Professional Documents

Culture Documents

Ultrasonic Distance Meter

Ultrasonic Distance Meter

Uploaded by

Pawan Kardam0 ratings0% found this document useful (0 votes)

12 views5 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views5 pagesUltrasonic Distance Meter

Ultrasonic Distance Meter

Uploaded by

Pawan KardamCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

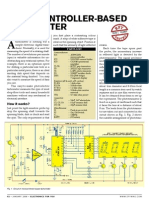

ConstruCtion

68 February 2008 electroni cs for you www. e F y ma g . c o m

K. Padmanabhan

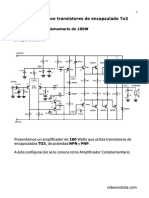

microcontroller-based

Ultrasonic distance meter

SUNIL KUMAR

T

here are several ways to meas-

ure distance without contact.

One way is to use ultrasonic

waves at 40 kHz for distance measure-

ment. Ultrasonic transducers measure

the amount of time taken for a pulse of

sound to travel to a particular surface

and return as the refected echo.

This circuit calculates the distance

based on the speed of sound at 25C

ambient temperature and shows it

on a 7-segment display. Using it,

you can measure distance up to 2.5

metres.

For this particular application, the

required components are AT89C2051

microcontroller, two 40kHz ultrasonic

transducers (one each for transmitter

higher pulse excitation voltage or a

better transducer.

Here the microcontroller is used to

generate 40kHz sound pulses. It reads

when the echo arrives; it fnds the time

taken in microseconds for to-and-fro

travel of sound waves. Using velocity

of 333 m/s, it does the calculations and

and receiver), current buffer ULN2003,

operational amplifer LM324, inverter

CD4049, four 7-segment displays, fve

transistors and some discreet com-

ponents. The ultrasonic transmitter-

receiver pair is shown in Fig. 1.

Ultrasonic generators use piezo-

electric materials such as zinc or lead

zirconium tartrates or quartz crystal.

The material thickness decides the

resonant frequency when mounted

and excited by electrodes attached on

either side of it. The medical scanners

used for abdomen or heart ultrasound

are designed at 2.5 MHz. In this cir-

cuit, a 40kHz transducer is used for

measurement in the air medium. The

velocity of sound in the air is around

330 m/s at 0C and varies with tem-

perature.

In this project, you excite the ul-

trasonic transmitter unit with a 40kHz

pulse burst and expect an echo from

the object whose distance you want to

measure. Fig. 2 shows the transmitted

burst, which lasts for a period of ap-

proximately 0.5 ms. It travels to the

object in the air and the echo signal

is picked up by another ultrasonic

transducer unit (receiver), also a 40

kHz pre-tuned unit. The re-

ceived signal, which is very

weak, is amplifed several

times in the receiver circuit

and appears somewhat as

shown in Fig. 2 when seen

on a CRO.

Weak echoes also occur

due to the signals being

directly received through

the side lobes. These are

ignored as the real echo

received alone would give

the correct distance. That

is why we should have a

level control. Of course,

the signal gets weaker if

the target is farther than

2.5 metres and will need a

Fig. 1: Ultrasonic transmitter and receiver pair

Fig. 2: The ultrasonic pulse, echo signal and time measurement

ParTs LisT

Semiconductors:

IC1 - AT89C2051

microcontroller

IC2 - ULN2003 current buffer

IC3 - CD4049 hex inverting

buffer

IC4 - LM324 quad operational

amplifer

IC5 - 7815, 15V regulator

IC6 - 7915, -15V regulator

IC7 - 7805, 5V regulator

T1-T4 - BC557 pnp transistor

T5 - 2N2222 npn transistor

D1, D2 - 1N4148 switching diode

D3-D6 - 1N4007 rectifer diode

DIS1-DIS4 - LTS 542 common-anode,

7-segment display

Resistors (all -watt, 5% carbon):

R1, R2 - 2-mega-ohm

R3 - 82-kilo-ohm

R4, R7-R10 - 10-kilo-ohm

R5 - 33-kilo-ohm

R6 - 100-kilo-ohm

R11 - 1-kilo-ohm

R12-R15 - 1.2-kilo-ohm

R16 - 220-ohm

RNW1 - 10-kilo-ohm resistor

network

VR1 - 1-kilo-ohm preset

Capacitors:

