Professional Documents

Culture Documents

Safe handling of sodium azide

Uploaded by

Indu BarwalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safe handling of sodium azide

Uploaded by

Indu BarwalCopyright:

Available Formats

Effective Date: November 8, 2005

Revision Date:

INSTRUCTIONS: Please have each staff member who will be working with this chemical review

this Standard Operation Procedure (SOP). In Section 6 Signatures, list each of the personnel assigned to the project, and have them initial in the box provided to indicate that he/she has read and understands this SOP. Send a completed copy to your campus EOHSS. The address can be found in section 7.

ENVIRONMENTAL AND OCCUPATIONAL HEALTH AND SAFETY SERVICES STANDARD OPERATING PROCEDURE for the Safe Use of Sodium Azide in the Laboratory

PHYSICAL AND HEALTH HAZARD SUMMARY

1. Sodium azide is highly acutely toxic by all routes of exposure. It can cause hypotension, hypothermia, headache, shortness of breath, faintness and convulsions or death. The oral LD50 (rat) for sodium azide is 27 mg/kg and the skin (rabbit) LD50 is 20 mg/kg. 2. 3. 4. When mixed with water or an acid, sodium azide rapidly hydrolyzes in water to form hydrazoic acid, a highly toxic and flammable gas. When heated to ~275C, sodium azide may undergo violent decomposition. Sodium azide reacts with lead, copper, silver, gold, and metal halides to form heavy metal azides which are explosive.

REQUIRED WORK PRACTICES FOR USING SODIUM AZIDE

1. Work with sodium azide should take place in a chemical hood that has been inspected within the past twelve (12) months. Work with the sash lowered. Check the hood monitor to verify hood function before beginning work. If the hood does not have a monitor, contact EOHSS for assistance. (See Section 4.4 for more information.) Wear two pairs of nitrile gloves, lab coat, and safety glasses when working with sodium azide. (See Section 4.5 for more information) Do not store on metal shelves or use metal items to handle sodium azide (i.e., spatulas). Store in tightly closed containers in a cool, well-ventilated area away from HEAT, AIR, LIGHT and MOISTURE. Sodium azide and all other acutely toxic materials should be stored in a secondary container and locked in a cabinet or drawer. Drain disposal of sodium azide solutions is not permitted. In the event of an emergency (spills, personal injury) involving sodium azide, follow the instructions on the Laboratory Emergency Response Guide. (See Section 5 for more information) All general safe work practices, i.e. No eating, drinking, chewing gum, or pipetting by mouth, are expected to be followed when working with sodium azide.

2. 3. 4.

5.

6. 7.

8.

1. INTRODUCTION This Standard Operating Procedure (SOP) establishes procedures for safe handling, transport and storage of sodium azide, also known as azide, azium, smite and the sodium salt of hydrazoic acid (CAS # 26628-22-8). This SOP addresses only the use of pure sodium azide and its solutions at 5% or greater in the laboratory. It assumes that all of the UMDNJ minimum safety requirements, as detailed in the latest version of the UMDNJ Laboratory Safety Plan, have been implemented. Background Dilute solutions of sodium azide are used in research laboratories as a preservative. This use generally presents no extraordinary dangers to the user, but it should be noted that weak solutions of sodium azide (0.1 to 1.0%) are eye and skin irritants. Of greater concern is the use and storage of pure sodium azide and solutions of 5% or greater sodium azide. Use of these materials presents both physical hazards, in the form of explosions, and heath hazards, as sodium azide is highly acutely toxic. Sodium azide can cause hypotension, hypothermia, headache, shortness of breath, faintness, convulsions and death. It is toxic by all routes of exposure. The oral LD50 (rat) for sodium azide is 27 mg/kg and the skin (rabbit) LD50 is 20 mg/kg. The LC

50

(rat) is 37 mg/m3.

