Professional Documents

Culture Documents

The Solar Chimney

Uploaded by

rmsdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Solar Chimney

Uploaded by

rmsdCopyright:

Available Formats

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

The Solar Chimney

Last update

. 2002

Page

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

Contents

1. 2. 3. 3.1. 3.2. 3.3. 3.4. 3.5. 4. 5. 6. 7.

Introduction The use of three old technologies The technology The collector The energy storage The chimney The turbines A 'hydroelectric power station for the desert The prototype in Manzanares Designing large solar chimneys Energy Production Costs References

3 4 6 6 6 7 7 8 8 10 12 14

Author: Schlaich Bergermann und Partner

Structural Consulting Engineers Hohenzollernstrae 1 D- 70178 Stuttgart Telefon + 49 (7 11) 6 48 71 - 0 Telefax + 49 (7 11) 6 48 71 - 66 info@sbp.de http://www.sbp.de sbp gmbh

Last update

. 2002

Page

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

1. Introduction

The future of this earth and mankind substantially depends on our ability to slow down the population increase in the Third World by civilized means. The key is to increase the standard of living, to overcome the inhumane poverty and deprivation.

Yearly average growth of population [%] Corresp. to a doubling in years [a]

14 5

Jord Saud CAN Norw

Energy consumption per capita [kWh/a]

120.000

4,5

100.000 18 4

Keni Iran Syri

North America

USA

3,5

thi Nige

Industrialized Countries

SWE Alge

80.000

23

Eastern Europe

Nied Trin Isra Bulg GB F AUS J CAN USA Nied Tsch GB D CH F J SWE Norw Tsch AUS D

2,5

Ugan gyp Usbe IND

Vene

60.000

35

Rul Peru Mexi Ukra Wei

Western Europe

CH

Saud Trin I

40.000

1,5 70

C Arge Vene I

0,5

0 0

low (65%)

Isra E GR Arge Pole Mexi Wei Rul GR Ukra E C gyp Jord E SWE Iran Developing Countries AUS

Usbe

Alge

20.000

0 20.000 25.000

5.000

medium (25 %)

10.000

15.000

high income ecconomies (10% of the worlds population of 5,5 Billion peoples)

Gross Domestic Product per Capita (US-$)

Fig. 1: Standard of living - energy consumption - population growth To achieve this traditional means will not suffice any longer as exemplified by a "paradoxon": Those countries where agriculture provides more than 20 % of the gross national product are those also stricken by starvation! Development requires mechanization and energy. Energy consumption increases proportionally to the gross national product or prosperity while simultaneously the population growth will decrease exponentially (Fig. 1). Many developing countries possess hardly any energy sources and their population doubles every 15 to 30 years! The results are commonly known: Civil wars and fundamentalism. If these developing countries are provided with only a humane and viable minimum of energy the global energy consumption will drastically increase! Who could supply such an enormous amount of energy without an ecological breakdown (because poor countries cannot afford environmental protection) and without safety hazards (because they are not acquainted with the safety requirements for nuclear power plants) and without a rapid depletion of natural resources at the expense of future generations? The sun! Many of these countries are lavishly provided with solar radiation in their desert areas.

Last update

. 2002

Page

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

This is common knowledge, stated already in Agenda 21 of the Rio-UN-conference, everybody is talking about it, nobody does anything. Why? Because apparently it must be a well-kept secret that large-scale solar energy utilization is possible today and that it is affordable and competitive!

2. The use of three old technologies

Man learned to make active use of solar energy at a very early stage: greenhouses helped to grow food, chimney suction ventilated and cooled buildings and windmills ground corn and pumped water. The solar chimney's three essential elements - glass roof collector, chimney, and wind turbines - have thus been familiar from time immemorial. A solar-thermal chimney simply combines them in a new way (Fig. 2).

