Professional Documents

Culture Documents

Evaluation and Improvement of The Procurement Process in Construction Projects

Uploaded by

nayangoelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evaluation and Improvement of The Procurement Process in Construction Projects

Uploaded by

nayangoelCopyright:

Available Formats

Evaluation and Improvement of the Procurement Process in Construction Projects

EVALUATION AND IMPROVEMENT OF THE PROCUREMENT PROCESS IN CONSTRUCTION PROJECTS

Luis F. Alarcn1, Rodrigo Rivas2, and Alfredo Serpell3 ABSTRACT A methodology to diagnose and evaluate the procurement process for investment projects, and launch a continuous improvement was developed and applied to selected projects. A thorough literature review was carried out along with study of cases, surveys and interviews to professionals involved in this area. As a result, a methodology for diagnosis and improvement was proposed and tested in selected projects. The results obtained show that the main problem of procurement is related to schedule delays and lack of specified quality for the project. To prevent this situation it is often necessary to dedicate important resources (money, personnel, time, etc.) to monitor and control the process. When applying the methodology to some projects, it was found that the main sources of waste were engineering, the system itself, the suppliers, and the policies. A great potential for improvement was detected if state of the art technologies such as, electronic mail, EDI (Electronic Data Interchange), bar codes, and other systems were applied to the procurement process. These technologies could help to eliminate the root causes for many types of wastes that were detected. KEY WORDS Lean construction, procurement, performance indicators, process improvement

Professor of Civil Engineering, Universidad Catlica de Chile, Escuela de Ingeniera, Casilla 306, Correo 22, Santiago, Chile, lalarcon@ing.puc.cl. Visiting Professor, The Ohio State University. Graduate Student, Universidad Catlica de Chile, Escuela de Ingeniera, Casilla 306, Correo 22, Santiago, Chile, rivlop@netline.cl. Associate Professor of Civil Engineering, Universidad Catlica de Chile, Escuela de Ingeniera, Casilla 306, Correo 22, Santiago, Chile, aserpell@ing.puc.cl.

Proceedings IGLC-7

219

Alarcn, Rivas, and Serpell

INTRODUCTION The term Procurement Process is used in this paper to describe the process required to supply equipment, materials and other resources required to carry out a project. This process usually involves sub-processes such as acquisition, purchasing, logistics, monitoring, quality assurance and contract administration (Stuckhart 1995). Currently there is a tendency to manage projects using a fasttrack approach in an effort to reduce project schedule. To be able to serve the needs of these projects, the Procurement Process is subject to important pressures to be carried out in the most expedite and fluid possible manner. According to the analysis of interviews and surveys carried out during the study of the Procurement Process described in this paper (Rivas 1998), five aspects can express the relevance of Procurement: a) Schedule pressures: the need of the project to be operative within the less possible time, avoiding excessive financial costs, minimizing project management costs, and other indirect costs. b) Cooperation and coordination with construction: by complying with the needs of the construction schedule procurement will act to construct. Improvement of the efficiency for procuring supplies may not only result on great savings for the process itself, but also important savings on other construction resources (Business 1983). c) High relative value: when the supplies managed by procurement represents 50%, 60%, and up to 70% of the total cost for the project, it is imperious to have a strict and permanent control of the acquisitions, having in mind the financial approach being represented by such situation. d) Relevance of the process equipment being supplied for the performance of the project. The equipment can be of such relevance, that the operation of the project depends on its adequate performance. e) Potential criticality of the supplies: due to precedence relationships and interrelation between different areas of the project. This paper describes an effort to analyze the Procurement Process from a Lean Construction perspective (Alarcn 1997), by generating strategies to improve the procurement process in investment projects. These strategies are the result of the application of a methodology to diagnose and evaluate the procurement process in construction projects. The methodology helps to select strategies after several analysis tools have been applied to give a comprehensive view of the procurement process. The methodology was applied to study several projects being performed or under execution in Chile, obtaining important data about the current situation of the procurement process in these projects. RESEARCH OBJECTIVES The general objectives of the research were to generate a means to evaluate the Procurement Process, and to launch an improvement of the process involving Procurement, by applying an improvement methodology, inspired on the principles and concepts of the new production philosophy. In order to comply with the general objectives, the following specific objectives were pursued:

220

26-28 July 1999, University of California, Berkeley, CA, USA

Evaluation and Improvement of the Procurement Process in Construction Projects

1. 2. 3. 4.

Understand the process of procurement in projects, emphasizing on process equipment. Identify key variables and problems in the procurement process. Determine causes of variability and problems related to information and material flow. Propose performance indicators, at management level as well as operational, for the process and sub-process related to procurement. 5. Provide means for continuous process improvement and for minimizing cycle times. 6. Diagnose the current situation in Chilean projects. RESEARCH METHODOLOGY The research methodology was based on five elements: literature review, study of cases, casual interviews, structured interviews and surveys, and the analysis of information sources. Companies within the mining, industrial and energy areas were considered owners as well as consultants (engineering companies), and industry experts participated in the interviews. A base questionnaire was applied to 12 projects; the interviews considered 22 people from 11 companies. The study of cases was focused on projects already performed or near the end of the project (industrial, mining, and engineering consulting companies) from which it was possible to obtain specific information regarding the procurement process. In particular, one owner company interested in the outcomes of this study provided the researchers with full access to the files of its projects. This allowed the researcher to review historical and current data of projects, particularly related to procurement, such as: purchase reports, follow-up reports, claim reports, supply reports, etc. It was also possible to interview the participants of these projects to verify, clarify or obtain information. Additionally, two cases present in the literature were analyzed (Ballard 1993, Cole 1989). From the information gathered from these sources, and from a posterior analysis, improvement strategies were obtained and a preliminary evaluation methodology was proposed. This methodology, described in the following section, was applied to the study of two real projects to perform its validation and adaptation. PROPOSED EVALUATION METHODOLOGY The methodology proposed to diagnose, evaluate, and improve the procurement process comprises five phases, as shown in Figure 1. One first step is a characterization of the company, the project and procurement process, as a starting point for a formal application. Then comes a diagnosis according to pre-defined questions. The third step is to obtain some initial performance indicators to help in the detection of improvement opportunities. The next phase of evaluation, identifies waste from different sources, and analyses them. And last, the fifth phase is used to design the improvement strategies of the process. Each step of the evaluation methodology has been documented and structured with specific tools, surveys, diagrams, and reports. The full version of the procedures can be found in (Rivas 1998). The different steps of the proposed methodology are briefly discussed in the following subsections, providing some examples of the tools used to carry out specific phases.