In addition, it is a mutagen, and should be treated as a possible carcinogen. Sodium azide rapidly hydrolyzes in water to form hydrazoic acid, a highly toxic and explosive gas. It is thermally unstable, and if heated to ~275C, sodium azide may undergo violent decomposition It can easily form explosive compounds when it comes in contact with or dries on metal surfaces. It can also react with metal pipe in laboratory sinks, traps and drains and with metal spatulas and lab

Page 2 of 13

equipment to form shock sensitive salts If sodium azide is introduced to waste water treatment systems in large volume or high concentration, the desirable anti-bacterial characteristics of this chemical can damage the water treatment process. 2. SCOPE This SOP addresses the use of sodium azide and solutions at 5% or greater concentrations in a research laboratory. This SOP assumes that all of the UMDNJ minimum safety requirements, as detailed in the latest version of the UMDNJ Laboratory Safety Plan have been implemented. 3. RESPONSIBILITY 3.1.All staff engaged in the use or handling of sodium azide, or working within a laboratory using sodium azide, are responsible for understanding all hazards associated with its use, and for using appropriate personal protective equipment (PPE). 3.2.The Principal Investigator is responsible for ensuring that his/her staff has been trained in the use, storage, handling and first aid procedures for sodium azide and maintaining records of this training. 3.3.Sodium azide use is restricted to the specific staff members who have had prior training in proper use, handling and storage, and first aid procedures. Each staff members name must appear on the listing in Section 6 of this document, and each staff member must initial by his/her name. 4. PROCEDURES 4.1.Training 4.1.1.Prior to conducting any work with sodium azide, the Principal Investigator must provide training to his/her laboratory personnel specific to the hazards involved in working with this substance, work area decontamination,

Page 3 of 13

and emergency procedures. 4.1.2.The Principal Investigator must provide his/her laboratory personnel with a copy of this SOP and a copy of the sodium azide MSDS provided by the manufacturer. 4.1.3.The Principal Investigator must ensure that his/her laboratory personnel have attended initial laboratory safety training or refresher training within the last two years. NOTE: EOHSS is available to assist in the education and/or training of personnel concerning safe work practices. 4.1.4.Prior to conducting any work with sodium azide, the Principal Investigator must provide training to all laboratory personnel in his/her laboratory specific to the hazards involved in working with this substance, the requirement to limit activities to a Designated Area, procedures to clean and decontaminate all work areas and equipment after completing work with sodium azide, as well as first aid and emergency procedures. 4.1.5.The Principal Investigator must provide his/her laboratory personnel with a copy of this SOP and a copy of the MSDS provided by the manufacturer for sodium azide or reagent purchased. A copy should also be inserted in the Laboratory Safety Plan binder 4.1.6.The Principal Investigator must ensure that his/her laboratory personnel have attended initial laboratory safety training or refresher training within the last two years. 4.2.Signage 4.2.1.When sodium azide is in use, warning signs must be posted on the chemical hood and laboratory door until the sodium azide has been returned to storage and the use area has been decontaminated.

Page 4 of 13

Designated Area Caution Caution Sodium In Use - Highly Toxic Sodium Azide Azide In- Use Highly Toxic Authorized Personnel Only 4.2.2.Signs will include the information shown in the following Material Safety Data Sheets are available in Room__________ samples: For more information, please contact:____________________ Sample Chemical Hood Sign In the event of a chemical spill, contact Public Safety at ____

and ask for EOHSS to respond.

Sample Door Sign for When Sodium Azide Is In Use

4.2.3

Labels should include the name of the solution (i.e. 5% aqueous sodium azide), the CAS # for sodium azide (26628-22-8) and any diluting solvents. The CAS # for other diluents can be obtained from their MSDS sheet. The hazard ratings for sodium azide that should appear on the label are: Health = 3; Flammability = 1; Reactivity = 3. Suspect Cancer Agent.