Fig. 2: Principle of the solar chimney: glass roof collector, chimney tube, wind turbines. Air is heated by solar radiation under a low circular glass roof open at the periphery; this and the natural ground below it form a hot air collector. Continuous 24 hours-operation is guaranteed by placing tight water-filled tubes under the roof. The water heats up during the daytime and emits its heat at night. These tubes are filled only once, no further water is needed. In the middle of the roof is a vertical chimney with large air inlets at its base. The joint between the roof and the chimney base is airtight. As hot air is lighter then cold air it rises up the chimney. Suction from the chimney then draws in more hot air from the collector, and cold air comes in from the outer perimeter. Thus solar radiation causes a constant updraught in the chimney. The energy this contains is converted into mechanical energy by pressure-staged wind turbines at the base of the chimney, and into electrical energy by conventional generators.

Last update

. 2002

Page

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

A single solar chimney with a suitably large glazed roof area and a high chimney can be designed to generate 100 to 200 MW continuously 24 h a day. Thus even a small number of solar chimneys can replace a large nuclear power station. Solar chimneys operate simply and have a number of other advantages:

The collector can use all solar radiation, both direct and diffused. This is crucial for tropical countries where the sky is frequently overcast. The other major large scale solar-thermal power plants, parabolic through and central receiver systems, which apply concentrators and therefore can use only direct radiation, are at a disadvantage there. Due to the heat storage system the solar chimney will operate 24h on pure solar energy. The water tubes laying under the glass roof absorb part of the radiated energy during the day and release it into the collector at night. Thus solar chimneys produce electricity at night as well. Solar chimneys are particularly reliable and not liable to break down, in comparison with other solar generating plants. Turbines, transmission and generator - subject to a steady flow of air - are the plant's only moving parts. This simple and robust structure guarantees operation that needs little maintenance and of course no combustible fuel. Unlike conventional power stations (and also other solar-thermal power station types), solar chimneys do not need cooling water. This is a key advantage in the many sunny countries that already have major problems with drinking water. The building materials needed for solar chimneys, mainly concrete and glass, are available everywhere in sufficient quantities. In fact, with the energy taken from the solar chimney itself and the stone and sand available in the desert, they can be reproduced on site. Solar chimneys can be built now, even in less industrially developed countries. The industry already available in most countries is entirely adequate for their requirements. No investment in high-tech manufacturing plant is needed. Even in poor countries it is possible to build a large plant without high foreign currency expenditure by using their own resources and work-force; this creates large numbers of jobs and dramatically reduces the capital investment requirement and the cost of generating electricity.

Solar chimneys can convert only a small proportion of the solar heat collected into electricity, and thus have a "poor efficiency level". But they make up for this disadvantage by their cheap, robust construction, and low maintenance costs. Solar chimneys need large collector areas. As economically viable operation of solar electricity production plants is confined to regions with high solar radiation, this is not a fundamental disadvantage, as such regions usually have enormous deserts and unutilized areas. And so "land use" is not a particularly significant factor, although of course deserts are also complex biotopes that have to be protected.

Last update

. 2002

Page

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

3. The technology

3.1. The collector

Hot air for the solar chimney is produced by the greenhouse effect in a simple air collector consisting only of a glass or plastic film covering stretched horizontally two to six meters above the ground. The height of the covering increases adjacent to the chimney base, so that the air is diverted to vertical movement with minimum friction loss. This covering admits the short-wave solar radiation component and retains long-wave radiation from the heated ground. Thus the ground under the roof heats up and transfers its heat to the air flowing radially above it from the outside to the chimney.

3.2.

The energy storage

Water filled black tubes are laid down side by side on the soil under the glass roof collector. They are filled with water once and remain closed thereafter, so that no evaporation can take place. The volume of water in the tubes is selected to correspond to a water layer with a depth of 5 to 20 cm depending on the desired power output characteristics.

glass roof

into the air into the soil and the water tubes into the air

soil

water tubes

soil

Day

Night

Fig. 3: Principle of heat storage underneath the roof using water-filled black tubes. Since the heat transfer between black tubes and water is much larger than that between the ground surface and the deeper soil layers, even at low water flow speed in the tubes, and since the heat capacity of water (4.2 kJ/kg) is much higher than that of soil (0.75 - 0.85 kJ/kg) the water inside the tubes stores a part of the solar heat and releases it during the night, when the air in the collector cools down.