Proceedings IGLC-7

221

Alarcn, Rivas, and Serpell

PHASE I

Characterization of the company and the project

SYMBOLOGY PHASE II

Diagnose

General

Sequence of application Contribution to process Phases of methodology

PHASE IV PHASE III

Selection and use of Indicators Evaluation

Problems,

PHASE V

Selection of Instruments and Strategies

Nonconformity

and cause - effect.

Figure 1: Phases in the Evaluation Methodology PHASE I: CHARACTERIZATION OF COMPANY AND PROJECT This phase seeks to characterize the company, in order to facilitate the process of problem review and later analysis within the methodology. This phase involves the characterization of the Company using pre-designed instruments to collect information about general aspects of the company, description of the way they face projects, and management of know how, and experience within the company. The characterization of the project and procurement process requires, in addition to general aspects, a detail of the participation of the project organization on the procurement process, project policies affecting procurement, project organization, procurement organization and staffing. The diagnosis example used in this paper does not address a specific project but it attempts a diagnosis of the procurement process in Chilean industrial projects using the information collected from several experts and multiple projects. PHASE II: GENERAL DIAGNOSIS In this phase, some elements of the process are checked, to detect the status of the procurement process compared with some general strategies or considerations that were found more appropriate during the current research. This stage involves analysis of the following items: procedures used, purchasing strategy, suppliers, programs, information flows, and technological instruments. This stage includes the development of an initial value stream map of the procurement process. PHASE III: PERFORMANCE INDICATORS Indicators are an important part of the methodology itself. They can give signals to management regarding how the process is performing and they can facilitate the evaluation within the methodology. Table 1 provides a list of potential indicators to serve as a starting point in selecting indicators for a specific project. These indicators were collected from the literature, interviews, surveys and case studies (Plemmons and Bell 1995, Koskela 1997, Alarcon 1997b, Rolstadas 1995). They were divided into five categories: 1. Cycle Times: for different activities within the procurement process.

222

26-28 July 1999, University of California, Berkeley, CA, USA

Evaluation and Improvement of the Procurement Process in Construction Projects

2. Milestone Events indicators: they check the fulfillment of specified milestones related to the supply of equipment or materials. They make evident the non-fulfillment of the program or/and non-fulfillment of the scheduled time. 3. Management indicators: make evident problems of planning or supply itself. 4. Cost indicators: make evident situations that may result in additional expenses to the procurement area. Obtained upon delivery of supplies, may be calculated monthly. 5. Referential values: provide standards for comparison to monitor deviations within the process, and provide valuable information to create monthly reports. The selection of indicators can be useful to verify if the systems being used to monitor the project provide the necessary information for managing the project. Indicators should be instruments for managing the process; they show a way of carrying out the work. In order to choose indicators for the project, there must be an identification of those supplies being most critical; this will provide some focus for the selection. Usually with the information available from the general diagnosis it is possible to identify not only critical supplies but also potential waste and waste sources, this information can be used to select indicators that could help to monitor and prevent potential problems and unnecessary waste during the project. In our example of the Chilean reality, that involved multiple projects, the long list of indicators was confronted with the problems detected during the research. The indicators that would be most appropriate to identify some of those problems were marked with a # sign in Table 1. These marked indicators can be considered as recommended indicators for the type of industrial projects included in this research. Nevertheless, the particular project considerations are the most important for the selection because not all the indicators might be necessary or might be available for a given project. On the other hand, some particular type of indicator (which might not even be in Table 1) might be more important in some cases. PHASE IV: EVALUATION OF THE PROCUREMENT PROCESS The evaluation stage comprises the following steps: establishing the group of people to be interviewed; value stream maps, general and detailed; project surveys; review of performance indicators; analysis of nonconformity reports; cause effect analysis regarding delays, costs, time cycles and others. Three tools are used below to diagnose the Chilean reality regarding procurement in projects: a survey of problems (all projects), analysis of nonconformity reports (case of industrial project) and cause-effect analysis for cycle times (all projects). Table 2 shows the most common problems grouped into four areas, they are weighted according to their frequency of occurrence in the project surveyed. The supply group is the one that shows most frequent problems, followed by the stages of the procurement process. The example shown in Figure 2 is project specific. Nonconformity reports issued during the execution of an industrial project (62 over 14 months) were analyzed and summarized as shown in Figure 2. The problems affected mainly bulk materials as can be noticed on Figure 2 a). This type of information was usually available for most projects but it was seldom used for management purposes. Periodic reports with processed information could greatly help managers to prevent and reduce problems that can affect the procurement process.

