Professional Documents

Culture Documents

Hfot2 PTW 20 02 2012

Hfot2 PTW 20 02 2012

Uploaded by

Georgia PapasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hfot2 PTW 20 02 2012

Hfot2 PTW 20 02 2012

Uploaded by

Georgia PapasCopyright:

Available Formats

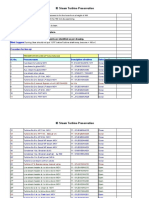

20th February 2012

HFOT 2

Description of work to be carried out: Transfer of water from HFOT 2 to HFOT 4 Isolations 400v isolator 81BHH03.R11 on F.O. Pumphouse 400V brd which feeds the 400V panel of HFOT2 (61BFD72) is locked open 400v mcb Q3 and Q4 in panel 61BFD82 for temp. control VVs tripped and taped

Valves locked shut for HFOT 4 1. Low suction and High suction outflow heaters (oil side). 2. Low suction steam isolating valve and bypass. 3. High suction steam isolating valve and bypass. 4. Low suction condensate drains isolating valve. 5. High suction condensate drains isolating valve. 6. HFOT filling isolating valve. 7. HFO return isolating valve. 8. Dirty Distillate oil supply to HFOT. 9. Sludge suction north side 10. Sludge suction south side and Sludge return. 11. Bottom Heating isolating valve north and south. 12. North bottom heating trap isolating vv 13. South bottom heating trap isolating vv 14. HFOT drain north. 15. HFOT drain south. 16. North cooling ring deluge isol vv. 17. South cooling ring deluge isol vv. 18. Foam njection deluge isol vv. Valves wired shut North and south cooling ring deluges vvs pilot line filling vvs. Foam injection deluges pilot line filling vv. Condensate return to system Trace heatin on high, low suction and filling lines HFO line top vent Tracing manifold 2 stean supply valves(x2)

Cautions: Hot working into or outside of the HFOT is NOT permitted. Entrance inside the HFOT 4 is forbitten. HFO pipe lines are not drained.

You might also like

- Operation - Manual Sondex A/S SFD 6: Customer: Newbuilding No: Order No.: Sondex Order No.: Encl.Document132 pagesOperation - Manual Sondex A/S SFD 6: Customer: Newbuilding No: Order No.: Sondex Order No.: Encl.AlexDor100% (1)

- Cooling Water System, V-EnginesDocument12 pagesCooling Water System, V-EnginesMuhammad Waleed Tariq100% (1)

- 01-HAZOP Worksheet Formaldehyde - (Corrosion)Document8 pages01-HAZOP Worksheet Formaldehyde - (Corrosion)Muhammad Zarif Amir100% (1)

- BOILER #1 Annual Shutdown Job List 15 Shift ADocument3 pagesBOILER #1 Annual Shutdown Job List 15 Shift ANoman NawabNo ratings yet

- Boiler Startup ProcedureDocument9 pagesBoiler Startup ProcedureKUNALJAYNo ratings yet

- Hydraulic Test of Boilerof 210 MW Set SpecificationDocument7 pagesHydraulic Test of Boilerof 210 MW Set SpecificationAhemadNo ratings yet

- Activities After Unit Shutdown (Short Shutdown 8Hrs To 72 HRS) Stage-1Document2 pagesActivities After Unit Shutdown (Short Shutdown 8Hrs To 72 HRS) Stage-1Shiftinchargeengineer dadri coalNo ratings yet

- Power FailureDocument2 pagesPower FailureSharad IvneNo ratings yet

- Boiler Shutdown ProcedureDocument3 pagesBoiler Shutdown ProcedureKUNALJAYNo ratings yet

- Hydro TestDocument2 pagesHydro TestMuhammad AbbasNo ratings yet

- St-1 Boiler Hydrotest Checklist During Short Shutdown Location: Turbine SideDocument3 pagesSt-1 Boiler Hydrotest Checklist During Short Shutdown Location: Turbine Sidenetygen1No ratings yet

- Furnace Water Cooling SystemDocument18 pagesFurnace Water Cooling Systemashirbad mohantyNo ratings yet

- JFD Installation Manual Online HEAT EXCHANGERDocument9 pagesJFD Installation Manual Online HEAT EXCHANGERJOÃO CARLOS SILVANo ratings yet

- Capitulo 9.Document6 pagesCapitulo 9.Enmanuel GonzalezNo ratings yet

- Fault List of Unit-I Emd-IDocument5 pagesFault List of Unit-I Emd-IMCR RGTPP Khedar, HisarNo ratings yet

- Emergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingDocument4 pagesEmergency Actions Code:Btpp/Turbine/011/Emergency Actions A.Actions To Be Taken in Case of Both CW Pumps TrippingPrakash ChoudharyNo ratings yet

- 5 HRSG 11 12Document7 pages5 HRSG 11 12M Moarraf Naeem100% (1)

- Beverage Cooler: Experiment #9Document17 pagesBeverage Cooler: Experiment #9PrecisioneticaNo ratings yet

