Professional Documents

Culture Documents

Wiki PDCA

Wiki PDCA

Uploaded by

Dawood PashaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wiki PDCA

Wiki PDCA

Uploaded by

Dawood PashaCopyright:

Available Formats

PDCA - Wikipedia, the free encyclopedia

Page 1 of 1

PDCA

From Wikipedia, the free encyclopedia

PDCA (plandocheckact) is an iterative four-step management method used in business for the control and continuous improvement of processes and products. It is also known as the Deming circle/cycle/wheel, Shewhart cycle, control circle/cycle, or plandostudyact (PDSA).

Contents

1 Meaning 2 About 3 See also 4 Further reading 5 References 6 External Links

Meaning

The steps in each successive PDCA cycle are[2][3] : PLAN Establish the objectives and processes necessary to deliver results in accordance with the expected output (the target or goals). By establishing output expectations, the completeness and accuracy of the specification is also a part of the targeted improvement. When possible start on a small scale to test possible effects. DO Implement the plan, execute the The PDCA cycle[1] process, make the product. Collect data for charting and analysis in the following "CHECK" and "ACT" steps. CHECK Study the actual results (measured and collected in "DO" above) and compare against the expected results (targets or goals from the "PLAN") to ascertain any differences. Charting data can make this much easier to see trends over several PDCA cycles and in order to convert the collected data into information. Information is what you need for the next step "ACT". ACT Request corrective actions on significant differences between actual and planned results. Analyze the differences to determine their root causes. Determine where to apply changes that will include

http://en.wikipedia.org/wiki/PDCA

10/11/2011

You might also like

- CPN TutDocument23 pagesCPN Tuttechnicaldepartment4888% (8)

- Process For Registering A TrustDocument2 pagesProcess For Registering A Trustamrutha chiranjeevi100% (1)

- Pdca CycleDocument3 pagesPdca CyclevinothksNo ratings yet

- What Is PDCA?: Continually Improving, in A Methodical Way Also Known As PDSA, The "Deming Wheel," and "Shewhart Cycle"Document10 pagesWhat Is PDCA?: Continually Improving, in A Methodical Way Also Known As PDSA, The "Deming Wheel," and "Shewhart Cycle"Gladys YaresNo ratings yet

- Process Approach-Tqm StudyDocument9 pagesProcess Approach-Tqm StudyShekinah Faith RequintelNo ratings yet

- Michael E. Porters Five Forces Model Ebook From WikipediaDocument27 pagesMichael E. Porters Five Forces Model Ebook From WikipediaD. Mumtaz.SNo ratings yet

- Basic Pipe Stress Analysis TutorialDocument34 pagesBasic Pipe Stress Analysis TutorialCüneyt Gökhan TosunNo ratings yet

- What Is PDSA Cycle in Quality Management?Document6 pagesWhat Is PDSA Cycle in Quality Management?Free The SoulNo ratings yet

- 5s and KaizenDocument28 pages5s and KaizenSatya KumarNo ratings yet

- Lean Six Sigma: Step by StepDocument1 pageLean Six Sigma: Step by StepgoleansixsigmaNo ratings yet

- Pdca - Plan Do Check ActDocument5 pagesPdca - Plan Do Check ActMohammad Jaid AlamNo ratings yet

- ISO 9001-2015 TrainingDocument14 pagesISO 9001-2015 TrainingZain AliNo ratings yet

- Republic of The Philippines Vs ManaloDocument2 pagesRepublic of The Philippines Vs ManaloDerick Torres100% (2)

- 1.3-1 Engage in Quality ImprovementDocument11 pages1.3-1 Engage in Quality ImprovementErwin BenitezNo ratings yet

- PDCADocument3 pagesPDCARicardo Damasceno Moreira FilhoNo ratings yet

- APQC Category 12.0Document10 pagesAPQC Category 12.0sudhirpatil6No ratings yet

- ASAP Accelerated SAP PhasesDocument11 pagesASAP Accelerated SAP PhasesvanessamacNo ratings yet

- Planning and Scheduling Engineer Sample ResumeDocument4 pagesPlanning and Scheduling Engineer Sample ResumeDawood PashaNo ratings yet

- When To Use Plan-Do-Check-ActDocument9 pagesWhen To Use Plan-Do-Check-ActRajesh NairNo ratings yet

- Tools/Enablers: PDCA Improvement CycleDocument7 pagesTools/Enablers: PDCA Improvement CycleaustinNo ratings yet

- Organizational Velocity - Improving Speed, Efficiency & Effectiveness of Business SampleDocument24 pagesOrganizational Velocity - Improving Speed, Efficiency & Effectiveness of Business SampleSTRATICXNo ratings yet

- Earned Value: Valerie Colber, MBA, PMP, SCPMDocument26 pagesEarned Value: Valerie Colber, MBA, PMP, SCPMHedilberto Armando DelgadoNo ratings yet

- Pre Trial Brief Accused Docx 1Document4 pagesPre Trial Brief Accused Docx 1kaizen shinichiNo ratings yet