Proceedings IGLC-7

223

Alarcn, Rivas, and Serpell

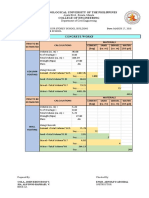

Table 1: Potential Performance Indicators for the Procurement Process

1 CYCLE TIMES 1.1 Cycle times for different activities of the process 3 MANAGEMENT INDICATORS

3.1 Frequency of days of delay/in advance, regarding target 3.2 Number of cases w/lack of supply on planned date for use in construction 3.3 Number of changes in specifications

# # # # #

2 EVENT INDICATORS

3.4 Number of change orders 3.5 Number of urgent dispatches 3.6 % of air transport

(% fulfill program, %comply with asigned time term, field breakdown)

2.1.1 Issue of specification of Q. R. By engineering 2.1.2 Procurement receives specification of Q. R. 2.2.1 Issue of Q. R. To suppliers 2.1.3 Delivery of Q. R. To Suppliers 2.1.4 Reception of bids 2.2.2 Delivery of bids for technical appraisal 2.1.5 Appraisal of bids 2.2.3 Negotiation 2.1.7 Reception from bidder (or responsible in organization) 2.1.8 Decision and Award 2.1.9 Notification of award 2.2.4 Aceptance of notification of award 2.2.5 Issue of acknowledgement letters 2.1.10 Issue of requisition by engineering 2.2.6 Reception of requisition by procurement 2.1.11 Issue of purchase order (P.O.) 2.2.7 Delivery of drawings for revision 2.2.8 Submit approved drawings 2.1.12 Certified approved drawings 2.2.9 End of material purchase for fabrication 2.2.10 Issue of orders for sub-suppliers 2.2.11 Supply out of fabric 2.2.12 FOB delivery 2.1.13 Embarkment 2.2.13 Arrival to port CIF 2.2.14 Customs Clearance 2.1.14 On site Note: Q.R.: Quotation Request.P. O.: Purchase Order.

Symbol #, reflects some problems detected .

3.7 Number of changes to air transport 3.8 Amount of supplies with reception problems 3.9 Cases with problems of reception, under and over deductible insurance 3.10 Cases where goods were not shipped 3.11 Damage on transport 3.12 Number of Bills of lading (B. L.) rejected by period

# #

3.13 Days of difference between gross and fine reception

# #

2.1.6 Delivery of appraisals to bidder (or responsible in organization) # 4 COST INDICATORS 4.1 Number of drops to ground/month (ship) 4.2 Number of days in warehouse (customs) / delivery (aircraft) 4.3 Number of days in customs / delivery 4.4 Number of rules 1 proceeded / Number of rules 1 possible

# # # # #

4.5 Number of fiscal credits proceeded / Number of possible fiscal credits 4.6 Number of (days spent) corrections, repairs 4.7 Number of special transports / period and accumulated 4.8 Time until release of container, for container at job site

# # #

5 REFERENTIAL VALUES 5.1 Amount of Q. R.'s issued / period and accumulated 5.2 Amount of P. O.'s issued / period and accumulated 5.3 Amount of Change orders issued / period and accumulated

5.4 Amounts involved in orders / period and accumulated 5.5 Embarkments by period (general and detail) 5.6 Embarkments in transit by period (general and detail)

5.7 Amount of money in embarkments by periods 5.8 Gross receptions performed 5.9 Fine receptions performed 5.10 % advance engineering (verification correlation engineering-procurement) 5.11 Domestic purchases / import purchases 5.12 Number of supplies according to criticality level (relationship industry - events) 5.13 Amount of inspection by order 5.14 Final amount of supply /budgeted amount

# # # # # #

Cause-effect diagrams were used to analyze three basic aspects within the procurement process, these were cycle times, costs, and delays (associated to variability). These diagrams helped to synthesize the main causes related to waste in the procurement process for these three aspects. Figure 3 shows one example that summarizes the causes of long procurement cycle times. The analysis of this type of diagram can help managers to focus on specific issues to introduce improvements in the process, for instance, in the example diagram it is apparent that by introducing changes in technologies and procedures improvements in systems could help to reduce cycle times. The information obtained from the different tools provides a comprehensive view of the procurement process performance, strengths and weaknesses. This information is also used to

224

26-28 July 1999, University of California, Berkeley, CA, USA

Evaluation and Improvement of the Procurement Process in Construction Projects

systematically design improvement strategies as explained in the following phase. Some general conclusions obtained about the Chilean projects are discussed later in the paper. Table 2: Main Problems Detected in Chilean Projects

AREA Supply Supply Supply Supply Supply Supply Supply Supply Supply

SUB AREA

TRUSSES (fabrication) EQUIPMENT EQUIPMENT EQUIPMENT EQUIPMENT EQUIPMENT BULK MATERIAL BULK MATERIAL BULK MATERIAL

DESCRIPTION

Delays on delivery of supplies Medium size equipment with delayed request, negotiate due to forced time term Spend more time to replace or repair equipment parts by sub suppliers Need for scheduled inspection, have same technical level as suppliers Equipment poorly designed, does not meet technical requirements, excess of confidence Closing and fusion problems, reorganization of suppliers Generally, critical route for projects Lack of experience or trained personnel for design, delays, replacements Too wide variety when designing, more standardization

