ConsultNo ratings yet

- Joyforce SDS - PVA Pellet - r2.ENDocument3 pagesJoyforce SDS - PVA Pellet - r2.ENjituniNo ratings yet

- Question & Answer For PSSR - 021739Document5 pagesQuestion & Answer For PSSR - 0217398173Shailesh YadavNo ratings yet

- Pyroscat Enclosure ManualDocument60 pagesPyroscat Enclosure ManualjasonsivertsenNo ratings yet

- Installing A Centrifugal Air Compressor: by Rick Stasyshan and Ian Macleod, Compressed Air & Gas InstituteDocument5 pagesInstalling A Centrifugal Air Compressor: by Rick Stasyshan and Ian Macleod, Compressed Air & Gas Institutehamedia83No ratings yet

- Chapter 14.-Preventing Methane Gas Explosions During Tunnel ConstructionDocument18 pagesChapter 14.-Preventing Methane Gas Explosions During Tunnel Constructionrahuldevpatel5No ratings yet

- CW50 BrochureDocument6 pagesCW50 Brochurezahee007No ratings yet

- Plant LayoutDocument10 pagesPlant LayoutvinojdrajNo ratings yet

- Climate Warm and HumidDocument15 pagesClimate Warm and HumidUzma MekraniNo ratings yet

- Material Safety Data Sheet BoraxDocument5 pagesMaterial Safety Data Sheet Boraxratnasari2223No ratings yet