Professional Documents

Culture Documents

Monthly Progress

Uploaded by

Kali DossOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Monthly Progress

Uploaded by

Kali DossCopyright:

Available Formats

Reinforced concrete beam is strengthened with two strips of CFRP laminates in its bottom to increase the flexural capacity

of the beam. Mainly it is conducted to analyze the failure mode of the plated beam. Normally, failure of the plated beam may be due to interfacial debonding, FRP fracture, failure due to flexure and shear cracks induced stresses etc. In that, debonding of the plate from the beam is seen as a vital failure mode as it prevents to attain the full ultimate flexural capacity of the retrofitted beam.

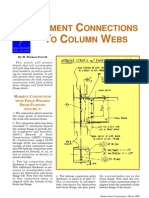

Two laminates are attached with the length, width of 2600 and 50mm respectively. It is attached either side from centerline of cross section of the beam. Instrumentation of the beam is consisting defelection measurement, strain measurent in reinforcement and concrete surface. Displacement is measured with LVDTs fixed at each L/6th location of the beam. Measuring the strain in reinforcing bar is achieved by fixing 5mm ERS gages at each L/8th location of the beam. 60mm ERS gages were used for the strain measurement of concrete surface. Interface stress variation takes place within 100mm from the plate cut off point. Electronic strain gauges are pasted both in the ATC interface (on concrete surface) and in PTA interface (on the FRP plate). Fig shows the instrumented strain gauges of the beam.fig 57 shows the typical instrumentation of the FRP bonded beam. Totally 90 strain gauges were mounted in the beam.

Fig.57 Plated beam instrumentation

Fig.58 Testing of FRP laminate beam.

Responses from the experimental investigation have been given below.

You might also like

- Ficha Técnica - ArmourJoint PDFDocument2 pagesFicha Técnica - ArmourJoint PDFDiego BarretoNo ratings yet

- Tie Requirements For RC Columns Bresler Gilbert ACI SJ 1961Document16 pagesTie Requirements For RC Columns Bresler Gilbert ACI SJ 1961oggy1844No ratings yet

- Bi 2011Document5 pagesBi 2011Zana QaderNo ratings yet

- Construction: Fig. 5.1. Near Surface Mounted FRP, Rectangular Shapes and RodsDocument10 pagesConstruction: Fig. 5.1. Near Surface Mounted FRP, Rectangular Shapes and RodsJubayer HasanNo ratings yet

- Shear Behaviour of Ferrocement Plates: Ms. Madhuri N. Savale, Prof. P. M. AlandkarDocument5 pagesShear Behaviour of Ferrocement Plates: Ms. Madhuri N. Savale, Prof. P. M. Alandkarluvjoshi1989No ratings yet

- RC Two-Way Slabs Strengthened With CFRP StripsDocument6 pagesRC Two-Way Slabs Strengthened With CFRP Stripsvishwanath malalanayakeNo ratings yet

- Prestressed ConcreteDocument8 pagesPrestressed ConcreteYeswanth RaghavendraNo ratings yet

- Seismic Retrofit of Shear-Critical R.C. Beams Using CFRP: FRPRCS-9 Sydney, AustraliaDocument4 pagesSeismic Retrofit of Shear-Critical R.C. Beams Using CFRP: FRPRCS-9 Sydney, AustraliaRodrigo LameirasNo ratings yet

- Pre Stressed ConcreteDocument8 pagesPre Stressed Concretevamsi_rsNo ratings yet

- Steel Fibers PDFDocument73 pagesSteel Fibers PDFjoseNo ratings yet

- 2017-APFIS Conference - Strengthening Concrete Columns Using NSM CFRP LaminatesDocument4 pages2017-APFIS Conference - Strengthening Concrete Columns Using NSM CFRP LaminatesThanoon AlmarwasyNo ratings yet

- Monti 2007Document11 pagesMonti 2007Tùng-65XD11 Nguyễn XuânNo ratings yet

- Shear Strengthening of Reinforced Concrete Beams With Rectangular Web Openings by FRP CompositesDocument20 pagesShear Strengthening of Reinforced Concrete Beams With Rectangular Web Openings by FRP CompositesYoga PratamaNo ratings yet

