Professional Documents

Culture Documents

Power Window System

Uploaded by

pavel35Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Window System

Uploaded by

pavel35Copyright:

Available Formats

POWER WINDOW SYSTEM

POWER WINDOW SYSTEM

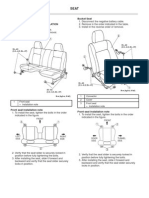

POWER WINDOW MAIN SWITCH REMOVAL/INSTALLATION 1. Disconnect the negative battery cable. 2. Disengage the clip using tapewrapped flathead screw driver. 3. Pull the switch panel forward to disengage the hook. (Vehicles built up to 07/2002)

(Vehicles built up to 07/2002)

SWITCH PANEL

POWER WINDOW MAIN SWITCH

SWITCH PANEL BODY CLIP

BODY SCREW

HOOK

(Vehicles built from 08/2002)

(Vehicles built from 08/2002)

6. Install in the reverse order of removal. POWER WINDOW MAIN SWITCH INSPECTION (VEHICLES BUILT UP TO 07/2002) Regular Cab, Stretch Cab 1. Remove the switch panel. (Refer to POWER WINDOW MAIN SWITCH REMOVAL/INSTALLATION.) 2. Inspect for continuity between the power window main switch terminals using an ohmmeter. 3. When inspecting the drivers side, connect the battery positive voltage to terminal F and connect the ground to terminal D. 4. When inspecting the passengers side, turn the power-cut switch to ON.

4. Disconnect the power window main switch connector. 5. Remove the screws to remove the power window main switch from the switch panel.

S10

POWER WINDOW SYSTEM

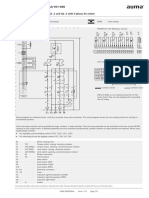

Power window switch Drivers side : Continuity

Switch position Manual close Off Auto open Manual open Terminal F D A (H) B (I)

Double Cab 1. Remove the switch panel. (Refer to POWER WINDOW MAIN SWITCH REMOVAL/INSTALLATION.) 2. Inspect for continuity between the power window main switch terminals using an ohmmeter. 3. When inspecting the driver s side, connect the battery positive voltage to terminal A (L.H.D.) or F (R.H.D.) and connect the ground to terminal H. 4. When inspecting the passenger s side and rear, turn the power-cut switch to ON. Power window switch Drivers side : Continuity

( ): R.H.D. Passenger s side : Continuity

Switch position Close Off Open Terminal F D H (A) I (B)

Switch position Manual close Off Auto open Manual open

Terminal A (F) H L (D) J (B)

( ): R.H.D. Passenger s side : Continuity : Continuity

Terminal D A (H) B (I) H (A) I (B) Switch position Close Off Open Terminal A (F) H D (L) B (J)

( ): R.H.D. Power-cut switch

Switch position ON OFF

( ): R.H.D.

( ): R.H.D. Rear left

F D POWER-CUT SWITCH MANUAL OPEN CLOSE AUTO CIRCUIT AUTO OPEN OPEN

: Continuity

Switch position Close Off Open Terminal A H K I

MANUAL CLOSE

I (B) H (A) PASSENGERS SIDE CLOSE A (H) B (I) DRIVERS SIDE H I ( ) : R.H.D. F D A B OPEN

( ): R.H.D. Rear right : Continuity

Switch position Close Off Open Terminal A H E C

5. If not as specified, replace the power window main switch.

( ): R.H.D.

S11

POWER WINDOW SYSTEM

Power-cut switch : Continuity

Terminal Switch position ON OFF H L (D ) J (B ) D (L ) B (J) E C K I

( ): R.H.D. L.H.D.

A H

D B PASSENGERS

C RIGH T

R.H.D.

