Professional Documents

Culture Documents

Air Force Handbook 32-1282 VOLUME 1 1 JULY 1999

Air Force Handbook 32-1282 VOLUME 1 1 JULY 1999

Uploaded by

Abdur Rehman MianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Force Handbook 32-1282 VOLUME 1 1 JULY 1999

Air Force Handbook 32-1282 VOLUME 1 1 JULY 1999

Uploaded by

Abdur Rehman MianCopyright:

Available Formats

AIR FORCE HANDBOOK 32-1282 VOLUME 1 1 JULY 1999

FIELD GUIDE FOR INSPECTION, EVALUATION, AND MAINTENANCE CRITERIA FOR ELECTRICAL SUBSTATIONS AND SWITCHGEAR DEPARTMENT OF THE AIR FORCE

THIS PUBLICATION CONTAINS COPYRIGHTED MATERIAL

AFH 32-1282V1

BY ORDER OF THE SECRETARY OF THE AIR FORCE

AIR FORCE HANDBOOK 32-1282V1 1 JULY 1999 Civil Engineering Field Guide for Inspection, Evaluation and Maintenance Criteria for Electrical Substations and Switchgear

This handbook summarizes procedures and guidance to Air Force electricians for the inspection, evaluation, and maintenance of substations, switchgear, and associated devices. It will also assist maintenance engineers and quality assurance evaluators in specifying and inspecting contractor performance.

Contents

Chapter 1 Overview of the Guide 1-1 Scope............................................................. 1-2 1-3 1-4 1 Table 1-1 Table 1-2 Equipment covered in this handbook.... Equipment covered in AFH 32-1282V2 1 8

Supplementary Information ........................... 8 Basis for Developing Field Procedures ......... 9 Preinspection Procedures ............................. 10

OPR: HQ AFCESA/CEOM (Capt Thomas E. Wahl) Certified by: HQ AFCESA/CEO (Col William R. Pearson) Pages 110/Distribution F

THIS PUBLICATION CONTAINS COPYRIGHTED MATERIAL

AFH 32-1282V1

Index

AFH 32-1282V1

Chapter 2. General Substation Guidance 2-1 Use of Substation One-Line Diagrams.......... 16 2-2 Operating Information.................................... 20 Table 2-1 Table 2-2 Chapter 3. Substation Support Elements 3-1 Substation Tests............................................ 23 Table 3-1 Table 3-2 3-2 Substation Support Elements EPM Reports . 26 Table 3-3 Table 3-4 Table 3-5 Table 3-6

Installation electrical one-line diagram deficiencies....................... Safety electrical one-line diagram features........................................... Recommended maintenance based in IR temperature rises ................... Maximum acceptable ground resistances ..................................... Substation support elements general data ................................... EPM column headings.......................... Substation support element readings or test values ................... Substation support element checks......

21 22 24 25 26 29 29 30

ii

AFH 32-1282V1

Index

Chapter 4. Circuit Breaker Performance 4-1 Circuit Breaker Basics ................................... 4-2 Circuit Breaker Conducting Contacts and Arc Extinguishing Processes .......................... 4-3 Circuit Breaker Operating Mechanisms......... 4-4 Circuit Breaker Elementary Diagrams ........... 4-5 Circuit Breaker Nameplates........................... 31 Table 4-1 32 35 Table 4-2 40 43 Table 4-3 Table 4-4 Chapter 5. Circuit Breaker Testing 5-1 De-Energized Circuit Breaker General Tests 5-2 48 Table 5-1

AFH 32-1282V1

Circuit breaker normal ratings............... Circuit breaker stored energy methods.

32 36

Low-voltage circuit breaker minimum nameplate information.................... 43 Medium and high voltage circuit breaker minimum nameplate information .... 45 Circuit breaker insulation-resistance test values ............................................. 49

De-Energized Tests Specific to the Circuit Breaker Type ............................................ 52 Chapter 6. Circuit Breaker Evaluations 6-1 Circuit Breaker EPM Reports ........................ 53 6-2 High-Voltage SF6 or Oil Insulated Circuit Table 6-1 Breakers.................................................. 54 Table 6-2 Table 6-3 Table 6-4 6-3 6-4 Medium-Voltage Vacuum or Air Insulated Metal-Clad Switchgear Circuit Breakers . 56 Table 6-5 Low-Voltage Circuit Breakers ........................ 60 Table 6-6

Circuit breaker general data ................. Circuit breaker readings or test values . External high-voltage circuit breaker checks ............................................ Internal high-voltage circuit breaker tank procedures and checks .......... Medium-voltage metal clad switchgear circuit breaker checks..................... Low-voltage circuit breaker checks.......

53 54 55 56 59 60

iii

AFH 32-1282V1

Index

AFH 32-1282V1

Chapter 7. Interrupter Switch Installations 7-1 Interrupter Switch Basics............................... 63 Table 7-1 Table 7-2 Table 7-3 Table 7-4 Interrupter Switch Operating Features .......... 67 Interrupter Switch De-Energized Device Tests ....................................................... 71 Table 7-5 7-4 Interrupter Switch EPM Reports .................... 72 Table 7-6 Table 7-7 Chapter 8. Switchgear and Switchboard Assemblies 8-1 Assembly Performance ................................. 74 Table 8-1 Table 8-2 8-2 De-Energized Assembly Tests ...................... 81 Table 8-3 8-3 Energized Assembly Tests ............................ 81 8-4 Assembly EPM Reports................................. 82 Table 8-4 Table 8-5 7-2 7-3

Interrupter switch ratings ...................... Fuse ratings .......................................... Interrupter switch minimum nameplate information...................................... Fuse minimum nameplate information.. Interrupter switch test requirements ..... Interrupter switch general data ............. Interrupter switch checks ...................... Industry classification for assemblies ... MC/MEI switchgear major differences .. Assembly test requirements ................. Assembly general data ......................... Assembly checks ..................................

64 65 66 67 72 72 73 79 80 81 83 84

iv

AFH 32-1282V1

Index

AFH 32-1282V1

Chapter 9. Battery Installation 9-1 Battery Installation Basics ............................. 85 9-2 Battery Installation Readings and Tests........ 89 Table 9-1 Table 9-2 Table 9-3 Table 9-4 9-3 Battery Installation EPM Reports .................. 93 Table 9-5 Table 9-6 Table 9-7 Table 9-8 Chapter 10. Protective Sensing, Processing, and Action Devices 10-1 Device Performance ...................................... 97 10-2 Device Testing............................................... 99 Table 10-1 Table 10-2 10-3 Installation-Wide Operating Systems ............ 102 10-4 Protective Sensing, Processing, and Action Device EPM Reports.................... 102 Table 10-3 Table 10-4

Battery installation readings.................. 90 Capacity test procedures ...................... 92 Battery capacity degradation ................ 92 Integrity test procedures ....................... 93 Battery installation general data ........... 94 Lead-acid battery installation corrective actions ............................................ 95 Nickel-cadmium battery installation corrective actions ........................... 96 Battery installation checks .................... 96

Relay tests ............................................ 100 Relay pickup parameters ...................... 101 Device general data .............................. 102 Instrument, metering and protective relay general checks ............................... 105

AFH 32-1282V1

AFH 32-1282V1

Acknowledgment

The Air Force wishes to express their sincere appreciation to the many companies and their representatives who kindly cooperated in supplying CAD illustration inputs and pictures for use in this handbook. Inputs used for CAD illustration inputs were supplied by Siemens Energy and Automation, Inc.; Square D Company/Groupe Schneider; and Westinghouse/Cutler Hammer. Some pictures were supplied by Keller & Gannon. The Air Force expresses particular appreciation to Williams Learning Network (formerly NUS Training Corporation) whose training videos were used to provide the rest of the pictures. NOTE: Product and manufacturer names are included in this handbook for the purposes of illustration and do not carry the specific endorsement of the Air Force.

vi

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

CHAPTER 1. OVERVIEW OF THE GUIDE 1-1. Scope. The condition of electrical power apparatus found in substations is crucial to the successful operation of all electrical power systems. Switchgear and related equipment are significant components of the systems. This handbook identifies field procedures which allow early detection of equipment degradation and other defects which will adversely affect reliability. Appropriate corrective actions can then be accomplished. a. General Categories of Substation Equipment. Table 1-1 lists the general categories of substation equipment covered in this Air Force maintenance handbook. Figures 1-1, 1-2, 1-3, 1-4, 1-5, and 1-6 have been provided to remind the technician of similar and differing features of various circuit breaker and switchgear types. Substation equipment categories discussed in AFH 32-1282V2 (Field Guide for Inspection, Evaluation, and Maintenance Criteria for Electrical Transformers) are listed in Table 1-2. Table 1-1. Equipment covered in this handbook

Substation support elements providing area safety Transmission/distribution power-line switching ! Circuit breakers ! Load interrupter switches Power-line switching unit/assembly necessary sub-elements ! Switchgear/switchboard assemblies ! Battery installations ! Protective sensing, processing, and action devices 1

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

1. 2. 3. 4. 5. 6. 7.

