Professional Documents

Culture Documents

Case Study On Culture and The Implementation of Manufacturing Strategy in Mexico

Case Study On Culture and The Implementation of Manufacturing Strategy in Mexico

Uploaded by

waqasalitunioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study On Culture and The Implementation of Manufacturing Strategy in Mexico

Case Study On Culture and The Implementation of Manufacturing Strategy in Mexico

Uploaded by

waqasalitunioCopyright:

Available Formats

~

Journalof Mam(facturingSystems

Vol. 23/No. 3 2004

Case Study on Culture and the Implementation of Manufacturing Strategy in Mexico

Carlos Acosta, Universidad de las Americas, Puebla, Mexico V. Jorge Leon, Charles Conrad, Roberto Gonzalez, and Cesar O. Malave, Texas A&M University,

College Station, Texas, USA

Abstract

Even under the best circumstances, organizational change generates resistance. When the change results from a company in one country purchasing a plant in a different country, the complexity of change management and the resistance to change increase considerably. This case analysis examines one such change effort. Initially, the effort failed because the management of the acquiring (U.S.) firm communicated ineffectively with workers in the acquired (Mexican) plant, failed to establish a reward system that encouraged acceptance of change, and ignored cultural and subcultural differences. However, management quickly learned from its mistakes and made the adjustments necessary to turn failure into success. Implications for cross-cultural change management are discussed.

Keywords: Global Manufacturing, Improvement Methods,

Culture

Introduction

Mexico is the number-two exporter to the United States, and the codependence of the two nations is obvious. United States investments in Mexico have grown considerably over the past years, especially since the North American Free Trade Agreement (NAFTA) began promoting industrial development. Initially, many U.S. firms moved to Mexico in search of cheap labor, in spite of evidence that cheap labor itself rarely enables companies to compete successfully in the global marketplace (Adler 1997; Earley 1993; Hamrin 1980). Many of these firms subsequently moved from Mexico to South Asia and Southeast Asia, attracted by even lower wage rates. Other firms have moved to Mexico to establish longterm relationships that secure a profitable place in developing Latin American markets. A large body of research has demonstrated that cultural values directly influence the success of

This research is partially funded by both the Consejo Nacional de Ciencia y Tecnologia (CONACYT - Mexico) contract No. 35981-U and the National Science Foundation (NSF - USA) contract No. DMI0116635.

organizational strategies and managerial actions in global organizations, especially when long-term relationships are desired. Consequently, it is important for all parties involved in international business efforts to understand key differences in national cultures, and the ways in which those differences influence the impact of new technologies and new production techniques. The case study presented in this paper describes how a U.S.-owned company adapted a manufacturing philosophy to successfully implement it in an acquired facility in Mexico. Two unique characteristics of this case study are that the manufacturing philosophy is of Japanese origin and that the Mexican facility is located in a state with a distinctive subculture as compared with neighboring Mexican regions. The next section describes how cultural differences can affect organizational changes, with the following sections presenting two phases of the case study. Presented next is an analysis of the case study from the cultural perspective, and finally, conclusions and recommendations are offered.

Culture Differences and Organizational Changes

Organizational change inevitably generates resistance (Deetz, Tracy, and Simpson 2000; Poole et al. 2000; Zaltman, Duncan, and Holbok 1973). In even the best of circumstances, change creates uncertainty and ambiguity, and employees respond to those anxieties in myriad ways, many of which undermine the organization's objectives (Ashford 1988; Menzies Lyth 1988; Noer 1993). Some changes also carry tangible threats to the status, self-esteem, incomes, or job security of particular groups of workers (Mulder 1977). As a result, even changes that on the surface seem to promise enhanced rewards or working conditions are resisted. When 204

Journal of Mamtjacturing Systems

Vol. 23/No. 3 2004

the changes are sudden; significant; imposed from the outside; involve employees from multiple, different cultures and subcultures; and/or are m i s h a n d l e d by m a n a g e m e n t , the likelihood of resistance increases substantially. Resistance to change is related to national culture in two ways. First, cultural assumptions influence the way in w h i c h m u l t i n a t i o n a l c o r p o r a t i o n s approach expansion into a new country or market. There are many possible forms of expansion. In terms of potential cultural integration, the two extremes are (1) "greenfield" starts and (2) acquisitions. In the former situation, a multinational company sends a small group of expatriates into an area to hire locals and gradually build a business. The potential for cultural clash is minimized, and the opportunity for the expatriates to learn the nuances of the new culture is maximized. At the opposite extreme are foreign acquisitions, in which a multinational firm purchases a local company or plant. Acquisitions are quick but are fraught with potential for culture clash. In the worstcase scenario, the acquiring firm blindly imposes its own way of doing things on members of a very different culture with little consideration of those differences or for the values of employees of the acquired firm: "Culture clashes are resolved through brute power: Key people are replaced by the corporation's own agents. In other cases, key people do not wait for this to happen and leave on their own account. Acquisitions often lead to a destruction of human capital, which is eventually a destruction of financial capital as well." (Hofstede 2001, p. 45). As a result, cross-cultural acquisitions tend to fail significantly more often than other forms of expansion, especially when the cultures of the acquiring and acquired firms/plants are substantially different (Barkema, Bell, and Pennings 1996; Kogut and Singh 1988; Li and Guisinger 1992). For a variety of reasons, most of which are related to the political, legal, and economic situation that characterizes the society in which an multinational is based, national culture and mode of intervention are strongly correlated. U.S. firms tend to acquire foreign firms or plants, as occurred in this case study, and tend to place the burden of adaptation on members of the acquired firm/plant rather than accepting that burden themselves (Hofstede 2001; Laurent 1978). In addition, U.S. managers tend to operate on a "one-