- Unit 6 Defect On 20.4.2023Document12 pagesUnit 6 Defect On 20.4.2023operation support IIINo ratings yet

- 300 MW ThermalPower Plant Cold Start UpDocument4 pages300 MW ThermalPower Plant Cold Start Upsunil481100% (1)

- Crude Distillation Unit - OdtDocument32 pagesCrude Distillation Unit - OdtfaresNo ratings yet

- Air Conditioning SystemDocument45 pagesAir Conditioning SystemLeonardo Gómez BernigaNo ratings yet

- Sporlan TXV Inst Service 12 Pgs New VersionDocument12 pagesSporlan TXV Inst Service 12 Pgs New Versionsilentsoldier781344No ratings yet

- Boiler Hydro Static TestDocument1 pageBoiler Hydro Static Testrashm006ranjanNo ratings yet

- Silenciamiento de Martilleo en Un Sistema de CondesamientoDocument9 pagesSilenciamiento de Martilleo en Un Sistema de Condesamientokelvin CarreroNo ratings yet

- 31-9118 Part2Document31 pages31-9118 Part2dreamyson1983No ratings yet

- HP LP HeatersDocument11 pagesHP LP HeatersPrakash ChoudharyNo ratings yet

- To Carry Out Cleanup ActivityDocument4 pagesTo Carry Out Cleanup Activitysarojdubey0107No ratings yet

- Name: Roll No.: Subject: Experiment No: 4Document12 pagesName: Roll No.: Subject: Experiment No: 4Savan PatelNo ratings yet

- FHP - HGRHDocument5 pagesFHP - HGRHdantron9000No ratings yet

- Vaq RaqDocument4 pagesVaq RaqgreismarNo ratings yet

- BFP Walkdown ReportDocument10 pagesBFP Walkdown ReportVijay Raj100% (1)

- Water Still Manual-2Document26 pagesWater Still Manual-2Medo O. EzzatNo ratings yet

- Sporlan ManualDocument12 pagesSporlan ManualsalamrefighNo ratings yet

- Reaper Mechanical and Electrical Operations 129Document16 pagesReaper Mechanical and Electrical Operations 129Yurii ChinovNo ratings yet

- Scope of ErectionDocument4 pagesScope of ErectionJKKNo ratings yet

- Shuang Liang Chiller (H2 Series IOM)Document66 pagesShuang Liang Chiller (H2 Series IOM)Adi KurdiNo ratings yet

- Turbine NotesDocument4 pagesTurbine NotesQuinton Tendai NyamhungaNo ratings yet

- Unit Sart Up 800mwDocument12 pagesUnit Sart Up 800mwVamsiKrishnaNo ratings yet

- Adtps ReportDocument35 pagesAdtps ReportMANASNo ratings yet

- IB Steam Turbine PreservationDocument6 pagesIB Steam Turbine PreservationUdhayakumar VenkataramanNo ratings yet

- FA + Solenoid Valve ICF 15/20 EVRAT: Installation GuideDocument8 pagesFA + Solenoid Valve ICF 15/20 EVRAT: Installation GuideramonmartinezcatalaNo ratings yet

- Alfa Laval PurifierDocument6 pagesAlfa Laval PurifierAnil MenonNo ratings yet

- General Aspect of BoilerDocument28 pagesGeneral Aspect of BoilerGurpreet SinghNo ratings yet

- Hydrotest WaiverDocument4 pagesHydrotest Waiverbidyut100No ratings yet

- Tech Sheet 128Document1 pageTech Sheet 128Sriram RamanujamNo ratings yet

- Precheck Before Light-Up: Drum Metal Temp. DiffDocument12 pagesPrecheck Before Light-Up: Drum Metal Temp. DiffAhemadNo ratings yet

- 39TD Iom - 2Document11 pages39TD Iom - 2Muhammad HerdiNo ratings yet

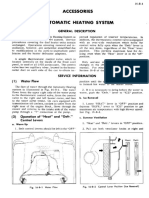

- Accessories Automatic Heating System: General DescriptionDocument4 pagesAccessories Automatic Heating System: General DescriptionLuis Fernando ZampieriNo ratings yet

- Aqua Heat Pumpn ManualDocument38 pagesAqua Heat Pumpn Manualmk saravananNo ratings yet

- Operation Procedures For MDBFPDocument7 pagesOperation Procedures For MDBFPJackSparrow86100% (1)

- Technical Instructions: Form TI410-5 v3Document8 pagesTechnical Instructions: Form TI410-5 v3薛泽绵No ratings yet

- 42 Identifier LOA/PTW NameDocument6 pages42 Identifier LOA/PTW Nameloli2323No ratings yet

- Futera XLF IOM (XLF-IOM-12) - 1Document44 pagesFutera XLF IOM (XLF-IOM-12) - 1Nafiz Ahmed FahimNo ratings yet

- Evans HDC Install Procedure Mack E7 Rev 02feb12Document5 pagesEvans HDC Install Procedure Mack E7 Rev 02feb12juanNo ratings yet

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet