Professional Documents

Culture Documents

KIRK Sep-Calc Software

KIRK Sep-Calc Software

Uploaded by

dhl_tuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KIRK Sep-Calc Software

KIRK Sep-Calc Software

Uploaded by

dhl_tuCopyright:

Available Formats

OIL & GAS PRODUCTION & TREATMENT TECHNOLOGIES

SEP-Calc Software

PROCESS SOLUTIONS

www.kirkprocess.com

ENABLING YOU TO PERFORM A WIDE RANGE OF OIL & GAS SEPARATION TASKS

Sep-Calc Software Modules

Using our proprietary Sep-Calc software, you can simulate the clients operating cases in a variety of separator arrangements to optimise the design concept, vessel size and internal components to meet the target performance characteristics.

Each module has been designed to be a simple, everyday tool for Process Engineers on a stand-alone basis. For this reason we provide the programs in MS-Excel format where the design outputs can be easily printed or saved to electronic pdf format. To encourage the use of the Sep-Calc suite of programs within your organisation there are no complex dongles, security codes or passwords and the License is per Client Site with unlimited users. However, these are licensed products and not free-ware or share-ware and Clients must ensure under the License Terms that the software is securely retained for use in their own organisation only. Much of the design code is viewable as part of a design audit trail if required.

Title

XSA-Calc XSV-Calc RT-Calc ME-Calc XID-Calc KO-Calc HSep-Calc VSep-Calc

Description

Calculates full and partial/segment vessel cross sectional areas. Calculates full and partial vessel volumes for horizontal and vertical vessels. Calculates multi-level liquid volumes and residence times in horizontal and vertical vessels. Mist eliminator sizing estimation for typical mesh, vane and axial cyclone products. Sizing and selection of suitable inlet distributor for vertical and horizontal vessels. Liquid in gas droplet carryover calculator for horizontal and vertical vessels e.g. flare KO drums. Basic horizontal gas/liquid separator sizing with nozzle velocities, pressure drops, level alarm settings, residence times, 2/3 phase options, demister sizing. Basic vertical gas/liquid separator sizing with nozzle velocities, pressure drops, level alarm settings, residence times, 2/3 phase options, demister sizing. for carryover in each phase.

HSep-Calc+ Advanced horizontal gas/liquid separator sizing with Basic features plus performance checks SJ-Calc PP-Calc

Design of fluidized-bed sand jet system and calculation of required headers and nozzles. Sizing of plate coalescing pack for liquid/liquid separation enhancement.

For complex designs or for applications requiring specialist internals we also offer a bespoke design consulting service.

CUSTOMISE DESIGNS TO DELIVER OPTIMUM SOLUTIONS

A TYPICAL PRODUCTION SEPARATOR for oilfield service is illustrated below, but the selection and optimisation of the appropriate technology is determined on a case by case basis.

INLET DEVICES Half-Pipe Bifurcator Tangential Splash Plate Multi-Vane Schoepentoeter Cyclone

FOAM BREAKERS Serpentine Packs Mesh Pads Structured Packs Cyclones Angled Plates Flow Straighteners

MIST ELIMINATORS Mesh Demisters Plain Vane Packs Pocketed Vanes Combination Packs High Surface Packing Axial Cyclones Gas Domes

DISTRIBUTORS Perforated Baffles Slotted Baffles Pipe Distributors Troughs Wave Breakers Gas Outlets

COALESCER PACKS Mesh Pads Dual Media Mesh Corrugated Plates Matrix Packs Plate Packs Liquid Boots

OTHER INTERNALS Vortex Breakers Submerged Weirs Overflow Weirs Oil Buckets Sand Jet Systems Sand Pans Ant-Motion (FPSO)

PROCESS DESIGN EXPERTISE CAN BE CAPTURED AND CONTINUALLY IMPROVED

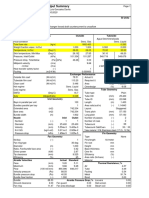

Example program page

Editable headers and footers show your own company name or logo and track revisions

Simple and clear data entry fields transmit design criteria across all calculation sheets for 2-4 cases

Key calculation outputs are highlighted on the summary sheet to assist the designer

Multiple choice selection of various internals types permits rapid optimization of sizing

Additional key data is shown on the summary page with further more detailed data on subsequent pages

For current pricing and further information see our website or contact

The designs presented using Sep-Calc software are not, except where specifically stated otherwise, based on any international design codes or recommended practices, or any operator or engineering companys standards. Rather, they represent, in our opinion, good process engineering practice and as such all design outputs should be checked and verified for any particular application by the customers own qualified personnel. Save as to certain trademarked products, the designs of named internals also are not based on any specific manufacturers rules or guidelines and should be independently checked by the selected supplier prior to manufacture. Many of the design factors and variables used in the Sep-Calc programs may be modified or adapted by the customer to suit his own range of products or view of design methods and margins. This flexibility also allows customization of product names and models used for many internals.

