Professional Documents

Culture Documents

Electro Pneumatic Adanced Level Workbook

Electro Pneumatic Adanced Level Workbook

Uploaded by

arufaizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electro Pneumatic Adanced Level Workbook

Electro Pneumatic Adanced Level Workbook

Uploaded by

arufaizCopyright:

Available Formats

Electropneumatics Advanced Level

Workbook TP 202

CD-ROM included

Festo Didactic 541091 en

Intended use

The Festo Didactic Learning system has been developed and produced solely for vocational and further training in the field of automation and technology. The training company and/or instructor need to ensure that trainees observe the safety precautions specified in this workbook. Festo Didactic hereby disclaims any legal liability for damages or injury to trainees, the training company and/or other parties, which may occur during the use/application of this equipment set other than in a training situation and unless such damages are caused with intention or through gross negligence on the part of Festo Didactic.

Order No.: Status: Authors: Editor: Graphics: Layout:

541091 04/2005 M. Pany, S. Scharf Frank Ebel Doris Schwarzenberger 10/2005

Festo Didactic GmbH & Co. KG, 73770 Denkendorf, Germany, 2005 Internet: www.festo-didactic.com e-mail: did@festo.com

The copying, distribution and utilisation of this document as well as the communication of its contents to others without express authorisation is prohibited. Offenders will be held liable for the payment of damages. All rights reserved, in particular the right to carry out patent, utility model or ornamental design registration. Parts of this documentation may be copied by the authorised user exclusively for training purposes.

Festo Didactic GmbH & Co. KG 541091

Contents

Preface ______________________________________________________________ 5 Introduction__________________________________________________________ 7 Notes on safety and operation ___________________________________________ 9 Technology packages for electropneumatics (TP200) _______________________ 11 Training aims of Advanced Level (TP202) _________________________________ 13 Allocation of training aims and exercises _________________________________ 15 Equipment set Advanced Level (TP202) _________________________________ 17 Allocation of equipment and exercises ___________________________________ 21 Methodological help for the trainer ______________________________________ 23 Methodological structure of the exercises_________________________________ 25 Designation of equipment _____________________________________________ 26 Contents of the CD-ROM _______________________________________________ 27 Equipment set Basic Level (TP201) _____________________________________ 29 Training aims Basic Level (TP201)______________________________________ 30

Part A Exercises Exercise 1: Realising a diverting device ___________________________________A-3 Exercise 2: Insertion of drinks bottles ___________________________________A-15 Exercise 3: Realising a selection station _________________________________A-23 Exercise 4: Machining of key blanks ____________________________________A-39 Exercise 5: Bending of mounting brackets _______________________________A-49 Exercise 6: Realising a filling system ____________________________________A-57 Exercise 7: Bonding of components _____________________________________A-67 Exercise 8: Selecting modes of operation ________________________________A-75 Exercise 9: Machining of key blanks and the use of an EMERGENCY-STOP function ______________________A-85 Exercise 10: Bending of mounting brackets and the use of an EMERGENCY-STOP function______________________A-95 Exercise 11: Conveying bars of chocolate and the use of an EMERGENCY-STOP function____________________ A-103 Exercise 12: Eliminating a fault on a machining station ___________________ A-113

Festo Didactic GmbH & Co. KG 541091

Contents

Part B Fundamentals

Part C Solutions Exercise 1: Realising a diverting device ___________________________________C-3 Exercise 2: Insertion of drinks bottles ___________________________________C-13 Exercise 3: Realising a selection station _________________________________C-21 Exercise 4: Machining of key blanks ____________________________________C-37 Exercise 5: Bending of mounting brackets________________________________C-47 Exercise 6: Realising a filling system ____________________________________C-57 Exercise 7: Bonding of components _____________________________________C-67 Exercise 8: Selecting modes of operation ________________________________C-75 Exercise 9: Machining of key blanks and the use of an EMERGENCY-STOP function ______________________C-85 Exercise 10: Bending of mounting brackets and the use of an EMERGENCY-STOP function______________________C-95 Exercise 11: Conveying bars of chocolate and the use of an EMERGENCY-STOP function_____________________C-107 Exercise 12: Eliminating a fault on a machining station ____________________C-117

Part D Appendix Organiser _________________________________________________________ D-2 Assembly technology ________________________________________________ D-3 Plastic tubing_______________________________________________________ D-4 Data sheets Circuit diagrams

Festo Didactic GmbH & Co. KG 541091

Preface

Festo Didactics Learning System for Automation and Technology is orientated towards different training and vocational requirements and is therefore structured into the following training packages: Basic packages to provide technology-spanning basic knowledge Technology packages to address the major subjects of open and closed-loop technology Function packages to explain the basic functions of automated systems Application packages to facilitate vocational and further training based on actual industrial applications The technology packages deal with the following technologies: Pneumatics, electropneumatics, programmable logic controllers, automation using a personal computer, hydraulics, electrohydraulics, proportional hydraulics and handling technology.

Festo Didactic GmbH & Co. KG 541091

Preface

The modular design of the learning system enables applications beyond the limits of the individual packages. For example, to facilitate PLC actuation of pneumatic, hydraulic and electrical drives. All the training packages are of identical structure: Hardware Teachware Software Seminars The hardware consists of didactically designed industrial components and systems. The didactic, methodological design of the teachware is harmonised with the training hardware and comprises: Textbooks (with exercises and examples) Workbooks (with practical exercises, additional information, solutions and data sheets) Overhead transparencies and videos (to create an interesting and lively training environment) Tuition and training media are available in several languages and are suitable for use both in the classroom and for self-tuition. Software is available in the form of computer training programs and programming software for programmable logic controllers. A comprehensive range of seminars dealing with the topics of the technology packages completes the range of vocational and further training available.