Weight 7 5 5 4 3 3 3 3 3 4 4 3 3 3 3 3 4 4 3 3 3 3 4 3 3 3

Procur. Proc ACTUATION & FOLLOW-UP Desinformation or lack of clarity from people on site regarding reception Procur. Proc WAREHOUSE & RECEPCTION eed to plan orders for easier management in warehouse N Procur. Proc QUOTATION APPLICATION Delay due to lack of information from engineering Procur. Proc NEGOTIATION Procur. Proc TRANSP. & LOGISTIC

Too many obstacles and clauses delay negotiations Late purchase makes system expensive, with air freight and urgent procedures

Procur. Proc WAREHOUSE & RECEPCTION oor explanation about items, coming more automized supply than in description P Procur. Proc WAREHOUSE & RECEPCTION aiting time for gross reception W Project Project Project Project Project Project External External External System

PROGR. & PLANNING PROGR. & PLANNING ENGINEERING PROGR. & PLANNING PROGR. & PLANNING PROGR. & PLANNING SUPPLIER SUPPLIER SUPPLIER PROCEDURES

Delays from engineering Programming forces change for air freight Delays on issueing specifications for quotations Programming forces to cut normal time terms for supplies Lack of forward thinking, late verification that there is no time left Delay on informing supplier Need for scheduled inspection, have same technical level as suppliers Lack of clarity from supplier market, recent study Do not meet requirements Too many obstacles and clauses delay negotiations

PHASE V: INSTRUMENTS AND STRATEGIES FOR IMPROVEMENT During this phase there is a search for appropriate solutions to reduce or eliminate waste detected in the process. It involves the following stages: generation of instruments and strategies, setting of priorities for the instruments proposed, and implementation of strategies and instruments for improvement. Instruments are specific tools, technologies, actions or simple methods. The strategies for improvement are compounds of instruments. To facilitate the generation stage, a collection of potential instruments or actions was generated from a brainstorming process performed with the interviewed and from the literature reviewed (Plemmons and Bell 1995, Stuckhart 1995, Ballard 1993, Beverley 1994, Houston 1996, Bell and McCullough 1988, O Brien 1997). The list shown in Table 3 is suggested for initial screening in generating improvement actions for a given project; the instruments were organized according to the area where the improvement is needed.

Proceedings IGLC-7

225

Alarcn, Rivas, and Serpell

An adaptation of the House of Quality is proposed (Akao 1997) to select the instruments that are more effective in eliminating or reducing waste. The House of Quality, shown schematically in Figure 4, is a matrix that spreads the requirements or needs on the rows (WHAT), and the technical answers satisfying such requirements, on the rows (HOW). The inputs of rows (WHAT) are proposed strategies or instruments selected from Table 3 after a preliminary screening process. To compose a strategy, it is necessary to carry out a preliminary verification of the relation between the proposed instruments, for possible implementation. On one side, their potential interaction must be checked, either positive (when complementing and/or reinforcing), or negative (excluding or contradictory); preliminary strategies for improvement can be formulated to be introduced in the columns of the matrix of Figure 4.

a) Problem areas

Other 3% Piping 34% Boilers 3% Electrical 5% Equipment 15%

b) Type of problems

Damages 16% Defects 2% Incomplete delivery 5% Out of Specifications 23%

Shortage of Materials 48%

Engines 5%

Instruments 35%

Excess of Materials 6%

Figure 2: Non-conformities at Reception in an Industrial Project

SUPPLIER TRANSPORTATION International

Chosen means air sea ground

PROJECT MANAGEMENT Approvals

SYSTEMS Used technologies Project Contracting Evaluations

Technology levels Take advantage of information Among systems

Sub-suppliers

Type of contract Price Domestic

Special cases

Manufacturing

Work plans

Travel distance

Procedures Spread of Information

Work load

Program requirements Output capacity World demand

Place of origin

Policies

Type of contract Scope of purchasing contract Purchasing strategy

Customs Agent

Requirements Tax exemptions rule 1 Fiscal credit Declaration Import

PROCUREMENT CYCLE TIME

Shipper

Service level

Procedures Evaluation and y ecomendation R Engineering resources to continue progress Negotiations Changes in specifications

Issue SC Issue P. O. Hired personnel

Training Skills experience

Info about project to continue progress Issue of specifications SC Issue of Requisition