- Shear Crack Induced Deformation of FRP RC Beams: FrprcsDocument10 pagesShear Crack Induced Deformation of FRP RC Beams: Frprcsmickey2523No ratings yet

- Perencanaan Penulangan Rigid Pavement: Austroads Pd-T-14-2003Document40 pagesPerencanaan Penulangan Rigid Pavement: Austroads Pd-T-14-2003Leejieun BusinessNo ratings yet

- Factored Load Factored StrengthDocument12 pagesFactored Load Factored Strengthhello whelloNo ratings yet

- Hutchinson and Diederichs - 1996 Cablebolting HandbookDocument5 pagesHutchinson and Diederichs - 1996 Cablebolting HandbookOciel Silva MartinezNo ratings yet

- FIP 8 Design and Specification of Fiber Reinforced Concrete 0219Document3 pagesFIP 8 Design and Specification of Fiber Reinforced Concrete 0219mohdfirdausNo ratings yet

- Strengthening of RCC BeamsDocument16 pagesStrengthening of RCC BeamsUsman ShahidNo ratings yet

- Losses in PrestressDocument43 pagesLosses in PrestressRiyaz SiddiqueNo ratings yet

- Full TextDocument3 pagesFull Textshanmugam200554No ratings yet

- Behavior of External Column New Paper Fprma11tDocument19 pagesBehavior of External Column New Paper Fprma11tUpali KarunarathneNo ratings yet

- ST7008 PrestressedStructuresquestionbankDocument11 pagesST7008 PrestressedStructuresquestionbankAshok AmmaiyappanNo ratings yet

- Hansen Et. Al. (Word 2003) Crack Propagation I Eset Specimens Strengthened With CFRP Sheets 20090602Document12 pagesHansen Et. Al. (Word 2003) Crack Propagation I Eset Specimens Strengthened With CFRP Sheets 20090602Microb IraniNo ratings yet

- Electromagnetic Stirring in Continuous Casting ProcessDocument4 pagesElectromagnetic Stirring in Continuous Casting ProcessJose Marval RodriguezNo ratings yet

- Report CMTDocument5 pagesReport CMTKhalil FurioNo ratings yet

- Bldgtec 3 Reading 3Document4 pagesBldgtec 3 Reading 3Danilo V. RavinaNo ratings yet

- Shear Behavior of MasonryDocument11 pagesShear Behavior of MasonryRazvan IonNo ratings yet

- amr.163 167.1251Document7 pagesamr.163 167.1251zana connorNo ratings yet

- Different CFRP Strengthening Techniques For Prestressed Hollow Core Concrete Slabs Experimental Study and Analytical Investigation - Copy (211434589)Document11 pagesDifferent CFRP Strengthening Techniques For Prestressed Hollow Core Concrete Slabs Experimental Study and Analytical Investigation - Copy (211434589)Sulaiman Mohsin AbdulAzizNo ratings yet

- Parametric Studies of Steel Cold-Formed Section Beam To Column Moment Connections With Self-Drilling ScrewsDocument11 pagesParametric Studies of Steel Cold-Formed Section Beam To Column Moment Connections With Self-Drilling ScrewsAhmed SalehNo ratings yet

- Fatigue Life of Double Angle Tension MembersDocument10 pagesFatigue Life of Double Angle Tension MembersalbertoxinaNo ratings yet

- FRP STRUCTURAL GUIDELINES, ACI 440.1 r06Document1 pageFRP STRUCTURAL GUIDELINES, ACI 440.1 r06Gohar ZamanNo ratings yet

- Externally Post-Tensioned Carbon FRP Bar System For de Ection ControlDocument12 pagesExternally Post-Tensioned Carbon FRP Bar System For de Ection ControlGedysonLimaNo ratings yet

- CE6702 PSCS Rejinpaul Important QuestionsDocument2 pagesCE6702 PSCS Rejinpaul Important QuestionsPar NawNo ratings yet

- AD 350 - Heating Pipes in Composite Floors - Effects On Slab Beam DesignDocument3 pagesAD 350 - Heating Pipes in Composite Floors - Effects On Slab Beam Designsymon ellimacNo ratings yet

- Passive and Active Near Surface Mounted FRP Rods For Flexural Strengthening of RC BeamsDocument12 pagesPassive and Active Near Surface Mounted FRP Rods For Flexural Strengthening of RC BeamsmarkicivanNo ratings yet