Festo Didactic GmbH & Co. KG 541091

Introduction

This workbook is a component part of the Learning System for Automation and Technology of Festo Didactic GmbH & Co. KG. This system provides a solid basis for practice-oriented vocational and further training. Technology package TP200 is comprised exclusively of electropneumatic control systems. Basic Level TP201 is suitable for basic training in electropneumatic control technology and provides knowledge regarding the physical fundamentals of electropneumatics and the function and use of electropneumatic equipment. The equipment set enables you to construct simple electropneumatic control systems. Advanced Level TP202 focuses on further training in electropneumatic control technology. The two equipment sets enable you to construct complex combinational circuits with logic operations of input and output signals and program controls Prerequisite for the assembly of control systems is a fixed workstation using a Festo Didactic profile plate, consisting of 14 parallel T-slots with 50 mm spacing. A shortcircuit protected power supply unit (input: 230 V, 50 Hz, output: 24 V, max. 5 A) is used for DC voltage supply. A mobile, silenced compressor (230 V, maximum 8 bar (800 kPa) can be used for compressed air supply. Working pressure must not exceed a maximum of p = 6 bar (600 kPa). Optimum operational reliability is achieved if the control system is operated unlubricated at a working pressure of p = 5 bar = 500 kPa. The equipment set of Basic Level TP201 is used to construct complete control systems for all of the 12 problem definitions. The theoretical fundamentals to help you understand this collection of exercises can be found in the textbook Electropneumatics Also available are data sheets in respect of the individual devices (cylinders, valves, measuring devices, etc.).

Festo Didactic GmbH & Co. KG 541091

Introduction

Festo Didactic GmbH & Co. KG 541091

Notes on safety and operation

The following advice should be observed in the interest of your own safety: Pressurised air lines that become detached can cause accidents. Switch off supply immediately. Do not switch on compressed air until tubing is securely connected. Caution! Cylinders may advance automatically as soon as the compressed air is switched on. Do not operate an electrical limit switch manually during fault finding (use a tool). Observe general safety regulations. (DIN 58126 and VDE 100). With electrical limit switches you need to distinguish between two designs Actuation from the left Actuation from the right. At high piston speeds, limit switches must be approached only in the designated direction of the trip cam of the cylinder. Limit switches must not be actuated from the front. Do not exceed the permissible working pressure (see data sheets). Only use extra-low voltage 24V. All components are equipped with 4 mm safety sockets, i.e. jack plugs. Only use cables with jack plugs for the electrical connections. Pneumatic circuit assembly: Connect devices using the silver-metallic plastic tubing of 4 mm outer diameter, the tubing is plugged into the push-in fitting up to the stop; no need for securing! Releasing of push-in fitting: The tubing can be released by pressing down the releasing ring (disconnection under pressure is not possible!) Switch off compressed air supply and power supply prior to dismantling the circuit.

Festo Didactic GmbH & Co. KG 541091

Notes on safety and operation

The mounting plates of the devices are equipped with mounting variants A to D: Variant A, latching system For lightweight non-loadable devices (e.g. directional control valves). Simply clip the device into the slot in the profile plate. Devices can be released by pressing the blue lever. Variant B, rotary system Medium weight loadable devices (e.g. actuators). These devices are clamped onto the profile plate by means of T-head bolts. Clamping and releasing is effected by means of the blue knurled nut. Variant C, screw system For heavy loadable devices rarely removed from the profile plate (e.g. On/off valves with filter regulating valve). These components are mounted by means of socket head screws and T-head bolts. Variant D, plug-in system Lightweight non-loadable devices with locking pins (e.g. indicating devices). These devices are attached by means of plug-in adapters. The data for the individual devices, as specified in the data sheets in Part D, must be observed.

10

Festo Didactic GmbH & Co. KG 541091

Technology package for electropneumatics (TP200)

The technology package TP200 consists of numerous individual training media as well as seminars. The subject matter of this package is exclusively electropneumatic control systems. Individual components from the technology package TP200 may also form a component part of other packages.

Important elements of TP200

Fixed workstation with Festo Didactic profile plate Compressor (230 V, 0.55 kW, maximum 8 bar (800 kPa) Equipment sets or individual components Optional training aids Practical training models Complete laboratory setups

Training documentation Textbooks Basic Level TP201 Fundamentals of pneumatic control technology Maintenance of pneumatic devices and systems Workbooks Basic Level TP201 Advanced Level TP202 Sets of overhead transparencies and overhead projector Magnetic symbols, drawing template WBT Fluid Studio Electropneumatics Cutaway model sets 1 + 2 with storage case Simulation software FluidSIM Pneumatic

Optional Teachware

Festo Didactic GmbH & Co. KG 541091

11

Technology package for electropneumatics (TP200)

Seminars P111 P121 IW-PEP

Fundamentals of pneumatics and electropneumatics Maintenance of and fault finding on pneumatic and electropneumatic systems

Maintenance and servicing in control technology pneumatic and electropneumatic control circuits

Electropneumatics for vocational training

EP-AL

Details of venues, dates and prices can be found in the current seminar planner. Information regarding further training media is available in our catalogues and on the Internet. The Learning System for Automation and Technology is continually updated and expanded. The sets of overhead transparencies, films, CD-ROMs and DVDs as well as technical books are available in several languages.