Schedule pressure

Price Willing to pay pay

Approval level Objectives

Follow-up and Actuation

Work plans supplier Shipment and transport Manufacturing

MOST SIGNIFICANT FACTORS

CUSTOMER

EXTERNAL SERVICES

ENGINEERING

PROCUREMENT

Figure 3: Cause-Effect Diagram for Long Cycle Times

226

26-28 July 1999, University of California, Berkeley, CA, USA

Evaluation and Improvement of the Procurement Process in Construction Projects

The inputs for columns (HOW), can be obtained from the analysis instruments used in Phase IV of the methodology: (a) a priority list of problems and waste detected upon evaluation, (b) nonconformity reports of the project (quantified), and (c) an analysis of the causes of the main problems and nonconformity. The matrix is then completed indicating how the technical answers (rows) contribute to reduce or eliminate the waste shown on the rows. The result is a ranking of the importance of the instruments, considering the diverse interactions, registered on the last rows. This analysis can be made separately for each of the results of the analysis instruments (a, b and c). It is quite possible that a different priority for each type of input can be obtained. Consolidation of the analysis should consider quantitative as well as qualitative consideration to select the improvement strategies, for instance, information from non-conformity reports can be more critical or more reliable than information from the causal analysis and could be given more importance in setting priorities to alternative strategies. FINDINGS ABOUT CHILEAN PROJECTS From analysis of information obtained from the different sources (interviews, surveys, case studies, and overall analysis) used in this research it was observed that: Each Owner presents a project organization adapted to its own reality, varying from company to company, and even, from one project to another. This has special relevance since it affects procurement and the way to face it. The problems present on procurement are of different types and origins. The most frequent problems detected were: delay at delivery, delay on ordering, repair and replacement at job site (equipment), poorly planned inspections (equipment supplier), lack of information on site about arrival for some supplies, delays on engineering (programming) and frequent changes to air transportation to make faster deliveries (programming), among others. The problem of procurement is basically related to delays (to comply with the requested time for the project, supply, or service) and lack of quality (specified for the project). It is common to request extra resources (capital, personnel, time, etc.) in order to avoid or overcome delays. The main sources for the problems detected were the system itself (forms and procedures to carry out things), Engineering (delays, errors, etc.), company policies, and the suppliers. Analyzing the value stream of the procurement process of an industrial project, only 18% of the activities were found to be value adding. Traditional systems (telephone, fax, and mail) are widely used; however, there was a low proportion of projects using modern IT to manage the procurement process. When applying the procedure described in Figure 4 to the multiple projects under study it was found that the strategies with highest potential were Information Technology strategies, including the implementation of technologies such as, electronic mail, EDI (Electronic Data Interchange), bar codes, and other systems. These technologies were the most effective to eliminate the root causes for many types of wastes that were detected, according to the above procedure. These results, however, can not be generalized because they might vary for

Proceedings IGLC-7

227

Alarcn, Rivas, and Serpell

specific projects where those technologies have been already implemented and where different sources of waste could be detected. Table 3: Potential Instruments for Improvement

Nmr

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

AREA

system system system system system system system system system organization organization organization programming programming programming programming project areas project areas project areas project areas project areas services to project services to project purchase arrangement purchase arrangement purchase arrangement traffic and proceedings traffic and proceedings follow-up arrangement follow-up arrangement follow-up arrangement supplier supplier supplier supplier supplier

PROPOSED INSTRUMENTS

Internal electronic mail External electronic mail EDI (traditional and/or owner) Integrated systems, data bases CAD 3D Bar codes, automized identification Filter for stabilization of performed purchases and to be performed Differential control for supply Clear procedures and regulations Transfer channels of know-how within the company Training and "comissioning" of procedures and systems Experience, capacity and preparation of procurement personnel Program adequate time terms Engineering must comply with time terms; apply resources Include float of security proactive attitude Apply a competent and valueable engineering Clearly know equipment and supplies to purchase (which is the objective market) Specification check lists Standarize design where posible Team work, work having the interests of the project in mind Adequate inspection, general preparation, technical knowledge at supplier level Simplify and subcontract to accelerate Prenegotiations, time terms and conditions with supplier (s) Avoid innecesary changes Purchase in order to facilitate reception, contracts, and follow-up Leasing of services Preestablished prices for freight, services Follow-up of targets internal to the project Follow-up of targets external to the project Follow-up activities of the supplier (emphasizing on drawings) Check up systems, quality asurance, ISO Previous experience, suppliers historial Study of the market of suppliers, "picture" of the supplier Tight contact with supplier (s) Promote joint ventures domestic / foreigners

228

26-28 July 1999, University of California, Berkeley, CA, USA

Evaluation and Improvement of the Procurement Process in Construction Projects

Direction of Improvement (Selected from Table 3)

Area 1

Strategies Instruments

Area 3

Area 2 Area 4

Instrument 2 Area 3 Instrument 1 Area 4 Objective 6 PS % Objective 5 PS % % Objective 7 Instrument 2 Area 4

Improvement strategies for (HOW's) Instruments for Analysis of the Procurement process (From Phase IV) (WHAT's)

Relevance (weight)

the procurement process

Instrument 1 Area 1

Instrument 2 Area 1

Instrument 1 Area 2 PS % Objective 3

Problems area 1

problem 1 problem 2

X1 X2 X3 X4 X5 Y Y Y Y Z Z Z Z Objective 1 Objective 2 Objective 4 PS %

PROBLEMS

ANALYSIS INSTRUMENTS

Problems area 2

problem 3 problem 4

Problems area 3 Affected areas

problem 5

NONCONFORMITY REPORTS

ResponsIble for nonconformity Main problems Given or proposed solutions EFFECT 1 Cause 1 Cause 2 Cause 3 Cause 4

CAUSE - EFFECT ANALYSIS

PRODUCED EFFECT 2 PRODUCED

Objectives for instruments

Absolute Relevance Relative Relevance

ROOF MATRIX 9 7 5 WEIGHT ARROWS

PS %

PS %

Instrument 1 Area 3

PS

Very Positive Positive Pos & neg Aspects Negative Very Negative

Minimize Strong Medan strong Maximize Median 3 Median Weak Normal

PS : Ponderated Sum of row (by instrument). Xi : obtained by the frequency on how the problem in the respective area is perccived or relevance given by experts. Y,Z : values to be defned, tipically 1.