Interrupters Bushings Control cabinet Pressure gauges and operation counter Current transformers Steel base Base legs

7

Figure 1-1 High-voltage SF6-gas-insulated circuit breakers

2

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

1 2 3

4 5

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11.

Compressor Pull rod Control panel Mechanism Reservoir Bushing Oil level indicator Oil vent Tank Mechanism housing Local control

6 7 8

9 10 11

Figure 1-2 High-voltage oil-insulated circuit breakers

3

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

8 9

10

6 5 4

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

Relays Switches Instruments/meters Compartment barriers Circuit breaker wheels Circuit breaker rails Drawout circuit breaker Circuit breaker mechanism Barriers Automatic shutters

3 2 1

Figure 1-3 Medium-voltage metal-clad vacuum circuit breaker switchgear

4

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

2 3 6

7 8 4 9 2 5

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14.

Switch operator Padlock location Inspection window Main door Door stop Safety barrier Door interlock Switch interlock Barriers Switch position indicator Padlock location Key interlocks Operating handle Nameplates

13 12 14 10 11 12

7 1

Figure 1-4 Medium-voltage metal-enclosed load-interrupter switchgear

5

AFH 32-1282V1

Chapter 1. Overview of the Guide

7 8

AFH 32-1282V1

12 13

19

6

18

5 9

4 10

1. 2. 3. 4. 5. 6. 7.

3 1 2 Finger clusters Extension rail Levering arm Moving contacts Stationary contacts Molded base Arcing contact spring

8. Stationary arcing contact 9. Moving arcing contact 10. Insulation link

16

11

15

14

17

11.Pole unit 12.Interface barriers 13.Secondary disconnect contacts 14. Levering device arm

15. Main disconnect contacts 16. Sensors 17. Drawout circuit breaker 18. Switchgear 19. Rail mounted lifter

Figure 1-5 Low-voltage air circuit breaker switchgear

6

AFH 32-1282V1

Chapter 1. Overview of the Guide

3 5 7

AFH 32-1282V1

9 1

1. Main circuit breaker 2. Group-mounted circuit breakers 3. Vertical bus behind 4. Hinged wiring access panels 5. Side access panel 6. Removable cover plates 7. Ventilation grille 8. Blank filler plates 9. Warning and manufacturers labels

8 6 4 2

Figure 1-6 Low-voltage molded-case circuit breaker switchboard

7

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

Table 1-2. Equipment covered in AFH 32-1282V2

Power/distribution transformers Bushings Instrument transformers Surge arresters b. Purpose. Equipment deterioration needs to be identified before the equipment malfunctions or fails (that is, preventative maintenance). This handbook allows local preparation of electrical preventative maintenance (EPM) procedures. It does not cover catastrophic or operational failures. Its purpose is to prevent equipment failures resulting from a lack of proper preventative maintenance. c. Technician Testing Limitations. The handbook is not a training guide. Air Force technicians should not use testing/metering/scanning devices around or on energized equipment unless they have been trained in their use and have satisfactorily demonstrated their knowledge of appropriate safety precautions.

1-2. Supplementary Information.

The maintenance technician should be familiar with and have available Air Force electrical design, maintenance, and safety manuals. a. Design. Refer to the installation requirements of AFMAN 32-1180(I) (Electrical Power Supply and Distribution) which provides Air Force policy and guidance for design criteria and standards for electrical power supply and distribution systems.

b. Maintenance. Refer to AFMAN 32-1280(I) (Facilities Engineering, Electrical Exterior Facilities) which amplifies the maintenance and repair guidance of this handbook. 8

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

c. Safety. Refer to AFMAN 32-1185 (Electrical Safe Practices) which provides safety standards for the work being done. Maintenance work should be done only by workers in accordance with the electrical work classifications of AFMAN 32-1185, including AFSC 3E011 equivalent (helper), AFSC 3E031 equivalent (apprentice), AFSC 3E051 equivalent (journeyman), or AFSC 3E071 equivalent (craftsman). AFH 32-1285 (Electrical Worker Safety Field Guide) should be available to you to use in the field. This handbook is intended as summary guidelines and procedures. Actual maintenance/repair program requirements should be adjusted as appropriate for your specific electrical apparatus. a. Handbook Information. This handbook covers generic apparatus performance, test data, and generally applicable component element checks. Use this handbook as a reminder of general maintenance requirements. (1) Performance. Each component of major electrical apparatus performs essentially a simple operation. Complexity in maintenance is caused by the large and varied types of electrical components in the apparatus. This handbook provides figures and pictures to illustrate the most important of these components. (2) capability. Tests. Electrical equipment must be tested to ensure its continuing operating

1-3. Basis for Developing Field Procedures.

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

(a) Test Descriptions. Descriptions of the most commonly used tests are included in this handbook. Acceptable values of the tests are provided when possible. Reference to the manufacturers literature may be required for other tests. (b) Comparisons for Trends. All tests/readings should be compared to previous values (acceptance, maintenance, or repair). This will assist in recognizing trends that indicate a need for more frequent testing. Permanent changes to equipment/devices that are overloaded, misapplied, or inadequate for the duty to which they are subjected may be required. (3) Component Element Checks. Tables are included in this handbook which outline the most important components to be checked. Additional information on these components can be found in AFMAN 32-1280(I) and the manufacturers literature. b. Locally Developed Field Procedures. Each facility should maintain a copy of all applicable documents related to the installation, operation, and maintenance of electrical systems. Locally developed EPM procedures are essential to proper maintenance.

1-4. Preinspection Procedures.

data and applicable safety requirements. a. checked.

Prior to performing any field work, review historical EPM

Apparatus Documentation. Assemble all documentation applying to the apparatus to be

10

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

(1) Documentation Maintenance. The Base Civil Engineer (BCE) should ensure all documentation is maintained for each specific item of electrical apparatus which makes up the facility electrical power systems. (a) Available From Design/Construction Files. The available data may include all of the inspection and testing procedures for the facility, copies of previous reports, single-line diagrams, schematic diagrams, electrical equipment plans, records of complete nameplate data, and manufacturers service manuals and instructions. (b) Locally Prepared. Prepare local EPM forms as necessary for installed equipment. Each item of apparatus should be shown on an equipment location plan. (See Paragraphs 3-2, 5-1, 6-1, 7-4, 8-4, 9-3, and 10-4). Provide unique apparatus designations along with a locally prepared safety electrical one-line diagram and equipment location plan. Table 2-2 summarizes the minimum recommended features of a safety electrical one-line diagram. (2) Specific Assembling of Data: Assemble the following data, if available, for each specific item of apparatus. ! ! ! Locally prepared forms. As-built drawings for electric equipment layouts and elevations. Trend analysis data which should include: (a) Installation acceptance data test results. (b) Previous EPM reports including any previous systematic evaluations.

11

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

Manufacturers service manuals including practices and procedures for: (a) Installation. (b) Disassembly/assembly (interconnection). (c) Wiring diagrams, schematics, bills of materials (d) Operation (set-up and adjustment) (e) Maintenance (including parts list and recommended spares) (f) Software programs. (g) Troubleshooting guidance. (3) Systematic Evaluation of Apparatus Condition. Electric apparatus should receive a systematic evaluation of its condition after an EPM which indicates repairs were necessary beyond normal expected maintenance. The systematic evaluation should include: ! Reasons for the required repairs. ! Work required to complete the repairs. ! Assessment of the remaining service life. ! Determination of the need for a more frequent EPM. c. Safety Requirements. Working on or near normally energized lines or parts requires observance of rules applying to safe working distances, work methods related to whether the line has been de-energized or left hot, and recognition of work hazards which require more than one worker for safety. Workers must be qualified for the work and use approved work methods and equipment. Refer to the requirements of AFH 32-1285 as amplified by AFMAN 32-1185. Always include a tailgate meeting to address existing site conditions and the procedures to be followed. Work will be done de-energized unless energized line work is specifically authorized. 12