size-fits-all" approach to day-to-day operations, insisting on using the same strategies and practices that have proven to be successful in other operations (Newman and Nollen 1996). When workers do resist change, supervisors tend to attribute their opposition to inadequate training and/or education, even when change is based on insightful analysis of problems with the new program or the way it is being i m p l e m e n t e d (Zorn, C h r i s t i a n s e n , and Cheney 1999). Although there are notable examples of U.S. firms successfully overcoming these tendencies, albeit often after an initial period of cross-cultural conflict and communication breakdown (e.g., Mann 1989), and there is also evidence that past experience operating in the culture of the acquired firm (or in similar cultures) increases the potential for a successful acquisition, U.S. firms face a unique set of culturerelated challenges when they acquire firms or plants in different national cultures. The potential for resistance is increased by d i f f e r e n c e s in c u l t u r a l a s s u m p t i o n s w i t h i n organizations. Hofstede (2001) and others have argued that the most important dimension that differentiates national cultures is Uncertainty Avoidance (UA), the intensity with which each culture's members feel a need to avoid uncertainty and the means through which they do so. Unlike fear and risk, which are focused on specific, known threats, anxiety and uncertainty are diffuse feelings of concern for the future. In general, "technology" (broadly defined as any human artifact) protects people against uncertainties caused by nature, law defends against uncertainty caused by other people, and religion defends people against uncertainties they cannot understand. O r g a n i z a t i o n s m a n a g e u n c e r t a i n t i e s in their environments by taking a short-term, reactive orientation and by attempting to negotiate protective a r r a n g e m e n t s with sources of e n v i r o n m e n t a l uncertainty (e.g., becoming a monopoly or part of an oligopoly, encouraging the creation of protective tariffs or restrictions on competitors). Organizations manage internal sources of uncertainty through the creation of rules of behavior, bureaucratic structures, and rituals (Cyert and March 1963). Cross-cultural differences in either the intensity of feelings of uncertainty avoidance or in terms of mechanisms for managing uncertainty are especially difficult to

205

Journal of Mant(f~tcturing Systems

Vol. 23/No. 3 2004

manage (Hofstede 2001). For example, rules are used to manage uncertainty in all cultures. But if rules mean different things in different countries, it is difficult to keep the organization together. In lowUA index cultures like the United States ... managers and nonmanagers alike feel definitely uncomfortable with systems of rigid rules, especially if it is evident that many of these rules are never followed. In highUA index cultures, like most of the Latin world, people feel equally uncomfortable without the structure of a system of rules, even if many of the rules are impractical .... At either pole of the uncertainty avoidance dimension, people's feelings are fed by deep psychological needs related to the control of aggression and to basic security in the face of the unknown (Hofstede 2001, p. 442). Although employees in all cultures resist change, the likelihood of resistance is highest in high-UA index cultures. There, change is very destabilizing, especially if it is unstructured, unclear, ambiguous, or makes employees' futures with the organization more tenuous. Even the act of planning for change is negatively valued because it increases uncertainty. When planning does take place, it tends to be very detailed and short term in focus, based on a narrow range of "relevant" information, and performed by specialists. Each of these characteristics reduces the uncertainties involved in the planning process. Subordinates in high-UA index cultures tend to believe that organizations/institutions are not concerned for the welfare of their employees or members and tend to perceive organizational actions as potentially harmful to those employees (Hofstede 2001, p. 382). As a result, organization-initiated changes stimulate especially high levels of suspicion and anxiety. The second important cultural difference involves "Power Distance" (PD), the extent to which members of a society view inequalities in power, wealth, and influence as inevitable, just, and positive in that they foster social stability or as a social problem that needs to be minimized or overcome. The United States is a relatively low PD society; Mexico has one of the highest PD scores among the nations that Hofstede and his successors have studied. Moreover, the PD scores of relatively uneducated Mexican workers in routine jobs are significantly higher than the Mexican average (Hofstede 2001, pp. 88-90). At first glance, this relationship suggests that Mexican workers would readily accept changes imposed from

the top of their organizations. However, research using the PD concept has found more complex relationships. First, in high-PD societies, employees' primary ties are to groups with which they are highly familiar and closely affiliated. These 'in-groups' include other people from their families or with the same backgrounds, training, class, and experience (Zurcher, Meadow, and Zurcher 1965). Security stems f r o m these relationships, not f r o m organizational rules or structures. Consequently, change is acceptable if it is supported by dominant members of workers' in-groups; it is likely to be resisted if imposed by members of "out-groups," especially if the out-group is composed of foreigners or members of a different race. Organizational policies and practices must be legitimized in terms of the values of the workers' in-group, and must be a c c e p t e d by r a n k i n g m e m b e r s of that group ( H o f s t e d e 2001, p. 97). D e c i s i o n m a k i n g is expected to be personal and political, rather than "strategic" or "rational," and filtered through dominant in-group members. Organizational theorist Stewart Clegg (1989) (also see Hobbes 1962) has pointed out that as early as the Renaissance Western society grappled with two very different views of social power. One view, based on the ideas of Thomas Hobbes, depicts p o w e r and d e c i s i o n m a k i n g as u n e m o t i o n a l , scientific processes. Decision makers function as dispassionate legislators, making rational choices among alternative courses of action. Described in mechanistic terms, decisions, and the inevitable exercise of power that accompanies them, are legitimate if they fulfill the standards of science When applied to organizations, this perspective suggests that managers should think strategically, rather than politically, and act via plans that are guides by formal rules. Subordinates will be persuaded to accept managers' decisions through rational processes of bargaining and reasoning based on practical considerations. When policies or programs fail, the outcome is attributed to systemic factors. Alternatively, a Machiavellian perspective views power and decision making as inherently political, strategic processes. Decision makers take on the role of an interpreter of multiple, conflicting political pressures. Power is located in patterns of coalitions and interpersonal relationships, and its exercise is

206

Journal e)f"Mam([?tcturing Systems

Vol. 23/No. 3 2004

legitimate if doing so successfully manages those pressures. Managers persuade their subordinates through relational appeals and rely on interpersonal ties with their subordinates to obtain support for their decisions. In high-PD, Machievellian societies, when policies or programs fail, the person(s) at the top of the organization is assumed to be responsible for those failures (Hofstede 200l, p. 382). Over time, Hobbesian views of power came to dominate the low-PD cultures of Britain and northern Europe; Machiavellian perspectives were more acceptable in high-PD cultures such as those of southern Europe and the Mediterranean (Hofstede 2001, especially chap. 3). Consequently, the acquisition of the particular plant outlined in this paper by a U.S. multinational promised to be exceptionally challenging. Typical methods of managing acquisitions, while consistent with U.S. cultural norms, are very much incongruent with the interpretive frames of employees in the acquired firm. Those differences, and the standard acquisition process, are likely to create high levels of uncertainty and anxiety for employees whose national culture makes uncertainty avoidance paramount. There are, however, cultural characteristics that the acquiring company could use to facilitate the transition. For example, in Mexico, establishing a more personal relationship between supervisors and workers is particularly important to establish loyalty between them. Also, everyone works mainly to get the money to live a life they can enjoy; hence, if the company relates the system objectives with an economic benefit to the employees, they are likely to work harder to achieve them. Training is fundamental for the implementation of new systems. Companies in Mexico should invest heavily on training if they want to succeed. For instance, relative to Americans, Mexicans are initially more reluctant to work with a stranger; however, once trust is developed they will be very loyal to the team. This suggests the importance of team training, in particular on team formation stages, when dealing with Mexican companies (Earley 1994). U.S.Mexican cultural differences do not doom acquisitions to failure; instead, the differences suggest that cultural sensitivity and cultural adaptation by both parties is especially important to the success of the venture.