- Parametric Study of Beams With Externally Bonded FRP ReinforcementDocument9 pagesParametric Study of Beams With Externally Bonded FRP ReinforcementpicottNo ratings yet

- Chapter-1: 1.1 GeneralDocument53 pagesChapter-1: 1.1 GeneralsmkdigitechNo ratings yet

- Asphalt Work PracticesDocument4 pagesAsphalt Work Practicesalaid melarNo ratings yet

- Shear Strengthening of RC Beams With NSM CFRP Laminates: FrprcsDocument10 pagesShear Strengthening of RC Beams With NSM CFRP Laminates: FrprcsaibpNo ratings yet

- RMR - Support Guidelines RMR - Semi-Empirical Support GuidelinesDocument100 pagesRMR - Support Guidelines RMR - Semi-Empirical Support GuidelinesSusett M TNo ratings yet

- Effectiveness of Near Surface Mounted FRP Reinforcement For Flexural Strengthening of Reinforced Concrete BeamsDocument8 pagesEffectiveness of Near Surface Mounted FRP Reinforcement For Flexural Strengthening of Reinforced Concrete BeamskhaNo ratings yet

- Moment Connections To Column WebsDocument3 pagesMoment Connections To Column WebsAmro Ahmad AliNo ratings yet

- Seccion 16 Abs SoldaduraDocument9 pagesSeccion 16 Abs SoldaduraRoberto DavilaNo ratings yet

- ST060 Anas PaultreDocument10 pagesST060 Anas PaultreRizki Nuursirullah MahibNo ratings yet

- Antonius HSC 15 PDFDocument12 pagesAntonius HSC 15 PDFyanimuhammadNo ratings yet

- Behaviour of FRP Reinforced Concrete Beam-Column Joints Under Cyclic Loading PDFDocument8 pagesBehaviour of FRP Reinforced Concrete Beam-Column Joints Under Cyclic Loading PDFAhmed NafieNo ratings yet

- ANSI-AISC 358-20 - C7SA - InglésDocument7 pagesANSI-AISC 358-20 - C7SA - InglésmanuelNo ratings yet

- Load Tests On 2-Span Reinforced Concrete Beams Strengthened With Fibre Reinforced PolymerDocument8 pagesLoad Tests On 2-Span Reinforced Concrete Beams Strengthened With Fibre Reinforced PolymerkrishnanunniNo ratings yet

- Simple Connections ETOOLKITDocument27 pagesSimple Connections ETOOLKITLesego MatojaneNo ratings yet

- Metall-Ceramic Framework Design Manual PDFDocument52 pagesMetall-Ceramic Framework Design Manual PDFCucu Constantin100% (1)

- Finite Element Analysis of Different Types of FRP On Beam Column Joint IJERTV7IS050232Document6 pagesFinite Element Analysis of Different Types of FRP On Beam Column Joint IJERTV7IS050232Syed Abdul QuddusNo ratings yet

- Axially and Eccentrically Loaded ColumnsDocument13 pagesAxially and Eccentrically Loaded ColumnsRefisa JiruNo ratings yet

- Study On Minimum Shear Reinforcement of Reinforced Concrete Flat SlabsDocument12 pagesStudy On Minimum Shear Reinforcement of Reinforced Concrete Flat SlabsMatheus L. G. MarquesiNo ratings yet

- 4th Yr Assignment CivilDocument3 pages4th Yr Assignment CivilArindam ER DeyNo ratings yet

- Fatigue-Resistant Detail Design Guide For Ship StructuresDocument6 pagesFatigue-Resistant Detail Design Guide For Ship Structuresy_596688032No ratings yet

- Designed and Detailed According To IS 456 As An Ordinary Moment Resisting Frame Also Called Ordinary Concrete FrameDocument3 pagesDesigned and Detailed According To IS 456 As An Ordinary Moment Resisting Frame Also Called Ordinary Concrete FrameAnonymous Gye18jNo ratings yet

- Code of Practice For Installation AND Observation of Cross Arms For Measurement of Internal Vertical Movement in Earth DamsDocument20 pagesCode of Practice For Installation AND Observation of Cross Arms For Measurement of Internal Vertical Movement in Earth DamsFaisal RizwanNo ratings yet