12

Festo Didactic GmbH & Co. KG 541091

Training aims of Advanced Level (TP202)

To familiarise yourself with the design and function of valve terminals. To be able to use valve terminals in accordance with requirements. To be able to design a displacement-step diagram for a sequence control. To be able to transcribe a function chart to GRAFCET . To be able to solve the problem of signal overlaps in a sequence control according to the group method. To be able to detect signal overlaps in a sequence control. To be able to design a sequence chain using spring-return valves. To be able to design a sequence chain using double solenoid valves. To familiarise yourself with the mode of operation of different proximity sensors. To be able to select proximity sensors in line with parameters. To familiarise yourself with logic operations and to be able to realise these. To familiarise yourself with the design and function of a pneumatic-electrical converter. To familiarise yourself with the options for sensing pressure and time in electropneumatic control systems. To familiarise yourself with the function and possible applications of a time relay with switch-on delay. To familiarise yourself with modes of circuit operation and to be able to design circuits with which single cycle and continuous cycle modes can be realised. To familiarise yourself with the function of an electrical preselect counter and to be able to use this in circuits. To be able to develop and design the EMERGENCY-STOP function for a control system with spring-return valves. To be able to develop and design the EMERGENCY-STOP function for a control system with double solenoid valves. To be able to design a specified motion sequence with EMERGENCY-STOP. To be able to design the EMERGENCY-STOP condition Cylinder remains in its current position during EMERGENCY-STOP. To familiarise yourself with the design and mode of operation of a 5/3-way valve. To be able to replace a 5/3-way solenoid valve with 3/2-way solenoid valves. To be able to integrate the mode of operation resetset. To be able to identify and eliminate faults in complex electropneumatic control systems.

Festo Didactic GmbH & Co. KG 541091

13

Training aims of Advanced Level (TP202)

14

Festo Didactic GmbH & Co. KG 541091

Allocation of training aims and exercises

Exercise Training aims To familiarise yourself with the design and function of valve terminals. To be able to use valve terminals in accordance with requirements. To be able to solve the problem of signal overlap in a sequence control according to the group method. To be able to design a displacementstep diagram for a sequence control. To be able to transcribe a function chart to GRAFCET. To be able to design a sequence chain with spring-return valves. To be able to detect signal overlaps in a sequence control. To be able to design a sequence chain using double solenoid valves. To familiarise yourself with the mode of operation of different proximity sensors. To be able to select proximity sensors in line with parameters. To familiarise yourself with logic operations and to be able to realise these. To familiarise yourself with the options for sensing pressure and time in electro-pneumatic control systems. To familiarise yourself with the design and function of a pneumatic-electrical converter. To familiarise yourself with the function and possible applications of a time relay with switch-on delay.

10

11

12

Festo Didactic GmbH & Co. KG 541091

15

Allocation of training aims and exercises

Exercise Training aim To familiarise yourself with modes of circuit operation and to be able to design circuits with which single cycle and continuous cycle modes can be realised. To familiarise yourself with the function of an electrical preselect counter and to be able to use this in circuits. To be able to develop and design the EMERGENCY-STOP function for a control system with spring-return valves. To be able to develop the EMERGENCY-STOP function for a control system using double solenoid valves. To be able to develop and design a specified motion sequence with EMERGENCY-STOP. To be able to design the EMERGENCYSTOP condition Cylinder remains in its current position during EMERGENCY-STOP. To familiarise yourself with the design and mode of operation of a 5/3-way solenoid valve. To be able to replace a 5/3-way solenoid valve with 3/2 way solenoid valves. To be able to integrate the mode of operation reset. To be able to identify and eliminate faults in complex electropneumatic control systems.

10

11

12

16

Festo Didactic GmbH & Co. KG 541091

Equipment set Advanced Level (TP202)

The equipment set for the advanced level has been compiled for further training in electro-pneumatic control technology. The two equipment sets (TP201 and TP202) contain all the components required to meet the specified training aims and can be expanded as desired with other equipment sets of the Learning System for Automation and Technology. Equipment set Advanced Level (TP202 Order No.: 540713)

Description EMERGENCY-STOP button Non-return valve, piloted Preselect counter, electrical Proximity sensor, capacitive Proximity sensor, inductive Relays, 3-off Signal input plate, electrical Time relay, 2-off Valve terminal with 4 valve slices (MMJJ) Order No. 183347 540715 162355 178575 178574 162241 162242 162243 540696 Quantity 1 2 1 1 1 2 1 1 1

Festo Didactic GmbH & Co. KG 541091

17

Equipment set Advanced Level (TP202)

Equipment set symbols

Description Relay, 3-off

Symbol

A1

12 14

22 24

32 34

42 44

A2 A1

11 12 14

21 22 24

31 32 34

41 42 44

A2 A1

11 12 14

21 22 24

31 32 34

41 42 44

A2

Signal input plate, electrical

11

13 23

21

31

31

41

41

14 13

24 23

32 31

42 41

14 13

24 23

32 31

42 41

14

24

32

42

18

Festo Didactic GmbH & Co. KG 541091

Equipment set Advanced Level (TP202)

Description Time relay, 2-off

Symbol

A1

with switch-on delay

17

27

35

45

A2

18

28

36

46

A1

with switch-off delay

17

27

35

45

A2

18

28

36

46

Preselect counter, electrical

A1

R1

A2

4 2

R2

Proximity sensor, inductive

Proximity sensor, capacitive

EMERGENCY-STOP button

13

21

14

Non-return valve, piloted

22

1 21

Festo Didactic GmbH & Co. KG 541091

19

Equipment set Advanced Level (TP202)

20

Festo Didactic GmbH & Co. KG 541091

Allocation of equipment and exercises

Equipment set TP202

Exercise Equipment Proximity sensor, inductive Proximity sensor, capacitive EMERGENCY-STOP button Relay Pushbutton, electrical, normally open Pushbutton, electrical, normally closed Non-return valve, piloted Valve terminal with 4 valve slices (MMJJ) Preselect counter, electrical Time relay, 2-off 1 1 1 1 1 1 1 1 1 1 1 2 1 1 2 2 6 1 6 1 6 1 6 1 6 1 1 4 1 5 2 1 1 1 6 1 1 6 1 6 3 6 1 1 2 3 4 5 6 7 8 9 10 11 12