1 Weak

Figure 4: Selecting Improvement Instruments and Actions CONCLUSIONS Traditional project management systems do not offer a clear view, in global terms, regarding how the procurement process is being developed because the criteria used to control the process is usually too general. This research proposes several instruments to better understand procurement process performance. They are summarized in a methodology that provides guidelines for diagnosis, evaluation, and improvement of the procurement process. If a particular organization is frequently involved in new projects, it is recommended to apply

Proceedings IGLC-7

229

Alarcn, Rivas, and Serpell

the methodology to the company in general, in order to work over the backgrounds and experience of the company. The use of performance indicators for the procurement process is recommended, since they complement the work of traditional systems for management of the procurement process, introducing concepts for continuous improvement and instruments of easy visualization. This research identified key areas of the procurement process that are currently failing in Chilean Projects. The analysis of this information is not exhausted in this paper and it can help to design procurement strategies for new projects. ACKNOWLEDGEMENTS The authors gratefully acknowledge the Universidad Catlica de Chile and the Chilean Fund for Science and Technology, FONDECYT (1980810), for partially supporting their work. REFERENCES Akao, Y. (ed.)(1990). Quality Function Deployment. Product. Press, Cambridge, MA, USA. Alarcn, L. (ed.)(1997). Lean Construction. A.A. Balkema, Rotterdam, The Netherlands, 497 pp. Alarcn, L. (1997b). Modeling Waste and Performance in Construction. In Alarcn L. (ed.), 51-66. Cole, V. (1989). Oakland Project (Class Syllabus). Department of Civil Engineering, University of California, Berkeley. Ballard, G. (1997). Lean Construction and EPC Performance Improvement. Lean Construction, In Alarcn L. (ed.), 79-92. Bell, L. and McCullough, B. (1988). Bar Coding applications in construction. Source Document 33. Construction Industry Institute (CII). Beverley, A. (1994). Electronic communication in the building industry. PMI 25th Ann. Seminar/Symposium. October 17-19, Vancouver, Canada, 310-316. The Business Roundtable (1983). More Construction for the Money: Summary of the Construction Industry Cost Effectiveness Project. Houston, C. (1996). Management of Project Procurement. The McGraw-Hill Companies. College Custom Series. USA, 533 pp. Koskela, L. (1997). Lean production in Construction. In Alarcon L. (ed.), 1-10. O Brien, W.J. (1995) Construction supply chains: Case study, integrated cost and performance analysis. In Alarcon L. (ed.), 187-222. Plemmons, J., and Bell, L. (1995). Measuring Effectiveness for the Materials Management Process. Journal of Management in Engineering. November/December pp. 26-32. Rivas, R. (1998). A Methodology for the Evaluation and Improvement of the Procurement Process in Construction Projects. M.S. Thesis, School of Engrg., Pontificia Universidad Catlica de Chile. Rolstadas, A. (1995). Performance Management. A Business Process Benchmarking Approach. Chapman & Hall, London. Stukhart, G. (1995). Construction Materials Management. Marcel Dekker, Inc. USA. 328 pp.

230

26-28 July 1999, University of California, Berkeley, CA, USA

You might also like

- Progress and Development of Information and Communication Technologies in HospitalityDocument19 pagesProgress and Development of Information and Communication Technologies in HospitalityDiana KudosNo ratings yet

- Challenges of Implementing World Class Manufacturing Techniques in Zimbabwe Zimwara and MbohwaDocument12 pagesChallenges of Implementing World Class Manufacturing Techniques in Zimbabwe Zimwara and MbohwaFatimah KhanNo ratings yet

- Rolls Royce SWOT AnalysisDocument1 pageRolls Royce SWOT Analysisbeat_nmmNo ratings yet

- Customer Centric SCMDocument10 pagesCustomer Centric SCMWilliam RebarickNo ratings yet

- The 4Ps of InnovationDocument9 pagesThe 4Ps of Innovationpavie raja100% (1)

- 2.changing Challenges For The Operations - Engineering Managers-1Document34 pages2.changing Challenges For The Operations - Engineering Managers-1b00199916No ratings yet

- A&D Supply ChainDocument12 pagesA&D Supply ChainVeera Lokesh AyireddyNo ratings yet

- 2004 Assessing Core Intangible ResourcesDocument13 pages2004 Assessing Core Intangible Resourceslengocthang100% (1)

- Analysis of The Use of E-Procurement in The Public and Private Sectors of The UK Construction IndustryDocument18 pagesAnalysis of The Use of E-Procurement in The Public and Private Sectors of The UK Construction IndustryCedric CheungNo ratings yet

- Rolls Royce Mind The GapDocument25 pagesRolls Royce Mind The Gapmarketfolly.comNo ratings yet

- Analysis of Everglo Manufacturer Case ScenarioDocument6 pagesAnalysis of Everglo Manufacturer Case ScenariostanleyNo ratings yet

- ProposalFinal 2Document17 pagesProposalFinal 2Amany HassanNo ratings yet

- Qualitative and Quantitative Analysis of BMW GroupDocument70 pagesQualitative and Quantitative Analysis of BMW GroupSyeda TasleemNo ratings yet

- Eisenhardt 1989 SummaryDocument9 pagesEisenhardt 1989 SummaryAdelson NascimentoNo ratings yet

- Applications of Operations Research in The Air Transport IndustryDocument26 pagesApplications of Operations Research in The Air Transport IndustryP.Umasankar SubudhiNo ratings yet

- Marketing Management (PDFDrive - Com) P. 65 PDFDocument306 pagesMarketing Management (PDFDrive - Com) P. 65 PDFFayez ShriedehNo ratings yet

- The Pros and Cons of Outsourcing Logistic Functions Among Manufacturing Firms in Southwest, NigeriaDocument9 pagesThe Pros and Cons of Outsourcing Logistic Functions Among Manufacturing Firms in Southwest, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Evolution of The Innovation Process: From Research To Development To Actual InnovationDocument7 pagesThe Evolution of The Innovation Process: From Research To Development To Actual InnovationPaolo BarbatoNo ratings yet