- 5S and Kaizen PDFDocument28 pages5S and Kaizen PDFShinta Nugraha Mughni100% (2)

- Lean Action Workout: Lean Six Sigma Project Execution Essentials, #5From EverandLean Action Workout: Lean Six Sigma Project Execution Essentials, #5No ratings yet

- A Sample Micro Winery Business Plan TemplateDocument13 pagesA Sample Micro Winery Business Plan Templatecvw0% (1)

- PDCADocument10 pagesPDCAAvinashRaiNo ratings yet

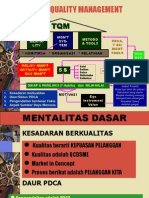

- Total Quality Management: Basic Menta-Lity MGN'T Sys - TEM Metodo & ToolsDocument25 pagesTotal Quality Management: Basic Menta-Lity MGN'T Sys - TEM Metodo & ToolsFaried Kurniawan100% (1)

- Plan Do Check Act: Lean Six Sigma Project Execution Essentials, #1From EverandPlan Do Check Act: Lean Six Sigma Project Execution Essentials, #1No ratings yet

- Hermann Herlinghaus Narcoepics A Global Aesthetics of SobrietyDocument273 pagesHermann Herlinghaus Narcoepics A Global Aesthetics of SobrietyAna Lucero Troncoso100% (1)

- Pdca WikiDocument4 pagesPdca WikiSuperlucido100% (1)

- The Deming CycleDocument2 pagesThe Deming CyclereginafernNo ratings yet

- Strat CostDocument9 pagesStrat CostalayhannyhNo ratings yet

- Q-4 Plan ISO 9001Document2 pagesQ-4 Plan ISO 9001syed muneeb shaheryarNo ratings yet

- Q-3 PDCA and ISO 9001Document2 pagesQ-3 PDCA and ISO 9001syed muneeb shaheryarNo ratings yet

- Report PdcaDocument3 pagesReport Pdcaarina1210No ratings yet

- Operations Management Assignment On: Plan-Do-Check-ActDocument14 pagesOperations Management Assignment On: Plan-Do-Check-ActPriyankaNo ratings yet

- PDCADocument4 pagesPDCAprabhuNo ratings yet

- FLXMGBESXSPDCAC - PDCA CycleDocument13 pagesFLXMGBESXSPDCAC - PDCA Cyclejose noe perezNo ratings yet

- PDCADocument13 pagesPDCAbala subramanianNo ratings yet

- What Is Demings PGDCA CycleDocument7 pagesWhat Is Demings PGDCA CycleprabhuNo ratings yet

- Walter Shewhart - TQMDocument5 pagesWalter Shewhart - TQMঅর্থী ইয়াসমিনNo ratings yet

- PDCA Cycle - What Is The Plan-Do-Check-Act Cycle - ASQDocument6 pagesPDCA Cycle - What Is The Plan-Do-Check-Act Cycle - ASQDanang WidoyokoNo ratings yet

- From Wikipedia, The Free EncyclopediaDocument5 pagesFrom Wikipedia, The Free EncyclopediaAthul JanardhananNo ratings yet

- PDCADocument6 pagesPDCAHshs hsHshahsNo ratings yet

- Quality Tools Plan Do Check ActDocument4 pagesQuality Tools Plan Do Check ActAhmed M. HashimNo ratings yet

- Dmaic and Approach of Six SigmaDocument4 pagesDmaic and Approach of Six Sigmaseemakasture75No ratings yet

- Quality Management TopicsDocument21 pagesQuality Management TopicsNazrul IslamNo ratings yet

- Difference Between PDCA and PDSA - Compare The Difference Between Similar TermsDocument6 pagesDifference Between PDCA and PDSA - Compare The Difference Between Similar TermsAman PooniaNo ratings yet

- Quality Management System QMS ISO9001 2015 1712022640Document165 pagesQuality Management System QMS ISO9001 2015 1712022640Alaa El-Sayed Saad Abd El-Halem BadranNo ratings yet

- Dmaic: From Wikipedia, The Free EncyclopediaDocument3 pagesDmaic: From Wikipedia, The Free EncyclopediasoorajNo ratings yet

- Lo3 Engage in Quality Improvement 1Document19 pagesLo3 Engage in Quality Improvement 1Jasmin OrielNo ratings yet

- DOMS403Document340 pagesDOMS403vsimanpalliNo ratings yet

- PDCADocument28 pagesPDCAhaseebrazikNo ratings yet

- Dmaic DmadvDocument8 pagesDmaic DmadvScott SummersNo ratings yet

- Unit 5Document39 pagesUnit 5aman shamsiNo ratings yet

- Lean Six SigmaDocument2 pagesLean Six SigmaAkash RathodNo ratings yet

- Report Written Quality ManagementDocument7 pagesReport Written Quality ManagementRod Dumala GarciaNo ratings yet

- Unit 3 - Learning JournalDocument3 pagesUnit 3 - Learning JournalherrajohnNo ratings yet