KIRK PROCESS SOLUTIONS LTD KIRK HOUSE 161 PARK CLOSE WALTON-ON-THAMES SURREY KT12 1EW UK

TEL

+44 (0)1932 250300

E-MAIL mkirk@kirkprocess.com WEB www.kirkprocess.com

You might also like

- TW6151A - Wake Freq CalcaDocument2 pagesTW6151A - Wake Freq Calcakkd3No ratings yet

- Dehydration Unit Sizing Chart - 12-13-13Document1 pageDehydration Unit Sizing Chart - 12-13-13Andres Crucetta100% (1)

- Orifice Sizing TemplateDocument2 pagesOrifice Sizing TemplaterajeevjayanathNo ratings yet

- RD 810Document73 pagesRD 810Ashish MishraNo ratings yet

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document15 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Mustafa AhsanNo ratings yet

- Wed Apr 08 12:32:21 2020 Case: TEG SIMULATION - HSC Flowsheet: Case (Main)Document1 pageWed Apr 08 12:32:21 2020 Case: TEG SIMULATION - HSC Flowsheet: Case (Main)IBIKUNLENo ratings yet

- PSV-1203 - 3632-I-DS-31001 WorkingDocument1 pagePSV-1203 - 3632-I-DS-31001 Workinganamaria ursuNo ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasNo ratings yet

- Instrument Process Datasheet (IPDS)Document3 pagesInstrument Process Datasheet (IPDS)Vraja KisoriNo ratings yet

- Selection of Separator With BootDocument2 pagesSelection of Separator With BootMaryJane Ayisha Sado-ObahNo ratings yet

- Separator Sizing SpreadsheetDocument10 pagesSeparator Sizing SpreadsheetEmmanuel ByensitaNo ratings yet

- GBH Enterprises, LTD.: GBHE-PEG-RXT-806Document7 pagesGBH Enterprises, LTD.: GBHE-PEG-RXT-806Sankar SasmalNo ratings yet

- Instrucalc ViDocument25 pagesInstrucalc ViNorberto Soto100% (1)

- Engineering Units ConverterDocument19 pagesEngineering Units Convertertitou_d8638No ratings yet

- Compressor Settle Out PressureDocument1 pageCompressor Settle Out PressureAhmed GattoufiNo ratings yet

- Template (Vessel Sizing-2phase)Document2 pagesTemplate (Vessel Sizing-2phase)mNo ratings yet

- Gbhe-Peg-015 Practical Guide On The Reduction of DiscDocument87 pagesGbhe-Peg-015 Practical Guide On The Reduction of DiscjrfmlNo ratings yet

- Hydraulics Basis OPALDocument13 pagesHydraulics Basis OPALGoutam GiriNo ratings yet

-  Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)Document16 pages Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)KalpeshJadhavNo ratings yet

- Scale-Up of Chemical Engineering Process: Prof H R ShahDocument27 pagesScale-Up of Chemical Engineering Process: Prof H R Shahatgtegtrhrh100% (1)

- Engineering Design Guideline-Hydrotreating Rev 02 WebDocument32 pagesEngineering Design Guideline-Hydrotreating Rev 02 WebPham TinNo ratings yet

- Volume and Wetted Area of Partially Filled Horizontal VesselsDocument11 pagesVolume and Wetted Area of Partially Filled Horizontal VesselsMelvin MagbanuaNo ratings yet

- MP Separator1Document2 pagesMP Separator1ToyinNo ratings yet

- GBH Enterprises, LTD.: GBHE-PEG-MAS-601Document48 pagesGBH Enterprises, LTD.: GBHE-PEG-MAS-601rahulNo ratings yet