Equipment set TP201

Exercise Equipment Cylinder, double-acting One-way flow control valve Pressure sensor Limit switch, electrical Proximity sensor, electronic Proximity sensor, optical Pushbutton, electrical, normally closed contact Relay Manifold On/off valve with filter regulating valve Power supply unit 24V DC 1 1 1 1 1 1 3 1 1 4 1 1 2 1 1 1 1 1 1 2 2 1 2 2 2 2 2 2 2 2 1 2 3 2 2 1 2 2 4 2 4 2 4 2 4 2 4 1 2 1 1 2 1 2 2 2 2 2 2 2 2 4 2 4 1 2 2 4 1 2 3 4 5 6 7 8 9 10 11 12

4 1 1

5 1 1

3 1 1

3 1 1

Festo Didactic GmbH & Co. KG 541091

21

Allocation of equipment and exercises

22

Festo Didactic GmbH & Co. KG 541091

Methodological help for the trainer

Training aims The overall aim of this collection of exercises is the systematic design of circuit diagrams and practical assembly of a control system on a profile plate. This direct interaction of theory and practice ensures quick progress with learning. The detailed training aims are documented in the table. Actual individual training aims are allocated to each problem and major training aims are shown in brackets. Time required The time required to work through a problem depends on the trainees prior knowledge. Skilled workers in the engineering and electrical fields require approximately 2 weeks. Technicians or engineers require approximately 1 week. Components of the equipment set The book of exercises and equipment set are harmonised. You will require the components of the equipment set for Basic Level TP 201 and Advanced Level TP202. Each of the Advanced Level exercises can be assembled on a profile plate. For exercise 11 you will require an additional electrical input or will need to assemble the circuit in a different form. Representation Abbreviated notation and motion diagrams are used for the represention of motion sequences and switching statuses.

Festo Didactic GmbH & Co. KG 541091

23

Methodological help for the trainer

24

Festo Didactic GmbH & Co. KG 541091

Methodological structure of the exercises

All 12 exercises in Part A are of identical methodological structure. The exercises are divided into: Title Training aims Problem definition Parameters as well as Project task Positional sketch Worksheets The proposed solutions in Part C are divided into: Circuit diagram Solution description as well as Circuit design Equipment list

Festo Didactic GmbH & Co. KG 541091

25

Designation of equipment

The designation of components in a circuit is effected in accordance with the DIN-ISO 1219-2 standard. All components of a circuit have the same main code number. Letters are assigned depending on components. Several components within a circuit are numbered consecutively. The designation of multiple pressure ports is P and these are consecutively numbered separately. Drives: Valves: Sensors: Signal input: Accessories: Pressure ports: 1A1, 2A1, 2A2, ... 1V1, 1V2, 1V3, 2V1, 2V2, 3V1, ... 1B1, 1B2, ... 1S1, 1S2, ... 0Z1, 0Z2, 1Z1, ... P1, P2, ...

26

Festo Didactic GmbH & Co. KG 541091

Contents of the CD-ROM

The CD-ROM supplied provides you with additional media. The contents of Part A Exercises, and Part C Solutions, are stored in the form of pdf files. The structure of the CD-ROM is as follows: Operating instructions Data sheets Demo Festo catalogue FluidSIM circuit diagrams Industrial applications Presentations Product information Videos

Operating instructions

Operating instructions are available for the various pieces of equipment of the technology package to assist you in the use and commissioning of the equipment.

Data sheets

The data sheets for the equipment of the technology package are available in the form of pdf files.

Demo

A demo version of the software package FluidSIM Pneumatic is stored on the CDROM. This version is suitable for the testing of the control system developed.

Festo catalogue

Pages from the Festo AG & Co. KG catalogue are provided for selected pieces of equipment. The representation and description of equipment in this form is intended to illustrate how such equipment is represented in an industrial catalogue. You will also find additional information here regarding the equipment.

FluidSIM circuit diagrams

FluidSIM circuit diagrams are stored in this directory for all 12 exercises in the technology package. For the introduction to logic programming, all FluidSIM circuit diagrams are also stored in a variant with logic control in addition to the circuit diagrams with relay control.

Festo Didactic GmbH & Co. KG 541091

27

Contents of the CD-ROM

Industrial applications

Photos and pictures are provided of industrial applications to enable you to illustrate your own problem definitions. These can also be added to project presentations.

Presentations

Brief presentations are stored in this directory regarding the equipment for this technology package. These presentations can for instance be used to create project presentations.

Product information

This directory provides you with the product information and data sheets of Festo AG & Co. KG regarding the equipment of the technology package and is intended to explain what information and data are provided for an industrial component.

Videos

A number of videos of industrial applications complete the media for the training package. Short sequences are shown of practice-related applications.

28

Festo Didactic GmbH & Co. KG 541091

Equipment set Basic Level (TP201)

This equipment set has been compiled for basic training in electropneumatic control technology. It comprises all the components required for the training aims specified and can be expanded in any way with other equipment sets. In addition you will also need a profile plate, electrical power supply unit and compressed air supply to assemble a fully functional control system. Equipment set Basic: Level (TP201 Order No.: 540712)

Description 2 x 3/2-way way solenoid valve, normally open 5/2-way double solenoid valve 5/2-way solenoid valve Blanking plug One-way flow control valve Pressure sensor On/off valve with filter regulating valve Limit switch, electrical, actuation from the left Limit switch, electrical, actuation from the right Plastic tubing 4 x 0.75, 10 m Proximity sensor, electronic Proximity sensor, optical Relay, 3-off Signal input plate, electrical Push-in sleeve Push-in T-connector Manifold Cylinder, double-acting Cylinder, single-acting Order No. 539776 539778 539777 153267 539773 539757 540691 183322 183322 151496 540695 178577 162241 162242 153251 153128 152896 152888 152887 Quantity 1 2 1 10 4 1 1 1 1 2 2 1 2 1 10 20 1 2 1