Case Study, Phase I

USA Home Products (USAHP) is an American multinational company that manufactures family,

personal, and household products (the company name has been changed and the specific product u n s p e c i f i e d for c o n f i d e n t i a l i t y reasons). This company has been in Mexico for more than 40 years. USAHP markets more than 200 brands to nearly five billion consumers in more than 140 countries. It has more than 100,000 employees in more than 80 countries around the world. USAHP is unique when it comes to innovation; it believes in creating a connection between what consumers want and what technology can deliver. USAHP revenues are on the order of $40 billion per year. To further expand its activities, USAHP purchased a plant in Axcala, Mexico, from a Mexican group called PAMEX. At the moment, this plant has more than 500 employees and has a production of a million cases of products per mouth. The plant has state-ofthe-art technology with almost completely automatic lines. The two companies had very different ways of c o n d u c t i n g business. P A M E X m a n a g e m e n t b e l i e v e d that its e m p l o y e e s should learn by experience and trial and error. PAMEX hired local e m p l o y e e s , m o r e on the basis of e s t a b l i s h e d relationships than on education and expertise. As a result, many of its employees had only an elementary education. On the other hand, USAHP relies heavily on systematic training and expertise when it makes hiring decisions, and only hires people who have at least some technical education. It prefers to hire outstanding new graduates who have studied in selected universities (mostly private universities), and it requires them to be very proficient in both written and spoken English. Selection decisions are made through a standard U.S. process--applicants are given a test to measure their ability to solve problems and then the few who pass that test go through a series of interviews. As a result, getting a job in the Axcala plant became much more difficult than before, especially for local people. The region where the plant is located has some technical schools that supply the labor force for local industries, however, the area lacks good universities. Therefore, USAHP largely recruited its new administrative personnel from neighboring, more developed, and culturally distinct (Mexican) states. Workers at the P A M E X plant s u d d e n l y w e r e confronted by newcomers who were both outsiders (either U.S. citizens or from neighboring states) and different in terms of their backgrounds, education,

207

Journal of Manuj~zcturing Systems

Vol. 23/No. 3 2004

and experience. Expatriates from the U.S. were doubly alien--they were U.S. citizens and they also chose to live in neighboring states because of its more attractive climate and educational institutions. For the managers and engineers remaining from the previous company, the culture change accompanying USAHP's acquisition of the Axcala plant was enormous. Most of the employees felt, accurately, that their jobs were in jeopardy because of the remarkable differences in philosophy between the two companies. PAMEX promoted, rewarded, and retained employees based on their loyalty to the firm and to their immediate supervisors, and based on interpersonal (usually family) connections. In contrast, USAHP's policy was to hire technical experts to start as supervisors and then grow within the company up to managerial positions. Similar differences were apparent in the reward systems of the two companies. Under PAMEX, managers' salaries were based on their friendships with the owner or the board of directors of the company. As a result, their salaries were far larger than the USAHP salary structure allowed, given their training, performance, and experience. Meanwhile, most of the technicians had salaries that were far below USAHP's standards. To bring the new plant into line with company standards, USAHP froze the salaries of the overpaid managers and fired those whose jobs were primarily based on their personal relationships with the previous owners. The managers whose salaries were frozen were unhappy with the change, but they were happy to keep their jobs. However, one of USAHP's first steps raised questions about the fairness of the company's reward system. Employees in all cultures view fairness as an important aspect of worker-organization relationships and react negatively to actions that they perceive are unfair (Leung 1987; Leung and Li 1990). However, the way in which "fairness" is defined varies across cultures, focusing on in-group relationships in Mexico and on "objective" assessments of credentials and performance in the United States. In sum, in the new plant, rewards, promotions, and retention were based on objective measures of individual performance. Each of these changes was appropriate given the strategic model within which USAHP operated. But, for PAMEX employees, the changes created uncertainty and ambiguity and directly threatened their job security. To make matters worse, the changes were imposed by outsiders, who in many ways had thus inadvertently exaggerated 208

their alien status. As a result, the changes created an exceptional level of uncertainty for employees whose society is especially focused on uncertainty avoidance.

Implementing the Total Productive Maintenance Concept

The new owners also required operators to learn a w h o l e new way of w o r k i n g . Workers w e r e accustomed to being mere button pressers and were not required to write or document anything. With USAHP, the workers had to change their everyday practices and adhere to strict working standards that required constant documentation. As a result of these changes, m a n y of the older workers accepted voluntary retirement packages because they just could not adapt to the new working systems. The ones who remained found ways to delay or shortcircuit the implementation of the change. USAHP uses Total Productive Maintenance (TPM) in its plants to r e m a i n competitive. TPM is a manufacturing strategy of Japanese origin that includes different working methodologies. Each company will decide which methodologies to use, but most companies include the following: Focused Improvement Autonomous Maintenance Planned Maintenance Education and Training Quality-Focused Maintenance Administration and Support Safety

Autonomous Maintenance (AM) is the backbone of TPM. The general objective of AM is to hold workers responsible for performing dally maintenance on their machinery. The main objectives of AM are: Avoid accelerated deterioration of equipment by using it correctly and making daily inspections. Return equipment to its initial operating conditions. Establish necessary conditions to keep equipment well maintained at all times. Use equipment as a means to teach new ways of thinking and working. The AM m e t h o d o l o g y c o n s i s t s of seven sequential steps: Step 1. Initial cleaning. Step 2. Elimination of all pollution sources and difficult-to-reach places.