- QIP ProcessDocument17 pagesQIP ProcessIvan LuzuriagaNo ratings yet

- PDCA WriteupDocument3 pagesPDCA Writeupakb1979No ratings yet

- CQI QualityDocument14 pagesCQI QualityAjay DewanganNo ratings yet

- Lean Six Sigma Glossary of TermsDocument9 pagesLean Six Sigma Glossary of TermsSeif CharafNo ratings yet

- Week 9 Continuous Improvement Quality ToolsDocument39 pagesWeek 9 Continuous Improvement Quality Toolsleila DNo ratings yet

- A SapDocument1 pageA SapvinoakhilNo ratings yet

- Plan Do Action CheckDocument10 pagesPlan Do Action Checkjose luisNo ratings yet

- Pdca Process - PsDocument8 pagesPdca Process - PsGabby xxxNo ratings yet

- III-3-3-2 PDCA Cycle Is Golden Cycle For KAIZEN: Past Performances or Future Forecasting of WorkDocument33 pagesIII-3-3-2 PDCA Cycle Is Golden Cycle For KAIZEN: Past Performances or Future Forecasting of WorkGashaw Fikir AdugnaNo ratings yet

- What Is Organizational DevelopmentDocument8 pagesWhat Is Organizational Developmentpatricia navasNo ratings yet

- Development of Quality Management 14-11Document38 pagesDevelopment of Quality Management 14-11Rochak VyasNo ratings yet

- Fees StructureDocument19 pagesFees StructureDawood PashaNo ratings yet

- Role Definition Job Title: Reporting ToDocument2 pagesRole Definition Job Title: Reporting ToDawood PashaNo ratings yet

- Spa EderDocument27 pagesSpa Ederbabis1980No ratings yet

- SOCIALSCIENCEDocument162 pagesSOCIALSCIENCES Lal100% (2)

- Do Small Businesses Get The Credit They Need?: Michaël Dewally, PH.DDocument4 pagesDo Small Businesses Get The Credit They Need?: Michaël Dewally, PH.DAnonymous Feglbx5No ratings yet

- Participation FormDocument2 pagesParticipation FormAdil ShahzadNo ratings yet

- SJCSI E Tech 2nd PDFDocument57 pagesSJCSI E Tech 2nd PDFGaco MarjorieNo ratings yet

- Beckett Waiting For Godot RevisionDocument12 pagesBeckett Waiting For Godot RevisionTracyBentleyNo ratings yet

- Mix N' Flair MechanicsDocument4 pagesMix N' Flair Mechanicstawan vNo ratings yet

- Allegro Agreement TermsDocument296 pagesAllegro Agreement TermsbdromeiraNo ratings yet

- View of Cultural Differences Polish Fandom of Welcome To Night Vale Transformative Works and CulturesDocument1 pageView of Cultural Differences Polish Fandom of Welcome To Night Vale Transformative Works and CulturesMarta TymińskaNo ratings yet

- Freedom of Expression Non V DamesDocument2 pagesFreedom of Expression Non V DamesNic NalpenNo ratings yet

- G3-Riding The Marketing Information WaveDocument8 pagesG3-Riding The Marketing Information WaveNorhan AymanNo ratings yet

- The Impact of Technology Orientation and Customer Orientation On Firm Performance Evidence Form Chinese FirmsDocument105 pagesThe Impact of Technology Orientation and Customer Orientation On Firm Performance Evidence Form Chinese Firmsrizki kurniawanNo ratings yet

- Good Fences Make Good Neighbors: Background For TeachersDocument4 pagesGood Fences Make Good Neighbors: Background For TeachersMuhammad Furqan Aslam AwanNo ratings yet

- 2016 EnszerDocument18 pages2016 EnszerTicking DoraditoNo ratings yet

- PDF Installment Sales Reviewer Problems - CompressDocument43 pagesPDF Installment Sales Reviewer Problems - CompressMischievous Mae0% (1)

- Buddhist Inference - Used To StructureDocument1 pageBuddhist Inference - Used To StructurebenjaminzenkNo ratings yet

- Company Profile (Without Cost)Document64 pagesCompany Profile (Without Cost)PAWANNo ratings yet

- 3.22 Mechanical Properties of Materials: Mit OpencoursewareDocument4 pages3.22 Mechanical Properties of Materials: Mit OpencoursewareMohan BangaruNo ratings yet

- Behavioral Based Interview QuestionsDocument9 pagesBehavioral Based Interview QuestionsArunNo ratings yet

- Blue Nile Case - McGraw-HillDocument3 pagesBlue Nile Case - McGraw-HillKathleen Wellman HerberNo ratings yet

- Gato BarbieriDocument1 pageGato Barbierireihuno0% (1)

- Kelucharan MohapatraDocument7 pagesKelucharan MohapatraKishore RajaramNo ratings yet

- Giant ListDocument978 pagesGiant ListMark van EschNo ratings yet

- Glasnik Srpskog Ucenog Drustva 1881Document441 pagesGlasnik Srpskog Ucenog Drustva 1881Деда ЈевремNo ratings yet