Festo Didactic GmbH & Co. KG 541091

29

Training aims of Basic Level (TP201)

To familiarise yourself with the design and mode of operation of a single-acting cylinder. To familiarise yourself with the design and mode of operation of a double-acting cylinder. To be able to calculate piston forces according to specified values. To familiarise yourself with the design and mode of operation of a 3/2-way solenoid valve. To familiarise yourself with the design and mode of operation of a double solenoid valve. To be able to select solenoid valves according to requirements. To be able to identify and draw the various types of actuation of directional control valves. To be able to convert solenoid valves. To be able to explain and design an example of direct actuation. To be able to explain and design an example of indirect actuation. To familiarise yourself with logic functions and to design these. To familiarise yourself with different types of end position control and to be able to select a suitable type. To be able to calculate electrical characteristic values. To familiarise yourself with latching circuits with different characteristics. To be able to explain and design an electrical latching circuit with dominant switch-off signal. To be able to design a pressure-dependent control system. To familiarise yourself with the design and mode of operation of magnetic proximity sensors. To familiarise yourself with displacement-step diagrams and to be able to design these for specified problem definitions. To be able to realise a sequence control using two cylinders. To be able to identify and eliminate errors in simple electropneuamtic control systems.

30

Festo Didactic GmbH & Co. KG 541091

Contents

Part A Exercises

Exercise 1: Realising a diverting device ___________________________________A-3 Exercise 2: Insertion of drinks bottles ___________________________________A-15 Exercise 3: Realising a selection station _________________________________A-23 Exercise 4: Machining of key blanks ____________________________________A-39 Exercise 5: Bending of mounting brackets _______________________________A-49 Exercise 6: Realising a filling system ____________________________________A-57 Exercise 7: Bonding of components _____________________________________A-67 Exercise 8: Selecting modes of operation ________________________________A-75 Exercise 9: Machining of key blanks and the use of an EMERGENCY-STOP function ______________________A-85 Exercise 10: Bending of mounting brackets and the use of an EMERGENCY-STOP FUNCTION ____________________A-95 Exercise 11: Conveying bars of chocolate and the use of an EMERGENCY-STOP function____________________ A-103 Exercise 12: Eliminating a fault on a machining station ___________________ A-113

Festo Didactic GmbH & Co. KG 541091

A-1

Contents

A-2

Festo Didactic GmbH & Co. KG 541091

Exercise 1: Realising a diverting device

Training aims

To familiarise yourself with the design and function of valve terminals. To be able to use valve terminals in accordance with requirements. Drinks bottles are to be diverted from one conveyor to another using a diverting device. By pressing a pushbutton the frame of the diverting device is to advance. A bottle is transferred and conveyed in the opposite direction. By pressing another pushbutton, the frame is to return into the initial position. A double-acting cylinder is to be used. Cylinder control is to be realised indirectly and via a pushbutton. In the event of a power failure the cylinder piston rod is to remain in the assumed position. 1. Answer the questions or carry out the exercises regarding the fundamentals of the training contents listed. 2. Draw the pneumatic and electrical circuit diagrams. 3. Simulate the electropneumatic circuit diagram and check its correct functioning. 4. Compile an equipment list. 5. Carry out the pneumatic and electrical circuit assembly. 6. Check the circuit operation.

Problem definition

Parameters

Project task

Festo Didactic GmbH & Co. KG 541091

A-3

Exercise 1: Realising a diverting device

Positional sketch

Diverting device for drinks bottles

1. Cylinder 1A1 is in the retracted end position. 2. The 5/2-way double solenoid valve 1V1 is to switch by pressing pushbutton S1 and the cylinder to move into the forward end position. 3. The 5/2-way double solenoid valve is to reverse by pressing pushbutton S2 and the cylinder to move into the retracted end position.

A-4

Festo Didactic GmbH & Co. KG 541091

Exercise 1: Realising a diverting device

Exercise 1: Realising a diverting device Name: Fundamentals: Installation costs Date: Sheet 1 of 5

The configuration, tubing and wiring of the components of an electropneumatic control system should be selected such as to keep the sum total of equipment, installation and maintenance costs as low as possible. The following choices are available as regards wiring: Conventional wiring technology, e.g. terminal strips Advanced installation concepts, e.g. wiring using multi-pin connectors

The following choices are available in respect of configuration, i.e. number of drives and tubing requirements: Individual mounting of solenoid operated directional control valves Block mounting (manifold or valve terminal)

Festo Didactic GmbH & Co. KG 541091

A-5

Exercise 1: Realising a diverting device

Exercise 1: Realising a diverting device Name: Fundamentals: Installation costs Date: Sheet 2 of 5

Compare the above listed concepts using the example of this control system in terms of reducing the tubing costs.

Note Use the individual valves from TP201 or the MPA valve terminal from TP202 and the respective technical descriptions.

Components

Individual mounting of directional control valves

Block mounting of directional control valves

Saving when using block mounting

Tubing Number of compressed air distribution units Amount of tubing for supply to compressed air distribution unit Amount of tubing for compressed air supply to control chains Amount of tubing between directional control valves and cylinders Silencers Number of silencers for control chains

A-6

Festo Didactic GmbH & Co. KG 541091

Exercise 1: Realising a diverting device

Exercise 1: Realising a diverting device Name: Fundamentals: Installation costs Date: Sheet 3 of 5

Which concept enables you to achieve a reduction in tubing costs? Explain the reason for your choice.

Note Use the individual valves from TP201 or the MPA valve terminal from TP202 and the respective technical descriptions.