C1, C2 - 3.3nF ceramic disk

C7, C10-C12 - 0.1F ceramic disk

C3 - 2.2nF ceramic disk

C4 - 10F, 16V electrolytic

C5, C6 - 22pF ceramic disk

C8, C9 - 1000F, 50V electrolytic

Miscellaneous:

X1 - 230V AC primary to

15V-0-15V, 500mA

secondary transformer

X

TAL

- 12MHz crystal

S1 - Push-to-on switch

S2 - On/off switch

TX1 - 40kHz ultrasonic

transmitter

RX1 - 40kHz ultrasonic receiver

ConstruCtion

70 February 2008 electroni cs for you www. e F y ma g . c o m

up pulse transformer, which steps-up

the transmitter output to 60V (peak-

to-peak).

The echo signal received by the

receiver sensor after refection is very

weak. It is amplifed by quad opera-

tional amplifer LM324. The frst stage

(A1) is a buffer with unity gain. The

received signal is directly fed to the

non-inverting input (pin 3) of A1 and

coupled to the second stage by a 3.3nF

(small-value) capacitor. If you use

the ubiquitous 0.01F capacitor for

coupling, there will be enormous hum

at the output. The second stage of the

inverting amplifer uses a 2-mega-ohm

resistor for feedback. The third stage

is a precision rectifer amplifer with a

gain of 10.

The rectifier functions, unlike a

simple diode, even for signal voltage

of less than 0.6V. The output is fltered

to accept 40kHz frequencies and fed to

pin 12 of microcontroller AT89C2051,

which is an analogue comparator. Pin

13 is the other pin of the comparator

used for level adjustment using preset

VR1.

The ultrasonic transducer outputs

a beam of sound waves, which has

more energy on the main lobe and less

energy (60 dB below the main lobe) on

the side lobes as shown in Fig. 4. Even

this low side-lobe signal is directly

picked up by the receiver unit. So

you have to space the transmitter and

receiver units about 5 cm apart. The

two units are fxed by cellotape onto a

cardboard, with the analogue circuit

at one end.

Microcontroller AT89C2051 is at

the heart of the circuit. Port-1 pins P1.7

through P1.2, and port-3 pin P3.7 are

connected to input pins 1 through 7 of

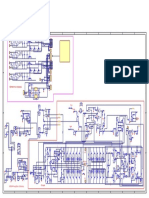

Fig. 3: Microcontroller based distance meter circuit

shows on the four

7- segment di s-

plays the distance

in centimetres and

millimetres (three

digits for centime-

tres and one for

millimetres).

circuit

description

Fig. 3 shows the

circuit of the mi-

crocontroller-based

distance meter. The

40kHz pulse bursts

from the microcon-

troller are ampli-

fied by transistor

T5. Inverting buff-

er CD4049 drives

the ultrasonic sen-

sor used as the

transmitter. Three

inverters (N1, N2

and N3) are con-

nected in paral-

lel to increase the

transmited power.

This inverted out-

put is fed to an-

other set of three

inverters (N4, N5

and N6). Outputs

of both sets of par-

allel inverters are

applied as a push-

pull drive to the

ultrasonic trans-

mitter.

The positive-

going pulse is ap-

plied to one of the

terminals of the

ultrasonic sensor

and the same pulse

after 180-degree

phase shift is ap-

plied to another

terminal. Thus the

transmitter power

is increased for in-

creasing the range.

If you want to

increase the range

up to 5 metres, use

a ferrite-core step-

Fig. 4: Two dimensional beam pattern of

ultrasonic signal showing main lobe and side

lobe energy levels

ConstruCtion

72 February 2008 electroni cs for you www. e F y ma g . c o m

IC2 (IC ULN2003), respectively. These

pins are pulled up with a 10-kilo-ohm

resistor network RNW1. They drive all

the segments of the 7-segment display

with the help of inverting buffer IC2.

Port-3 pins P3.0 through P3.3 of

the microcontroller are connected

to the base of transistors T1 through

T4 to provide the supply to displays

DIS1 through DIS4, respectively. Pin

P3.0 of microcontroller IC1 goes low

to drive transistor T1 into saturation,

which provides supply to the com-

mon-anode pin (either pin 3 or 8) of

display DIS1. Similarly, transistors T2

through T4 provide anode currents to

the other three 7-segment displays.