Last update

. 2002

Page

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

3.3.

The chimney

The chimney itself is the plant's actual thermal engine. It is a pressure tube with low friction loss (like a hydroelectric pressure tube or penstock) because of its optimal surface-volume ratio. The upthrust of the air heated in the collector is approximately proportional to the air temperature rise Tcoll in the collector and the volume, (i.e. the height Hc multiplied by the diameter Dc ) of the chimney. In a large solar chimney the collector raises the temperature of the air by about 35 K. This produces an updraught velocity in the chimney of about 15m/s. It is thus possible to enter into an operating solar chimney plant for maintenance without difficulty. Chimneys 1,000 m high can be built without difficulty. The television tower in Toronto, Canada, is almost 600 m high and serious plans are being made for 2,000 metre skyscrapers in earthquake-ridden Japan. But all that is needed for a solar chimney is a simple, large diameter hollow cylinder, not particularly slender, and subject to very few demands in comparison with inhabited buildings. There are many different ways of building this kind of chimney. They are best built freestanding, in reinforced concrete. But guyed tubes, their skin made of corrugated metal sheet, as well as cable-net designs with cladding or membranes are also possible. All the structural approaches are well known and have been used in cooling towers. No special development is needed.

3.4.

The turbines

Using turbines, mechanical output in the form of rotational energy can be derived from the air current in the chimney. Turbines in a solar chimney do not work with staged velocity like a free-running wind energy converter, but as a cased pressure-staged wind turbogenerator, in which, similarly to a hydroelectric power station, static pressure is converted to rotational energy using a cased turbine - in this application installed in a pipe. The power output of a cased pressure-staged turbine of this kind is about eight times greater than that of a speed-stepped open-air turbine of the same diameter. Air speed before and after the turbine is about the same. The output achieved is proportional to the product of volume flow and the fall in pressure at the turbine. With a view to maximum energy yield the aim of the turbine regulation system is to maximize this product under all operating conditions. Blade pitch is adjusted during operation to regulate power output according to the altering airspeed and airflow. If the flat sides of the blades are perpendicular to the airflow, the turbine does not turn. If the blades are parallel to the air flow and allow the air to flow through undisturbed there is no drop in pressure at the turbine and no electricity is generated. Between these two extremes there is an optimum blade setting: the output is maximized if the pressure drop at the turbine is about two thirds of the total pressure differential available.

Last update

. 2002

Page

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

3.5.

A 'hydroelectric power station for the desert '

Solar chimneys are technically very similar to hydroelectric power stations - so far the only really successful large scale renewable energy source: the collector roof is the equivalent of the reservoir, and the chimney of the penstock. Both power generation systems work with pressure-staged turbines, and both achieve low power production costs because of their extremely long life-span and low running costs. The collector roof and reservoir areas required are also comparable in size for the same electrical output. But the collector roof can be built in arid deserts and removed without any difficulty, whereas useful (often even populated) land is submerged under reservoirs. Solar chimneys work on dry air and can be operated without the corrosion and cavitation typically caused by water. They will soon be just as successful as hydroelectric power stations. Electricity yielded by a solar chimney is in proportion to the intensity of global solar radiation, collector area and chimney height. Optimum dimensions can be calculated only by including specific component costs (collector, chimney, turbines) for individual sites. And so plants of different sizes are built from site to site - but always at optimum cost: if glass is cheap and concrete expensive then the collector will be large with a high proportion of double glazing and a relatively low chimney, and if glass is expensive there will be a smaller, largely single-glazed collector and a tall chimney.

