Professional Documents

Culture Documents

Pipe Mill

Uploaded by

trukistrukisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Mill

Uploaded by

trukistrukisCopyright:

Available Formats

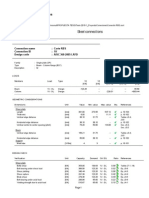

PIPEMILL - Piping Engineering, Design and Analysis

Version: 3.01 DEMO

PIPE SUPPORT TRUNNION STRESS CALCULATION

____________________________________________________________________________________________________________

Calculation by: ____________________

File Name: File name

Checked by: ______________________

mircoles,ago 11,2010

Project / Description:

Calculation Details:

Tp

Lt

Tr

Lw

Tt

INPUT DATA:

Lt

FA

FL (FC in plane of paper / screen)

PARENT PIPE:

Outside Diameter

Wall Thickness

Corrosion Allw.

Mill Tolerance

Design Pressure

Hot Allowable Stress

Dp

Tp

ca

mtp

P

Sh

323,85 mm.

9,525 mm.

1,5 mm.

12,5 %

24,8 bar G.

117 MPa.

TRUNNION:

Outside Diameter

Wall Thickness

Mill Tolerance

Trunnion Length

Dt

Tt

mtt

Lt

219,075 mm.

8,1788 mm.

12,5 %

6000 mm.

APPLIED LOADS:

Longitudinal

FL 2530 N.

DETAILS:

Reinforcing Pad Thk

Tr 9,525 mm.

Circumferential

FC 610 N.

Weld Length

Lw 6 mm.

Axial (direct)

FA 4516 N.

__________________________________________________________________________________________________

CALCULATED RESULTS:

GLOBAL STRESS:

TRUNNION BENDING STRESS:

SHEAR STRESS IN FILLET WELD:

Applied force Fs = 2602,5 N.

Section mod. Zt = 2,407 e+5 mm3.

Shear area in weld:

Asw = 0.707 pi Dt Lw

Asw = 2918,95 mm2.

Bending stress

Sbt = Fs . Lt / Zt

Sbt = 64,88 MPa.

Shear stress in weld:

Sw = Fs / Asw

Sw = ,89 MPa.

Allowable bending stress:

Allowable shear stress:

Sh = 117, MPa.

(0.8 Sh) = 93,6 MPa.

Shear area is approximated, assuming trunnion is welded to a flat plate.

LOCAL STRESS:

Dimensions:

Pipe radius

Trunnion radius

Corr. pipe + pad thk.

R = 161,5 (mm.)

r = 109,5 (mm.)

Tc = 15,92 (mm.)

Pressure stress:

SCP = P.R/Tc

SCP = 24,35 (MPa.)

SLP = P.R/2.Tc SLP = 12,17 (MPa.)

Line loads:

FFl = FL.Lt/(pi.r^2) FFl = 402,99 (N/mm.)

FFc = FC.Lt/(pi . r^2) FFc = 97,16 (N/mm.)

FFa = FA/(2.pi.r)

FFa = 6,56 (N/mm.)

Local stress:

fac = (R^0.5) / (Tc^1.5)

SL = 1.17 FFl .fac SL= 94,33 (MPa.)

SC = 2.34 FFc .fac SC= 45,49 (MPa.)

SA = 1.75 FFa .fac SA= 2,3 (MPa.)

Combined local stresses:

SL + SA + SLP = 108,8 MPa.

Allowable local stress: (1.5 Sh)

SC + SA + SCP = 72,13 MPa.

SAL = 175,5 MPa.

__________________________________________________________________________________________________

SUMMARY:

REINFORCING PAD SPECIFIED.

Local stress acceptable.

Global stress acceptable.

End of Calculation

You might also like

- Guides For Shoes CalculationDocument16 pagesGuides For Shoes CalculationgopaltryNo ratings yet

- Vessel Saddle SupportsDocument5 pagesVessel Saddle SupportsAzwa Onexox75% (4)

- Limit State Criteria Theory For Pipeline Subsea Installation ProcessesDocument39 pagesLimit State Criteria Theory For Pipeline Subsea Installation Processesarchitectintx100% (2)

- Piping, Fittings, and ValvesDocument9 pagesPiping, Fittings, and ValvesaasattiNo ratings yet

- Caesar II TrainingDocument61 pagesCaesar II TrainingReaderRRGHT86% (7)