Microcontroller IC1 provides the

segment data and display-enable sig-

nal simultaneously in time-division

multiplexed mode for displaying a

particular number on the 7-segment

display unit.

Segment data and display-enable

pulse for the display are refreshed eve-

ry 5 ms. Thus the display appears to be

continuous, even though the individual

LEDs used in it light up one by one.

Using switch S1 you

can manually reset

the microcontroller,

while the power-

on reset signal for

the microcontrol-

ler is derived from

the combination of

capacitor C4 and re-

sistor R8. A 12MHz

crystal is used to

generate the basic

clock frequency for

the microcontroller.

Resistor R16 con-

nected to pin 5 of

DIS2 enables the

decimal point.

The comparator is inbuilt in micro-

controller AT89C2051. The echo signal

will make port-3 pin 3.6 low when it

goes above the level of voltage set on

pin 13. This status is sensed by the mi-

crocontroller as programmed.

When port-3 pin P3.6 goes high, we

know that the echo signal has arrived;

the timer is read and the 16-bit number

is divided by twice the velocity of

sound and then converted into decimal

format as a 4-digit number.

Power supply. Fig. 5 shows the

circuit of the power supply. The 230V

AC mains is stepped down by trans-

former X1 to deliver the secondary

output of 15V-0-15V, 500 mA. The

transformer output is rectifed by a

full-wave bridge rectifer comprising

diodes D3 through D6, fltered by

capacitors C8 and C9 and then regu-

lated by ICs 7815 (IC5), 7915 (IC6)

and 7805 (IC7). Regulators 7815, 7915

and 7805 provide +15V, -15V and

+5V regulated supply, respectively.

Capacitors C10 through C12 bypass

the ripples present in the regulated

power supply.

construction and testing

An actual-size, single-side PCB for the

microcontroller-based distance meter

is shown in Fig. 6 and its component

layout in Fig. 7.

Assemble the PCB and put the

programmed microcontroller into the

socket. After switching on the power

supply and microcontroller automati-

cally getting reset upon power-on,

Fig. 5: Power supply circuit for distance meter

Fig. 6: Actual-size, single-side PCB for the microcontroller-based ultrasonic distance meter

ConstruCtion

electroni cs for you February 2008 73 www. e F y ma g . c o m

pin 8 will pulse at 40kHz bursts. This

can be seen using an oscilloscope.

Give this signal to channel 1 of the

oscilloscope. Adjust the time base to

2 ms per division and set it to trigger

mode instead of normal mode. Adjust

the potmeter on the oscilloscope la-

beled level such that the trace starts

with the burst and appears steady as

shown in Fig. 2.

Connect the transmitter and re-

ceiver ultrasonic units either by a

twisted pair of wire or by a shielded

cable to the board. Give the received

signal to channel 2 of the oscilloscope.

Then, place an A4-size plastic sheet in

front of the ultrasonic transducers and

observe the echo signal. It will appear

as shown in Fig. 2.

The two transducers can be fxed

to a thick cardboard with two wires

leading to the circuittwo 40cm long

shielded cables will do. The laser

pointer is fxed such that it is axial

to the transducers. Channel 2 is con-

nected to pin 12, which is the positive

non-inverting terminal of AT89C2051s

comparator. The negative inverting ter-

minal (pin 13) is connected to a preset

reference. Adjust the preset such that

the voltage is 0.1V-0.2V at pin 13. This

will enable detection of weak echoes

also.

When the echo signal goes above

Fig. 7: Component layout for the PCB

the level of reference voltage set on pin

13, it will make P3.6 low; the arrival of

echo is sensed by the program using

jnb p3.6 (jump not bit) instruction.

software

The software is written in Assembly

language and assembled using 8051

cross-assembler. It is well commented

and easy to understand.

The pulse train for 0.5 ms is started

by making pin 8 high and low alter-

nately for 12.5 microseconds so that the

pulse frequency is 40 kHz. After 25 such

pulses have passed, a waiting time is

given to avoid direct echoes for about

20 s. Then the signal is awaited, while

the timer runs counting time in micro-

seconds. When the echo arrives, port-3

pin P3.6 goes high, the timer reads and

the 16-bit number is divided by twice

the velocity and converted into decimal

format as a 4-digit number.