F H

J PASSENGERS D B K L I J

E H F

C D

A B

5. If not as specified, replace the power window main switch.

S12

POWER WINDOW SYSTEM

POWER WINDOW MAIN SWITCH INSPECTION (VEHICLES BUILT FROM 08/2002) Drivers Side 1. Remove the driverside front door trim. 2. Connect the power window main switch connector. 3. Measure the voltage at the power window main switch terminals as indicated below. 4. Disconnect the power window main switch connector before inspecting for continuity at terminals 1M and 1F. D If not as specified, inspect the parts listed under Action. D If the parts and wiring harnesses are okay but the system still does not work properly, replace the power window main switch. Terminal voltage list (Reference)

Terminal

Signal

Connected to

Test condition Any door is open (door switch is on): inspect for continuity to ground All doors are closed (door switch is off): inspect for continuity to ground

Voltage (V)/ Continuity Yes

Action

1F

Door switch

Door switch

D Inspect door switch D Inspect related

No B+ Below 1.0

harness

D Inspect P.WIND 30 A

1H

IG1

P. WIND 30 A fuse

Ignition switch is at ON position Ignition switch is at LOCK position

fuse

D Inspect relate

harness

D P. WIND 15 A fuse D Inspect related

1J

Power supply Close output Ground Close output

P. WIND 15 A fuse Power window motor GND Power window motor Power window motor

Under any condition While door glass is opening While door glass is closing Under any condition: inspect for continuity to ground While door glass is opening While door glass is closing Under any condition: inspect for continuity to ground

B+ Below 1.0 B+ Yes Below 1.0 B+ Yes Alternates between 0 and 9 0 or 9 Alternates between 0 and 9 0 or 9 9

harness

D Power window motor D Inspect related

1L (1D) 1M 1N (1B)

harness

D Inspect GND D Power window motor D Inspect related

harness

D Power window motor D Inspect related

2A

Ground

harness

D Power window motor D Inspect related

2B

SEN2

Power window motor

Door glass is in motion Door glass is not in motion

harness

D Power window motor D Inspect related

2C

SEN1

Power window motor

Door glass in motion Door glass is not in motion

harness

D Power window motor D Inspect related

2D

Power supply

Power window motor

Under any condition

harness

( ) : R.H.D.

S13

POWER WINDOW SYSTEM

Except Driver s Side 1. Remove the power window main switch. 2. Turn the powercut switch to UNLOCK. 3. Inspect for continuity between the power window main switch terminals using an an ohmmeter. D If not as specified, replace the power window main switch. Passenger s side Rear right

Rear left

Powercut switch

S14

POWER WINDOW SYSTEM

POWER WINDOW SUBSWITCH REMOVAL/INSTALLATION (VEHICLES BUILT UP TO 07/2002) Passenger s side 1. Disconnect the negative battery cable. 2. Disengage the clip using a tape-wrapped flathead screwdriver. 3. Pull the power window subswitch forward, and disengage the hook.

4. Remove the power window subswitch. 5. Install in the reverse order of removal.

BODY CLIP POWER WINDOW SUBSWITCH

BODY

Rear 1. Disconnect the negative battery cable. 2. Disengage the clip using a tape-wrapped flathead screwdriver. 3. Pull the power window subswitch panel forward to disengage the hook.

HOOK

4. Disconnect the power window subswitch connector. 5. Install in the reverse order of removal. Rear 1. Disconnect the negative battery cable. 2. Remove the hook by inserting a tape-wrapped, flathead screwdriver between the switch and the rear door trim.

HOOK

4. Remove the screw. 5. Remove the power window subswitch.

POWER WINDOW SUBSWITCH

3. Disconnect the connector, and remove the power window subswitch. 4. Install in the reverse order of removal. POWER WINDOW SUBSWITCH REMOVAL/INSTALLATION (VEHICLES BUILT FROM 08/2002) Passenger s side 1. Disconnect the negative battery cable. 2. Remove the screw. 3. Remove the switch panel.

6. Install in the reverse order of removal.

S15

POWER WINDOW SYSTEM

POWER WINDOW SUBSWITCH INSPECTION (VEHICLES BUILT UP TO 07/2002) 1. Remove the power window subswitch. (Refer to POWER WINDOW SUBSWITCH REMOVAL/INSTALLATION.) 2. Inspect for continuity between the power window subswitch terminals using an ohmmeter. Passenger s side : Continuity

Switch position Off Close Open Terminal A B D E F

E CLOSE OPEN F D

A B

Rear : Continuity

Switch position Close Off Open Terminal A B D E F

FRONT POWER WINDOW REGULATOR REMOVAL/INSTALLATION 1. Raise the rear edge of the front door glass 80 mm {3.1 in} from the fully lowered position. 2. Disconnect the negative battery cable. 3. Remove the front glass guide and the rear glass guide. (Refer to DOOR, FRONT DOOR DISASSEMBLY/ASSEMBLY.) 4. Remove in the order indicated in the table. 5. Install in the reverse order of removal.

