Professional Documents

Culture Documents

Diametral Pitch Spur Gears

Uploaded by

abhishekghatgeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diametral Pitch Spur Gears

Uploaded by

abhishekghatgeCopyright:

Available Formats

Call us at (800) 491-1073 and ask for Design Support * commercialgear.

com

DIAMETRAL PITCH SPUR GEARS

TO GET Module HAVING Diametral pitch RULE Divide 25.4 by the diametral pitch Divide 25.4 by the module Divide by the circular pitch FORMULA m = 25.4 / Pd

Module Circular pitch Pitch diameter and number of teeth Diametral pitch Outside of gear and number of teeth

Pd = 25.4 / m Pd = / P

Divided the number of teeth Pd = N / D by pitch diameter Divide number of teeth plus 2 by the outside diameter Divide the base pitch by the cosine of the pressure angel then divide by

Pd = N + 2 / Do

Base pitch and pressure angle

Pd=(Pb / cos. ) /

Operating diametral pitch

Center distance between 2 gears and number of teeth in both

Add the number of teeth in both gears and divide dp = (n1 + n2 / by 2, then divide 2) / C by center distance Divide the base diameter by cos. = Db / D

Pressure angle

Base diameter and pitch

diameter Base pitch and diametral pitch

pitch diameter Divide by diametral pitch, then divide by the base pitch Divide the base pitch by the circular pitch = cosine pressure angle cos. = Pb / (/Pd)

Base pitch and circular pitch

cos = Pb / P

Divide the Number of teeth number of teeth and diametral D = N / Pd by the diametral pitch pitch Divide the product of the Number of teeth outer diameter D = N * Do / n and outer and number of +2 diameter teeth by number of teeth +2 Pitch diameter Subtract from the outside diameter, the quotient of 2 divided by the diametral pitch Multiply addendum by the number of teeth Divide the base diameter by the cosine of the pressure angle

Outside diameter and diametral pitch

D = Do - 2 / pd

Addendum and number of teeth

D=a*n

Base diameter and pressure angle Outside diameter

dp = Db / cos.f

Divide number Number of teeth of teeth plus 2 and diametral Do = N + 2 / Pd by the diametral pitch pitch

Pitch diameter and diametral pitch

Add the pitch diameter to the quotient of 2 divided by the diametral pitch

Do = D + 2 / Pd

Pitch diameter and number of teeth

Divide the number of teeth plus 2 by the Do = N + 2 / N / quotient of D number of teeth divided by the pitch diameter

Multiply the Number of teeth number of teeth Do = (N + 2) a plus 2 by and addendum addendum Pitch diameter and diametral pitch Number of teeth Outside diameter and diametral pitch Multiply pitch diameter by the diametral pitch Multiply outside diameter by the diametral pitch and subtract 2 N = D * Pd

N = Do * Pd - 2

Std. thickness of Diametral pitch tooth Std. addendum Diametral pitch

Divide 1.5708 by the diametral t = 1.5708 / Pd pitch Divide 1 by the diametral pitch a = 1 / Pd

Std. dedendum

Diametral pitch

Divide 1.157 (or 1.25) by the b = 1.157 / Pd diametral pitch Divide 2.157 (or 2.25) by the ht = 2.157 / Pd diametral pitch Divide .157 (or .250) by the diametral pitch c = .157 / Pd

Std. whole depth

Diametral pitch

Clearance

Diametral pitch Thickness of

Divide thickness c = t / 10

tooth

of tooth at pitch line by 10 Add number of teeth in both gears together and divide by 2, then divide result by the normal diametral pitch Add the number of teeth in both gears together and divide by 2, then divide results by operating diametral pitch Multiply the pitch diameter by cosine of the pressure angle Divide the diametral pitch by , then multiply by cosine of pressure angle

Center distance

Normal diametral pitch and number of teeth in both gears

dp = ((n1 + n)2 / 2) / Pnd

Operating diametral pitch Operating center and number of distance teeth in both gears

dp = (n1 + n2 / 2) / Pod

Base diameter

Pitch diameter and pressure angle

Db = D * cos.

Base pitch

Diametral pitch and pressure angle

Pb = cos. * / Pd

DISCLAIMER AND LIMITED LIABILITY Commercial Gear and Sprocket Company, Inc. has provided this Designers & Engineers Resource in an effort to help you conceptualize your design. Due to the complex nature of designing and its interaction with an assortment of components, Commercial Gear and Sprocket Company, Inc. does not warrant that the usage of this site and the information therein is completely error free or fit for your specific design. Commercial Gear and Sprocket Company, Inc. makes no warranties, express or implied, with respect to the usage of the information provided or as to its fitness for any particular purpose. Commercial Gear and Sprocket Company, Inc. shall not be liable for any damage or loss of any kind, whether direct or indirect, incidental or consequential, regardless of whether such liability is based in Tort, Contract or otherwise including without limitation damages for loss of business, business profits, business interruption, or any other pecuniary loss arising out of or relating to the use of this site. Commercial Gear and Sprocket Company, Inc. is however, standing by to assist you or design and fabricate to your specifications. Our third generation family owned company has been producing quality gears and other power transmission products at competitive prices since 1946. Call us at (800) 491-1073 and ask for Design Support