- Strategic Management of British AirwaysDocument23 pagesStrategic Management of British AirwaysKADİR KOÇNo ratings yet

- Shashank Yadvendra (19035322) MBA Sheffield Hallam UniversityDocument23 pagesShashank Yadvendra (19035322) MBA Sheffield Hallam Universityshashankyadav100% (2)

- Aviation and Climate Change IATADocument2 pagesAviation and Climate Change IATAChinmai Hemani100% (1)

- Dissertation Study On The Airline IndustryDocument91 pagesDissertation Study On The Airline IndustryNeeyorNo ratings yet

- Starting Technology Based New Venture: Chapter TwoDocument37 pagesStarting Technology Based New Venture: Chapter TwoAnuka YituNo ratings yet

- Libro - Building A Project-Driven Enterprise - How To Slash Waste and Boost Profits Through Lean Project Management (2002) PDFDocument384 pagesLibro - Building A Project-Driven Enterprise - How To Slash Waste and Boost Profits Through Lean Project Management (2002) PDFtlatuani1000No ratings yet

- Assessment Guide MK7041 2020 21 Component 1 - Managing Inward Value ChainsDocument8 pagesAssessment Guide MK7041 2020 21 Component 1 - Managing Inward Value Chainsmanpreet kaurNo ratings yet

- Employees Come FirstDocument4 pagesEmployees Come FirstLeonWilfanNo ratings yet

- Determinants of Sustainability Reporting A Review of Results, TrendsDocument17 pagesDeterminants of Sustainability Reporting A Review of Results, TrendsramiraliNo ratings yet

- Global Value ChainsDocument5 pagesGlobal Value ChainsAmrit KaurNo ratings yet

- PD3 Case Study November 2016Document20 pagesPD3 Case Study November 2016Anonymous 8ayfd1HmNo ratings yet

- Literature Review On Property Management SystemDocument4 pagesLiterature Review On Property Management Systempym0d1sovyf3No ratings yet

- Achieving Value For Money (VFM) in Construction ProjectsDocument11 pagesAchieving Value For Money (VFM) in Construction Projectsolatos4jesusNo ratings yet

- A Solution For Cross-Docking Operations Planning For Cross-Docking Operations PlanningDocument7 pagesA Solution For Cross-Docking Operations Planning For Cross-Docking Operations PlanningCem YuceltenNo ratings yet

- An Approach For Condition Monitoring of Rolling Stock Sub-SystemsDocument12 pagesAn Approach For Condition Monitoring of Rolling Stock Sub-SystemsDamigo DiegoNo ratings yet

- Ajmal, Et Al., 2019Document22 pagesAjmal, Et Al., 2019states mphinyaneNo ratings yet

- Strategic Dimensions of Maintenance Management: Albert H.C. TsangDocument33 pagesStrategic Dimensions of Maintenance Management: Albert H.C. TsanghuseNo ratings yet

- Anderson SlidesDocument28 pagesAnderson Slides11zhengNo ratings yet

- 04.CNOOC Engages With Canadian Stakeholders PDFDocument14 pages04.CNOOC Engages With Canadian Stakeholders PDFAdilNo ratings yet

- The Impact of Green Supply Chain Management Practices On Firm Performance: The Role of Collaborative CapabilityDocument47 pagesThe Impact of Green Supply Chain Management Practices On Firm Performance: The Role of Collaborative Capabilityadyatma taufiqNo ratings yet

- CIB8942Document6 pagesCIB8942Shepherd NhangaNo ratings yet

- RFP For Jet Airways v2Document17 pagesRFP For Jet Airways v2rahulalwayzzNo ratings yet

- Group 3 WESCODocument18 pagesGroup 3 WESCOGaurav ChoukseyNo ratings yet

- Strategic AlliancesDocument15 pagesStrategic AlliancesAli AhmadNo ratings yet

- B2B Assignment OnDocument20 pagesB2B Assignment OnRaju Kumar SharmaNo ratings yet

- Individual Presentation: International Market Expansion of AstrazenecaDocument12 pagesIndividual Presentation: International Market Expansion of AstrazenecaSami Ur Rehman0% (1)

- Full Text PDFDocument332 pagesFull Text PDFManish Singh100% (1)

- Continental Airlines Case StudyDocument7 pagesContinental Airlines Case Studytimduncan801044No ratings yet

- Postponement Strategy From A Supply Chain PerspectiveDocument26 pagesPostponement Strategy From A Supply Chain PerspectiveakashkrsnaNo ratings yet

- Introduction To Bussiness ReserchDocument60 pagesIntroduction To Bussiness ReserchBiniam MershaNo ratings yet

- Introduction To The Digital Supply Chain of The Future - Technolog PDFDocument3 pagesIntroduction To The Digital Supply Chain of The Future - Technolog PDFCindy Christine NoveraNo ratings yet

- SNOP Framework: Supply Chain Management (MGB LSC 114)Document8 pagesSNOP Framework: Supply Chain Management (MGB LSC 114)Madhav Chowdary TumpatiNo ratings yet

- M.B.A. Export ManagementDocument25 pagesM.B.A. Export Managementrejipaul2No ratings yet

- Technology Diffusion Adoption ProcessDocument20 pagesTechnology Diffusion Adoption ProcessLeah NarneNo ratings yet

- Assignment 1 Project MGMT .HyperloopDocument9 pagesAssignment 1 Project MGMT .HyperloopAmrit AcharyaNo ratings yet

- Pull PlanningDocument58 pagesPull Planninganon_258786007No ratings yet

- Technology ManagementDocument20 pagesTechnology ManagementSWAPNARUN BANERJEENo ratings yet