4.3. Storage 4.3.1.Pure sodium azide and 5% or greater solutions must be stored in a location that is secure to unauthorized access. Examples are a locked drawer or cabinet, or a refrigerator within a laboratory that is locked

Page 5 of 13

when authorized personnel are not present. A refrigerator containing sodium azide must be labeled with a caution sign noting the presence of sodium azide and its hazards (highly toxic). 4.3.2.Store pure sodium azide and its solutions greater than 5% in appropriate, sealed containers within unbreakable secondary containment (i.e., a bottle or vial within a sealed compatible jar). Select a wellventilated, cool, dry area. Store away from metals, acids, carbon disulfide, bromine, chromyl chloride, hydrazine and dimethyl sulfate. Label all containers, including secondary containment, with the chemical name and hazard warning. 4.4. Handling and Solution Preparation 4.4.1.Sodium azide powder should be purchased in the smallest practical amount. Whenever possible, sodium azide should be purchased as a pre-mixed stock solution of less than 5%. 4.4.2.Whenever laboratory procedures require handling a fresh sodium azide powder or concentrated solutions of 5% or greater quantities, that may require assistance in case of a spill or accident, it is recommended that a second trained individual be present in the lab or in the vicinity. 4.4.3.Bottles containing solutions of sodium azide at 5% or greater or the pure powder must be opened and handled only in a chemical hood that has been certified within the last 12 months. The operation of the chemical hood must be verified by the use of a chemical hood monitoring device, a smoke test using a smoke generating tube, or a mechanical or electronic device that indicates airflow If there is any reason to believe the chemical hood is not operating properly

Page 6 of 13

(e.g., unusual noise, detectible odor or low flow), contact EOHSS to have the hood checked before using the hood. During use, the sash must be lowered to operating height or below. Containers of sodium azide must always be closed when not in use. 4.4.4.Use glassware with a wide base (such as Erlenmeyer flask) to increase stability. Triple rinse glassware in a hood with water or appropriate solvent to decontaminate before reusing. 4.4.5.Work with sodium azide should take place over polyethylene secondary containers or spill trays to facilitate cleanup and decontamination. 4.4.6.Wash hands thoroughly immediately after working with any concentration of sodium azide. 4.5. Personal Protective Equipment 4.5.1.The following minimum Personal Protective Equipment must be worn during operations involving sodium azide: 4.5.2.Splash-proof chemical goggles. 4.5.3.Wear disposable nitrile gloves. Doublegloving is recommended when working with pure sodium azide or sodium azide solutions greater than 5%. Change gloves frequently and when contaminated, punctured or torn. Wash hands immediately after removing gloves. Wash hands immediately after removing gloves. 4.5.4.Wear a standard or disposable laboratory coat or disposable coveralls. A standard laboratory coat may be reused before laundering if it has not been contaminated with sodium azide. 4.5.5.A chemical-resistant apron with attached sleeves should be worn over the laboratory coat if working with larger amounts of solution or if there is a greater potential for splashing during the procedure. 4.5.6.A standard or disposable laboratory coat or

Page 7 of 13

disposable coveralls. A standard laboratory coat may be reused before laundering if it has not been contaminated with sodium azide. If a garment is contaminated, it must be washed in a controlled area to prevent sodium azide contamination of drains. 4.5.7.Closed-toed, leather shoes (not fabric or mesh). 4.5.8.In case of a significant spill resulting in grossly contaminated lab wear or personal clothing EOHSS should be contacted for information on proper handling. 5. EMERGENCIES 5.1 Spill of Sodium Azide Outside of the Chemical Hood: Phone the Public Safety Emergency number (Newark: 2-4490; Piscataway/New Brunswick: 5-4000; Camden and Stratford: 7-7777) immediately. Ask them to have EOHSS respond. DO NOT attempt to clean up a spill. Isolate the area to prevent the spread of contamination (e.g., close doors to affected area and post a warning sign). Alert personnel in the immediate area to evacuate. Attend to any injured personnel. Direct the EOHSS response team to the location of the spill. NOTE: Personnel must not attempt to clean up a spill of pure sodium azide or its solutions at 5% or greater that occur outside of a chemical hood.