- Design and Thermal Analysis of Thermal Expansion Joint in Industrial ApplicationDocument6 pagesDesign and Thermal Analysis of Thermal Expansion Joint in Industrial ApplicationIJIRSTNo ratings yet

- EDS 06-0013 Grid and Primary Substation Earthing DesignDocument59 pagesEDS 06-0013 Grid and Primary Substation Earthing DesignShiva Naga KumarNo ratings yet

- Vivek Paul Engineer (Tech.) KLG Systel LTDDocument61 pagesVivek Paul Engineer (Tech.) KLG Systel LTDFirasat AliNo ratings yet

- L T Piping Engineering 3 Day ProgremmeDocument352 pagesL T Piping Engineering 3 Day ProgremmenndhoreNo ratings yet

- FE Pipe DocumentacionDocument160 pagesFE Pipe Documentacionricardobarort100% (2)

- Steel Expert ECDocument35 pagesSteel Expert ECglasscrankerNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Process Plant Piping OverviewDocument133 pagesProcess Plant Piping Overviewskdalalsin100% (8)

- BOREAID - New HDD Design ToolDocument21 pagesBOREAID - New HDD Design Toolarobertomedeiros100% (1)

- CSI Shear Wall Design Manual ACI318Document71 pagesCSI Shear Wall Design Manual ACI318Mustafa Uzyardoğan100% (1)

- ShoeDocument1 pageShoePhornlert Wana100% (1)

- XPS User Facility Sample Information Sheet (P.1)Document3 pagesXPS User Facility Sample Information Sheet (P.1)Jay NeilNo ratings yet

- XPS User Facility Sample Information Sheet (P.1)Document3 pagesXPS User Facility Sample Information Sheet (P.1)Jay NeilNo ratings yet

- Comparison Corrosion Mapping Solutions Using Phased Array and Conventional UT TechniquesDocument11 pagesComparison Corrosion Mapping Solutions Using Phased Array and Conventional UT TechniquesDairo Damian MelendezNo ratings yet

- Conexión RBS CorteDocument2 pagesConexión RBS CorteJose Luis AnayaNo ratings yet

- Awla Ngineering TD.: Product: (To Be Packed) WeightDocument3 pagesAwla Ngineering TD.: Product: (To Be Packed) WeightNavneet SheoranNo ratings yet

- 11May08-Geological Model Documentation UpdatedDocument4 pages11May08-Geological Model Documentation UpdatedPoetra Gembong MbajougNo ratings yet

- (Tính Toán L M ) Deliverable - 11 - d1 - 2Document54 pages(Tính Toán L M ) Deliverable - 11 - d1 - 2Huy Dao NgocNo ratings yet

- WellFlo Group ProjectDocument8 pagesWellFlo Group ProjectAngel NgoNo ratings yet

- C0832332 PDFDocument10 pagesC0832332 PDFrahil_sangNo ratings yet

- 01 Saip 02Document6 pages01 Saip 02malika_00No ratings yet

- Software Design Descriptions: Semester September 2018 - January 2018Document7 pagesSoftware Design Descriptions: Semester September 2018 - January 2018nurul syafiqah nadiaNo ratings yet

- Knowledge-Based System For Supporting The Design of A Plate-PressDocument5 pagesKnowledge-Based System For Supporting The Design of A Plate-PressDineshNewalkarNo ratings yet

- 0918-SI-138-00 - Toolbox Talks Attendance Sheet - enDocument2 pages0918-SI-138-00 - Toolbox Talks Attendance Sheet - enAli HassanNo ratings yet

- PCC HelpDocument103 pagesPCC HelpshamoojeeNo ratings yet

- Hydro Electronic Devices: Date: 8-12-2009 HED Document Number: ES-300 Revision: ADocument21 pagesHydro Electronic Devices: Date: 8-12-2009 HED Document Number: ES-300 Revision: Asudar1477No ratings yet

- Acts Computer College - Infanta, Inc.: Information and Computer Studies DepartmentDocument2 pagesActs Computer College - Infanta, Inc.: Information and Computer Studies DepartmentCristy Balubayan NazarenoNo ratings yet

- D2015r2-Ataatapi Command Set - 2 Acs-2Document542 pagesD2015r2-Ataatapi Command Set - 2 Acs-2kr0465No ratings yet

- Desthex ManualDocument6 pagesDesthex ManualJoseNo ratings yet

- Swd-Csa-A23.3-04 (Etabs2013)Document81 pagesSwd-Csa-A23.3-04 (Etabs2013)BJERNo ratings yet