4. The prototype in Manzanares

Detailed theoretical preliminary research and a wide range of wind tunnel experiments led to the establishment of an experimental plant with a peak output of 50 kW on a site made available by the Spanish utility Union Electrica Fenosa in Manzanares (about 150 km south of Madrid) in 1981/82, with funds provided by the German Ministry of Research and Technology (BMFT). The aim of this research project was to verify, through field measurements, the performance projected from calculations based on theory, and to examine the influence of individual components on the plant's output and efficiency under realistic engineering and meteorological conditions. To this end a chimney 195 m high and 10 m in diameter was built, surrounded by a collector 240 m in diameter. The plant was equipped with extensive measurement data acquisition facilities. The performance of the plant was registered second by second by 180 sensors. Since the type of collector roof primarily determines a solar chimney's performance costs, different building methods and materials for the collector roof were also to be tested in Manzanares. A realistic collector roof for large-scale plants has to be built 2 to 6 metres above ground level. For this reason the lowest realistic height for a collector roof for large-scale technical use, 2 metres, was selected for the small Manzanares plant. (For output, a roof height of 50 cm only would in fact have been ideal.) Thus only 50 kW could be achieved in Manzanares, but this realistic roof height also permitted convenient access to the turbine at the base of the chimney. This also meant that experimental planting could be carried out under the roof to investigate additional use of the collector as a greenhouse.

Last update

. 2002

Page

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

Fig. 4: Prototype of the solar chimney at Manzanares. The experimental plant in Manzanares operated for about 15,000 hours from 1982 onwards. The following tests were run in the course of the project: In 1986 the structural improvement work that made occasional operational interruptions necessary was completed. After that, from mid 1986 to early 1989 it was possible to run the plant on a regular daily basis, except for a period of four months which was set aside for special measurements and specific modifications. During this 32 month period, the plant ran, fully automatically, an average of 8.9 hours per day for a total of 8611 operating hours. One person at the most was needed for supervision. Thus there is no doubt that solar chimneys can be built, run in the long term and reliably maintained even in countries that are technologically less developed. During the 32 month period, plant reliability was over 95 %. Sporadic storm damage to the old plastic film area of the collector was repaired without switching off the plant. The 5 per cent non-operational period was due to automatic plant switch-off at the weekend when the Spanish grid occasionally failed.

Last update

. 2002

Page

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

5. Designing large solar chimneys

Measurements taken from the experimental plant in Manzanares and solar chimney thermodynamic behaviour simulation programs were used to design large plants with outputs of 200 MW and more. Detailed investigations, supported by extensive wind tunnel experiments, showed that thermodynamic calculations for collector, tower and turbine were very reliable for large plants as well. Despite considerable area and volume differences between the Manzanares pilot plant and a projected 100 MW facility, the key thermodynamic factors are of similar size in both cases. Using the temperature rise and wind speed in the collector as examples, the measured temperature rise at Manzanares was up to 17 K and the wind speed up to 12 metres per second, while the corresponding calculated figures for a 100 MW facility are 35 K and 16 metres per second.

chimney tube

turbine glass collector

Fig. 5: Essential components of a solar chimney: the collector, a flat glass roof, the chimney, a vertical tube supported on radial piers, and the wind turbines at the chimney base. In this way the overall performance of the plant, by day and by season, given the prescribed climate and plant geometry, considering all physical phenomena including single and double glazing of the collector, ground storage, condensation effects and losses in collector, tower and turbine, can be calculated to an accuracy of 5%.

Last update

. 2002

Page

10

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

Structural design of large plants showed that the glazed collector can be used for large plants without major modifications. This was successfully demonstrated in the Manzanares experimental plant, and thus represents a proven, robust and reasonably priced solution. The Manzanares experience also provided cost calculation data for the collector.