5.2

Spill of Sodium Azide Inside the Chemical Hood: Small spills of sodium azide crystals should be swept up and surfaces cleaned with pH-adjusted water (pH greater than 9.0). Spills of sodium azide solution should be addressed by covering with absorbent material then cleaning surfaces with pH-adjusted water. Spill clean-up materials should be disposed of as hazardous waste. Notify EOHSS of the spill and spill cleanup procedure.

Page 8 of 13

If the spill is large or you are unsure of your ability to thoroughly address it, call the Public Safety Emergency number (above, Section 5.1.1) and ask EOHSS to respond.

5.3

Accidental Exposure to Sodium Azide 5.3.1 5.3.2 If sodium azide or hydrazoic acid has been inhaled, move the victim to fresh air immediately. If sodium azide has been spilled on skin or clothing, wash the affected area with large amounts of soap and water, using a safety shower or eyewash, as appropriate, for a minimum of 15 minutes. During washing, remove contaminated clothing and footwear. Remove goggle last. Those assisting the victim should wear protective gloves. A disposable laboratory coat or jumpsuit should be available for the exposed individual to wear after using a safety shower. If sodium azide has contacted the eyes, immediately flush for at least 15 minutes without stopping. Hold upper and lower eyelids open and away from the eyes during irrigation. Do not allow victim to rub eyes or keep eyes closed. Remove contact lenses if possible (Note: contact lenses should not be worn when working with this material). If necessary, continue flushing with personal eyewash or apply ice water compresses during transport to medical facility or eye specialist. Avoid rubbing of the eyes. Seek medical attention immediately. If you are sure the victim has ingested sodium azide, do not attempt mouth-tomouth CPR. When sodium azide is ingested, it mixes with stomach acid and forms hydrazoic acid. Performing mouth-to-mouth

5.3.3

5.3.4

Page 9 of 13

5.3.5

5.3.6

5.3.7

CPR on someone who has ingested sodium azide could expose you to hydrazoic acid. If sodium azide is ingested, do not induce vomiting, flush mouth immediately and give plenty of water to drink. Never give anything by mouth to an unconscious person. Get medical attention immediately. Person should receive medical follow-up treatment as for inhalation. Sodium azide exposure requires immediate first aid and medical treatment. Prompt first aid is essential, even if the victim does not exhibit any signs or symptoms, or feel any pain. First aid must be followed by treatment by a physician as soon as possible. Notify the victims supervisor, if immediately available. The supervisor, a co-worker, or the victim must contact the campus Employee/ Occupational Health Program to determine what additional steps should be taken.

Newark: Employee Health (973) 972-2900 Piscataway/New Brunswick: EOHSI Employee Health Services (732) 445-0123 Stratford: Kennedy Hospital (856) 346-7816 Camden: Cooper Occupational Health Services (856) 342-2990 If the incident occurs off-hours, or an ambulance is needed because of injury, contact Public Safety to advise them of the medical emergency. Newark: 2-4490 Piscataway/New Brunswick: 5-4000 Camden and Stratford: 7-7777 5.3.8 Arrangements with local medical resources should be made ahead of time to ensure

Page 10 of 13

that medical personnel are familiar with the toxicity and treatment of sodium azide exposure.If sodium azide has been inhaled, move the victim to fresh air immediately. If breathing is difficult, oxygen should be administered. If breathing has stopped, artificial respiration using oxygen and a suitable mechanical device such as a bag or mask should be provided. Speed is essential, medical attention must be obtained immediately. Staff must know how to obtain medical assistance quickly.

6.