Reason

Individual mounting of directional control valves

Block mounting of directional control valves

Festo Didactic GmbH & Co. KG 541091

A-7

Exercise 1: Realising a diverting device

Exercise 1: Realising a diverting device Name: Fundamentals: Installation costs Date: Sheet 4 of 5

Compare the above listed concepts using the example of this control system with regard to reducing wiring costs

Note Use the individual valves of TP201 or the MPA valve terminal from TP202 and the respective technical descriptions.

Wiring table Components Cables Number of terminals/components Conventional wiring technology Control cabinet Terminal strip 1 in control cabinet Earthing cable Supply voltage (24 V) PLC outputs (actuation of solenoid coils) PLC inputs (evaluation of proximity sensors) Terminal strip 1 in control cabinet, overall Cable from control cabinet to terminal box Cable from terminal strip 2 (in terminal box) Cable between terminal strips 1 and 2 Proximity sensors (3 wires per proximity sensor) Solenoids (2 wires per solenoid) Terminal strip 2, overall Cable to directional control valves and sensors Connection of solenoid coils Connection of sensors 1 Number of terminals/components Multi-pin wiring concept

A-8

Festo Didactic GmbH & Co. KG 541091

Exercise 1: Realising a diverting device

Exercise 1: Realising a diverting device Name: Fundamentals: Reducing the wiring costs Date: Sheet 5 of 5

Which concept enables you to achieve a reduction in wiring costs? Explain the reason for your choice.

Note Use the individual valves from TP201 or the MPA valve terminal from TP202 and the respective technical descriptions.

Reason

Conventional wiring technology

Multi-pin wiring concept

Festo Didactic GmbH & Co. KG 541091

A-9

Exercise 1: Realising a diverting device

Exercise 1: Realising a diverting device Name: Completing the pneumatic and electrical circuit diagrams Date: Sheet 1 of 3

Complete the pneumatic circuit diagram for the diverting device.

Pneumatic circuit diagram with individual valve

A-10

Festo Didactic GmbH & Co. KG 541091

Exercise 1: Realising a diverting device

Exercise 1: Realising a diverting device Name: Completing the pneumatic and electrical circuit diagrams Date: Sheet 2 of 3

Complete the pneumatic circuit diagram for the diverting device.

0V1 S -VM 4 2 -VM 4 2 1V1 J 4 2 -VJ 4 2

14

-M1

14

-M1

14

1M1

1M2

12

14

-M1

-M2

12

3/5 82/84 12/14 1 1

3/5 82/84 12/14 1

3/5 82/84 12/14 1

3/5 82/84 12/14 1

3/5 82/84 12/14 1

3/5 82/84 12/14 1

Pneumatic circuit diagram with valve terminal (circuit diagram in DIN A3 format in Part D)

Festo Didactic GmbH & Co. KG 541091

A-11

Exercise 1: Realising a diverting device

Exercise 1: Realising a diverting device Name: Completing the pneumatic and electrical circuit diagrams Date: Sheet 3 of 3

Complete the electrical circuit diagram for the diverting device.

+24 V 1 2 3 4

A1 A2 0V

11 21 31 41

A1 A2

12 14 22 24 32 34 42 44

11 21 31 41

12 14 22 24 32 34 42 44

Electrical circuit diagram

A-12

Festo Didactic GmbH & Co. KG 541091

Exercise 1: Realising a diverting device

Exercise 1: Realising a diverting device Name: Compiling the equipment list Date: Sheet 1 of 1

Apart from the circuit diagram, comprehensive project documentation also requires an equipment list. Compile the equipment list by entering the required equipment in the table below.

Quantity Description

Equipment list

Festo Didactic GmbH & Co. KG 541091

A-13

Exercise 1: Realising a diverting device

A-14

Festo Didactic GmbH & Co. KG 541091

You might also like

- Workbook Pneumatics Basic LevelDocument152 pagesWorkbook Pneumatics Basic LevelTRAN TAN73% (15)

- FESTO - EP211 - Introduction To Electropneumatics SolutionDocument33 pagesFESTO - EP211 - Introduction To Electropneumatics SolutionFrancisco Olguín RodríguezNo ratings yet

- DieboldDocument2 pagesDieboldMary-na Rajbhandari67% (3)

- Workbook TP201 EN 541090Document144 pagesWorkbook TP201 EN 541090xxicbkru0% (2)

- Workbook Pneumatics Basic LevelDocument168 pagesWorkbook Pneumatics Basic Levelvrjr57% (7)

- FESTO - Mechatronics Training MaterialDocument398 pagesFESTO - Mechatronics Training MaterialFrancisco Olguín Rodríguez100% (2)

- Hydraulics Workbook Basic Level TP 501-551141 - ResumoDocument33 pagesHydraulics Workbook Basic Level TP 501-551141 - ResumoPcfs50% (4)

- FESTO Electropneumatics WorkbookDocument144 pagesFESTO Electropneumatics WorkbookAbdallah SalahNo ratings yet

- Festo-Hydraulics Advanced LevelDocument164 pagesFesto-Hydraulics Advanced Levelarm43994% (16)

- Gender and SocietyDocument6 pagesGender and SocietyMaricel RaguindinNo ratings yet

- Handling Station: ManualDocument54 pagesHandling Station: ManualBrayan MedinaNo ratings yet

- Pneumatics Advanced Level: Workbook TP 102Document36 pagesPneumatics Advanced Level: Workbook TP 102samah eskanderNo ratings yet

- Safety in Pneumatic Systems: Workbook TP 250Document25 pagesSafety in Pneumatic Systems: Workbook TP 250Ganabpaty ThiagarajanNo ratings yet

- Pneumatics Basic Level: Workbook TP 101Document40 pagesPneumatics Basic Level: Workbook TP 101dso29No ratings yet