If the echo does not arrive even

after 48 milliseconds, the waiting loop

is broken and the pulse train sequence

is started once again. If the echo comes

within this time, it is displayed for half

a second before proceeding to another

measurement. Thus, the display ap-

pears continuous and ficker-free.

other uses

Simply by changing this program, the

same unit can be made to detect mov-

ing objects (such as cars racing on the

street) and fnd their range and speed.

It can also be used with suitable addi-

tional software as a burglar alarm unit

for homes or offces.

EFY note. All the relevant fles of

this project are included in this months

EFY-CD.

ultrsnd.asm

Program listing:

$mod51

ORG 0H

AJMP 30H

ORG 0BH ;TIMER 0 INTERRUPT VECTOR

; AJMP TIMER0ISR ;Timer 0 Interrupt

service routine address

ORG 30H

MOV SP,#60H ;set stack pointer

MOV P3,#0FFH ;set all port 3 bits high

to enable inputs also

MOV P1,#03 ;set port 1 to all zeros

expect bits 0,1

MOV TMOD,#01100001B ;TIMER 1 - MODE 2

COUNTER,TIMR-0 TO MODE 1

BEG: MOV TH0,#0H ;TIMER REG.0 IS SET TO

0, GIVES 64ms

MOV TL0,#0 ; timer low reg. is also so

;TOTAL CYCLE TIME IS 64.6ms ,350m/s

gives 0.35mx65=22.5m

; up and down 10 metres say! .35 m/ms,

.35 mm/us, 1mm per 3 micros

; up and down .35/2 mm/us = 1/6 mm/us

; VELOCITY OF SOUND IN AIR IS 350 M/S

; AFTER 100 TIMES, WE HAVE TO STOP

TRANSMITTING FOR A TIME OF ABOUT .1 S

; SO WE STOP FOR THIS AMOUNT OF TIME

and expect an echo.

mov r2,#25 ; 25 pulses 26 us =.53 ms

(343m/s*.5ms=17cm)

pulse: setb p3.4 ;generates 40KHz

mov r1,#5

djnz r1,$

clr p3.4

mov r1,#5

djnz r1,$ ;wait for 13 us

djnz r2, pulse ;20pulses

setb tr0 ;start timer

ConstruCtion

74 February 2008 electroni cs for you www. e F y ma g . c o m

mov r0,a

mov a,r7 ;get rem. saved before the

mov r3,a ;last subtraction.

mov a,r6

mov r2,a

ret

;16 Bit Hex to BCD Conversion for 8051

Microcontroller

; This routine is for 16 bit Hex to BCD

conversion;

;Accepts a 16 bit binary number in

R1,R2 and returns 5 digit BCD in

;R7,R6,R5,R4,R3(upto 64K )

Hex2BCD: ;r1=high byte ;r7 most sig-

nifcant digit

;R2 = LSByte

MOV R3,#00D

MOV R4,#00D

MOV R5,#00D

MOV R6,#00D

MOV R7,#00D

MOV B,#10D

MOV A,R2

DIV AB

MOV R3,B ;

MOV B,#10 ; R7,R6,R5,R4,R3

DIV AB

MOV R4,B

MOV R5,A

CJNE R1,#0H,HIGH_BYTE ; CHECK FOR HIGH

BYTE

SJMP ENDD

HIGH_BYTE: MOV A,#6

ADD A,R3

MOV B,#10

DIV AB

MOV R3,B

ADD A,#5

ADD A,R4

MOV B,#10

DIV AB

MOV R4,B

ADD A,#2

ADD A,R5

MOV B,#10

DIV AB

MOV R5,B

CJNE R6,#00D,ADD_IT

SJMP CONTINUE

ADD_IT: ADD A,R6

CONTINUE: MOV R6,A

DJNZ R1,HIGH_BYTE

MOV B, #10D

MOV A,R6

DIV AB

MOV R6,B

MOV R7,A

ENDD: ret

DISP1:

REFRESH: ; content of 18 to 1B memory

locations are output on LEDs

; only numbers 0 to 9 and A to F are

valid data in these locations

mov r1,41h

mov r2,40h

CALL HEX2BCD

MOV 18H,r3 ; least signifcant digit

MOV 19H,r4 ; next signifcant digit

MOV 1AH,r5

mov r2,#10

djnz r2,$ ;wait 20 us

check_echo:

jnb p3.6,checktimeout

MOV 40h,TL0 ; read timer count

MOV 41h,TH0

mov r0,40h

mov r1,41h

mov r3,#0

mov r2,#6

call UDIV16 ;divide by 6

mov 40h,r0

mov 41h,r1

mov 50h,#25

disp: call disp1 ; show the value on

LED

djnz 50h,disp ; so many times for a

visible time limit

jmp beg

checktimeout: mov a,th0

cjne a,#0c0h,check_echo ;upto 4 metres

jmp beg

;subroutine UDIV16

;16 bit/16bit unsigned divide

;input r1,r0 =dividend X

;input r3,r2 =divisor Y

;output r1,r0 =quottient q of x/y

;output r3,r2 = remainder

; alters acc,r4-47,fags,dptr

UDIV16: mov r7,#0 ;clear partial re-

mainder

mov r6,#0 ;

mov B,#16 ;set loop count

div_loop: clr C ;clear carry fag

mov a,r0 ; shift the highest bit of

dividend into

rlc a

mov r0,a

mov a,r1

rlc a

mov r1,a

mov a,r6 ;... the lowest bit of partial

remainder

rlc a

mov r6,a

mov a,r7

rlc a

mov r7,a

mov a,r6

clr C

subb a,r2

mov dpl,a

mov a,r7

subb a,r3

mov dph,a

cpl C

jnc div_1 ;update partial reaminder

if borrow

mov r7,dph

mov r6,dpl ; update parital reminder

div_1: mov a,r4

rlc a

mov r4,a

mov a,r5

rlc a

mov r5,a

djnz B,div_loop

mov a,r5

mov r1,a ; put qt. in r0,r1

mov a,r4

MOV 1BH,R6 ; most signifcant digit

(max:9999)

refresh1: MOV R0,#1bh ; 1b,1a,19,18,

holds values for 4 digits

MOV R4,#8 ; pin p3.3_ 0 made low one by

one starts wth 18

mov r7,#2 ; decimal pt.on 3rd digit

from left (2 nd fromright)

PQ2: CALL SEGDISP

deC R0

mov a,r4

rrc a

mov r4,a

jnc pQ2

PV3:

RET

SEGDISP:

mov dptr,#ledcode

MOV A,@R0

ANL A,#0FH

MOVC A,@A+dptr

segcode:

MOV R5,A

ORL A,#03H ; WE WANT TO USE PORT 1 BITS

0 AND 1 FOR INPUT ANLOG

; so retain them high

S3: MOV P1,A ; SEGMENT_PORT

MOV A,R5 ;we use p3.7 for the segment

a of display

RRC A ;so get that bit D0into carry

; cpl c

; mov p3.5,c ; dec pt is D0 bit that is

wired to p3.5

rrc a

mov p3.7,c ;segment a;

S1: MOV A,R4 ; get digit code from r4

00001000

cpl a ;11110111

rrc a ;11111011-1

mov p3.0,c ; output to drive transsi-

tors for digit lighting

rrc a ;11111101-1

mov p3.1,c

rrc a ;11111110-1

mov p3.2,c

rrc a ;1111111-0 yes low makes leftmost

digit show msdigit

mov p3.3,c

S5:

S4: ACALL DELAY1 ; let it burn

for some time

MOV A,#0ffH ; extinguish

the digit after that time

MOV P3,A ; to prevent shadow

s6: RET

ledcode:

DB 7EH,0CH,0B6H,9EH,0CCH,0DAH,0FAH

DB 0EH,0FEH,0CEH,0EEH,0F8H,72H,0BCH,0

F6H,0E2H

;these are code for

the numbers 0 to 9 and A to F

DELAY1: MOV R1,#0ffH

N: NOP

DJNZ R1,N

RET

END

You might also like

- Teac MC DX10 Service ManualDocument26 pagesTeac MC DX10 Service ManualVaishakNo ratings yet

- Onkyo Service Manual 1Document129 pagesOnkyo Service Manual 1SergioJuniorNo ratings yet