Journal of Mant(f~wturing Systems

Vol. 23/No. 3 2004

Step 3. Establish standards of lubrication, clean ing, and bolt tightening. Step 4. Inspect the equipment. Step 5. Inspect the processes. Step 6. Systematic AM. Step 7. Self-administered system. The First Years of AM in U S A H P Axeala To begin the AM implementation, USAHP started training at the top managerial level as a way to convince the rest of the plant that autonomous maintenance was so important that even managers would get their hands dirty working on the machines. For the startup of AM, all the leaders of the plant including the plant manager cleaned their assigned workcenters and documented the status of their work. The next step was to involve all of the plant to work in a u t o n o m o u s m a i n t e n a n c e . An e x c h a n g e of personnel from different sites where AM was already in place was promoted. The company provided all the necessary equipment, such as computers, for exclusive AM use. Autonomous maintenance was first applied to those operations and equipment identified as most critical for the manufacturing process. On the one hand, one would expect topdown change fostered by recognized experts to be readily accepted by members of a high powerdistance (PD) society. However, the key personnel involved in this change were outsiders, not members of the operators' existing 'in-groups.' Ruben Salas was the AM leader chosen by the plant leadership team. He was transferred from a n o t h e r M e x i c a n site w h e r e a u t o n o m o u s maintenance had been implemented successfully. Forty teams were formed to pilot the AM project. However, from the beginning, Salas had leadership problems with the production department. Arturo Suarez was the production department's manager. He was local to the region, had worked in the factory for over 10 years, and had gained the respect of the workers in the plant. Suarez started as a supervisor when the plant was owned by PAMEX and worked his way up to his current position. Suarez was under constant management pressure to meet the production requirements set by the sales department. As a result, he opposed having the department's employees go to AM training sessions because their absence could j e o p a r d i z e m e e t i n g p r o d u c t i o n quotas. The production workers also noticed that the managers

could not come to an agreement on the importance of autonomous maintenance. The new managers had no direct experience on the shop floor and could not produce persuasive evidence of the positive effects of the system on the workers' lives. As a result, the workers decided to listen to Suarez, the boss with whom they had worked for more than a decade and whom they were loyal to. They did not embrace the autonomous maintenance philosophy and thought that cleaning the equipment was pointless because 'it would get dirty again anyway.' During this time, the c o m p a n y struggled to p r o v i d e AM t r a i n i n g to its e m p l o y e e s . The employees were negatively influenced by Suarez, never understanding why they had to go to training. It seemed like a waste of time to them, and they chose not to go or showed up late. In fact, the implementation of AM seemed to penalize the operators because it eliminated their piece-rate reward system, and now they could not blame the maintenance group for any production losses due to machine breakdowns. They believed it was unreasonable for the managers to ask them to fix their own equipment when they had no maintenance experience and previously had been served by a specialized maintenance department. Furthermore, they thought there was no reason to change the current methods because 'they had worked fine' all this time for PAMEX. In summary, the workers had no i n c e n t i v e s to i m p l e m e n t a u t o n o m o u s m a i n t e n a n c e J a n d had significant disincentives for doing so. As often observed in intact groups with long histories of working together, the resistance was not individual but collective (Salancik and Pfeffer 1978). The workers' resistance to AM was also related to the ambiguity of the system itself. There are no predefined, detailed recipes on how to apply AM. Instead, the methodology relies heavily on active worker involvement, a common feature of many methodologies of Japanese origin. For instance, the guidelines state that one should achieve zero defects without explicitly saying how to achieve that goal. The methodology states that every member of a work group is responsible for finding and implementing new solutions. In contrast, Mexican workers are culturally predisposed to obey established rules p r o c e d u r e s and to f o l l o w a leader. Both predispositions provide stability and protection in

209

Journal ~/" Mam(/?wturing Systems

Vol. 23/No. 3 2004

uncertain situations. Because most of the workers from P A M E X had, at best, e l e m e n t a r y school educations, the new managers decided that the work standards and procedures should be created from the supervisor level instead of from the workers themselves, as required by AM. Although planning by specialists is expected in high-PD societies, the respect afforded them depends on the expertise they demonstrate, the success of their efforts, and their ability to create detailed designs and short feedback loops that minimize uncertainty (Hofstede 2001, p. 382). These operators laughed at the standards created by the outside experts because it was obvious that the supervisors did not know how the "real world" was. Without a demonstration of relevant expertise and success, the advantages granted to superiors in high-PD cultures become disadvantages. During this initial attempt to implement AM, the combination of cultural preferences and a badly designed reward system probably d o o m e d the system from the outset. After two and a half years, only six groups out of 40 had progressed enough to be moved to step two of the seven-step AM methodology procedure.

Interpretation of Phase I

In many ways, Phase I of the Axcalan acquisition provides a textbook case of the kinds of problems involved in operations across cultures. In those cases, the U.S. firm attempts to change Mexican operations, which inevitably engenders resistance. As Kirkman and Shapiro (1997) conclude: "Change agents, who often are U.S. born because so few host nationals have experience with the latest North American management initiatives (Appelbaum and Batt 1994), can make cross-cultural mistakes when working in foreign affiliates, leading direction to employee (change target) resistance." (p. 735) However, Hofstede (2001) notes that "textbook" interpretations of intercultural encounters often o v e r g e n e r a l i z e cultural tensions and ignore complexities and nuances. In Phase I of this case, two complications were especially important. The first complicaton involved the local culture of Axcala, which is special even within Mexico. Axcalans are a closed society, distrust foreigners, and are very traditionalist and regionalist. This distinctiveness has

it roots in pre-colonial times. The people of Axcala were never subordinated by the Aztecs. Later, they allied with the Spaniards in the conquest of the Aztecs, obtaining special treatment during colonization (Rendrn 1996). In contrast, the neighboring provinces r e a d i l y accepted Aztec control; they are an economically wealthier and culturally distinct people who in the past have been enemies of the Axcalan people. U S A H P expatriates chose to live in neighboring provinces for wholly rational reasons-the climate, intellectual attractions, and quality of schools for their children. We found no evidence that U S A H P ' s management knew that Axcalans are exceptionally sensitive to incursions by "outsiders," or that they perceive their neighboring Mexican states and the people who live there as especially alien, or that upsetting a tradition of e m p l o y m e n t and a d v a n c e m e n t through i n t e r p e r s o n a l / f a m i l y relationships would seriously threaten the core of Axcalan culture and the organizational culture of the plant. But, when USAHP management made those choices and hired new employees from those areas, it exacerbated the problems created by differences between national cultures. The second complication involves the concept of power distance (PD). Scholars and practitioners alike generally have interpreted power distance as a preference for hierarchy and an acceptance of topd o w n leadership. But, f r o m the b e g i n n i n g of Hofstede's work, it has been clear that the concept is mediated by the distinction between 'in-group' and 'out-group' ties. Similarly, while the PD factor is statistically independent of uncertainty avoidance, the two factors overlap in practice. Change creates uncertainty. In some cultures, the anxiety that stems from change is managed through interpersonal ties. When the changes circumvent or undermine those ties, uncertainty is increased. USAHP's decision to bring a large numbers of outsiders, to make radical changes in personnel and the hiring/reward system, and to suddenly impose a new production system with little explanation magnified the uncertainty further. In short, USAHP acted in ways that maximized u n c e r t a i n t y in a culture in w h i c h u n c e r t a i n t y avoidance is highly salient. As a result, it was very difficult to have the workers themselves develop and improve their rules, procedures, and standards as required by the autonomous maintenance (AM) methodology.