You might also like

- Spur Gear Calculations and FormulasDocument2 pagesSpur Gear Calculations and FormulasBilal Tayyab100% (2)

- Spur Gear Calculations and FormulasDocument3 pagesSpur Gear Calculations and FormulasTan Cheehou100% (2)

- Spur Gear CalculationsDocument2 pagesSpur Gear CalculationsPuneet Verma100% (3)

- OmniGear Tech Info BinderDocument86 pagesOmniGear Tech Info BinderMiguel Matias ReineroNo ratings yet

- Gear FormulaeDocument13 pagesGear Formulaeian_newNo ratings yet

- Diametral PitchDocument2 pagesDiametral Pitchbrpnaidu2157No ratings yet

- Basic Gear Terminology and Calculation - KHK Gears PDFDocument8 pagesBasic Gear Terminology and Calculation - KHK Gears PDFMinhas ArshadNo ratings yet

- Basic Gear Terminology and Calculation - KHK GearsDocument8 pagesBasic Gear Terminology and Calculation - KHK GearsSuyandi SinagaNo ratings yet

- GearDocument14 pagesGearAnimesh ManiNo ratings yet

- Basic Gear Terminology and CalculationDocument10 pagesBasic Gear Terminology and CalculationTesseract spyderNo ratings yet

- Safari - May 16, 2022 at 9:00 PMDocument1 pageSafari - May 16, 2022 at 9:00 PMDagneNo ratings yet

- How To Measure The Pressure Angle of A Physical Spur GearDocument16 pagesHow To Measure The Pressure Angle of A Physical Spur Gearian_new100% (2)

- a R i z m mn b α β fo c x Ψ Ψm ΨyDocument6 pagesa R i z m mn b α β fo c x Ψ Ψm ΨykuttuasrNo ratings yet

- Gear Dimension Calculation Tips DP CP ModDocument3 pagesGear Dimension Calculation Tips DP CP ModGilbertoUGONo ratings yet

- Circular Pitch Spur GearsDocument1 pageCircular Pitch Spur Gearsਗਗਨ ਜੋਤNo ratings yet

- Basic Gear Terminology and Calculation - KHK GearsDocument10 pagesBasic Gear Terminology and Calculation - KHK GearsJoab Max Apaza MartinezNo ratings yet

- Gear Formulae - Engineers EdgeDocument2 pagesGear Formulae - Engineers EdgeleovenuNo ratings yet

- Spur Gear CalculatorDocument16 pagesSpur Gear CalculatorMinh Trí KnightNo ratings yet

- Gear Formulae - Engineers EdgeDocument2 pagesGear Formulae - Engineers EdgePawankumar PagoteNo ratings yet

- CH08 2Document52 pagesCH08 2abdallah ghannamNo ratings yet

- Gears PDFDocument8 pagesGears PDFmgualdiNo ratings yet

- Chapter 05Document15 pagesChapter 05Muhammad Nur IkhwanNo ratings yet

- 8mm HTD Timing Belt Pulley PD and OD ChartDocument2 pages8mm HTD Timing Belt Pulley PD and OD ChartNikolas FabryNo ratings yet

- Metric Module DetailsDocument2 pagesMetric Module DetailsAriful IslamNo ratings yet

- External Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDocument3 pagesExternal Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkAgil RamadhanNo ratings yet

- External Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDocument3 pagesExternal Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDhian WijayaNo ratings yet

- External Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDocument3 pagesExternal Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkMoorthy GanesanNo ratings yet

- External Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDocument3 pagesExternal Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkTran DucNo ratings yet

- External Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkDocument4 pagesExternal Gear Pump Parameter Calculation Sheet: 2.972 Understanding How Things WorkRichard De Medeiros CastroNo ratings yet

- Involute Gear Gear NomenclatureDocument9 pagesInvolute Gear Gear NomenclatureGraham MutumaNo ratings yet

- Gear Notes - SlideDocument19 pagesGear Notes - SlideNEF RIDERSNo ratings yet

- Tooth ThicknessDocument9 pagesTooth ThicknessPraveen VundrajavarapuNo ratings yet

- Module Gear DataDocument2 pagesModule Gear DataMuhammad HaiderNo ratings yet

- Design of Spur GearsDocument29 pagesDesign of Spur GearsAishwarya RameshNo ratings yet

- Spur GearDocument5 pagesSpur GearMelindaNo ratings yet

- Chapter 5 GearDocument9 pagesChapter 5 GearNEF RIDERSNo ratings yet

- Gear TerminologyDocument19 pagesGear TerminologyZandro GagoteNo ratings yet

- Basic Gear FormulasDocument3 pagesBasic Gear FormulasAshok DevihosurNo ratings yet

- Gear Tooth Thickness MeasurmentDocument7 pagesGear Tooth Thickness MeasurmentYohannes Mengistu AbebeNo ratings yet

- Boston Eng Info - SpurGearsDocument5 pagesBoston Eng Info - SpurGearsMauro TognocchiNo ratings yet