- ThermalAnalysisbyFiniteElementsofHotendsfor3D Q2Document6 pagesThermalAnalysisbyFiniteElementsofHotendsfor3D Q2Satyam KNo ratings yet

- Toshiba: Steel ConnectionsDocument2 pagesToshiba: Steel ConnectionsJose Luis AnayaNo ratings yet

- Investmech (Design of Aluminium Alloys Structures) TR R0.0Document35 pagesInvestmech (Design of Aluminium Alloys Structures) TR R0.0romalan govenderNo ratings yet

- A Numerical Methodology For Lifetime Estimation of HDPE Pressure PipesDocument10 pagesA Numerical Methodology For Lifetime Estimation of HDPE Pressure PipesClasesvirtuales AFUCVNo ratings yet

- Design Request Form:: Other BuildingDocument1 pageDesign Request Form:: Other BuildingHonie's ClayNo ratings yet

- K10 Software Manual ENDocument12 pagesK10 Software Manual ENfarhad2004No ratings yet

- Contam 3.1 PDFDocument307 pagesContam 3.1 PDFReinhart85No ratings yet

- Ced11 (7732) PDocument24 pagesCed11 (7732) Praviteja036No ratings yet

- B2PC MNDocument61 pagesB2PC MNvajrahastaNo ratings yet

- SS7 Technical Reference-GlenayreDocument76 pagesSS7 Technical Reference-GlenayreJason2017No ratings yet

- Dibello Resume 1pg 2016Document1 pageDibello Resume 1pg 2016api-251134706No ratings yet

- DTNData AIA User ManualDocument29 pagesDTNData AIA User ManualelkaNo ratings yet

- UEMK4353 Assignment - Mech DesignDocument2 pagesUEMK4353 Assignment - Mech DesignSaints Burner ChristopherNo ratings yet

- Kiefner & Associates, Inc. Pipe Assessment Spreadsheet DocumentationDocument8 pagesKiefner & Associates, Inc. Pipe Assessment Spreadsheet DocumentationkmprabhaNo ratings yet

- FRM It 01 01 It Maintenance Form Rev01Document1 pageFRM It 01 01 It Maintenance Form Rev01rowlandNo ratings yet

- DSTV Format VS7 PDFDocument23 pagesDSTV Format VS7 PDFQuốc KhánhNo ratings yet

- 000 B3.026.02.00 GL-EN Software PLC Part2 CPU319F V50.00Document159 pages000 B3.026.02.00 GL-EN Software PLC Part2 CPU319F V50.00Venypierre ParraNo ratings yet

- ION BeginningDocument78 pagesION BeginningRolm BrosNo ratings yet

- TR Ele Ba GB 0008Document38 pagesTR Ele Ba GB 0008borrallaNo ratings yet

- IT Infrastructure ProformaDocument3 pagesIT Infrastructure Proformavivekrajbhilai5850No ratings yet

- Fitness For Service AnalysisDocument6 pagesFitness For Service AnalysisGuido KünstlerNo ratings yet

- Earth Energy Designer: User ManualDocument43 pagesEarth Energy Designer: User ManualBorja MonDe YorkNo ratings yet

- Design and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesFrom EverandDesign and Test Strategies for 2D/3D Integration for NoC-based Multicore ArchitecturesNo ratings yet

- Solar Energy Engineering: Processes and SystemsFrom EverandSolar Energy Engineering: Processes and SystemsRating: 3 out of 5 stars3/5 (1)

- Carbon Nanotube Devices: Properties, Modeling, Integration and ApplicationsFrom EverandCarbon Nanotube Devices: Properties, Modeling, Integration and ApplicationsNo ratings yet

- CarnitinaDocument11 pagesCarnitinatrukistrukisNo ratings yet

- Carnitina e HipertiroidesDocument16 pagesCarnitina e HipertiroidestrukistrukisNo ratings yet

- Acceptable Pipe Branch Connections - by Abdel Halim GalalaDocument1 pageAcceptable Pipe Branch Connections - by Abdel Halim Galalatrukistrukis100% (1)

- Tekla StructureDocument128 pagesTekla StructureVicky TetereaNo ratings yet

- CAEPIPE Users ManualDocument457 pagesCAEPIPE Users ManualCamilo SanchezNo ratings yet

- Marian PDSDocument8 pagesMarian PDStrukistrukisNo ratings yet