210

Journal of Manu/?tcturing Systems

Vol. 23/No. 3 2004

Case Study, Phase II

After two and a half years, USAHP's management realized that its efforts to implement AM at the Axcala plant had failed. This realization is important in itself because there is abundant evidence that managers of U.S. firms tend to persist in falling courses of action long after there is abundant evidence that they indeed are failing by demanding that the host culture do all the changing (Tegar 1980). To the credit of USAHP management, it accepted the failure and changed to i m p l e m e n t m o r e culturally sensitive strategies developed with the intervention of personnel with experience in the local culture. The transformation began when the c o m p a n y implemented a new reward system based on clearly stated objectives and performance standards. Clearer working standards were created for autonomous maintenance, including a new audit system where everyone was held directly accountable for their participation in AM activities. New procedures and metrics to evaluate the involvement of the personnel in autonomous maintenance were implemented, such as attendance at AM-related meetings and activities. All AM teams now meet each week to share their results and assign each m e m b e r with speCific responsibilities. Each employee's ranking, promotion, and salary in the company depend on the level of c o m m i t m e n t they have s h o w n to autonomous maintenance. The operators still have a lot of pressure to produce, but now they have preestablished hours to receive training in AM. Teams are rewarded with small prizes for achieving the set g o a l s . S p e c i a l r e c o g n i t i o n is g i v e n to t h o s e c o m p l e t i n g i m p o r t a n t m i l e s t o n e s in the Total Productive Maintenance (TPM) process. Just as important, the team itself decides when to be audited and what its objectives are. Before the team is audited, it has a pre-audit using the same criteria used by the real auditors. If the team covers at least 90 points out of 100, then the team is said to be ready for audit. The audit can be done by any plant worker who is already certified in a u t o n o m o u s m a i n t e n a n c e , including the plant manager. In this particular situation, workers f r o m the previous company were tightly bonded by traditional A x a c a l a n r e g i o n a l i s m and by A r t u r o S u a r e z ' leadership role, which resulted in rejection of the changes required for T P M implementation. Suarez

was relocated to a nonproductive area where he could still be accessible for his valuable technical expertise. Juan Ruiz, an experienced AM manager who is committed to the process, replaced Suarez as the AM team leader and new production manager. Giving the same person both roles helped eliminate conflicts and uncertainties. The new system also used existing in-group relationships to the company's advantage. Ruiz' i m m e d i a t e subordinate is Campos, an old PAMEX supervisor who is supportive of the AM initiative. Ruiz trained three technicians, who were put in charge of antonomous maintenance in the different p r o d u c t i o n areas of the plant. T h e s e technicians will, in turn, pass on the knowledge to the workers in their corresponding areas. A new l e a d e r s h i p t e a m was f o r m e d , w h i c h i n c l u d e d members f r o m all of the production areas. New subcommittees were created in each area, composed o f a f u n c t i o n a l l e a d e r (a w o r k e r w i t h A M experience), the leader of the area, and a Planned Maintenance (PM) planner. In the incorporation of other TPM components, such as Planned Maintenance, care was taken to establish a hierarchy of team leaders w h o had previous experience and who were committed to the TPM program. The members of each shift form their a u t o n o m o u s maintenance teams and w o r k on a specific machine in their area. There is a central leader who is one of the three technicians responsible for the areas. Each of the operators is responsible for his or her machine. The responsibility includes operating the equipment, documenting the problems observed, and repairing minor faults. Examples of m i n o r faults are c h a n g i n g belts and/or plates, tightening bolts, and lubricating bearings. For major defects, the operators prepare a list that is passed to the central technician. The central technician collects all of the lists and sends them to the production department. Whenever there is a general planned stoppage of the plant, all AM teams work in the maintenance of their respective equipment. The responsibility of the previous maintenance team was limited to specialized and complicated maintenance activities; therefore, they are not responsible for routine maintenance activities. Another important change was consideration of the operators' educational level. In Phase I, this b e c a m e a source of increased u n c e r t a i n t y and resistance. Educational level was critical to the

211

Jourual of Manz([ktcturing Systems

Vol. 23/No. 3 2004

success of the program because TPM requires that w o r k e r s d o c u m e n t p r o c e s s e s and p r o c e s s improvement solutions. Once the workers became involved in the program, they understood why it was important. It was now possible to apply statistical quality control tools such as control charts to register the total defects found versus the defects repaired in all the plant. Additionally, workers had to fill in a daily form to check if the cleaning standards are being followed. Today, there are 38 teams who have been certified in step 1 and two teams who have been certified in step 2.

Case StudyAnalysis

Years of delays in the successful implementation of autonomous maintenance could have been avoided if USAHP's management had had a better understanding of PAMEX's national and regional cultures. In particular, the case study illustrates differences among U.S. business and Mexican and Axcalan cultures in uncertainty avoidance and power distance as related to rules, leadership, teamwork, work ethics, and workforce educational level. This section will discuss these differences and their impact on T o t a l P r o d u c t i v e M a i n t e n a n c e ( T P M ) implementation. The new reward system uses rules to manage worker uncertainty, instead of using the relationship culture of Axcala. The rules themselves are clear and known to all and are a welcome improvement over the ambiguities and uncertainties of the past two and a half years; however, just as importantly, the rules are implemented in a manner that relies on in-group links instead of threatening them. A main flaw in the initial attempt to implement TPM was that USAHP overlooked how differently people in U.S. and Mexican cultures relate to leaders in a c o m p a n y - - t h a t is, p o w e r - d i s t a n c e (PD) differences. The initial resistance to i m p l e m e n t a u t o n o m o u s m a i n t e n a n c e (AM) was very h i g h because of the failure to recognize the importance of getting 'in-group' leaders (such as Arturo Suarez) to wholeheartedly accept the TPM philosophy, and the failure to recognize that the workers were not responsive to the expertise, status, or p o w e r of outsiders. The workers were culturally predisposed to follow Suarez as a local leader. In the second attempt, U S A H P e l i m i n a t e d this resistance by removing Suarez from the leadership.