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

(1) De-Energized Electrical Line Work. Follow the safe clearance (lockout/tagout) procedures given in AFH 32-1285. Remember lines are considered energized if the de-energized systems have not been provided with proper protective grounding. The safe clearance may require a job hazard analysis. (2) Energized Electrical Line Work. Work on energized lines and equipment only when authorized by the electrical supervisor/foreman/lead electrician (per local organization) based on the need to support a critical mission, to prevent injury to persons, or to protect property. Insulating means must be provided to isolate workers from a source of potential difference. A job hazard analysis is required for energized line work. (See AFH 32-1285). d. Understanding Maintenance Frequencies. Frequency of maintenance should be locally adjusted based on the application of the equipment. See additional guidance in NFPA 70B (Electrical Equipment Maintenance). Adjust the frequency of inspection based on the criticality of the apparatus, the severity of the loading conditions, and an environment where unusual service conditions stress the equipment. Generally, usual service conditions extend only to elevations of not more than 3,300 feet (1 kilometer) and ambient temperatures of no more than 30 to 40 degrees C. Check with the manufacturer for other than normal service conditions. e. Inspection Materials/Devices. Basic items needed for an EPM include the following: ! A facility electrical truck ! Available documentation. ! EPM forms. ! Directions as to any input or approval needed from the appropriate using or operating agency 13

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

Test equipment such as an

(1) (2) (3) (4) (5) (6) (7) Automatic insulation test set Dielectric test set Digital ground resistance test set Fault gas analyzer Infrared imager Circuit breaker test set Corona tester (8) Motion analyzer (9) Null balance (megohmmeter) earth test set (Megger7) (10) Power factor test set (11) True root-mean-square (rms) digital multi-electrical parameters meter (12) SF6 gas moisture analyzer (4) (5) (6) (7) Multirange noninductive load resister Phase shifter Phase angle meter Three-phase sequence indicator

Measurement instruments and miscellaneous devices such as a

(1) Cycle counter or timer (2) Digital thermometer (3) Multirange ac and dc voltmeters and ammeters

! !

Contamination washing devices such as a portable nozzle washer truck Miscellaneous tools such as

(1) (2) (3) (4) Binoculars Flashlights (insulated) Insulated fuse puller Magnifying glass (5) Tape recorder, tape, and batteries (6) Video camera and accessories (7) Oil sample bottle and syringes and gas sample bottles

14

AFH 32-1282V1

Chapter 1. Overview of the Guide

AFH 32-1282V1

Cleaning devices (1) Vacuum cleaner (2) Compressed air cleaner (not for use in medium or high voltage enclosures or other locations where dust could cause flashover) Miscellaneous materials as necessary to clean, wipe, paint, insulate, solder, or for other small field-fix repairs.

15

AFH 32-1282V1

Chapter 2. General Substation Guidance

AFH 32-1282V1

CHAPTER 2. GENERAL SUBSTATION GUIDANCE 2-1. Use of Substation One-Line Diagrams. A substation is an area

or an equipment group which contains switches, circuit breakers, buses, and transformers. It provides for the switching of power circuits and for the transforming of electrical power from one voltage to another or from one system to another. Stations without transformers are more properly called switching stations, but for simplicity the word substation will be used to include switching stations. a. Determine Systems Circuit Arrangement. A system is designed to meet load requirements, reliability, and flexibility. The criticality of the load also means maintainability must be considered.

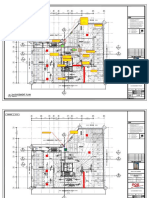

b. Basic Circuit Arrangements. Various common distribution systems are shown on Figures 2-1, 2-2, 2-3, 2-4, 2-5, and 2-6. Understanding how your facilitys distribution system is configured is the key to providing safe clearing or isolating procedures for any portion of the system needing maintenance and repair. Figure 2-1 is the simplest circuit arrangement. This simple system provides no backup reliability and loads cannot be backfed as is the case with Figure 2-2. Selective systems (Figures 2-3 and 2-4) provide alternate sources of input power. Network systems (Figures 2-5 and 2-6) provide the ultimate in service reliability.

16

AFH 32-1282V1

Chapter 2. General Substation Guidance

SOURCE OF SUPPLY TRANSFORMER

TRANSFORMER

AFH 32-1282V1

SOURCE OF SUPPLY CIRCUIT BREAKER LOAD CENTER

MAIN DISTRIBUTION BOARD CIRCUIT BREAKER FEEDER

LOAD CIRCUITS

LOOP PRIMARY FEEDER

DISCONNECT SWITCH

LOAD CIRCUITS

LOAD UNITS

Figure 2-1 Radial system

17

Figure 2-2 Primary loop system

AFH 32-1282V1

Chapter 2. General Substation Guidance

SOURCE OF SUPPLY CIRCUIT BREAKER

SOURCE OF SUPPLY

AFH 32-1282V1

CIRCUIT BREAKER

SELECTIVE SWITCH TRANSFORMER LOAD CENTER

PRIMARY FEEDERS DISCONNECT SWITCH

LOAD CIRCUITS

PRIMARY FEEDERS

LOAD CIRCUITS

TO OTHER LOADS

TRANSFORMER TO OTHER LOADS

Figure 2-3 Primary selective system

18

Figure 2-4 Secondary selective system

AFH 32-1282V1

Chapter 2. General Substation Guidance

SOURCE OF SUPPLY CIRCUIT BREAKER TRANSFORMER

DISCONNECT SWITCHES LOAD CENTERS SOURCE OF SUPPLY

AFH 32-1282V1

CIRCUIT BREAKER PRIMARY FEEDERS TRANSFORMER NETWORK PROTECTOR

PRIMARY FEEDERS

NETWORK PROTECTOR

LOAD CIRCUITS SECONDARY TIES

LOAD CIRCUITS

DISCONNECT SWITCH NETWORK PROTECTOR

LIMITER LUGS

LOAD CENTERS

Figure 2-5 Spot network system

19

Figure 2-6 Distributed network system

AFH 32-1282V1

Chapter 2. General Substation Guidance

AFH 32-1282V1

2-2. Operating Information.

For maintenance to be done safely, operating information must define energy paths and switching control components. Each component should be provided with a unique identification and a specific location. a. One-Line Diagram Preparation. As a part of the Apparatus Documentation (see Paragraph 1-4) each installation should prepare safety electrical one-line diagrams. Develop safety electrical one-line diagrams from the installation electrical one-line diagrams. Installation electrical oneline diagrams are design documents made for construction and contain unnecessary installation data. Safety electrical one-line diagrams should be prepared by facility personnel and should show only data relevant to safe operating procedures. Table 2-1 indicates installation electrical one-line diagram deficiencies that make this document a poor substitute for a safety electrical one-line diagram. Installation electrical one-line diagrams may still need to be consulted for design information for replacements. Table 2-2 summarizes the minimum recommended features of safety electrical one-line diagram b. Equipment Location Plan Preparation. As a part of the Apparatus Documentation (see Paragraph 1-4) each installation should prepare a simplified electric equipment layout corresponding to the safety electrical one-line diagram. The plan should locate all the components shown on the safety electrical one-line diagram using the same identification. Also show power circuit routing which cannot be observed at the site.

20

AFH 32-1282V1

Chapter 2. General Substation Guidance

AFH 32-1282V1

Table 2-1. Installation electrical one-line diagram deficiencies

Inaccuracies Generally not correct due to electrical system changes. Illegibility Generally not designed for field service under poor lighting conditions. Drawings may be faded with small lettering and close linework obscuring safe switching (isolation) requirements. Distinctive Identification A unique component identification is not provided. Drawings may indicate only one apparatus item or switchgear section while other items or sections are noted to be similar. Unessential Safety Data Design data such as instrument transformer ratios, surge arrester ratings, and other design information only complicates understanding safety requirements.1

1

This information should be covered by the EPM apparatus documentation.

21

AFH 32-1282V1

Chapter 2. General Substation Guidance

AFH 32-1282V1

Table 2-2. Safety electrical one-line diagram features

Correctness Diagrams must be kept up to date, otherwise they are useless. Clarity Diagrams should ensure that lines are heavy, at least a 1/4-inch (6.5-millimeters) apart, with printing at least a 1/4-inch (6.5-millimeters) high, preferably done by computer-aided design (CAD). The drawings will be used under less than desirable conditions so prepare them on the number of sheets necessary to provide legibility, manageability, and durability. Component Identification Each component must have a unique identification shown on the diagram and placed on each component. Identification means on the actual component must be durable and large enough to be read at a distance. Place as often as necessary so that there is no question as to the component being identified. Short alphanumeric designations are better than operating names. Avoid geographic descriptions. Do not put special warnings on the identification means. Components Shown The components to be shown on a diagram are all sources of electrical energy, the devices that can interrupt this energy, and other major components such as power conductors, power/distribution and instrument transformers, surge arresters, capacitors, automatic controls, interlocks, and loads. 22

AFH 32-1282V1

Chapter 3. Substation Support Elements

AFH 32-1282V1

CHAPTER 3. SUBSTATION SUPPORT ELEMENTS 3-1. Substation Tests.