0,25 m 1000 m

840 m

660 m 0,25 m

0,32 m

500 m

0,41 m

0,53 m

0,68 m

0,87 m 0,99 m

wall thickness

section

170 m

Fig. 5: Wall thickness of a chimney tube 1.000 m high and 170 m in diameter and a 1.000m chimney tube under construction. Reliable statical and dynamic calculation and construction for a chimney about 1,000 metres high (slenderness ratio = height : diameter < 10) is possible without difficulty today. With the support of a German and an Indian contractor especially experienced in building cooling towers and chimneys, manufacturing and erection procedures were developed for various types in concrete and steel and their costs compared. The type selected is dependent on the site. If sufficient concrete aggregate materials are available in the area and if anticipated seismic acceleration is less than g/3, then reinforced concrete tubes are the most suitable. Both conditions are fulfilled world-wide in most arid areas suitable for solar chimneys. Detailed statical/structural research showed that it is appropriate to stiffen the chimney at about four levels with cables arranged like spokes within the chimney, so that thinner walls can be used. Detailed research by the Indian contractor showed that it is possible to build such tall concrete chimneys in India, and that construction would be particularly reasonable in terms of cost.

Last update

. 2002

Page

11

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

For mechanical design, it was possible to use a great deal of experience with wind power stations, cooling tower ventilation technology and the Manzanares solar chimney's years of operation. Although for plants up to approx. 100 MW one vertical axis turbine at the base of the tower is seen as the correct solution, the cost estimate was based on horizontal axis turbines arranged concentrically at the periphery of the tower, in order to be able to utilize turbines of existing sizes - particularly with regard to rotor diameter. Aerodynamic design for entrance area and turbines was achieved by means of wind tunnel airflow experiments. As already shown, there is no physical optimum for solar chimney cost calculations, even when meteorological and site conditions are precisely known. Tower and collector dimensions for a required electrical energy output can be determined only when their specific manufacturing and erection costs are known for a given site.

6. Energy Production Costs

With the support of construction companies, the glass industry and turbine manufacturers a rather exact cost estimate for a 200 MW solar chimney could be compiled. We asked a big utility "Energie Baden-Wrttemberg" (formerly EVS/BW) to determine the energy production costs compared to coal- and combined cycle power plants based on equal and common methods.

Solar Chimney

Coal Pf/kWh 3,89 3,87 0,78 0,92 0,27 1,16 0,69 11,58

2 x C.C. Pf/kWh 2,12 6,57 0,31 0,83 0,12 0,03 0,37 10,35

Proportion of Investment Fuel Personnel Repair Insurance Other running costs Tax Total

Commissioning in 2001 Power: 400 MW Running hours: 7445 h/a Yearly energy: 2978 GWh

Pf/kWh 11,32 0,00 0,10 0,52 0,01 0,00 2,10 14,05

Own investment 1/3 at 13,5% External investment 2/3 at 8% Total interest rate: 10,67% Tax rate: 30%

Table 1: Comparison between the energy production costs of a solar chimney (2 solar chimneys with 200 MW each) and 400 MW coal and combined cycle power plants according to the present business managerial calculations. Purely under commercial aspects with a gross interest rate of about 11 % and a construction period of 4 years during which the investment costs increase already by 30 %(!) electricity from solar chimneys is merely 20 % more expensive than that from coal. In case of the solar chimney the interest on the fix investment governs the price of electricity, whereas in the case of fossil fuel power plants the variable fuel costs are the deciding factor.

Last update

. 2002

Page

12

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

By just reducing the interest rate to 8 % electricity from solar chimneys would become competitive today. In low-wage-countries the costs will decrease further especially those of the glass roof collector which alone amounts to 50 % of the overall costs. On the other hand there are a number of advantages: No ecological harm and no consumption of resources, not even for the construction. Solar chimneys predominantly consist of concrete and glass which are made from sand and stone plus self-generated energy. Consequently in desert areas - with inexhaustible sand and stone - solar chimneys can reproduce themselves. A truly sustainable source of energy!

20,00 18,00 Running cost: 16,00

S.C.: Coal: C.C.: 0,63 Pf/kWh 7,00 Pf/kWh 7,86 Pf/kWh

Energy Cost [Pf/kWh]

14,00 12,00 10,00 8,00 6,00 4,00 2,00 0,00 0

Solar Chimney

Result: EVS/BW/SBP

Coal Power Plant

Result: EVS/BW/SBP

Combined Cycle [C.C.]