- Bending Formulas For Tube Bending ToolsDocument3 pagesBending Formulas For Tube Bending ToolsVikash SharmaNo ratings yet

- 2 - 3 Involute Spur Gear 1Document13 pages2 - 3 Involute Spur Gear 1jiteshpaul100% (1)

- DFM Guidebook Sheetmetal Design Guidelines Issue XVDocument11 pagesDFM Guidebook Sheetmetal Design Guidelines Issue XVRushil ShahNo ratings yet

- RDT High Torque ConnectionsDocument4 pagesRDT High Torque ConnectionsJohan Medina TovarNo ratings yet

- Straight Spur Gears and RACKSDocument10 pagesStraight Spur Gears and RACKSIRONSAVIORNo ratings yet

- Formular Formula - HTMDocument3 pagesFormular Formula - HTMTomy GeorgeNo ratings yet

- DFM Guidebook Sheetmetal Design Guidelines Issue XVIII PDFDocument11 pagesDFM Guidebook Sheetmetal Design Guidelines Issue XVIII PDFNandang KuroshakiNo ratings yet

- ACME Threads TypeDocument2 pagesACME Threads TypeCahya Adi YeftaNo ratings yet

- ACME Threads PDFDocument2 pagesACME Threads PDFzbhdzpNo ratings yet

- Gears, Splines, and Serrations: Unit 24Document8 pagesGears, Splines, and Serrations: Unit 24Satish Dhandole100% (1)

- Parts of A Spur GearDocument18 pagesParts of A Spur GearAnthony FajardoNo ratings yet

- DJJ 10033-Chapter 5.GEARDocument34 pagesDJJ 10033-Chapter 5.GEARStepianus JtNo ratings yet

- DJJ 10033-Chapter 5Document45 pagesDJJ 10033-Chapter 5Abbas SeuNo ratings yet

- Inventor-Gears - Jeffery J Jensen Wiki PDFDocument30 pagesInventor-Gears - Jeffery J Jensen Wiki PDFEndalkachew Abate100% (1)

- AcmeDocument2 pagesAcmeShatish KumarNo ratings yet

- SolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)From EverandSolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Rating: 4.5 out of 5 stars4.5/5 (5)

- SolidWorks 2017 Black Book: SolidWorks Black BookFrom EverandSolidWorks 2017 Black Book: SolidWorks Black BookRating: 3.5 out of 5 stars3.5/5 (3)

- Solidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingFrom EverandSolidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingNo ratings yet

- 3p2 PRINT PDFDocument52 pages3p2 PRINT PDFमनोज चौधरीNo ratings yet

- "Standard"Hopper Dryer - SHDDocument28 pages"Standard"Hopper Dryer - SHDमनोज चौधरीNo ratings yet

- VendorList 1Document27 pagesVendorList 1मनोज चौधरीNo ratings yet

- Autodesk Moldflow Insight Standard: Tushar P ChaudhariDocument1 pageAutodesk Moldflow Insight Standard: Tushar P Chaudhariमनोज चौधरीNo ratings yet

- Resignation Letter 2Document1 pageResignation Letter 2मनोज चौधरी0% (1)

- Engineering MaterialsDocument93 pagesEngineering MaterialsVinaya Almane DattathreyaNo ratings yet

- Property Test Method Units Polypropylene CopolymerDocument1 pageProperty Test Method Units Polypropylene Copolymerमनोज चौधरीNo ratings yet

- Mechanical Design EngineerDocument1 pageMechanical Design Engineerमनोज चौधरीNo ratings yet

- Automation and Situation Awareness - EndsleyDocument11 pagesAutomation and Situation Awareness - Endsleyमनोज चौधरीNo ratings yet

- Seniority Report: Directorate of Employment and Self EmploymentDocument1 pageSeniority Report: Directorate of Employment and Self Employmentमनोज चौधरीNo ratings yet

- Non-Conventional Manufacturing ProcessesDocument2 pagesNon-Conventional Manufacturing Processesमनोज चौधरीNo ratings yet

- GD&TDocument1 pageGD&TBharath Kumar0% (1)

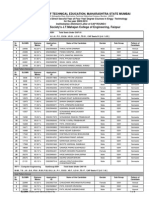

- Directorate of Technical Education, Maharashtra State MumbaiDocument6 pagesDirectorate of Technical Education, Maharashtra State Mumbaiमनोज चौधरीNo ratings yet

- Employment ApplicationformDocument4 pagesEmployment Applicationformमनोज चौधरीNo ratings yet

- Advanced Manufacturing Processes: Phase Four: Assignment and Self-Study QuestionsDocument1 pageAdvanced Manufacturing Processes: Phase Four: Assignment and Self-Study Questionsमनोज चौधरीNo ratings yet

- Advanced Manufacturing Processes: Phase Four: Assignment and Self-Study QuestionsDocument1 pageAdvanced Manufacturing Processes: Phase Four: Assignment and Self-Study Questionsमनोज चौधरीNo ratings yet

- Mold Maintenance ProgramDocument6 pagesMold Maintenance Programमनोज चौधरी100% (1)