Tests of support elements are generally limited to infrared tests on connections and grounding resistance tests on permanent ground systems. a. Infrared (Thermographic) Testing. An infrared (IR) temperature measurement locates high-resistance or hot spot thermal variations due to component failure, fatigue, and mechanical misalignment. (1) Precautions. The object being examined will radiate both emitted and reflected IR energy. Only the emitted IR energy is a measure of the objects temperature. Measurements will vary as the geometry of observation varies the angle of incidence. Changing the angle of incidence changes the reflected IR energy. The IR equipment used should be capable of detecting at least a 1 degree C temperature difference between the object and the 30 degree C reference area by detecting emitted radiation and converting it to a visual signal. The IR equipment should allow the user to mathematically compensate for reflected energy. Correction may be made by entering an estimated emmissivity value provided by the IR equipment manufacturer or based in the installations experience. (2) Action. Scan all current-carrying equipment and conductor connections during periods of maximum possible loading. Generally a reading for an equipment/conductor load below 40 percent of its rating will not locate any hot spots. Always measure the IR temperature from several different positions to minimize the chance of error from reflected IR energy or from solar gain for outdoor installations. 23

AFH 32-1282V1

Chapter 3. Substation Support Elements

AFH 32-1282V1

(3) Interpretation. Infrared hot-spot temperature gradients indicating possible deficiencies are given in AFMAN 32-1280(I) for equipment. Table 3-1 lists temperature rises above ambient which have been found practical in regard to equipment problems.

Table 3-1. Recommended maintenance based on IR temperature rises

Temperature rise above ambient (degrees C) <10 10-39 40-75 >75 Recommendation Repair in regular maintenance schedule; little probability of physical damage. Repair in near future. Inspect for physical damage. Repair in the immediate future. Disassemble and check for probable damage. Critical problem; repair immediately

b. Permanent Ground System Resistance Tests. A ground resistance test set can be used to determine the effectiveness and integrity of the grounding system. See AFMAN 32-1280(I) and AFMAN 32-1185 for the importance of adequate grounding in operating and maintaining electrical systems safely. (1) Precautions. Testings of grounds can create hazardous conditions as all electrical conductive paths for overvoltage and fault currents are connected to the substation ground system. Rubber gloves, blankets, and other protective devices are recommended. 24

AFH 32-1282V1

Chapter 3. Substation Support Elements

AFH 32-1282V1

(2) Action. Measure the ground path resistance of all branches of the grounding system from ground connections at support structure, equipment enclosures, and neutral conductors to the ground system. Measure other resistances covered in Table 3-2 which indicates maximum acceptable ground resistances.

Table 3-2. Maximum acceptable ground resistances

Resistances 1 to 25 ohms 0.5 ohm 0.5 ohm

1 2

Measured Substation Gates and gateposts2 Operating rods and handles of group operated switches and their supporting structures

In accordance with departmental standards. Measurement of flexible gate ground connection adequacy.

(3) Recommendations. Where no departmental standards are available it is recommended that substations of 1,000 kVA or less have a maximum ground resistance of 5 ohms and substations over 1,000 kVA have a maximum ground resistance of 3 ohms. c. Corona. Check for corona as covered in Paragraph 8-3.

25

AFH 32-1282V1

Chapter 3. Substation Support Elements

AFH 32-1282V1

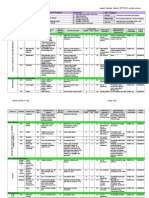

3-2. Substation Support Elements EPM Reports. Each installation should prepare local blank EPM report forms to be filled out by the inspecting technicians. (See Paragraph 1-4). The following tables indicate the data to be recorded.

a. Basic Substation Support Elements Information to Be Determined Before the Inspection. Provide a suitable record header with blank spaces for insertion of the following data given in Table 3-3. Pictures 3-1, 3-2, 3-3, and 3-4 show actual substation support elements.

Table 3-3. Substation support elements general data1

General Designation Date of inspection Location Single line diagram drawing no(s) Equipment location plan drawing no(s) System voltages and design kVA Approximate area Year installed Last inspection date

1

Type Switching only High- to medium-voltage Medium- to low-voltage Aerial service Underground service

For guidance on EPM reports covering bushings, instrument transformers, and surge arresters see AFH 32-1282V2.

26

AFH 32-1282V1

Chapter 3. Substation Support Elements

AFH 32-1282V1

Picture 3-1 Low-profile substation

Picture 3-2 Bus structure

27

AFH 32-1282V1

Chapter 3. Substation Support Elements

AFH 32-1282V1

Picture 3-3 Circuit breaker bay

Picture 3-4 Transformer bays and secondary underground line structures

28

AFH 32-1282V1

Chapter 3. Substation Support Elements

AFH 32-1282V1

29

AFH 32-1282V1

Chapter 3. Substation Support Elements

AFH 32-1282V1

b. Basic Inspection Items to be Checked. Provide an EPM inspection report with column headings covering items to be checked off for each listed item number given in Table 3-4.

Table 3-4. EPM column headings

Item no. (for easy referral) Inspection item (name) Operating mode (in-service or de-energized and grounded) Passing criteria (list) Inspection method (visual, test, or other) Corrective action (if necessary)

c. Inspection Items to be Covered. List inspection items to be covered. Table 3-5 indicates substation support element readings or test values and appropriate evaluation paragraphs for passing criteria. Table 3-6 indicates substation support element components and appropriate inspection actions.

Table 3-5. Substation support element readings or test values

1. 2. 3.

1

Readings or test values Ambient temperature Infrared temperature rise Ground resistance

Evaluation reference paragraph -3-1a1 3-1b1

Readings should identify location or be provided with such identification in a separate report.

30

AFH 32-1282V1

Chapter 3. Substation Support Elements

AFH 32-1282V1

Table 3-6. Substation support element checks

Buildings a. General housekeeping b. Lighting c. Ventilation d. Heaters 2. e. Structure condition f. Fire protection 6. Capacitors a. Operable fuses b. Operable internal resistors c. Verify automatic operation d. Test and reading per 3. AFMAN 32-1180(I) 7. Electrical connections and buses Tightness a. b. Hot spots c. Contamination d. Corrective Action. Describe corrective actions taken. Deficiencies requiring action beyond the technicians at the site should be indicated as see note X. Note X should explain reasons. Such a note might indicate that an aerial bus, insulators, and air disconnect switches need suitable washing to eliminate excessive contamination. 31 1. Fences and support structures a. Structural (security) integrity b. Grounding c. Surface condition Yards a. Adequate warning signs b. Acceptable surface treatment c. General housekeeping d. Workable lighting system e. Environment compliance Insulators and air disconnect switches a. Fractures b. Contamination 4.

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

CHAPTER 4. CIRCUIT BREAKER PERFORMANCE 4-1. Circuit Breaker Basics.

Circuit breaker switching is simple to understand. The complexity arises from the diverse variety of available operating mechanisms and their associated controls which direct the circuit breaker switching. Circuit breaker maintenance requires close checking of the circuit breaker manufacturers instructions along with understanding the operating and protective controls for the overall electrical system. a. Actions. Circuit breakers are switching devices that can make (close), carry, and break (open) an electrical circuit under both normal and abnormal conditions. Circuit breakers consist essentially of make-and-break conducting contacts, an arc extinguishing system, an operating mechanism, and an abnormal-conditions current-detection system. (1) Normal conditions. Normal conditions are manual and automatic actions occurring within the circuit breakers ratings and when operational conditions require circuit switching. (2) Abnormal Conditions. Abnormal conditions are those where excessive or fault current conditions require automatic opening and possibly automatic reclosing after an overcurrent opening. b. Ratings. Circuit breaker normal ratings are based on ANSI C37.06 (AC High Voltage Circuit Breakers Rated on a Symmetrical Current Basis - Preferred Ratings and Related Required Capability). Maximum ratings are given in Table 4-1. Other continuous current ratings not shown are 1200 and 2000 amperes. Check circuit breaker nameplates for rated short-circuit current. 32

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

Table 4-1. Circuit breaker normal ratings

Maximum voltage kV rms 4.76 8.25 15/15.51 25.8 38 48.3 72.5 121

1 2

Maximum continuous current, amperes 3,000 2,000 3,000 2,000 3,000 3,000 3,000 3,000

Interrupting time cycles2 5 5 5 5 5 5 5 3

First number is for indoor oiless circuit breakers. Second number is for outdoor circuit breakers. Oil circuit breakers manufactured before 1975 may have an 8 cycle rating. This rating affects coordination and short circuit studies; it does not affect maintenance requirements.