B A

8.912.7 {90130, 79112}

D C

F D

B A B F CLOSE OPEN E A D C

6.879.80 {70100, 60.886.7}

3. If not as specified, replace the power window subswitch. POWER WINDOW SUBSWITCH INSPECTION (VEHICLES BUILT FROM 08/2002) 1. Inspect for continuity between the power window subswitch terminals. D If not as specified, replace the power window subswitch.

Nm {kgfcm, inlbf}

1 2 3 4

Front power window regulator connector Bolt Nut Front power window regulator

S16

POWER WINDOW SYSTEM

FRONT POWER WINDOW REGULATOR DISASSEMBLY/ASSEMBLY 1. Disassemble in the order indicated in the table. 2. Assemble in the reverse order of disassembly.

A

D C

6.879.80 Nm {70100 kgfcm, 60.886.7 inlbf}

3.04.9 Nm {3050 kgfcm, 2743 inlbf}

1 2 3

Rear power window regulator connector Bolt Rear power window regulator

1 2

Bolt Power window motor + Disassembly Note + Assembly Note Frame

REAR POWER WINDOW REGULATOR DISASSEMBLY/ASSEMBLY 1. Disassemble in the order indicated in the table. 2. Assemble in the reverse order of disassembly.

3.14.8 Nm {3149 kgfcm, 2742 inlbf}

Power Window Motor Disassembly Note D Make marks on the gear and base of the frame before disassembling the power window motor.

BASE MARK

GEAR

Power Window Motor Assembly Note D Align the marks of the gear and the frame to install the power window motor. REAR POWER WINDOW REGULATOR REMOVAL/INSTALLATION 1. Raise the rear door glass completely. 2. Disconnect the negative battery cable. 3. Remove the door screen. (Refer to DOOR, REAR DOOR DISASSEMBLY/ASSEMBLY.) 4. Remove in the order indicated in the table. 5. Install in the reverse order of removal.

1 2

Bolt Power window motor + Disassembly Note + Assembly Note Frame

S17

POWER WINDOW SYSTEM

Power Window Motor Disassembly Note D Make marks on the gear and base of the frame before disassembling the power window motor.

MARK

D If not as specified, replace the power window motor. Voltage Pulse wave: MAX. 5V, MIN. 0V

Motor operation UP DOWN Terminal 2A GND B+ 2B B+ GND

BASE

GEAR

Power Window Motor Assembly Note D Align the marks of the gear and base of the frame to install the power window motor. POWER WINDOW MOTOR INSPECTION (VEHICLES BUILT UP TO 07/2002) 1. Remove the power window motor. (Refer to FRONT POWER WINDOW REGULATOR DISASSEMBLY/ASSEMBLY.) (Refer to REAR POWER WINDOW REGULATOR DISASSEMBLY/ASSEMBLY.) 2. Apply battery positive voltage to the power window motor terminals and inspect the operation of the power window motor. B+: Battery positive voltage

Connection B+ A B

UP

Except Driver s Side 1. Apply battery positive voltage to the power window motor terminals and inspect the power window motor. D If not as specified, replace the power window motor.

Motor operation UP DOWN Terminal A GND B+ B B+ GND

GND B A

DOWN

Motor operation Up Down

A B

3. If not as specified, replace the power window motor. POWER WINDOW MOTOR INSPECTION (VEHICLES BUILT FROM 08/2002) Drivers side 1. Disconnect the power window motor connector. 2. Apply battery positive voltage to the power window motor terminals 2A and 2B and inspect the power window motor operation. D If not as specified, replace the power window motor. 3. Apply battery positive voltage to the power window motor terminal 1D and connect terminal 1A to ground. 4. Measure the voltage at terminal 1B and 1C while performing Step 3.