- Synopsis of The BCG Matrix For Qatar AirlinesDocument4 pagesSynopsis of The BCG Matrix For Qatar AirlinesMd.Ismail HossainNo ratings yet

- Canadian Airlines CaseDocument5 pagesCanadian Airlines CaseSrihari KurupNo ratings yet

- QuesDocument6 pagesQuesCanute McinnisNo ratings yet

- Business Improvement Districts: An Introduction to 3 P CitizenshipFrom EverandBusiness Improvement Districts: An Introduction to 3 P CitizenshipNo ratings yet

- Spare Parts MangmntDocument24 pagesSpare Parts MangmntGopal Singh Parmar100% (1)

- 100 Ways To Motivate OthersDocument37 pages100 Ways To Motivate OthersGopal Singh ParmarNo ratings yet

- Mathematics of LifeDocument9 pagesMathematics of LifeGopal Singh ParmarNo ratings yet

- Got Defeated For Legislature: 1. Lost His JobDocument7 pagesGot Defeated For Legislature: 1. Lost His JobGopal Singh ParmarNo ratings yet

- Power Plant EngineeringDocument91 pagesPower Plant EngineeringknikhileshNo ratings yet

- Improve Your EyesightDocument14 pagesImprove Your EyesightGopal Singh ParmarNo ratings yet

- Puzzle: Find The All Answers and Make The Correct SequenceDocument1 pagePuzzle: Find The All Answers and Make The Correct SequenceGopal Singh ParmarNo ratings yet

- 5G Transport Network Requirements, Architecture and Key TechnologiesDocument27 pages5G Transport Network Requirements, Architecture and Key TechnologiesFreedomNo ratings yet

- Netscreen Concepts and ExamplesDocument476 pagesNetscreen Concepts and ExamplesKeshri SekhonNo ratings yet

- SST-2000 SeriesDocument33 pagesSST-2000 SeriesLeyverMBNo ratings yet

- EnCase Forensics Edition Primer - Getting StartedDocument37 pagesEnCase Forensics Edition Primer - Getting StartedJason KeysNo ratings yet

- Topology of ComputersDocument23 pagesTopology of ComputerssantoshguptaaNo ratings yet

- Pulsar Spare Parts PriceDocument3 pagesPulsar Spare Parts Pricemansoormsk84% (25)

- CNC Programming & Application: Federal TVET Institute Manufacturing Technology Department Addis Abeba EthiopiaDocument58 pagesCNC Programming & Application: Federal TVET Institute Manufacturing Technology Department Addis Abeba EthiopiaGezae MebrahtuNo ratings yet

- Accenture 2014 Celent Claims ABCD Acn Duck Creek Dec14Document28 pagesAccenture 2014 Celent Claims ABCD Acn Duck Creek Dec14Ainia Putri Ayu KusumaNo ratings yet

- Azure 104Document25 pagesAzure 104HjhjhNo ratings yet

- Waaree Corporate PPT - V3Document53 pagesWaaree Corporate PPT - V3Bhushan MalsheNo ratings yet

- Cybot Baseboard LCD SchematicDocument6 pagesCybot Baseboard LCD Schematicapi-584352705No ratings yet

- TSP071 BNV Cctalk Protocol Manual V2 (1) .4Document47 pagesTSP071 BNV Cctalk Protocol Manual V2 (1) .4nost winNo ratings yet

- ISO 9001 - 2015 Awareness Training at PuneDocument1 pageISO 9001 - 2015 Awareness Training at PunematrixmazeNo ratings yet

- Artist II PreampDocument1 pageArtist II PreampSteve MashiterNo ratings yet

- QL 320 TDocument109 pagesQL 320 TSteven SalweyNo ratings yet

- 2 Concrete Works CompuDocument14 pages2 Concrete Works CompuALFONSO RAPHAEL SIANo ratings yet

- XDocument2 pagesXkrimo11No ratings yet

- Quality System Process Map: Customer RequirementsDocument1 pageQuality System Process Map: Customer RequirementsDaniel PradityaNo ratings yet

- Installation Licensing and ActivationDocument46 pagesInstallation Licensing and ActivationnerittoNo ratings yet

- Conversion Rule in ALE - IDOC ScenarioDocument27 pagesConversion Rule in ALE - IDOC ScenariokarthikbjNo ratings yet

- Library Management System Using PHP and MYSQL Database Project ProposalDocument2 pagesLibrary Management System Using PHP and MYSQL Database Project ProposalRick RanteNo ratings yet

- Education Course Catalog enDocument8 pagesEducation Course Catalog enlipasot781No ratings yet

- Classified 2015 01 19 000000Document7 pagesClassified 2015 01 19 000000sasikalaNo ratings yet

- Java For Loop (With Examples)Document12 pagesJava For Loop (With Examples)Redan PabloNo ratings yet

- Adobe PageMakerDocument3 pagesAdobe PageMakerAquarius MGNo ratings yet

- E2E - QoS - Design - Main Ver 0.97Document104 pagesE2E - QoS - Design - Main Ver 0.97Tshego MasegoNo ratings yet

- Inotec Mixer BrochureDocument11 pagesInotec Mixer Brochureyyukin1No ratings yet

- Las Activities q2Document3 pagesLas Activities q2Anna Jane AdanNo ratings yet

- OFBS Enrollment Form v.2Document2 pagesOFBS Enrollment Form v.2Abrera ReubenNo ratings yet

- Positioning The EventDocument16 pagesPositioning The EventStephanie Aira LumberaNo ratings yet