Result: EVS/BW/SBP

10

12

14

16

18

Interest Rate [%]

Fig. 6: Energy production costs from solar chimneys, coal and combined cycle power plants depending on the interest rate. The (high) investment costs are almost exclusively due to labour costs. This creates jobs, and a high net product for the country with increased tax income and reduced social costs (= human dignity, social harmony), and in addition no costly imports of coal, oil, gas which is especially beneficial for the developing countries releasing means for their development. We have no choice but to do something for the energy consent, the environment and above all for the billions of underprivileged people in the Third World. But we should not offer them hand-outs, a multiple of which we deceitfully regain by imposing a high interest rate on their debt. Instead we should opt for global job sharing. If we buy solar energy form Third World countries, they can afford our products. A global energy market with large scale solar energy generation supplementing substantially hydropower, fossil and nuclear fuels is not an utopian dream! Therefore, now it is absolutely essential to build and operate a large solar chimney.

Last update

. 2002

Page

13

The Solar Chimney

Schlaich Bergermann und Partner

Structural Consulting Engineers

7. References

[1] Schlaich, J. Das Aufwindkraftwerk: Strom aus der Sonne. Stuttgart: Deutsche Verlagsanstalt, 1994, ISBN 3-421-03074-X. [2] Schlaich, J.; Schiel, W.; Friedrich, K. Abschlussbericht Aufwindkraftwerk: bertragbarkeit der Ergebnisse von Manzanares auf grere Anlagen. BMFT-Foerderkennzeichen 03242490. Schlaich Bergermann und Partner 1990. [3] Becker, M.; Meinecke, W. Solarthermische Anlagen-Technologien im Vergleich. Springer-Verlag, Berlin, Heidelberg, New York, 1992. [4] VDEW Vereinigung deutscher Elektrizittswerke: Stromerzeugungskostenvergleich 1990 in Betrieb gehender groer Kern- und Steinkohlekraftwerksblcke. [5] Heise, O. Schadensvermeidung. Ein Weg zur Abschtzung der externen Kosten der Energieversorgung. BWK, Band 45, 1993, Nr. 3.

Last update

. 2002

Page

14

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- RESUME MMR Updated On Feb 08 2018 PDFDocument11 pagesRESUME MMR Updated On Feb 08 2018 PDFKhanekar VaibhavNo ratings yet

- Affiliated With University of Engineering & Technology TaxilaDocument18 pagesAffiliated With University of Engineering & Technology TaxilaSohail KhanNo ratings yet

- Solar Heat For Industrial Processes: Detailed Papers To Newsletter No. 1Document15 pagesSolar Heat For Industrial Processes: Detailed Papers To Newsletter No. 1jhongreenNo ratings yet

- Comparative Analysis of Solar Thermal Cooling and Solar Photovoltaic Cooling SystemsDocument7 pagesComparative Analysis of Solar Thermal Cooling and Solar Photovoltaic Cooling SystemsSagarNo ratings yet

- 10kWel SOLAR ORGANIC RANKINE CYCLE SYSTEM FOR BRAZILDocument10 pages10kWel SOLAR ORGANIC RANKINE CYCLE SYSTEM FOR BRAZILMarcel Senaubar AlvesNo ratings yet

- Milton Margai College Assignment on Solar Energy and Pure SubstancesDocument11 pagesMilton Margai College Assignment on Solar Energy and Pure SubstancesTheophilus WilliamsNo ratings yet

- New Renewables for Power: Wind, Solar, Geothermal & MoreDocument16 pagesNew Renewables for Power: Wind, Solar, Geothermal & MoreSanketDhande100% (3)

- Yuri Waterbasedwindows PDFDocument26 pagesYuri Waterbasedwindows PDFRenata MansueloNo ratings yet

- Thermodynamic Design and Optimization of An Integrated Solar Combined Cycle (ISCC) Power Plant Using Heat Recovery Steam Generators (HRSG) .Document61 pagesThermodynamic Design and Optimization of An Integrated Solar Combined Cycle (ISCC) Power Plant Using Heat Recovery Steam Generators (HRSG) .Andrew RoxburghNo ratings yet