INITIAL POSITION SETTING Note D A driverside window will not fully close automatically under the following conditions: The battery has been disconnected during vehicle maintenance or for other reasons. The power window main switch connector, or driverside power window motor connector has been disconnected. Carry out the following procedure to resume operation: 1. Turn the ignition switch to the ON position. 2. Press the driver side power window main switch and fully open the driverside window.

S18

POWER WINDOW SYSTEM

3. Pull up the driver side power window main switch to manualup position to fully close the driver side window, and keep holding the switch up at the position for about 2 seconds to complete initial setting.

S19

You might also like

- Power Door Lock SystemDocument9 pagesPower Door Lock Systempavel35No ratings yet

- Outside Mirror: A C Up C A Down C D Left D C Right UpDocument2 pagesOutside Mirror: A C Up C A Down C D Left D C Right Uppavel35No ratings yet

- Interior Lighting SystemDocument3 pagesInterior Lighting Systempavel35No ratings yet

- Power Window Control System Parts LocationDocument5 pagesPower Window Control System Parts LocationAstolfo AraujoNo ratings yet

- Theft-Deterrent SystemDocument8 pagesTheft-Deterrent Systempavel35No ratings yet

- 93FWD 8SDocument10 pages93FWD 8SChristian MartinezNo ratings yet

- Windshield Window GlassDocument163 pagesWindshield Window GlassElias Castro SalazarNo ratings yet

- Exterior Lighting SystemDocument12 pagesExterior Lighting Systempavel35No ratings yet

- 08T - Power Mirror SystemsDocument6 pages08T - Power Mirror SystemsjohnqevilNo ratings yet

- Instrument Panel Removal and Installation PDFDocument8 pagesInstrument Panel Removal and Installation PDFMichael Hernandez100% (1)

- Troubleshooting (Power Window System)Document7 pagesTroubleshooting (Power Window System)pavel35No ratings yet

- Golf 3 SIBER - RoofDocument9 pagesGolf 3 SIBER - RoofDejan Djukic100% (1)

- TIS - Lexus 2006 GX470 Repair Manual (RM00V0U)Document4 pagesTIS - Lexus 2006 GX470 Repair Manual (RM00V0U)Joe AlveyNo ratings yet

- Audio: Speaker Installation Note Double CabDocument3 pagesAudio: Speaker Installation Note Double Cabpavel35No ratings yet

- 2007 - JS - Sebring - Stratus Power WindowsDocument3 pages2007 - JS - Sebring - Stratus Power WindowsCarlos LimadaNo ratings yet

- Instrument Panel Removal and Installation PDFDocument9 pagesInstrument Panel Removal and Installation PDFMichael HernandezNo ratings yet

- SB-14-12-001 Power Folding Mirror Installation R1Document11 pagesSB-14-12-001 Power Folding Mirror Installation R1Conrad Aixart ForesNo ratings yet

- Masterpact NT: User ManualDocument56 pagesMasterpact NT: User Manualanurag_jay12464No ratings yet

- RF PDFDocument10 pagesRF PDFJessica EdwardsonsNo ratings yet

- Antrieb Actuators O & M CatalogueDocument12 pagesAntrieb Actuators O & M Catalogueysr3ee6926100% (3)

- Diagnosis and Testing - Power WindowsDocument22 pagesDiagnosis and Testing - Power WindowsMuhammad ZamanNo ratings yet

- 1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part9Document197 pages1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part9CandieApple100% (4)

- Toyota Camry 2006-2011 2AZ-FE ChargingDocument21 pagesToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsNo ratings yet

- 08S - Power Window SystemsDocument4 pages08S - Power Window SystemsjohnqevilNo ratings yet

- Power Sunroof: Calibration & Timing NoteDocument23 pagesPower Sunroof: Calibration & Timing NoteEngine Tuning UPNo ratings yet

- Inspection Front Door Lock ActuatorDocument4 pagesInspection Front Door Lock ActuatorVinnie IngallsNo ratings yet

- Automatic Sliding Door Retrofit Drive Assembly Installation ManualDocument19 pagesAutomatic Sliding Door Retrofit Drive Assembly Installation ManualOscar Vazquez EspinosaNo ratings yet