- Basic Level of Electro PneumaticsDocument48 pagesBasic Level of Electro PneumaticsViduranga Bandara0% (1)

- Process Automation Festo DidacticDocument28 pagesProcess Automation Festo DidacticHAMIT100% (8)

- FluidLab-PA CWS 3 0 Manual enDocument82 pagesFluidLab-PA CWS 3 0 Manual enarthur_maqmoveisNo ratings yet

- Manual PCS Compact Workstation en V2Document51 pagesManual PCS Compact Workstation en V2thuyennguyenviet100% (3)

- Hydraulics Advanced Level: Workbook TP 502Document44 pagesHydraulics Advanced Level: Workbook TP 502Jyotirmoy BarmanNo ratings yet

- Festo PLC Basic Level TP301-218Document218 pagesFesto PLC Basic Level TP301-218Marcos Aldana Villalda0% (1)

- Festo Electrical, Pneumatic and Logic SymbolsDocument1 pageFesto Electrical, Pneumatic and Logic SymbolsAvtomatika Kole Nehtenin67% (3)

- Electropneumatics Basic LevelDocument48 pagesElectropneumatics Basic LevelHamsini712No ratings yet

- Electropneumatics Basic LevelDocument44 pagesElectropneumatics Basic Levelupendra35No ratings yet

- En v1.0 LW Programming MicrocontrollerDocument80 pagesEn v1.0 LW Programming MicrocontrollerDiegoNo ratings yet

- Sensors in Pneumatics: Festo WorldwideDocument26 pagesSensors in Pneumatics: Festo WorldwideNur Farah Hani AzizanNo ratings yet

- Basic Principles of Digital TechnologyDocument68 pagesBasic Principles of Digital Technologyirijskivrtovi4973No ratings yet

- Close Loop PneumaticsDocument310 pagesClose Loop Pneumaticsabrap_dNo ratings yet

- Electroneumatica BasicaDocument270 pagesElectroneumatica BasicaReinaldo CorderoNo ratings yet

- FESTO Electro-Hydraulics - Basic LevelDocument203 pagesFESTO Electro-Hydraulics - Basic LevelAnonymous nOqqYoDvz100% (2)

- Electropneumatics Basic Level: Workbook TP 201Document54 pagesElectropneumatics Basic Level: Workbook TP 201Saúl Ríos0% (2)

- Electron Pneumatic CircuitDocument59 pagesElectron Pneumatic CircuitArun SìvaNo ratings yet

- Festo Study MaterialDocument70 pagesFesto Study Materialrammysi100% (3)

- Festo Basic PneumaticDocument274 pagesFesto Basic Pneumaticshellafaye100% (16)

- Elektropneumatika Seminari PDFDocument296 pagesElektropneumatika Seminari PDFjaynard_alejandrinoNo ratings yet

- Elektropneumatika SeminariDocument296 pagesElektropneumatika Seminaribranko502100% (2)

- Workbook Edukit Pa Project Kit Process Automation: With Cd-RomDocument37 pagesWorkbook Edukit Pa Project Kit Process Automation: With Cd-RomSali ÁdámNo ratings yet

- Prolog: Manual Commissioning StationDocument48 pagesProlog: Manual Commissioning Stationpablo elias perez ortegaNo ratings yet

- 01 Distributing C H4Document50 pages01 Distributing C H4Brayan MedinaNo ratings yet

- Manual MPS-PA Compact Workstation EN PDFDocument72 pagesManual MPS-PA Compact Workstation EN PDFstoka seljacka0% (1)

- Servo Drive TechnologyDocument102 pagesServo Drive Technologyirijskivrtovi4973No ratings yet

- 2011 12 Prolog Manual A004Document106 pages2011 12 Prolog Manual A004Andres GuzmanNo ratings yet

- Leseprobe 548591 en PDFDocument29 pagesLeseprobe 548591 en PDFabrap_dNo ratings yet

- MPS PA Level Fluid Lab PA GBDocument73 pagesMPS PA Level Fluid Lab PA GBMarco IslasNo ratings yet

- 171 Conveyor Instructor RelC PDFDocument239 pages171 Conveyor Instructor RelC PDFAndres David zapa AvilezNo ratings yet

- Leseprobe enDocument46 pagesLeseprobe enRizkie Denny PratamaNo ratings yet

- Prolog TripleStackMagazine A003Document53 pagesProlog TripleStackMagazine A003pablo elias perez ortegaNo ratings yet

- Prolog Testing A003Document51 pagesProlog Testing A003pablo elias perez ortegaNo ratings yet

- Mps500 Manual As Rs s7 A003Document52 pagesMps500 Manual As Rs s7 A003yossefNo ratings yet

- FESTO MPS500 Manual Vision A004Document53 pagesFESTO MPS500 Manual Vision A004Oscar X. CámaraNo ratings yet

- MPS PA Flow Fluid Lab PA GBDocument75 pagesMPS PA Flow Fluid Lab PA GBMarco IslasNo ratings yet

- MPS500 Manual Robot Assembly CNC105 Siemens A002Document63 pagesMPS500 Manual Robot Assembly CNC105 Siemens A002yossefNo ratings yet

- MPS PA Compact Fluid Lab PA GBDocument138 pagesMPS PA Compact Fluid Lab PA GBMarco IslasNo ratings yet

- iCIM FC Robot RV2AJ Assembly Vision A008Document69 pagesiCIM FC Robot RV2AJ Assembly Vision A008tnbangNo ratings yet

- Fundamentals of Alternating Current Technology: WorkbookDocument40 pagesFundamentals of Alternating Current Technology: WorkbookShaikh md azharuddinNo ratings yet

- FluidLab-PA MPS-PA 3 0 Manual EN PDFDocument90 pagesFluidLab-PA MPS-PA 3 0 Manual EN PDFAngelica May BangayanNo ratings yet