SIGNATURES Principal Investigators: Use the following table to list all personnel who will handle sodium azide. The staff members initials indicate that the staff member has read this SOP and understands the hazards and safe work practices as detailed in this therein. Name Job Title

Initials*

Principal /Responsible Investigator (Print):___________________________ Principal /Responsible Investigator (Signature):_______________________ Date: _____________ 7. IF ADDITIONAL ASSISTANCE IS REQUIRED 7.1.The current version of this form and additional information will

Page 11 of 13

be posted at: http://www2.umdnj.edu/eohssweb/forms.htm 7.2.EOHSS Campus Contact Information: Newark 65 Bergen Street Bergen Building Room 443 Newark, NJ 07107 (973) 972-4812 Fax (973) 972-3694 Piscataway 675 Hoes Lane - Trailer #1 Piscataway, NJ 08854 (732) 235-4058 Fax (732) 235-5270 New Brunswick Liberty Plaza Building Suite 2119 335 George Street New Brunswick, NJ 08903 (732) 235-8376 Fax (732) 235-8370 Camden/Stratford University Educational Center 40 E. Laurel Road Suite 1031 Stratford, NJ 08084 (856) 566-6189 Fax (856) 566-6352 8. REFERENCES

8.1. CDC Chemical Emergencies Fact Sheet: Facts About Sodium

Azide. May 2003, Department of Health and Human Services, Centers for Disease Control and Prevention, http://www.bt.cdc.gov/agent/sodiumazide/basics/facts.asp 8.2.Mallinckrodt Baker Inc. MSDS #S2906, Sodium Azide, 11/2/01. 8.3.American Azide Corporation MSDS, Sodium Azide, 9/19/2003. 8.4. Prudent Practices in the Laboratory: Handling and Disposal of Chemicals. 1995, National Academy of Sciences, National Academy Press, Washington, D.C., Section 7.D.3.3, p. 165. 8.5. Prudent Practices in the Laboratory: Handling and Disposal of Chemicals. 1995, National Academy of Sciences, National Academy Press, Washington, D.C. Laboratory Chemical Safety

Page 12 of 13

Summary (LCSS), Sodium Azide, http://www.hhmi.org/research/labsafe/lcss/lcss.html

Page 13 of 13

You might also like

- Safe Use of Sodium Azide SOPDocument8 pagesSafe Use of Sodium Azide SOPAustin LaneNo ratings yet

- Standard Operating Procedure: Sulfuric AcidDocument9 pagesStandard Operating Procedure: Sulfuric AcidshakaNo ratings yet

- Sodium Amide Sarpong FinalDocument11 pagesSodium Amide Sarpong FinalGeorgeNo ratings yet

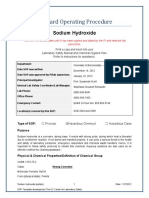

- Standard Operating Procedure (SOP) For ( - Sodium Hydroxide - )Document9 pagesStandard Operating Procedure (SOP) For ( - Sodium Hydroxide - )Sandeep ShettyNo ratings yet

- Nitric Acid SOPDocument7 pagesNitric Acid SOPnlmiNo ratings yet

- Standard Operating Procedure for Hydrochloric AcidDocument10 pagesStandard Operating Procedure for Hydrochloric AcidArunkumar ChandaranNo ratings yet

- Sulphuric Acid (98% Solution) : 1. Identification of The Material and SupplierDocument7 pagesSulphuric Acid (98% Solution) : 1. Identification of The Material and SupplierDiana SafiNo ratings yet

- Standard Operating Procedure For Laboratory and Chemical SafetyDocument4 pagesStandard Operating Procedure For Laboratory and Chemical Safetyahmed alghrablyNo ratings yet

- Hypogear 80W-90 - BP Australia Pty LTDDocument5 pagesHypogear 80W-90 - BP Australia Pty LTDBiju_PottayilNo ratings yet

- MSDS Engine Oil TitleDocument4 pagesMSDS Engine Oil TitleBiju_PottayilNo ratings yet

- Standard Operating Procedure: Sodium HydroxideDocument7 pagesStandard Operating Procedure: Sodium HydroxideSandeep ShettyNo ratings yet

- Material Safety Data Sheet: Sodium SulfiteDocument6 pagesMaterial Safety Data Sheet: Sodium Sulfiteeng20072007No ratings yet

- Acido Citrico / Citric Acid (EN)Document4 pagesAcido Citrico / Citric Acid (EN)Melany GuacaranNo ratings yet