- EmersonDocument21 pagesEmersoncrustytheclown99No ratings yet

- Natural Gas Liquids Recovery Processes in Natural Gas ProcessingDocument27 pagesNatural Gas Liquids Recovery Processes in Natural Gas ProcessingVictor Ali MentaNo ratings yet

- 3-Phase Separator Sheet (GPSA)Document12 pages3-Phase Separator Sheet (GPSA)WickyNo ratings yet

- Petronas Design Manual: Column SizingDocument10 pagesPetronas Design Manual: Column SizingHazizi AkmarNo ratings yet

- ProMax PipeDocument23 pagesProMax PipechenguofuNo ratings yet

- Distillation Column Complete DesignDocument59 pagesDistillation Column Complete DesignViswanath KapavarapuNo ratings yet

- Orifice Plate Calculator Pressure Drop CalculationDocument6 pagesOrifice Plate Calculator Pressure Drop Calculationlutfi awnNo ratings yet

- Steam CoilDocument6 pagesSteam CoilMyung Ho SynNo ratings yet

- Design BasisDocument1 pageDesign BasismuhdqasimNo ratings yet

- Cvts - Tag No. Mpt-tv-4161Document2 pagesCvts - Tag No. Mpt-tv-4161biswasdipankar05No ratings yet

- 3Ph Vert Sep 2010 Weir VerA FPS PDFDocument5 pages3Ph Vert Sep 2010 Weir VerA FPS PDFhaiderNo ratings yet

- Diseño Aeroenfriador para Agua Desmineralizada 66 Tubos - 2 PassesDocument25 pagesDiseño Aeroenfriador para Agua Desmineralizada 66 Tubos - 2 PassesLuis AlexanderNo ratings yet

- Vertical KO Drum Sizing (Ver 1.0.0) : 1.0 DescriptionDocument21 pagesVertical KO Drum Sizing (Ver 1.0.0) : 1.0 Descriptionrameshkarthik810No ratings yet

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801No ratings yet

- Three Phase Separator Sizing Overflow WeirDocument3 pagesThree Phase Separator Sizing Overflow WeirDazzy 265No ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- 15-501-EP-RP-003 - Rev.3 (Blowdown and Vent Study)Document238 pages15-501-EP-RP-003 - Rev.3 (Blowdown and Vent Study)Umair A. KhanNo ratings yet

- Rho v2Document1 pageRho v2Myung Ho SynNo ratings yet

- Skills For Process Engineer Sr. No - Technical SkillsDocument2 pagesSkills For Process Engineer Sr. No - Technical SkillsAnonymous QSfDsVxjZNo ratings yet

- Installing Chemcad Building A Spreadsheet Inputting Data: Process Design Laboratory Fall 15Document36 pagesInstalling Chemcad Building A Spreadsheet Inputting Data: Process Design Laboratory Fall 15Justin D. BrownNo ratings yet

- Overview of PV EliteDocument35 pagesOverview of PV EliteVishaka ThekkedathNo ratings yet

- Flare Stack Design PDF ReportDocument2 pagesFlare Stack Design PDF Reportrutuja100% (2)

- Benzene: Benzene Nameplate+ Capacity+kt/yr No.+of+++++ CompaniesDocument3 pagesBenzene: Benzene Nameplate+ Capacity+kt/yr No.+of+++++ CompaniesShitalbioNo ratings yet

- Korf ManualDocument85 pagesKorf Manualzubair1951No ratings yet

- Pump Sizing CalculationDocument6 pagesPump Sizing CalculationIBIKUNLENo ratings yet

- Thermosyphon Reboiler Hydraulics: ResultDocument5 pagesThermosyphon Reboiler Hydraulics: ResultVaishnavi RaghavNo ratings yet

- Excess Flow ValveDocument2 pagesExcess Flow ValveSyed Waqas HaiderNo ratings yet

- Hydraulic Study of GRE Piping Using Pipenet SimulationDocument5 pagesHydraulic Study of GRE Piping Using Pipenet SimulationpsycopaulNo ratings yet

- Unilab Cold Storage: Over 300 Customers in 50 CountriesDocument2 pagesUnilab Cold Storage: Over 300 Customers in 50 CountriesUnilabNo ratings yet

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- 00000-Jds-003 (Level Trans DS) Rev 0Document4 pages00000-Jds-003 (Level Trans DS) Rev 0sithulibraNo ratings yet

- PSV Releiving TempDocument3 pagesPSV Releiving TempOthman Mat YamanNo ratings yet