- Manual MPS-PA Compact Workstation enDocument72 pagesManual MPS-PA Compact Workstation enospidera100% (1)

- 131 Processing Instructor RelC PDFDocument170 pages131 Processing Instructor RelC PDFDenni de LeónNo ratings yet

- Proportional Hydraulis TP701Document152 pagesProportional Hydraulis TP701vqiriaNo ratings yet

- Leseprobe enDocument58 pagesLeseprobe enاحمد البحيريNo ratings yet

- Estacion de TransporteDocument33 pagesEstacion de TransporteLuis GsNo ratings yet

- AppendicesDocument48 pagesAppendicesAizul IzannieNo ratings yet

- Hydraulics Basic Level: Workbook TP 501Document46 pagesHydraulics Basic Level: Workbook TP 501Hoang Vu TranNo ratings yet

- 112 Distribution Trainee RelC PDFDocument170 pages112 Distribution Trainee RelC PDFFerney BecerraNo ratings yet

- Festo Inventario PDFDocument32 pagesFesto Inventario PDFHectOr Muñoz MottaNo ratings yet

- EMCS Technology Exercises Worksheets V2Document143 pagesEMCS Technology Exercises Worksheets V2alexosi7No ratings yet

- Festo Hydraulics Workbook Basic Level TP501 204Document204 pagesFesto Hydraulics Workbook Basic Level TP501 204Avtomatika Kole NehteninNo ratings yet

- Ansys Multiphysics Solutions 13 PDFDocument4 pagesAnsys Multiphysics Solutions 13 PDFConstantin Dorinel100% (1)

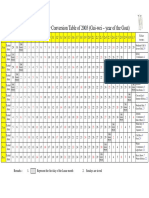

- Gregorian-Lunar Calendar Conversion Table of 2003 (Gui-Wei - Year of The Goat)Document1 pageGregorian-Lunar Calendar Conversion Table of 2003 (Gui-Wei - Year of The Goat)I Am Geprek Bensu FinanceNo ratings yet

- Power TrainDocument257 pagesPower TrainStorm SpiritNo ratings yet

- What Is PanchakDocument2 pagesWhat Is PanchakHNTHAKURNo ratings yet

- Op Amp PresentationDocument23 pagesOp Amp PresentationAnonymous GTIfWmmENo ratings yet

- Myob Ace Payroll: Accounting &Document2 pagesMyob Ace Payroll: Accounting &Muhammad RamadhanNo ratings yet

- ABRAHIM Research .2021.update .Document43 pagesABRAHIM Research .2021.update .Abdi Mucee TubeNo ratings yet

- Assignment 2 Updated AIMLDocument2 pagesAssignment 2 Updated AIMLVismitha GowdaNo ratings yet

- PIP STS02380, Application of ACI336.1-01 Specification For The Construction of Drilled PiersDocument9 pagesPIP STS02380, Application of ACI336.1-01 Specification For The Construction of Drilled PiersErik PerezNo ratings yet

- Flat Plate Boundary LayerDocument47 pagesFlat Plate Boundary LayerKlevin GeorheNo ratings yet

- Prevalence of ScaDocument8 pagesPrevalence of ScaUsman Ahmad TijjaniNo ratings yet

- Plumbing Submittal - VIR - BMW SHOWROOM ValvesDocument135 pagesPlumbing Submittal - VIR - BMW SHOWROOM Valvessenthilonline15No ratings yet

- Acts of Teaching Chapter 14Document2 pagesActs of Teaching Chapter 14api-350726106No ratings yet

- Charts Using VbaDocument6 pagesCharts Using VbaPallab DattaNo ratings yet

- Renewable and Sustainable Energy Reviews: Peeyush Kala, Sudha AroraDocument27 pagesRenewable and Sustainable Energy Reviews: Peeyush Kala, Sudha AroraUvais MustafaNo ratings yet

- Sukhoi Su-30MKI - WikipediaDocument35 pagesSukhoi Su-30MKI - WikipediaHaq se NationalistNo ratings yet

- Rockfon Medicare Standard: DatasheetDocument4 pagesRockfon Medicare Standard: Datasheetאורלי בן יוסףNo ratings yet

- Solar Parks: Accelerating The Growth of Solar Power in IndiaDocument5 pagesSolar Parks: Accelerating The Growth of Solar Power in IndiaNiket DalalNo ratings yet

- Health Risk Assessment: Practical Steps To Conduct HraDocument14 pagesHealth Risk Assessment: Practical Steps To Conduct HraPris RodriguezNo ratings yet

- M4 TechnicalDocument14 pagesM4 TechnicalBethany VillarojoNo ratings yet

- Tech Manual: Tech-5.12 10K Es54 Dual QcmaDocument24 pagesTech Manual: Tech-5.12 10K Es54 Dual QcmaRiski KurniawanNo ratings yet

- Kak Bahasa Inggeris THN 1 - 6Document4 pagesKak Bahasa Inggeris THN 1 - 6Sea HunterNo ratings yet

- 10 Social Science Economics Revision Notes Ch2 Economic SectorsDocument5 pages10 Social Science Economics Revision Notes Ch2 Economic SectorsKartikeya RockNo ratings yet

- Lec 1Document60 pagesLec 1Peerayot SanposhNo ratings yet

- Rigid-Body Dynamics With Friction and ImpactDocument37 pagesRigid-Body Dynamics With Friction and ImpactMDR PRAPHUNo ratings yet

- Arabic Sigi LsDocument15 pagesArabic Sigi LsCosmicEnigma75% (8)

- When Mystery Shopping Goes BadDocument4 pagesWhen Mystery Shopping Goes BadEric LarseNo ratings yet

- Component Detail Report 3288Document2 pagesComponent Detail Report 3288Богдан РудюкNo ratings yet