4-2. Circuit Breaker Conducting Contacts and Arc Extinguishing Processes. Circuit opening of the conducting contacts causes an arc to form which is extinguished

by various methods. Examples of the various types of arc extinguishing media are shown on Pictures 4-1, 4-2, 4-3, and 4-4. 33

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

Picture 4-1 Air-magnetic circuit breaker

Picture 4-2 Oil-insulated circuit breaker

34

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

Picture 4-3 Vacuum circuit breaker

Picture 4-4 SF6-insulated puffer-type circuit breaker

35

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

a. Conducting Contact Opening. An energized circuit breaker draws an arc when its conducting contacts are separated. The temperature of the arc ionizes the insulating medium and sustains the arc. On current zero, arcing ceases and the voltage across the contacts increases. The voltage buildup results in an arcing restrike from the electric field and from thermal effects of the initial arcs charged particles Only when the arc is cooled well below its ionization temperature at current zero will the arc be fully extinguished and current interruption accomplished. b. Extinguishing Methods. Various methods provide arc extinguishing. All methods involve either cooling the arc or providing an insulating atmosphere unfavorable to ionization or to reionization. Arc chutes in air magnetic circuit breakers with their barriers use side-by-side fins through which the arc is drawn by the establishment of a magnetic field. This longer arc is then cooled by convection. Air magnetic circuit breakers have both main and arcing contacts. (See Paragraph 7-2.a.) Oil in oil-insulated circuit breakers vaporizes and forms air bubbles whose hydrogen is unfavorable to ion production. Sulfur hexafluoride (SF6) in SF6-insulated circuit breakers is about 100 times more effective than air in extinguishing the arc. Vacuum in vacuum circuit breakers is an even better arc extinguisher since its high dielectric does not allow ionization to maintain itself and restrike after a current zero.

4-3. Circuit Breaker Operating Mechanisms.

An operating mechanism needs some form of energy to open and close the circuit breaker contacts at the required speed. The circuit breaker mechanism must cause acceleration, movement, and deceleration at each opening and closing stroke. Equally important the circuit breaker must stay open or closed until directed either manually or automatically to perform otherwise.

36

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

a. Operating Energy. All operating mechanisms use some form of stored energy for opening and closing the circuit breaker. Pictures 4-5, 4-6, 4-7, and 4-8 show examples of various operating mechanisms. (1) Stored Energy Methods. Table 4-2 indicates some of the various methods of stored energy used to open and close circuit breakers. The method used to close the circuit breaker may not be the same method used to open the circuit breaker. It takes more energy to close a circuit breaker than to open the unit. In both cases the contact motion is slowed by dampers at the end of the stroke.

Table 4-2. Circuit breaker stored energy methods

Electrical energy inputs to electrical operators System Voltage to operate Batteries dc Control power transformer (CPT) ac CPT charging a capacitor supplying a dc half-wave rectifier Electrical operators Motor wound charged springs 2. Solenoids Compressed gas methods Hydraulic systems 2. Pneumatic systems 37

1. 2. 3.

1. 1.

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

Picture 4-5 Motor/spring operating mechanism

Picture 4-6 Blocking a closing spring before maintenance work

38

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

Picture 4-7 Pneumatic operating mechanism

Picture 4-8 Hydraulic operating mechanism

39

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

b. Spring-Operating Mechanisms. The stored energy is usually provided by springoperating mechanisms. Motor-wound springs store closing/opening energy. Springs are latched either in the closed or the open position until a manual or automatic direction releases them. (1) Closing. A latch must hold against a large force to prevent the spring from unwinding. By providing a main latch, an in-between latch, and a trip latch in series the necessary releasing electromechanical devices becomes a low-energy system. The three latches act as a mechanical amplifier. A small amount of corrosion, lack of lubrication, proper alignment on the lowenergy end of the amplifier can prevent the trip latch from operating. A much greater amount of these defects are needed to prevent the main latch from operating. (2) Opening. On energizing the trip coil a latch is released or a pilot valve is actuated and the opening operation goes to completion without necessarily requiring the tripping coil to be energized through the entire operation. c. Pneumatic/Hydraulic Operating Mechanisms. Pneumatic/hydraulic amplifiers have a main valve operated by a pilot valve (directed by the closing or tripping coil). Their design lowers the electromechanical energy requirement. d. Auxiliary Devices. Auxiliary contacts indicate the circuit breaker position by energizing indicating lights. Auxiliary contacts signal the need for early replacement of stored energy spring winding motors, hydraulic pump/air compressors, and other auxiliary devices when contacts are provided that monitor the adequacy of that stored energy device.

40

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

e. Interlocks. Interlocks prevent releasing the closing spring when the circuit breaker is already closed or operating the unit as it is moved from the connected position to the test or to the disconnected position. f. Safety. Isolate control and current, and voltage instrument transformer secondary circuits to protect against unintentional operation. (1) Control Circuits. Understand the control method including interconnecting circuits and remove control fuses, open test switches, and disable any other control inputs. Lockout/tagout precautions should cover all isolating requirements. (2) Closing/Opening. Circuit breakers are both opened and closed with stored energy mechanisms which may remain charged even when a circuit breaker has been withdrawn from its enclosure. The mechanisms may be still capable of operating the circuit breaker in the withdrawn position. If the circuit breaker is closed, make sure the opening device circuit is discharged before you approach it with your tools or fingers. If the circuit breaker is open, block it and wire the trip latch to prevent the circuit breaker from closing. Above all, read the manufacturers instructions so that you can predict the condition of the circuit breaker.

4-4. Circuit Breaker Elementary Diagrams. Review the circuit breaker elementary diagram provided in the manufacturers instructions. Check any modifications given in the operations manual for the specific system. The effect of open-close-trip actuators, control operating power input, open and close activating and monitoring devices, and safety interlocks all impact on the circuit breaker operating mode. That impact can affect the safety of the maintenance technician and the continued operation of the device. An elementary diagram of a spring-operated circuit breaker mechanism is shown on Figure 4-1 and the mode of operation discussed in Figure 4-2.

41

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

P CS C GL RL CS T PR ABBREVIATIONS 1 3A M Y 52 2 3 4 7 Y b SR b LC LS1 bb 4 24 N LS1 aa PS1 Y a LS2 bb LS2 14 aa 21 20 10 52 b 52 13 5 9 52 ST 1 a a 6 CS - BKR. CONTROL SWITCH - CLOSE C CS - BKR. CONTROL SWITCH - TRIP T Y - ANTI PUMP RELAY SR - SPRING RELEASE COIL (CLOSE COIL) M - SPRING CHARGING MOTOR ST - SHUNT TRIP COIL PR - PROTECTIVE RELAY V - SECONDARY DISCONNECT V 52 - CIRCUIT BREAKER 19 a - OPEN WHEN 52 IS OPEN b - CLOSED WHEN 52 IS OPEN

AFH 32-1282V1

SPRING CHARGED INDICATING LIGHT D C S O U R C E 3

WL

OPERATION LS1 OPEN UNTIL SPRINGS aa ARE FULLY CHARGED LS1 CLOSED UNTIL SPRINGS bb ARE FULLY CHARGED LS2 OPEN UNTIL SPRINGS aa ARE FULLY CHARGED LS2 CLOSED UNTIL SPRINGS bb ARE FULLY CHARGED LC OPEN UNTIL MECHANISM IS RESET

PS2

PS1 OPEN IN ALL EXCEPT BETWEEN TEST AND CONNECTED POSITIONS PS2 CLOSED IN ALL EXCEPT BETWEEN TEST AND CONNECTED POSITIONS

Figure 4-1 A typical circuit breaker elementary diagram

42

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

As soon as the secondary disconnects engage, the spring charging motor automatically starts charging the closing springs provided the control power is available. When the springs are charged, the motor cut off (LS1/bb and LS2/bb) switch turns the motor off. The breaker may be closed by making the control switch close (CS/C) contact. Automatically upon closing of the breaker, the motor starts charging the closing springs. The breaker may be tripped any time by making the control switch trip (CS/T) contacts. Note the position switch (PS) contact in spring release (SR) circuit in the scheme. This contact remains made while the breaker is being levered between Test and Connected position. Consequently it prevents the breaker from closing automatically even though control switch close contact may have been made while the breaker is levered to the Connected position. When the CS/C contact is made, the SR closes the breaker. If the CS/C contact is maintained after the breaker closes, the Y relay is picked-up. The Y/a contact seals in Y until CS/C is opened. The Y/b contact opens the SR circuit so that even though the breaker would subsequently open, it could not be re-closed before the CS/C were released and remade. This is the anti-pump function.

