Professional Documents

Culture Documents

Book 1

Book 1

Uploaded by

Mahajan PranshuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Book 1

Book 1

Uploaded by

Mahajan PranshuCopyright:

Available Formats

FLOW PROCESS FOR YP8 PROJECT

FLOW

START

RULES TO BE FOLLOWED

Receive material from Pune plant

1. boxes/cages containing left side tail parts are stored in LH and those containing right side parts in RH area. 2. A single column must contain boxes/cages

Determine the location to store the received lot in Hall 1

boxes/pallets belonging to a single lot only. 3. a cell can either contain cages to a maximum of 3 stacked over each other or boxes to maximum of 12 in form of 6 layers maximum of 12 in 6 layers. 4. Storage of material starts from A1 for LH area and G1 for RH area. 5. Storage of material in a column starts only if the material assigned to its precessor column has been placed. 6. Fill the balance sheet for incoming to Hall1

Placed the material at the defined locations.

1. Material lots are moved out in same sequence

Transfer the material to Hall 2

they are brought in. 2. Fill the balance sheet for outgoing from Hall 1.

Boxes/cages are brought to inspection line

1. boxes/cages containing left side tail lamps are brought to eft side those containing right side tail LH and RH inspection line. 1. A part is verified okay only if if all bulbs function nly

GLOW YES TEST NO

accurately and sensors detect the presence of washers, pivots and caps. 1. Paste a yellow tag, describing details of the

Rejection Area VISUAL INSOECTIO N TEST OK? YES A2

defect, on the part and place the part in yellow bin. 1. Part is verified okay only if there are no scratches flashes,bubble marks, flow marks, finger prints

NO Rejection Area

1. Paste a yellow tag, describing details of the defect, on the part and palce the part in yellow bins.

You might also like

- Work Instruction - Loading-TamilDocument28 pagesWork Instruction - Loading-Tamilshanmugam86100% (2)

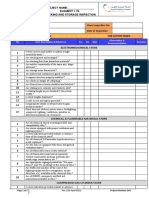

- PLU Building Safety Inspection ChecklistDocument5 pagesPLU Building Safety Inspection Checklistwidodo6286No ratings yet

- Daily Sanitation Inspection ChecklistDocument3 pagesDaily Sanitation Inspection ChecklistJames Christian Hermetanio LopezNo ratings yet

- ChecklistDocument3 pagesChecklistsidra malikNo ratings yet

- Chemistry Class 11 Practical BookDocument30 pagesChemistry Class 11 Practical BookAnonymous XuiUo2Th50% (4)

- Pharmaceutical WarehouseDocument2 pagesPharmaceutical WarehousePrince Moni71% (7)

- Work Instruction For Inspection of Raw MaterialDocument28 pagesWork Instruction For Inspection of Raw Materialm.manikandan maniNo ratings yet

- SOP StorageDocument2 pagesSOP StorageAnikBudiany0% (1)

- Work Instruction - Loading-TamilDocument28 pagesWork Instruction - Loading-Tamilshanmugam8678% (23)

- Standard Operating ProceduresDocument13 pagesStandard Operating Proceduresroshan_1986No ratings yet

- 1.7b Stacking - Storage Inspection ChecklistDocument2 pages1.7b Stacking - Storage Inspection ChecklistShafie Zubier78% (9)

- TO17P SamplingInstructionsDocument1 pageTO17P SamplingInstructionsAdem YildirimNo ratings yet

- Note For All 202L Sections - Spring2014Document82 pagesNote For All 202L Sections - Spring2014yangNo ratings yet

- Cold Supply LocationDocument2 pagesCold Supply LocationMark KyloNo ratings yet

- Sip 4th Week c04-059Document3 pagesSip 4th Week c04-059Mugundan N ManiNo ratings yet

- SOP Waste Management July 2016Document3 pagesSOP Waste Management July 2016vibinNo ratings yet

- BMWDocument2 pagesBMWshah007zaadNo ratings yet

- Hydraulic Load CellDocument1 pageHydraulic Load CellmanibabuNo ratings yet

- ENGN 311/311L Fluid Mechanics Experiment #1 Hydrostatic Force On An Inclined PlaneDocument3 pagesENGN 311/311L Fluid Mechanics Experiment #1 Hydrostatic Force On An Inclined PlanenidhalsaadaNo ratings yet

- Audit 5S StorageDocument1 pageAudit 5S StorageNouha AbardazzouNo ratings yet

- Lab 6: Introduction To Total StationsDocument3 pagesLab 6: Introduction To Total StationsMathiTwadCNo ratings yet

- LayoutDocument2 pagesLayoutPerez Mark JoshuaNo ratings yet

- Lab Safety Survey ChecklistDocument5 pagesLab Safety Survey ChecklistTanbir HossainNo ratings yet