- Prospects and challenges of Solar Power in IndiaDocument72 pagesProspects and challenges of Solar Power in Indiasandeep_singh90No ratings yet

- Mini Project TopicsDocument15 pagesMini Project TopicsKalai SelvanNo ratings yet

- Liquid Desiccant Air ConditionersDocument6 pagesLiquid Desiccant Air ConditionersBurak YükselNo ratings yet

- NREL Plan Cuts Costs of Solar Thermal PowerDocument45 pagesNREL Plan Cuts Costs of Solar Thermal PowerMie DtsNo ratings yet

- Motivation Letter PhD Scholarship Solar Thermal TechnologyDocument7 pagesMotivation Letter PhD Scholarship Solar Thermal TechnologyAli Seid100% (2)

- Unit-II Solar Energy (MCQ) With AnswersDocument17 pagesUnit-II Solar Energy (MCQ) With AnswersSourabh Singh0% (1)

- 9918031015-Manual On Renewable Energy and Green TechnologyDocument77 pages9918031015-Manual On Renewable Energy and Green TechnologyKaruppusamyNo ratings yet

- An Integrated Energy Storage Scheme For A Dispatchable Solar and Wind Powered Energy SystemDocument13 pagesAn Integrated Energy Storage Scheme For A Dispatchable Solar and Wind Powered Energy SystemManohar ChamanaNo ratings yet

- Solar DryingDocument15 pagesSolar DryinggetsweetNo ratings yet

- Design and Fabrication of Spice DryersDocument80 pagesDesign and Fabrication of Spice DryersANAND KRISHNAN100% (2)

- Calico PMPDDocument712 pagesCalico PMPDchris-clarke-5915No ratings yet

- ELEC9715 Exam PrepQuestionsDocument25 pagesELEC9715 Exam PrepQuestionsDavid VangNo ratings yet

- Non-Conventional Energy Resouces and UtilisationDocument3 pagesNon-Conventional Energy Resouces and UtilisationThilagavathi KumaranNo ratings yet

- Experiment No.3 Title: Solar Energy DemonstrationDocument6 pagesExperiment No.3 Title: Solar Energy DemonstrationHazem AlsemiriNo ratings yet

- The BRE Innovation Park Some Lessons Learnt From The Demonstration Buildingsdesign and Management of Sustainable Built EnvironmentsDocument25 pagesThe BRE Innovation Park Some Lessons Learnt From The Demonstration Buildingsdesign and Management of Sustainable Built EnvironmentsEman AshrafNo ratings yet

- Status of Solar Thermal-Driven Reverse Osmosis Desalination: Agustín M. Delgado-Torres, Lourdes García-RodríguezDocument10 pagesStatus of Solar Thermal-Driven Reverse Osmosis Desalination: Agustín M. Delgado-Torres, Lourdes García-RodríguezBilal AhmadNo ratings yet

- Non-conventional energy sources and techniquesDocument17 pagesNon-conventional energy sources and techniquesSaidulla MeerNo ratings yet

- Solar Thermal Collectors and Thermal Storage: Dr. Cynthia A. CruickshankDocument55 pagesSolar Thermal Collectors and Thermal Storage: Dr. Cynthia A. CruickshankbehaosziNo ratings yet

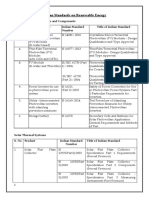

- Indian standards for solar energy systemsDocument2 pagesIndian standards for solar energy systemsCE CERTIFICATENo ratings yet

- Solar Water Heater Guide Helps Consumers Harness the SunDocument20 pagesSolar Water Heater Guide Helps Consumers Harness the Sunfsilassie8012100% (1)

- Nptel - Ac.in Courses 108108078 PDF Chap3 Student Slides03Document51 pagesNptel - Ac.in Courses 108108078 PDF Chap3 Student Slides03Suresh DoosaNo ratings yet