Another cultural issue disregarded by USAHP in the i n i t i a l i m p l e m e n t a t i o n was t h e d i f f e r e n t predisposition that Americans and Mexicans have for working in self-managed teams~ In the U.S., most people leave their parents' home early in their lives, either to go to college or once they get their first jobs after high school graduation. It is very different in Mexico, as in most Latin American cultures, where most people live with their families until they get married, even if this is long after they could be financially self sufficient. So, early in their lives, U.S. workers learn to trust coworkers with w h o m they have no personal or family relationship, while Latin American workers are more used to the security of being surrounded and supported by family and tend to distrust strangers. As a result, Americans are more predisposed to rapidly become effective working in teams, while it may take longer for Mexicans to trust arbitrarily a s s i g n e d t e a m m a t e s (Earley 1994). Conversely, the extreme individualism of American culture makes it difficult for those from the U.S. to u n d e r s t a n d the responses of m o r e c o m m u n i t y o r i e n t e d cultures like t h o s e of L a t i n A m e r i c a (Hofstede 2001). The United States has the highest ranking in individualism when compared to every other country in the study; Mexico scores on the opposite side of the same scale. In the workplaces o f an individualist society, 'others' are seen as 'resources,' and 'tasks' prevail over 'relationships,' m a k i n g t e a m w o r k a natural w o r k m e t h o d . It is conjectured that this difference is more obvious in less-educated layers of the society, thus the significant resistance of the workers to outsider-managed teams in the USAHP case. In the second attempt, USAHP gave more power to the team leaders, and the reward system directly penalized team members for not p a r t i c i p a t i n g in the a u t o n o m o u s m a i n t e n a n c e program. Kirkman and Shapiro (1997) state: "North American managers are likely to encounter cultures that might be receptive to teams (i.e., low in individualism) but not necessarily to self-management (i.e., high in power distance, being orientation, and determinism) in such countries as Malaysia, Indonesia, the Philippines, and Mexico (p. 750)." The former type of system, like the one used by USAHP, largely maintains a centralized structure of power and authority. As a result, it is the kind of s y s t e m that one would expect to be m i n i m a l l y u p s e t t i n g in a culture with high-PD. U S A H P ' s

212

Jourttal of Mamtfktcturing Systems Vol. 23/No. 3 2004

management modified its implementation of some autonomous maintenance methods to those that were more appropriate to the Axcala plant. The specific m o d i f i c a t i o n s to the A M m e t h o d o l o g y are summarized in Table 1. Because the company's initial goal was to use the same practices in all of its plants, this willingness to adapt is both surprising and a credit to its management. The results suggest that successful implementation would have occurred sooner if those involved had recognized the impact of regional cultural differences from the beginning.

Conclusions and Recommendations

To fully understand the Mexican culture, one needs to differentiate among the regions of the country. E x p e r t s in i n t e r c u l t u r a l c o m m u n i c a t i o n h a v e recognized for some time that treating a nation as a h o m o g e n e o u s culture is u n w i s e ( D o w l i n g and Schuler 1994; Kirkman and Shapiro 1997; Stohl and Cheney 2001). U S A H P m a d e a rational decision to apply a production system that had been successful in its

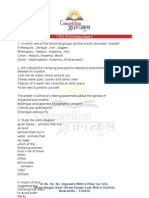

Table 1

Summary of Differences in Total Productive Maintenance (TPM)/Autonomous Maintenance (AM) Implementation Between U.S. and Mexico

T P M / A M Implementation Establishment of team responsibilities Team formation

In the U.S, (Standard) All team members are equally responsible Basic team training sufficient

In Mexico Team leader must play a more active role More emphasis in team training necessary, with special attention to team training Recognition of achievements must be accompanied by more material compensation Standards and rules are needed to provide a sense of security People need to be taught more about the benefits of improving what is already working A must

Explanation More paternalistic nature of the Mexican --more power distance Americans are more used to interacting with others outside of their 'in-groups' Mexico is a poorer country Higher uncertainty avoidance of Mexicans Mexican workers prefer to be told what to do: high uncertainty avoidance and power distance Americans are more predisposed to follow produres and documenting Americans tend to be short-term, results oriented; Mexicans have to think more long-term; they place more importance on relationships Education level in Mexico is lower; skilllevel definitions are not equivalent Collectivistic societies need to share a vision

Performance appraisal

Recognition of achievements works well Standard and rules serve as guidelines People accept continuous improvement as part of the job

Standards and rules Japanese continuous improvement

Training for procedures

Meeting times and due dates

To be on time is part of the culture

Being on time must be taught

Technical training

Additional training may be required

Initial cleaning

Deep and continuous cleaning of the equipment

Before this step, there is a negotiation with the workers' union to share the system objectives. There is also training involved to teach the workers how to fill out the forms properly. A lot reinforcement is needed. From time to time, the AM leader inspects all equipment Leaders should expect to be more involved in reviewing the suggestions

Inspection of equipment Continuous improvement

Workers inspect their own machines Team members make suggestions to improve the process

Paternalistic culture in Mexico Skill level of the worker may be lower in Mexico

213

Journal o f Manuf?~cturing Systems Vol. 23/No. 3 2004

other plants, including some in Latin America, to its new acquisition in Axcala. Increasing the educational level of its workforce, redesigning its reward system to focus on productivity rather than interpersonal ties, and implementing a proactive system of equipment operation and maintenance all are consistent with m o d e r n m a n a g e m e n t and o p e r a t i o n s theory. Additionally, there is no sense that, even if USAHP had been thoroughly knowledgable and exquisitely sensitive to the overall differences between AngloU.S. and Mexican cultures, it would have understood and adapted at first to the nuances of the local culture of the Axcalan plant. Fortunately, USAHP was willing to recognize that its change effort was failing and to make appropriate adjustments, something that is unfortunately rare among U.S. organizations (Tegar 1980). As a result, USAHP was able to succeed when it had been on the brink of failure. Finally, just to highlight the importance of the cultural aspects when trying to implement a new manufacturing system, since the new implementation the company has been able to reduce machine stoppages by more than 50%, which can represent significant savings for the company running a high-volume, continuous process.