- Material Name /Q U A N T I T Y / F R E E From Damage As Per P.Ovisual Inspection /weighing Machine5 B A G S / L O TDocument4 pagesMaterial Name /Q U A N T I T Y / F R E E From Damage As Per P.Ovisual Inspection /weighing Machine5 B A G S / L O Tconcrete fastenersNo ratings yet

- Warehouse Inspection Checklist 1Document3 pagesWarehouse Inspection Checklist 1opticalypus spyNo ratings yet

- BioChem Procedures S15Document61 pagesBioChem Procedures S15Tyler DuncanNo ratings yet

- Lab ShopDocument2 pagesLab Shop0takecil179No ratings yet

- GWP Checklist - Prifood WHDocument1 pageGWP Checklist - Prifood WHAlexander MorfeNo ratings yet

- AsphaltDocument112 pagesAsphaltDWIGHT GERONIMONo ratings yet

- Biochemistry Manual by FabulousDocument34 pagesBiochemistry Manual by FabulousIbrahim AkindapoNo ratings yet

- Pig Valve Orientation Diagram PDFDocument1 pagePig Valve Orientation Diagram PDFAlfredo OrellanaNo ratings yet

- Plant Physiology Practical ExamDocument11 pagesPlant Physiology Practical ExamPopa IrinaNo ratings yet

- Autoclave OperationDocument1 pageAutoclave OperationBrandon CastilloNo ratings yet

- Oregon State Public Health Laboratory: Courier System HandbookDocument22 pagesOregon State Public Health Laboratory: Courier System HandbookRohit KumarNo ratings yet

- General Lab Inspection ChecklistDocument2 pagesGeneral Lab Inspection ChecklistTaarani AmbigavathyNo ratings yet

- TechSpecs of Total-StationsDocument1 pageTechSpecs of Total-Stationsmtbctb qmaxNo ratings yet

- Activity No. 2 Guiding Principles in Collection, Packing, Preservation and Identification of Blood and Bloodstained EvidencesDocument3 pagesActivity No. 2 Guiding Principles in Collection, Packing, Preservation and Identification of Blood and Bloodstained EvidencesAugold UrbanoNo ratings yet

- House KeepingnewlDocument18 pagesHouse KeepingnewlAdufe RufaiNo ratings yet

- UntitledDocument25 pagesUntitledDr.Marufa FaruqiNo ratings yet

- SOP Raw MaterialDocument3 pagesSOP Raw MaterialDSP PVCNo ratings yet

- 2.BIOBASE-Sapphire Installation ProcessDocument10 pages2.BIOBASE-Sapphire Installation ProcessRoland VegaNo ratings yet

- Warehouse Address - Board Hang at TopDocument16 pagesWarehouse Address - Board Hang at TopSantosh KumarNo ratings yet

- SOP StorageDocument3 pagesSOP Storagedickson86100% (3)

- Guide For The Utilization of ContainersDocument33 pagesGuide For The Utilization of Containerskukuriku13100% (1)

- Guidlines For PracticalsDocument6 pagesGuidlines For PracticalsKrishan JayaweerarathnaNo ratings yet

- H9 Installation GuideDocument33 pagesH9 Installation Guidegerente soportecNo ratings yet

- H 11 Centre PressureDocument10 pagesH 11 Centre PressureKevin David Leal GodoyNo ratings yet

- SopDocument1 pageSopTbondsNo ratings yet

- Location RM StoreDocument2 pagesLocation RM StoreAnonymous 6sxVrzNOD3No ratings yet

- Title: Leveling: Equipments: 1. Tripod - 1 UnitDocument3 pagesTitle: Leveling: Equipments: 1. Tripod - 1 Unitbiskut_marie_1No ratings yet

- 2nd Alternative NaDocument2 pages2nd Alternative Naharoldmiralles3No ratings yet

- Reefer Container Stuffing Condition ReportDocument2 pagesReefer Container Stuffing Condition ReportDarius AgaNo ratings yet

- Experiment 1 - Common Laboratory OperationsDocument10 pagesExperiment 1 - Common Laboratory OperationsrairasheneNo ratings yet

- CHEM LAB-worDDocument51 pagesCHEM LAB-worDsamapronNo ratings yet

- Electronic Balance SOPDocument3 pagesElectronic Balance SOPNishchaya Singh100% (1)

- Kitchen Food Safety Inspection ChecklistDocument4 pagesKitchen Food Safety Inspection ChecklistShehzadNo ratings yet

- Laboratory 1.1Document68 pagesLaboratory 1.1jmarafolsjoreNo ratings yet

- Nitrogen3 1 SafetyDocument8 pagesNitrogen3 1 SafetychkzaNo ratings yet

- SOP BoxFurnaces Toll1357 14JUL2015ewDocument2 pagesSOP BoxFurnaces Toll1357 14JUL2015ewEngr KamalNo ratings yet