- Sulfuric Acid Sarpong FinalDocument10 pagesSulfuric Acid Sarpong FinalHussain RizviNo ratings yet

- Sodium Hydride HandlingDocument9 pagesSodium Hydride HandlingAdamNo ratings yet

- Safety Data Sheet: Iron (Ii) SulfideDocument4 pagesSafety Data Sheet: Iron (Ii) SulfideAzhma UlyaNo ratings yet

- Standard Operating Procedure Concentrated AcidsDocument6 pagesStandard Operating Procedure Concentrated AcidsDibyendu GhoshNo ratings yet

- Sulphuric Acid (98 Solution)Document7 pagesSulphuric Acid (98 Solution)poloniusNo ratings yet

- Sodium Metabisulfite MsdsDocument6 pagesSodium Metabisulfite MsdsMas CamachoNo ratings yet

- Hydrocholoric AcidDocument4 pagesHydrocholoric AcidchapulincoloradoNo ratings yet

- Procedure Acid and Base BathDocument10 pagesProcedure Acid and Base BathNgurah MahasviraNo ratings yet

- Solfac Pro MsdsDocument8 pagesSolfac Pro Msdsenvi techNo ratings yet

- Microwave SopDocument6 pagesMicrowave SopmambojumbNo ratings yet

- MSDS 1Document7 pagesMSDS 1Areesha RanaNo ratings yet

- Caustic Soda Handling ProcedureDocument7 pagesCaustic Soda Handling ProcedureBenbaro0% (1)

- MSDS Tetrasodium EDTA Dissolvine E 39Document9 pagesMSDS Tetrasodium EDTA Dissolvine E 39Mostafa FawzyNo ratings yet

- Standard Operating Procedure: Hydrogen SulfideDocument5 pagesStandard Operating Procedure: Hydrogen SulfideJesseNo ratings yet

- Organic SolventsSOPDocument6 pagesOrganic SolventsSOPNikhilesh KumarNo ratings yet

- MSDS Drabkin's Reagent.Document4 pagesMSDS Drabkin's Reagent.Eva Fahmadiyah50% (2)

- Safety Data Sheet: 1 - Identification of The Substance/preparation and Company/undertaking Komatsu EO15W40-DHDocument5 pagesSafety Data Sheet: 1 - Identification of The Substance/preparation and Company/undertaking Komatsu EO15W40-DHHarinta Dwi SeptianaNo ratings yet

- Hydrofluoric AcidDocument3 pagesHydrofluoric AcidYusri WyeuserieyNo ratings yet

- Ferrous Sulfate Safety Data SheetDocument4 pagesFerrous Sulfate Safety Data Sheetmek00sNo ratings yet

- Lsfo MSDS 2021Document8 pagesLsfo MSDS 2021jayson lacuestaNo ratings yet

- Safety Data Sheet for XF-25 Film Processing ChemicalDocument7 pagesSafety Data Sheet for XF-25 Film Processing ChemicalPrasetya SiregarNo ratings yet

- Unit 1. Introduction Laboratory Safety and Waste Management A. Laboratory Safety Policies, Safety Data Sheet, Waste ManagementDocument15 pagesUnit 1. Introduction Laboratory Safety and Waste Management A. Laboratory Safety Policies, Safety Data Sheet, Waste ManagementShekinah BandiezNo ratings yet

- 3.msds Caustic Soda SachloDocument12 pages3.msds Caustic Soda SachloMoustafa GamilNo ratings yet

- Ferrous SulphateDocument5 pagesFerrous SulphateGolam RabbaneNo ratings yet

- Safety Policy For Chemical and Biological SectorDocument13 pagesSafety Policy For Chemical and Biological SectorIbrahim I. HamzehNo ratings yet

- DMSO SOP GuideDocument7 pagesDMSO SOP GuidesliphNo ratings yet

- Laboratory chemical spill proceduresDocument3 pagesLaboratory chemical spill proceduresRandiAndhikaNo ratings yet