Figure 4-2 Operating control modes for Figure 4-1

43

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

4-5. Circuit Breaker Nameplates.

Circuit breaker nameplate data can provide useful information when Apparatus Documentation data is not available or has been lost. Tables 4-3 and 4-4 show minimum circuit breaker information required on circuit breaker nameplates for low-voltage circuit breakers and for medium and high voltage circuit breakers respectively.

Table 4-3. Low-voltage circuit breaker minimum nameplate information

Manufacturers name Type of circuit breaker Rated continuous current of trip devices (where applicable) and type designation Frame size Rated maximum voltage(s) Rated short-circuit current at each rated maximum voltage Power circuit breakers Rated short-time current (where applicable) Suitable fuse type and sizes (where applicable) Rated frequency Rated control voltage (where applicable) Year of manufacture, by date or code Identification number Manufacturers data sheets or instruction book reference

44

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

Table 4-3. Low-voltage circuit breaker minimum nameplate information (cont.)

Molded-case circuit breakers Manufacturers name or trademark LINE and LOAD (if it is an interchangeable trip circuit breaker or is not suitable for reverse Type designation or identification number connection) Rated current Rated short-time withstand current (if applicable) Rated operational voltages with ON and OFF for indicating the closed and open corresponding rated short-circuit breaking positions at the place of operation.3 1 current Indication of a required barrier2

1

For circuit breakers rated 250 V maximum with short circuit breaking current of 5000 amperes, the short circuit breaking current shall be permitted to be omitted. If the proper operations or installation is a dependent upon an insulation barrier If symbols are used, O will be used to indicate the open and I will indicate the closed position.

2 3

45

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

Table 4-4. Medium and high voltage circuit breaker minimum nameplate information

Circuit breaker Manufacturers name Rated line closing switching surge factor Manufacturers type designation Rated short-circuit current Manufacturers serial number Rated interrupting time Year of manufacture Normal operating pressure Rated frequency Minimum operating pressure Rated continuous current Gallons of oil per tank or weight of gas per breaker Rated maximum voltage (kV) Weight of circuit breaker complete (with oil or gas) Rated voltage range factor K Instruction book number Rated full wave impulse withstand voltage (kV) Parts list number Rated switching-impulse withstand voltage Assigned out-of-phase switching current rating ! Terminal to ground - circuit breaker closed ! Terminal to terminal - circuit breaker open

46

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

Table 4-4. Medium and high voltage circuit breaker minimum nameplate information (cont.)

Ratings for capacitance current switching Transient overvoltage factor Back-to-back shunt capacitor bank current Open-wire line charging current Transient inrush current peak Isolated shunt capacitor bank current Transient inrush current frequency Manufacturers name Manufacturers type designation Manufacturers serial number Year of manufacture Closing control voltage range Tripping control voltage range Closing current Tripping current Operating mechanism Compressor control switch closing and opening pressures Low pressure alarm switch closing and opening pressures Low pressure lockout switch closing and opening pressures Wiring diagram number Instruction book number Parts list number

47

AFH 32-1282V1

Chapter 4. Circuit Breaker Performance

AFH 32-1282V1

Table 4-4. Medium and high voltage circuit breaker minimum nameplate information (cont.)

Current transformers1 Manufacturers name Connection chart showing: Manufacturers type designation ! Full winding developing Rated frequency, if other than 60 cycles ! Taps American National Standard accuracy class ! Ratio in terms of primary and secondary currents Instruction book number ! Polarity Curve sheet ! Pole and pocket location Accessories Identification Pertinent operating characteristics

1

Nameplates located at respective terminal blocks. Includes mutual reactance and self-impedance (resistance, reactance, and impedance) for linear couplers.

48

AFH 32-1282V1

Chapter 5. Circuit Breaker Testing

AFH 32-1282V1

CHAPTER 5. CIRCUIT BREAKER TESTING 5-1. De-Energized Circuit Breaker General Tests.

Always test circuit breakers in the test position. If there is no test position (stationary circuit breakers) test only after the circuit breaker has been de-energized and grounded. Tests must be done in accordance with the safety requirements for de-energized electrical line work given in Paragraph 1-4. Convert measured insulation resistances and power factors from the test temperature to the reference temperature of 20 degrees C (AFMAN 32-1280(I)). a. Contact Resistance Tests. Repeated arcing or excessive corrosion of circuit breaker contacts increases contact resistance which is detrimental to the contacts ability to carry current. Increased contact resistance may also indicate loose joints or misaligned contacts. (1) Application. Apply a direct-current source (of at least 100 amperes of current for medium and high voltage circuit breakers) from the circuit breakers input terminal/bushing to its output terminal/bushing. Close the circuit breaker and with a low-resistance instrument measure the resistance of each pole. The average resistance values for 15-kV-class circuit breakers should normally be between 200 and 250 micro-ohms. (2) Test Values. The resistance should not exceed the values specified by the circuit breaker manufacturer for the type, voltage, and current rating of the circuit breaker. Contact resistance varies with low-voltage circuit breakers and usually is measured by millivolt drop rather than micro-ohm resistance. In the absence of manufacturers data compare the measured poles contact resistance to adjacent poles and/or to similar circuit breakers ratings. Investigate any deviations exceeding the 49

AFH 32-1282V1

Chapter 5. Circuit Breaker Testing

AFH 32-1282V1

manufacturers tolerance or any deviation of more than 50 percent if compared to similar circuit breakers or adjacent poles. b. Insulation Resistance Pole-to-Pole Tests. This test is meaningful only on a comparative basis. A gradual decline in resistance with age is normal; however, a sudden decline means insulation failure is imminent. A continued downward trend indicates insulation deterioration, even through measured resistance values are above the minimum acceptable limits. (1) Application. Use a megohmeter to measure insulation resistance with the circuit breaker in both the open and closed positions. (a) Circuit Breaker Open. Connect the megohmeter lead to one input or output pole terminal of the circuit breaker with all other five pole terminals grounded. Repeat for the other five terminals. (b) Circuit Breaker Closed. Connect the megohmeter lead to one closed pole (either input or output) terminal of the circuit breaker with either the input or output of the other two closed pole terminals grounded. Repeat for the other two phases. (c) Test Values. Take the ambient temperature during measurements. Correct the measured insulation resistance and record. Compare with acceptance and previous test values. See Table 5-1 for test voltages and minimum insulation resistances.

Table 5-1. Circuit breaker insulation-resistance test values

Voltage rating 0-250 volts 251-600 volts 601-5000 volts Minimum dc test voltage 500 volts 1000 volts 2500 volts Recommended minimum insulation resistance in megohms 50 100 1000

50

AFH 32-1282V1

Chapter 5. Circuit Breaker Testing

5001-15000 volts 15001-25000 volts 35,000 - 69,000 volts 2500 volts 5000 volts 15,000 volts

AFH 32-1282V1

5000 20000 100000

c. Control Wiring Insulation-Resistance Tests. Perform insulation-resistance tests at 1000 volts direct current. Do not perform the test on wiring connected to solid-state components. Insulation resistance should be a minimum of 2 megohms. d. Insulation Power Factor Tests. Use an insulation power factor test set in accordance with the test sets instructions. The use of the set requires previous training and the set manufacturer should supply test-data forms. Limit test voltages to below the line-to-line voltage rating of the circuit breaker. Take measurements which allow computation of the power factor based on the measured insulation watts loss divided by the volt-amperes applied. Check power factor for both open and closed positions of the circuit breaker. Power factor test results should be evaluated on the basis of previous results but any value above 1 percent warrants investigation. (1) Precautions. Power factor measurement instrumentation must be well shielded if it is used in a substation area where there may be a significant level of electrostatic interference. Using a higher frequency power supply may help solve the interference problem. (2) Advantages: The insulation power factor test can detect defective insulation in series with good insulation, a condition that may be masked when using the insulation resistance test. The insulation resistance test may indicate a false low value of resistance because of the many parallel paths and the variation due to the volume of the insulation system. A negative power factor is an indication of tracking across the insulation system. 51