- Service Manual RCI 6900F150 ENG PDFDocument41 pagesService Manual RCI 6900F150 ENG PDFRichardson Almeida0% (1)

- Gemini Sound X-2 Service ManualDocument24 pagesGemini Sound X-2 Service Manualbizzinifra5522No ratings yet

- Yorkville AM100 Service ManualDocument10 pagesYorkville AM100 Service Manualcaimanater100% (1)

- Hfe Kef Psw3500 Service enDocument30 pagesHfe Kef Psw3500 Service enTiromancino Tiromancino100% (1)

- Easy VibeDocument1 pageEasy VibepincopirolaNo ratings yet

- Ups Aros Sentinel XR 3300 6000 PDFDocument37 pagesUps Aros Sentinel XR 3300 6000 PDFVasile Bulibasa67% (3)

- SearchDocument9 pagesSearchMartin JimenezNo ratings yet

- Voyager VB777 MosfetDocument1 pageVoyager VB777 MosfetLuis CarlosNo ratings yet

- Service Manual Cobra 200GTL DX ENGDocument31 pagesService Manual Cobra 200GTL DX ENGBuzarin DanielNo ratings yet

- Metal Detector ReportDocument13 pagesMetal Detector ReportAnonymous ytZsBOVNo ratings yet

- DX 1227Document11 pagesDX 1227Marcos Daniel Muñoz ToledoNo ratings yet

- Simple Bass Treble Tone ControlDocument1 pageSimple Bass Treble Tone ControlsanapashokNo ratings yet

- CTK 4000Document26 pagesCTK 4000JorgeBaquéNo ratings yet

- Bassman Bass Preamp: Mod+layout Deadastronaut 2013Document1 pageBassman Bass Preamp: Mod+layout Deadastronaut 2013Jezz Mort0% (1)

- Sony HCD Rv222 Ver 1.1Document86 pagesSony HCD Rv222 Ver 1.1Carlos Raul100% (2)

- JVC Service Manual mxgt80 PDFDocument48 pagesJVC Service Manual mxgt80 PDFAlex GuerreroNo ratings yet

- HC 14000 MH 9400 SCHDocument1 pageHC 14000 MH 9400 SCHGustavo de Vargas DiasNo ratings yet

- Peavey PR15D Service ManualDocument12 pagesPeavey PR15D Service ManualMartín SayagoNo ratings yet

- PV T-Max 1Document9 pagesPV T-Max 1akkNo ratings yet

- ELECTROINDIA - 150 Watts Mono Amplifier Board DIY With 2sc5200, 2sa1943 & TDA7294 PDFDocument3 pagesELECTROINDIA - 150 Watts Mono Amplifier Board DIY With 2sc5200, 2sa1943 & TDA7294 PDFChornosDjajal100% (1)

- General Description: Multi-Mode Primary Side Regulation (PSR) CV/CC ControllerDocument11 pagesGeneral Description: Multi-Mode Primary Side Regulation (PSR) CV/CC ControllertoolsNo ratings yet

- Silicon PNP Power TransistorsDocument4 pagesSilicon PNP Power Transistorsjavier byronNo ratings yet

- Cobra Modification and Tuning ListDocument2 pagesCobra Modification and Tuning ListTodd HoferNo ratings yet

- MA5002VZ SM 130446-1amplificator ManualDocument140 pagesMA5002VZ SM 130446-1amplificator Manualtiganiada100% (1)

- STK433 070 eDocument11 pagesSTK433 070 evanuzalopeslopes1No ratings yet

- stk412 240Document1 pagestk412 240luisclaudio31No ratings yet

- Pioneer Sx-4, 5, 6, 7 SMDocument14 pagesPioneer Sx-4, 5, 6, 7 SMvali dNo ratings yet

- Active 3 Band Tone ControlDocument1 pageActive 3 Band Tone ControlAnonymous vKD3FG6RkNo ratings yet

- GTO Series: Service ManualDocument32 pagesGTO Series: Service ManualHardikNo ratings yet

- 2 Band Onboard PreampDocument7 pages2 Band Onboard PreampDanny RachmanNo ratings yet

- 4d4fe32593743 - SiA 208RDocument8 pages4d4fe32593743 - SiA 208RManoj VattavilaNo ratings yet

- Rca 29521 Chasis CTC184Document61 pagesRca 29521 Chasis CTC184Leopoldo UrquizaNo ratings yet