References

Adler, N.I. (1997). International Dimensions o f Organizational Behavior, 3rd ed. South-Western College Publishing. Appelbaum, E. and Batt, R. (1994). The New American Workplace: Transforming Work Systems in the United States. Ithaca. NY: ILR Press. Ashford, S.J. (1988). "Individual strategies for coping with stress during organizational transitions." Journal of Applied Behavioral Science (v24), pp19-36. Barkema, H.G.; Bell, J.H.; and Pennings, M. (1996). "'Foreign entry, cultural barriers, and learning." Strategic Mgmt. Journal (v17), pp151-166. Clegg, S.R. (1989). Frameworks of Power. London: Sage Publications. Cyert, R.M. and March, J.G. (1963). A Behavioral Theory of the Firm. Englewood Cliffs, NJ: Prentice-Hall. Deetz, S.; Tracy, S.; and Simpson, J.L. (2000). Leading Organizations Through Transition. London: Sage Publications. Dowling, P. and Schuler, Randall (1994). International Dimensions o f Human Resource Management, 2nd ed. Belmont, CA: Wadsworth. Earley, P.C. (1993). "East meets West meets Mideast." Academy of Mgmt. Journal (v36), pp565-581. Earley, P.C. (1994). "Self or group? Cultural effects of training on self-efficacy and performance." Administrative Science Quarterly (v39), pp89-117. Hamrin, R.D. (1980). Managing Growth in the 1980s. Praeger. Hobbes, T. (1962). Leviathan, M. Oakeshott, ed. London: CollierMacmillan. Hofstede, Geert (2001). Culture Consequences, 2nd ed. London: Sage. Kirkman, B.L. and Shapiro, D.L. (1997). "The impact of cultural values on employee resistance to teams." Academy of Mgmt. Review (v22), pp730-757. Kogut, B. and Singh, H. (1988). "The effect of national culture on the choice of entry mode." Journal of Int'l Business Studies (v19), pp411-432.

Laurent, A. (1978). "Matrix organizations and Latin cultures." Working paper 78-28. Brussels: European Institute for Advanced Studies in Management. Leung, K. (1987). "Some determinants of reactions to procedural models for conflict resolution." Journal of Pelwonality and Social Psychology (v53), pp898-908. Leung, K. and Li, W. (1990). "Psychological mechanism of process control effects." Journal of Applied Psychology (v75), pp 1134-1140. Li, J.T. and Guisinger, S. (1992). "The globalization of service multinationals in the triad regions: Japan, Western Europe and North America." Journal of htt'l Business Studies (v23), pp675-696. Mann, J. (1989). Beijing Jeep: The Short, Unhappy Romance of American Business in China. New York: Simon & Schuster. Menzies Lyth, I. (1988). Containing Anxiety in h,stitutions: Selected Essays. London: Free Association Press. Mulder, M. (1977). The Daily Power Game. Leiden, Netherlands: Martinus Nighoff. Newman, K.L, and Nollen, S.D. (1996). "Culture and congruence: the fit between management practices and national culture." Journal of Int'l Business Studies (v27), pp753-779. Noer, D.M. (1993). Healing the Wounds. Indianapolis, IN: Jossey-Bass. Poole, M.S.; Van de Ven, A.; Dooley, K.; and Holmes, M. (2000). Organizational Change and Innovation Processes. Oxford, UK: Oxford University Press. Rend6n, R. (1996). Breve Historia de Tlaxcala. Fondo de Cultura Econ6mica, M6xico, DE Salancik, G. and Pfeffer, J. (1978). "A social information-processing approach to job attitudes and task design." Administrative Science Quarterly (v23), pp224-253 Stohl, C. and Cheney, G. (2001). "Participatory processes/paradoxical practices." Mgmt. Communication Quarterly (v14), pp349-407. Tegm, A. (1980). Too Much Invested to Quit. New York: Pergamon Press. Zaltman, G.; Duncan, R.; and Holbok, J. (1973). Innovations and Organizations. New York: John Wiley & Sons. Zorn, T.; Christensen, L.; and Cheney, G, (1999). Do We Really Want Constant Change? Beyond the Bottom Line Series, Vol. 2. San Francisco: Berrett-Koehler.Zurcher, L.A.; Meadow, A.; and Zurcher, S.L. (1965). "Value orientation, role conflict, and alienation from work: a cross-cultural study." American Sociological Review (v30), pp539-548.

Authors' Biographies

Carlos Acosta is professor and chair of the Mechanical Engineering Dept. at the Universidad de Las Americas (Puebla, Mexico). His research interests are in the areas of global manufacturing, dualhydroforming process, and automotive product localization. V. Jorge Leon is the Allen-Bradley Professor in Factory Automation and is the program coordinator of the Manufacturing and Mechanical Engineering Technology program at Texas A&M University. His research interests are in the areas of manufacturing systems optimization, distributed-systems under partial-information sharing, and globalization. Charles Conrad is a professor in the Dept. of Communication at Texas A&M University. He is the author of Strategic Organizational Communication, editor of The Ethical Nexus, a study of the role of values in organizational decision making, and editor of the Management Communication Quarterly. Dr. Conrad's research has been recognized by the National Communication Association's Organizational Communication Division and the Southern Communication Association. Cesar Malave is a professor of industrial engineering and assistant dean for recruitment and international programs for the Dwight Look College of Engineering at Texas A&M University. Dr. Malave's research interests are in the area of manufacturing systems planning. Roberto Gonzales-Cervantes is a master's degree student in industrial engineering at Texas A&M University. His interests are in global and lean manufacturing.