AFH 32-1282V1

Chapter 5. Circuit Breaker Testing

AFH 32-1282V1

e. Dynamic Travel Tests. Use a motion analyzer to check mechanical operation of the circuit breaker at full speed. Compare circuit breaker travel and velocity values to the manufacturers acceptable limits and with the historical record for the circuit breaker. Small variations in speed or travel can indicate deteriorating conditions of the circuit breakers closing mechanism, stored energy system, shock absorbers, and other mechanical parts. f. Trip and Close Coil Minimum Operating Voltage Tests. For circuit breakers without integral diagnostic capabilities, connect a switch and rheostat in series with the coil circuit (trip or close) being checked and across the terminals to the applicable remote control switch. Connect a voltmeter across the coil. Starting at below 50 percent of rated coil voltage, gradually increase the voltage until the coil plunger picks up and successfully operates the circuit breaker. Make several trial operations of the circuit breaker, and record the minimum operating voltage. (1) Tripping. Most circuit breakers should trip at about 55 percent of rated trip-coil voltage. Measure the trip-coil resistance and compare it with the factory test value to disclose shorted turns. Many modern circuit breakers have trip coils which will overheat or burn out if left energized for more than a short period. An auxiliary switch is used, in series with the coil, to open the circuit as soon as the circuit breaker has opened. The auxiliary switch must be properly adjusted to successfully break the arc without damage to the contacts. (2) Closing. Follow the same procedure for determining the minimum closing coil voltage. Record the minimum voltage that will close the breaker and the closing coil resistance.

52

AFH 32-1282V1

Chapter 5. Circuit Breaker Testing

AFH 32-1282V1

5-2. De-Energized Tests Specific to the Circuit Breaker Type. The voltage rating and the type of insulation requires tests specific to the circuit breaker design. a. Low-Voltage Circuit Breakers. The protective tripping device is an integral part of the circuit breaker. The unit may be equipped with an electromechanical trip unit or a static trip unit. Electromechanical units may have a thermal (inverse time overload) protection, magnetic (instantaneous short-circuit) protection, or a thermal-magnetic combination. Static units are solid-state electronic devices which provide many additional protective features. All tripping times should be checked to assure they meet the manufacturers time-current characteristic tolerance band. Use a circuit breaker test set and make field adjustments in accordance with the test sets instruction. Do not compromise the protection by exceeding the trip units adjustable range. Field repair is not recommended. If the trip unit is not functioning properly it should be replaced. It may also be advisable to replace the entire circuit breaker. b. Oil-Insulated Circuit Breakers. Check oil dielectric strength, power factor, interfacial tension, and color in accordance with requirements given for insulating liquid tests in AFH 32-1282V2. c. SF6-Insulated Circuit Breakers. Check for moisture content. Service-aged moisture content should be less than 300 parts per million (ppm) by volume (10 ppm new). Do not energize any gas-insulated equipment where the gas density is less than 50 percent of nominal or if the moisture content exceeds 1,000 ppm. Moisture content should be checked with a moisture analyzer approved for SF6 gas. Follow the procedures in and as often as recommended by the manufacturers instructions. Some SF6 bottles have a sample valve. Some SF6 bottles are sampled through a filling valve using a valved sampling tube arrangement which prevents contaminants from entering the SF6 bottle. It is recommended that trained contract personnel do the checking.

53

AFH 32-1282V1

Chapter 6. Circuit Breaker Evaluations

AFH 32-1282V1

CHAPTER 6. CIRCUIT BREAKER EVALUATIONS 6-1. Circuit Breaker EPM Reports. Each installation should prepare local blank EPM report forms to be filled out by the inspecting technicians. (See Paragraph 1-4.) The following tables indicate data which may need to be recorded. Evaluate the extent of data required based on your installation needs and maintenance ability.

a. Basic Circuit Breaker Information To Be Determined Before The Inspection. Provide a suitable record header with blank spaces for insertion of the following data given in Table 6-1.

Table 6-1. Circuit breaker general data

Designation Voltage rating Date of inspection Rated continuous amperes Location Rated interrupting amperes Serial no. Operation (manual, electrical, remote control) Year installed Volts close: ac_____ dc______ Last inspection date Volts trip: ac_____ dc______ Manufacturer Assembly (switchboard, switchgear, none) Instruction manual Type (stationary, drawout) Insulation (air, vacuum, SF6, oil) Protective device type and settings b. Basic Inspection Items To Be Checked. Provide an inspection listing with column headings covering items to be checked off for each listed number as given in Table 3-4. 53

AFH 32-1282V1

Chapter 6. Circuit Breaker Evaluations

AFH 32-1282V1

c. Inspection Items To Be Covered. Inspection items to be covered will vary dependant upon the voltage level and insulation type of the circuit breaker as covered in the following paragraphs of this chapter. Table 6-2 indicates circuit breaker readings and appropriate evaluation paragraphs for passing criteria applying to the various circuit breaker types. See AFH 32-1282V2 for bushing, instrument transformer, and surge arrester requirements.

Table 6-2. Circuit breaker readings or test values

Readings or test value Evaluation reference paragraph 1. Ambient temperature .......................................................................... -2. Number of operations ......................................................................... -3. Peak indicating amperes .................................................................... -4. Contact resistance pole-to-pole (microhms)....................................... 5.1a 5. Insulation resistance (megohms) open, closed1................................. 5.1b 6. Control wiring insulation resistance (megohms) ................................ 5.1c 7. Power factor ....................................................................................... 5.1d 8. Closing speed..................................................................................... 5.1e 9. Opening speed ................................................................................... 5.1e 10. Trip and close minimum operating voltage......................................... 5.1f 11. Low-voltage circuit breaker tripping times .......................................... 5.2a 12. SF6 moisture content ......................................................................... 5.2c

1

For six open terminals, and for three closed phases.

6-2. High-Voltage SF6 or Oil Insulated Circuit Breakers.

Inspection includes both external and internal inspections. External inspections are covered in Table 6-3. Follow procedures of Table 6-4 for internal tank inspections. 54

AFH 32-1282V1

Chapter 6. Circuit Breaker Evaluations

AFH 32-1282V1

Table 6-3. External high-voltage circuit breaker checks

Component Inspection 1. Tanks a. Paint condition b. Bulging, cracking, leaks c. Gasketing or other sealing adequacy d. Valves open or closed e. Pressure, air or gas f. Support adequacy 2. Operating mechanisms1 a. General condition b. Control cabinet condition c. Mechanical clearances d. Pneumatic operating systems e. Hydraulic operating systems 3. Electrical connections a. Tightness b. Hot spots2

1 2

Component Inspection 4. Protective device operation/calibration a. Control circuits b. Relays c. Alarms d. Gauges e. Relief devices f. Calibrations 5. Oil insulation a. Filling b. Filtering c. Sampling 6. SF6 insulation3 7. Operation under load a. Malfunctions b. Friction 8. Heater operation

May require lubrication, cleaning, adjusting, and aligning. For infrared checking see Paragraph 3.1.a. 3 See Table 6-2.

55

AFH 32-1282V1

Chapter 6. Circuit Breaker Evaluations

AFH 32-1282V1

Table 6-4. Internal high-voltage circuit breaker tank procedures and checks

1. Accessing the tank a. Remove covers, lower tank, extract oil or gas and transfer to approved storage or processing equipment b. Ventilate and wipe down oil-insulated units. Pull a vacuum on gas insulated units. c. Check, measure, adjust, lubricate, align, and repair: (1) Contacts (2) Interrupters (3) Internal current transformers (4) Resistors, capacitors, and lift rods d. Replace any desiccant material, if applicable 2. Seal the tank and: a. Refill oil-insulated units to the proper level and inspect for leaks b. Pull a vacuum per manufacturers specified time for gas-insulated units and if no leaks are present refill tank to the proper pressure

6-3. Medium-Voltage Vacuum or Air Insulated Metal-Clad Switchgear Circuit Breakers. Pictures 6-1 and 6-2 indicate protective features on all metal-clad switchgear. Pictures 63 and 6-4 indicate details of air-magnetic arc chutes. Table 6-5 indicates circuit breaker components and appropriate inspection actions for circuit breakers withdrawn from the switchgear and de-energized unless indicated to be in the test position. BE CAUTIONED THAT HIGH POTENTIAL TESTING OF VACUUM BOTTLES CAN CAUSE X-RAY EMISSION. USE MANUFACTURERS SAFETY PRECAUTIONS. 56