- Precision Monolithic Quad SPST CMOS Analog Switches V411: Features Benefits ApplicationsDocument7 pagesPrecision Monolithic Quad SPST CMOS Analog Switches V411: Features Benefits ApplicationsCesar MenesesNo ratings yet

- Ar7240 Ah1a PDFDocument1 pageAr7240 Ah1a PDFOscar Luis Quincoses Del ValleNo ratings yet

- Complementario 180w To3Document11 pagesComplementario 180w To3Horacio Sendrós100% (1)

- 8577835-Building An Electronic Signal TracerDocument12 pages8577835-Building An Electronic Signal TracerLyckholm Sam100% (1)

- Midas VeniceDocument46 pagesMidas Venicemirescualin100% (1)

- Class D Ucd Beta01 06.12Document1 pageClass D Ucd Beta01 06.12luizcpimentaNo ratings yet

- Od3 Schematic Carrillo Values Jan 2012Document4 pagesOd3 Schematic Carrillo Values Jan 2012Pablo Carrillo SanmartínNo ratings yet

- LCR-0202 Analog Linear CouplingDocument3 pagesLCR-0202 Analog Linear CouplingJaPan Life100% (1)

- CV3393BL G 20 CultraviewDocument15 pagesCV3393BL G 20 CultraviewSamuel Ulises Leon GonzalezNo ratings yet

- Simply Ph03-070808 Chassis Ph03Document4 pagesSimply Ph03-070808 Chassis Ph03Hector Arias100% (2)

- FORMPREDocument8 pagesFORMPREFouquetNo ratings yet

- Peavey XR680E Mixer AmplifierDocument7 pagesPeavey XR680E Mixer AmplifierRafael Tinajero Rafles100% (1)

- Inter M r150 r300 r500 Power Amplifier Service ManualDocument11 pagesInter M r150 r300 r500 Power Amplifier Service Manualn_hakimNo ratings yet

- M-1008K - 050712-2 TesterDocument20 pagesM-1008K - 050712-2 Testermaq67No ratings yet

- SMPS Half Bridge Compacta 2.0Document3 pagesSMPS Half Bridge Compacta 2.0ชาญณรงค์ สมพรไพลินNo ratings yet

- DV k584n SJDocument123 pagesDV k584n SJinformscribdNo ratings yet

- Cobra 148fgtl DX+ FetDocument5 pagesCobra 148fgtl DX+ Feteliud_buenoNo ratings yet

- Kit 49. Ultrasonic Movement Detector Ii: ComponentsDocument2 pagesKit 49. Ultrasonic Movement Detector Ii: Componentsbhavyasri14No ratings yet

- 125-Electronics Projects Vol 26Document6 pages125-Electronics Projects Vol 26Ye Min OoNo ratings yet

- REGENERATIVE SHORTWAVE RECEIVER - Circuit Diagram - Forum - SeekICDocument1 pageREGENERATIVE SHORTWAVE RECEIVER - Circuit Diagram - Forum - SeekICdaniNo ratings yet

- Microcontroller-Based Tachometer: ConstructionDocument4 pagesMicrocontroller-Based Tachometer: Constructionjoniakom100% (1)

- SW Radio PDFDocument5 pagesSW Radio PDFAhmed BoubakerNo ratings yet

- HomeworkDocument7 pagesHomeworkDoutimiye Tonlagha EddieNo ratings yet

- Experimental CW QRP Transceiver: ANTENTOP-01 - 2006, # 008Document4 pagesExperimental CW QRP Transceiver: ANTENTOP-01 - 2006, # 008Al FrenchNo ratings yet

- Remote Control Fan RegulatorDocument42 pagesRemote Control Fan Regulatorshiningstar_abhi376567% (3)

- IR Remote ExtenderDocument5 pagesIR Remote ExtenderfaisalbceNo ratings yet

- K63 One-Chip Am Radio: Sensitivity Is The Ability To Pick Up Weak Signals WhileDocument2 pagesK63 One-Chip Am Radio: Sensitivity Is The Ability To Pick Up Weak Signals WhileJuan Manuel Hernandez B.No ratings yet

- Spice Mosfet Model IntroDocument50 pagesSpice Mosfet Model Intro高慶樺No ratings yet