- Standard Operating ProcedureDocument3 pagesStandard Operating Procedureabcd efgNo ratings yet

- Barite (Barium Sulfate)Document4 pagesBarite (Barium Sulfate)monarisosughisaNo ratings yet

- MSDS Sulphuric Acid 95-98%Document8 pagesMSDS Sulphuric Acid 95-98%Lim Jun XinNo ratings yet

- SOP for Handling Hydrochloric AcidDocument4 pagesSOP for Handling Hydrochloric AcidIjas ahmedNo ratings yet

- MSDS - Nitric AcidDocument5 pagesMSDS - Nitric AcidFkr JabarNo ratings yet

- Oil Spill Remover MSDSDocument7 pagesOil Spill Remover MSDSவனச்செல்வன் நாடார்No ratings yet

- SOP Template Sulfuric AcidDocument3 pagesSOP Template Sulfuric AcidAzirul SambasNo ratings yet

- Cu SO4Document9 pagesCu SO4Bao Duy NguyenNo ratings yet

- Week 1 SafetyLabAVCDocument7 pagesWeek 1 SafetyLabAVCJJ PMNo ratings yet

- Sulfuric Acid MSDS SummaryDocument5 pagesSulfuric Acid MSDS SummaryDipen DoshiNo ratings yet

- Msds B50Document3 pagesMsds B50PETERNo ratings yet

- Corrosives IrritantsDocument11 pagesCorrosives IrritantsSafety ManagerNo ratings yet

- SOP HydrogenPeroxideSOPDocument5 pagesSOP HydrogenPeroxideSOPRaven SwordNo ratings yet

- SelfHeatingChemicals SarpongDocument10 pagesSelfHeatingChemicals SarpongSilvi DelaNo ratings yet

- Ferrous Chloride Solution PDFDocument5 pagesFerrous Chloride Solution PDFzamburittiNo ratings yet

- Na HSO3Document8 pagesNa HSO3Bao Duy NguyenNo ratings yet

- Hydrogen Sulfide (H S) Code of Practice: 1.0 Introduction and ScopeDocument4 pagesHydrogen Sulfide (H S) Code of Practice: 1.0 Introduction and ScopeJesseNo ratings yet

- Spent Metal Catalyst 901Document16 pagesSpent Metal Catalyst 901manipalaniusaNo ratings yet

- 12 at Material Safety Original at RevisedDocument6 pages12 at Material Safety Original at RevisedRajesh KtrNo ratings yet

- Safety Data Sheet: Tridur Max BLDocument9 pagesSafety Data Sheet: Tridur Max BLAmandeep SinghNo ratings yet

- Notes Class 1Document9 pagesNotes Class 1Mahir MahmoodNo ratings yet

- Astm D1755 - 09Document6 pagesAstm D1755 - 09Deisabel Crespo100% (1)

- Article Wjpps 1435648856Document11 pagesArticle Wjpps 1435648856Rio ImbaoNo ratings yet

- Documents - Tips Direct Determination of Tin in Whole Blood and Urine by GF AasDocument5 pagesDocuments - Tips Direct Determination of Tin in Whole Blood and Urine by GF AasRozzy RamanandaNo ratings yet

- Reactive Dyeing: An Overview of Classification, Properties and Application MethodsDocument34 pagesReactive Dyeing: An Overview of Classification, Properties and Application Methodssanjay shetti100% (1)

- Identifying Casting Defects - AFSDocument3 pagesIdentifying Casting Defects - AFStalk2sumantaNo ratings yet

- CoA - Rosemary Antioxidant, Odorless (Organic) - 35495 - 332107 - 027.050 - ENDocument2 pagesCoA - Rosemary Antioxidant, Odorless (Organic) - 35495 - 332107 - 027.050 - ENvalentin.sabatetNo ratings yet

- Ruian Chengyu Auto Parts Co Oil, Fuel & Coolant FiltersDocument17 pagesRuian Chengyu Auto Parts Co Oil, Fuel & Coolant FiltersRizal RaishedNo ratings yet