AFH 32-1282V1

Chapter 6. Circuit Breaker Evaluations

AFH 32-1282V1

Picture 6-1 Closed protective shutters

Picture 6-2 Open protective shutters

57

AFH 32-1282V1

Chapter 6. Circuit Breaker Evaluations

AFH 32-1282V1

Picture 6-3 Exposing arc chutes

Picture 6-4 Cleaning an arc chute

58

AFH 32-1282V1

Chapter 6. Circuit Breaker Evaluations

AFH 32-1282V1

Table 6-5. Medium-voltage metal-clad switchgear circuit breaker checks

Component inspection 1. Anchorage and grounding 2. Operating mechanism check a. Electrical operations functions1, tripping, closing, trip-free, antipump, and protective relaying b. Mechanical operations, tripping, closing, charging, and contact alignment in all positions c. Tightness of hardware d. Cleanliness e. Lubrication requirements f. Racking mechanism, cell fit, and element alignment g. Inspect wiring for security, damage, and terminal connections Component inspection 3. Air magnetic unit inspections2 a. Main contacts wipe and gap3 b. Arcing contacts wipe3 c. Finger clusters d. Secondary disconnect contacts e. Latches wipe and clearance3 f. Contact travel4 g. Clearances3 h. Speed, opening and closing3 i. Moving parts, linkages, closing/tripping mechanisms, freedom of movement position for quick actions j. Interlocks properly operating k. Arc chutes 4. Vacuum unit inspections a. Contact erosion and wipe5 b. Adequate vacuum

1 With circuit breaker in the test position and using a test coupler. 2Remove arc chutes for inspection 3 Record manufacturers recommendation, as found condition, and as left condition. 4 Measure overtravel and determine from manufacturers instructions if any measured overtravel is acceptable. 5

Provide a one-minute alternating-current high potential in accordance with the manufacturers instructions. caution.

See previous

59

AFH 32-1282V1

Chapter 6. Circuit Breaker Evaluations

AFH 32-1282V1

6-4. Low-Voltage Circuit Breakers.

Table 6-6 indicates circuit breaker components and appropriate inspection actions. Drawout circuit breakers should be removed from their enclosures. Stationary circuit breakers should be de-energized and grounded. Pictures 6-5 and 6-6 show the two usual type of low-voltage circuit breakers. Pictures 6-6 and 6-7 show drawout contacts for power and control respectively.

Table 6-6. Low-voltage circuit breaker checks

Component inspection 1. General a. Mounted properly and grounded b. Undamaged and clean c. Operates correctly d. Tight connections e. Arc chutes and contacts1

1

Component inspection 2. Drawout units a. Racking mechanism, cell fit and element alignment. Verify contact wipes and other adjustments are correct. b. Operating mechanism functions both electrically and mechanically c. Lubrication requirements d. Control devices

On nonsealed units.

60

AFH 32-1282V1

Chapter 6. Circuit Breaker Evaluations

AFH 32-1282V1

Picture 6-5 Molded case circuit breaker

Picture 6-6 Power circuit breaker

61

AFH 32-1282V1

Chapter 6. Circuit Breaker Evaluations

AFH 32-1282V1

Picture 6-7 Power contact fingers

Picture 6-8 Control contact fingers

62

AFH 32-1282V1

Chapter 7. Interrupter Switch Installations

AFH 32-1282V1

CHAPTER 7. INTERRUPTER SWITCH INSTALLATIONS 7-1. Interrupter Switch Basics.

use of medium-voltage circuit breakers. a. Actions. Interrupter switches can make (close), carry, and break (open) electrical circuits. They operate as well as circuit breakers under normal conditions. Under abnormal conditions their fault-interrupting capabilities (fused interrupter switches) do not approach that of a similarly rated circuit breaker. Closing in on faults can be dangerous if the switch does not have a duty-cycle faultclosing rating (fault-initiating switch). Motor operators for remote opening/closing of switches are available. Their use has diminished in recent years because of their many operating problems. b. Ratings and Nameplates. Standard switch and fuse ratings from manufacturers are given in Tables 7-1 and 7-2 respectively. Verify ratings with the applicable switch nameplate. Tables 7-3 and 7-4 show minimum switch and fuse nameplate information required by industry standards. Interrupter switches provide an economical alternative to the

63

AFH 32-1282V1

Chapter 7. Interrupter Switch Installations

AFH 32-1282V1

Table 7-1. Interrupter switch ratings.

Rated maximum kV 5 5 5 15 15 15 15 27 27 38 Impulse withstand kV 60 60 60 95 95 95 95 125 125 150 Continuous and load-break amperes 600 600 1200 600 1200 600 1200 600 600 600 Fault-close and momentary amperes kA rms asym. 40 61 61 40 40 61 61 40 60 30 Rated shorttime current (2 seconds) kA rms sym. 25 38 38 25 25 38 38 25 38 25

64

AFH 32-1282V1

Chapter 7. Interrupter Switch Installations

AFH 32-1282V1

Table 7-2. Fuse ratings

Continuous Current Range Amperes 10-200 .5-400 .5-400 .5-720 .5-300 .5-540 20-450 20-250 7-100 10-80 Interrupting rating at kV 4.8 kV 15 kV 25.8 kV kA symmetrical Boric acid type 10.5 ------21 21 27 kV 38 kV

19 37.5 --37.5 ----50 -------

14.4 29.4 34.8 29.4 ------50 -----

6.9 ------16.8 16.8 ----35 ---

6.9 ------16.8 16.8 ------12.5

Current-limiting type --------65

AFH 32-1282V1

Chapter 7. Interrupter Switch Installations

AFH 32-1282V1

Table 7-3. Interrupter switch minimum nameplate information

Interrupter switches Rated interrupting current and the following, Manufacturers name and address where applicable: Manufacturers type and designation number ! Operating life expectancy Rated maximum voltage ! Rated switching current - single 1 Rated continuous current capacitance 1 Short-time current ratings ! Rated switching current - parallel! Rated momentary current connected capacitance ! Rated three-second current ! Rated differential capacitance voltage (maximum) Rated impulse withstand voltage [basic impulse insulation level (BIL)] ! Rated differential capacitance voltage (minimum) Rated frequency 1 ! Rated capacitance switching transient Allowable continuous-current class overvoltage ratio Fault-initiating switches All the above information except as noted Rated closing time Rated making current Operating life expectancy

1

Not required for fault-initiating switches.

66

AFH 32-1282V1

Chapter 7. Interrupter Switch Installations

AFH 32-1282V1

Table 7-4. Fuse minimum nameplate information

Manufacturers name or trademark or monogram Manufacturers type or identification number Rated continuous current1 Rated maximum voltage Rated maximum interrupting current

1

Type identification C, E, or R where applicable for fuse interchangeability identification.

7-2. Interrupter Switch Operating Features.

Operation may be electrically or mechanically initiated. Safety interlocks may prevent operation. Optional monitoring devices are available. Interrupter switches, like circuit breakers, have a contact and arc extinguishing system, an operating mechanism, and an abnormal-conditions current-detection system. Air is the usual insulating medium and switches are designed only for use on medium-voltage systems. a. Contact and Arc Extinguishing Process. Generally switches are constructed with both main and arcing contacts. The main contacts carry the continuous current and the arcing contacts break the arcing current. Arc chutes are coated to generate a de-ionizing gas under the heat of the arc. The design lengthens and thus cools the arc promoting rapid extinguishing. 67

AFH 32-1282V1

Chapter 7. Interrupter Switch Installations

AFH 32-1282V1

b. Operating Mechanism. Stored energy from a heavy-duty spring provides the force necessary to open or close the switch. The switch handle charges the spring when operated either up for closing or down for opening. The stored energy of the spring operates independently of the operator. Switches cannot be teased into any intermediate position. All mechanisms can be manually operated. Many interrupter switches are provided with motor operators controlled by the current-detection system. Motor operators have a well documented history of operating problems. c. Current Detection Systems. The drawback to interrupter switches as compared to circuit breakers is their current-detection system under abnormal operating conditions. (1) Overloads. On overloads fuses will operate to open the circuit. (2) Fault Conditions. Fuses will operate properly on line-to-line faults. They may not operate on line-to-ground faults. Therefore safety precautions must be observed when manually opening switches. d. Precaution in Opening or Closing Switches. These operations can be extremely dangerous if they are performed when there is an uncleared fault condition at the switch. Safety orders should be very clear that the operator must stand to the side of the switch and wear a blast suit and fireresistant clothing. e. Safety Interlocks. Interlocks are required by industry standards to prevent contact with energized switch components. Pictures 7-1, 7-2, 7-3, and 7-4 show features that ensure energized parts are isolated from operating personnel.

68

AFH 32-1282V1

Chapter 7. Interrupter Switch Installations

AFH 32-1282V1

Picture 7-1 Interrupter switch door open

Picture 7-2 Operating mechanism