214

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Project Management C2Document8 pagesProject Management C2CristianaGonçalvesNo ratings yet

- Project ManagementDocument354 pagesProject ManagementKish Ore100% (1)

- Steel SAE O-Rings AdaptersDocument3 pagesSteel SAE O-Rings Adaptersgeav25653855No ratings yet

- Formulation of Manufacturing StrategyDocument30 pagesFormulation of Manufacturing StrategywaqasalitunioNo ratings yet

- Manufacturing StrategyDocument30 pagesManufacturing StrategywaqasalitunioNo ratings yet

- 95-0110 Management of Contractors HSEDocument99 pages95-0110 Management of Contractors HSEClive Nicli100% (2)

- Controlling Quality by Waqas Ali TunioDocument24 pagesControlling Quality by Waqas Ali TuniowaqasalitunioNo ratings yet

- Management of Service Supply Chains With A Service - Oriented Reference Model: The Case of Management Consulting - Research Review by Waqas Ali TunioDocument1 pageManagement of Service Supply Chains With A Service - Oriented Reference Model: The Case of Management Consulting - Research Review by Waqas Ali TuniowaqasalitunioNo ratings yet

- What Is Plain Language?: "Plainness Does Not Mean The Absence of All Ornaments, Only The More Obvious Ones."Document3 pagesWhat Is Plain Language?: "Plainness Does Not Mean The Absence of All Ornaments, Only The More Obvious Ones."KM MacatangayNo ratings yet

- Catalogo Telefonia Movil 2008Document220 pagesCatalogo Telefonia Movil 2008pmn_23No ratings yet

- Business Ethics and Sustainability in Steel Industry - Tata Steel by Waqas Ali TunioDocument25 pagesBusiness Ethics and Sustainability in Steel Industry - Tata Steel by Waqas Ali TuniowaqasalitunioNo ratings yet

- Project 2013 Quick ReferenceDocument2 pagesProject 2013 Quick ReferencewaqasalitunioNo ratings yet

- Hai Buri Yeh Gali (From Faizan-e-Muhabbat by Hazrat Maulana Shah Hakeem Muhammad Akhtar SB)Document1 pageHai Buri Yeh Gali (From Faizan-e-Muhabbat by Hazrat Maulana Shah Hakeem Muhammad Akhtar SB)waqasalitunioNo ratings yet

- Project Management Training by TunyooDocument1 pageProject Management Training by TunyoowaqasalitunioNo ratings yet

- Motors (Electric, Hydraulic, Pneumatic) in Computer Integrated Manufacturing by Waqas Ali TunioDocument34 pagesMotors (Electric, Hydraulic, Pneumatic) in Computer Integrated Manufacturing by Waqas Ali TuniowaqasalitunioNo ratings yet

- The Reality of Worldly LifeDocument197 pagesThe Reality of Worldly LifeMoulana Mohammad Musa ShakirNo ratings yet

- Planning and ControlDocument27 pagesPlanning and ControlwaqasalitunioNo ratings yet

- Value Stream MappingDocument33 pagesValue Stream Mappingwaqasalitunio100% (2)

- Planning and ControlDocument27 pagesPlanning and ControlwaqasalitunioNo ratings yet

- Decision TreeDocument7 pagesDecision TreewaqasalitunioNo ratings yet

- Learning & Experience CurveDocument28 pagesLearning & Experience CurvewaqasalitunioNo ratings yet

- Learning Curve CalculatorDocument2 pagesLearning Curve CalculatorwaqasalitunioNo ratings yet

- Flexible Manufacturing Systems (FMS)Document30 pagesFlexible Manufacturing Systems (FMS)waqasalitunio100% (2)

- Catia V5 Cheat Sheet: GeneralDocument1 pageCatia V5 Cheat Sheet: GeneralAS 15 SATHIYAMOORTHI MNo ratings yet

- Special Instruction Heat ExchangerDocument26 pagesSpecial Instruction Heat ExchangerDhiyo MulyadiNo ratings yet

- CTET EVS Previous Paper 5Document8 pagesCTET EVS Previous Paper 5Competition GurukulNo ratings yet

- HRUM - Laporan Keuangan Tengah Tahun 2022Document115 pagesHRUM - Laporan Keuangan Tengah Tahun 2022Irfan RosihanNo ratings yet

- UndecidabilityDocument58 pagesUndecidabilityAbhinav KumarNo ratings yet

- 01-01 Introduction To BSCDocument6 pages01-01 Introduction To BSCAwa StelkNo ratings yet

- Architectural Heritage - EssayDocument2 pagesArchitectural Heritage - EssayJessy RitaNo ratings yet

- Fast and Frugal HeuristicsDocument17 pagesFast and Frugal HeuristicsJanice YangNo ratings yet

- 11th English Poem 1, 2 Notes - Nauman SadafDocument13 pages11th English Poem 1, 2 Notes - Nauman Sadafali adilNo ratings yet

- Maruthi Case BE EPGDM 2019 AssignmentDocument11 pagesMaruthi Case BE EPGDM 2019 Assignmentsantosh vighneshwar hegde0% (1)

- BRKNMS-2573 (2020)Document120 pagesBRKNMS-2573 (2020)Paul ZetoNo ratings yet

- 2003IDDocument3 pages2003IDAlyssa LNo ratings yet

- Medtronic Company OverviewDocument35 pagesMedtronic Company OverviewIhsan DisiniNo ratings yet

- Saferstein CH 04 - Physical Properties Glass and SoilDocument36 pagesSaferstein CH 04 - Physical Properties Glass and SoilLalit AmbasthaNo ratings yet

- Fill in The BlanksDocument3 pagesFill in The Blanksvidhyaeswaran2143No ratings yet

- Viper 20000 PCDocument176 pagesViper 20000 PCrop703406No ratings yet

- Eng Moti 0Document2 pagesEng Moti 0Barış ErçeNo ratings yet

- Blue and White Simple Technology Keynote PresentationDocument15 pagesBlue and White Simple Technology Keynote PresentationPsicología ULS 2018No ratings yet

- Design of Column Using StrucExPro.Document1 pageDesign of Column Using StrucExPro.pobre3nga3bataNo ratings yet

- 8Document43 pages8myNo ratings yet

- BOX Type WPDocument3 pagesBOX Type WPShreyans DodiaNo ratings yet

- Jabra Talk 65 Tech Sheet ENDocument2 pagesJabra Talk 65 Tech Sheet ENTaj BurryNo ratings yet

- DDM Cad For Solidworks Training ManualDocument72 pagesDDM Cad For Solidworks Training ManualDiego ReggianiniNo ratings yet

- EThics WrittenDocument16 pagesEThics WrittenVinod Thomas EfiNo ratings yet

- MSDS Colateric ZF-50Document3 pagesMSDS Colateric ZF-50mndmattNo ratings yet