- Tiny Predictive Fan Failure Detector: Features General DescriptionDocument14 pagesTiny Predictive Fan Failure Detector: Features General DescriptionAkoKhalediNo ratings yet

- 01 - Difference Between WCDMA and GSMDocument11 pages01 - Difference Between WCDMA and GSMAdil SumantriNo ratings yet

- NPN Silicon Epitaxial Planar Transistor: Absolute Maximum Ratings (T 25 C)Document2 pagesNPN Silicon Epitaxial Planar Transistor: Absolute Maximum Ratings (T 25 C)Luis Carlos OrtegaNo ratings yet

- Basic Laws of Electric Circuits: Nodal AnalysisDocument29 pagesBasic Laws of Electric Circuits: Nodal AnalysisLeila CheropNo ratings yet

- Votano 100Document26 pagesVotano 100buicongbinhNo ratings yet

- Computer Cooling MethodsDocument11 pagesComputer Cooling Methodssiva0182No ratings yet

- Nassif Alexandre Fall+2009Document201 pagesNassif Alexandre Fall+2009aramirezbenitesNo ratings yet

- History of ComputerDocument24 pagesHistory of ComputerraviNo ratings yet

- CSEC Physics Past Papers Jan 2017 Q5 Logic GatesDocument4 pagesCSEC Physics Past Papers Jan 2017 Q5 Logic GatesjoeNo ratings yet

- Manual Gateway DLMS-MODBUS Landis+Gyr RS485Document9 pagesManual Gateway DLMS-MODBUS Landis+Gyr RS485MARCOM SRLNo ratings yet

- Ham Radio Workbench-QRP Dummy Load-ManualDocument4 pagesHam Radio Workbench-QRP Dummy Load-ManualBenjamin Dover100% (1)

- Sensor Signal ConditioningDocument366 pagesSensor Signal Conditioningwagnalang1639100% (1)

- Microwave System DescriptionDocument16 pagesMicrowave System DescriptionNavi NaviNo ratings yet

- Conveyor Belt Motor Using Control Grafcet As Programming ToolDocument27 pagesConveyor Belt Motor Using Control Grafcet As Programming Toolcacung100% (3)

- DX79TO ProductGuide01 EnglishDocument86 pagesDX79TO ProductGuide01 EnglishqwarztNo ratings yet

- 50 Years of Piezoelectric Transformers. Trends in The TechnologyDocument12 pages50 Years of Piezoelectric Transformers. Trends in The TechnologyYYedow100% (1)

- T7 Datasheet Export 20150407Document115 pagesT7 Datasheet Export 20150407mehralsmenschNo ratings yet

- Computer QUIZDocument22 pagesComputer QUIZNayan KumarNo ratings yet

- Smart Cameras in Embedded SystemsDocument8 pagesSmart Cameras in Embedded SystemsVivekSonkerNo ratings yet

- Board Tester Series: Yascaxxx Data SheetDocument4 pagesBoard Tester Series: Yascaxxx Data SheetJORDAN ABEL SOSA VILLEGASNo ratings yet

- FP12xxC FP28xxC Installation EnglishDocument48 pagesFP12xxC FP28xxC Installation EnglishRemus BobeNo ratings yet

- Kerala University B.tech 2008 Scheme Syllabus For 1&2 SemDocument4 pagesKerala University B.tech 2008 Scheme Syllabus For 1&2 Semjoyasams100% (1)

- F510 Instruction ManualDocument438 pagesF510 Instruction ManualMitzi Coleene BuezaNo ratings yet

- Why Partner With TI in Blood Glucose Meters?Document3 pagesWhy Partner With TI in Blood Glucose Meters?userNo ratings yet

- Device Package Parts Description Qty: Flipmouse MainboardDocument4 pagesDevice Package Parts Description Qty: Flipmouse MainboardjlnederNo ratings yet

- Audison Forza Apf8.9bit-24v Tech-Sheet 2019Document1 pageAudison Forza Apf8.9bit-24v Tech-Sheet 2019Erwin HernandezNo ratings yet

- Esquema Elétrico LG H422 LG Volt - Manual de ServiçoDocument116 pagesEsquema Elétrico LG H422 LG Volt - Manual de ServiçoValmirSousaSilva33% (3)