- 25 List of Global Testing and Consultancy For Rubber G Tacr LaboratoriesDocument3 pages25 List of Global Testing and Consultancy For Rubber G Tacr Laboratoriessimbua72No ratings yet

- LWT - Food Science and Technology: Deba Krishna Das, Himjyoti Dutta, Charu Lata MahantaDocument7 pagesLWT - Food Science and Technology: Deba Krishna Das, Himjyoti Dutta, Charu Lata Mahantaelisa1027No ratings yet

- Production of Copper Sulphate in Solution From Metallic or Scrap Copper and ..Document2 pagesProduction of Copper Sulphate in Solution From Metallic or Scrap Copper and ..Laura GreenNo ratings yet

- 9 - Bhattiacademy - Com - Chemistry - 1. Scholar Series PDFDocument14 pages9 - Bhattiacademy - Com - Chemistry - 1. Scholar Series PDFSumair Khan MasoodNo ratings yet

- Acid-Base Equilibria ModuleDocument15 pagesAcid-Base Equilibria ModuleSteinerNo ratings yet

- Chemical Resistance of Styrene Copolymers: BASF Plastics Key To Your SuccessDocument12 pagesChemical Resistance of Styrene Copolymers: BASF Plastics Key To Your SuccessLuisNo ratings yet

- Paper CocrystalDocument14 pagesPaper CocrystalTanaz NathaniNo ratings yet

- A Review On The Study of Self Curing ConcreteDocument7 pagesA Review On The Study of Self Curing ConcretePRAJWAL srNo ratings yet

- I) If Any of The Three Components Are Missing, Then A Fire Cannot Start. Ii) If Any of The Three Components Are Removed, Then The Fire Will Go OutDocument3 pagesI) If Any of The Three Components Are Missing, Then A Fire Cannot Start. Ii) If Any of The Three Components Are Removed, Then The Fire Will Go OutRohit YadavNo ratings yet

- Quicklime For Structural PurposesDocument2 pagesQuicklime For Structural PurposesMostafa KamelNo ratings yet

- Aminochelates in Plant Nutrition A ReviewDocument13 pagesAminochelates in Plant Nutrition A ReviewMohammad Kazem souriNo ratings yet

- Chemeo 18-027-2 TrioleinDocument3 pagesChemeo 18-027-2 TrioleinklpiNo ratings yet

- DDC SVC Bro 0001Document38 pagesDDC SVC Bro 0001David PomaNo ratings yet

- Ammonia Vapor Test For Determining Susceptibility To Stress Corrosion Cracking in Copper AlloysDocument4 pagesAmmonia Vapor Test For Determining Susceptibility To Stress Corrosion Cracking in Copper AlloysDanZel DanNo ratings yet

- THPS 75Document4 pagesTHPS 75dalton2003No ratings yet

- Calcined Magnesite As An Adsorbent For Cationic and Anionic Dyes: Characterization, Adsorption Parameters, Isotherms and Kinetics StudyDocument31 pagesCalcined Magnesite As An Adsorbent For Cationic and Anionic Dyes: Characterization, Adsorption Parameters, Isotherms and Kinetics StudySyarifahNo ratings yet

- Draft 316LSS Biomass&BioenergyDocument25 pagesDraft 316LSS Biomass&BioenergyHenry PedrazaNo ratings yet

- AC510U/AC520U: High Performance Turning Grade For Heat Resistant AlloyDocument4 pagesAC510U/AC520U: High Performance Turning Grade For Heat Resistant AlloyFabianoKovalechenNo ratings yet

- Isotherm Model of The Adsorption of Nitrate Ions Onto Surface of Silica From Sugarcane BagasseDocument13 pagesIsotherm Model of The Adsorption of Nitrate Ions Onto Surface of Silica From Sugarcane BagassefaniNo ratings yet

- Vitec 1000Document1 pageVitec 1000eduardoNo ratings yet

- Steel Castings HandbookDocument58 pagesSteel Castings Handbookgalici2002100% (3)