- C6 Remove and Refit Steering Wheel Rotary ControlsDocument5 pagesC6 Remove and Refit Steering Wheel Rotary Controlsstephen.hollis5146No ratings yet

- Splendide: Technical Education Group PresentsDocument20 pagesSplendide: Technical Education Group PresentsmikepuiuNo ratings yet

- IP68 Actuator With CC Spares CatalogueDocument8 pagesIP68 Actuator With CC Spares CatalogueParameswararao BillaNo ratings yet

- Power Door Lock Control System Parts LocationDocument5 pagesPower Door Lock Control System Parts LocationAstolfo AraujoNo ratings yet

- Body, Lock & Security System: SectionDocument30 pagesBody, Lock & Security System: SectionFrancesca AckumburNo ratings yet

- Daewoo Matiz 2000-2013 Engine Electrical 19-42Document24 pagesDaewoo Matiz 2000-2013 Engine Electrical 19-42Hector Osorio100% (3)

- Astra v10Document9 pagesAstra v10toni100% (4)

- Rear Window Defroster: Lead of The Circuit Tester PushDocument1 pageRear Window Defroster: Lead of The Circuit Tester Pushpavel35No ratings yet

- 2500 User ManualDocument27 pages2500 User ManualDAVNIALNo ratings yet

- 74 Sliding Roof ConvertibleDocument16 pages74 Sliding Roof ConvertibleTung NguyenNo ratings yet

- GARD G6000: Installation Instructions For Swift Road BarriersDocument24 pagesGARD G6000: Installation Instructions For Swift Road BarriersShah JeeNo ratings yet

- Control System: Blower Motor InspectionDocument1 pageControl System: Blower Motor Inspectionpavel35No ratings yet

- Treadmill Ironman Service Manual Rev. BDocument70 pagesTreadmill Ironman Service Manual Rev. BSteven100% (1)

- F-55 Troubleshooting PotentiometerDocument29 pagesF-55 Troubleshooting PotentiometerNiko DalmaNo ratings yet

- Masterpact NT: User ManualDocument56 pagesMasterpact NT: User ManualkubikNo ratings yet

- Meter / Gauge System: PrecautionDocument76 pagesMeter / Gauge System: PrecautionlogammicNo ratings yet

- SM 35Document6 pagesSM 35Communications ShipyardNo ratings yet

- Valve Adjustment PDFDocument34 pagesValve Adjustment PDFlilo6romeroNo ratings yet

- Electrical System of EngineDocument12 pagesElectrical System of EngineGreg HannaNo ratings yet

- Supplement 1988Document10 pagesSupplement 1988Greg HannaNo ratings yet

- All Engine Manual (OCR)Document580 pagesAll Engine Manual (OCR)Alberto Mansilla Tejeda100% (1)

- Keyless Receiver Inspection 5HBDocument2 pagesKeyless Receiver Inspection 5HBDuy KhánhNo ratings yet

- 93ZJ Secc 8S Power WindowsDocument4 pages93ZJ Secc 8S Power WindowsBLAZEPSINo ratings yet

- Zivan Adjustments: To Adjust Zivan NG3 Output Voltage Please Observe Safety PrecautionsDocument2 pagesZivan Adjustments: To Adjust Zivan NG3 Output Voltage Please Observe Safety PrecautionsMatias CNo ratings yet

- GMLAN Communication Issues, No Crank, Warning Lamps & More FixedDocument12 pagesGMLAN Communication Issues, No Crank, Warning Lamps & More Fixedأمجد راضي هادي /A1No ratings yet

- COUPE OR SEDAN BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITYDocument27 pagesCOUPE OR SEDAN BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITYFSR1407No ratings yet

- Air Conditioning PDFDocument113 pagesAir Conditioning PDFAndrey Gladyshev100% (3)

- MV distribution metalclad switchgear withdrawable circuit-breaker 1 to 17.5 kV Operation guideDocument28 pagesMV distribution metalclad switchgear withdrawable circuit-breaker 1 to 17.5 kV Operation guideMohamed MagdyNo ratings yet

- 005 Joystick 2Document8 pages005 Joystick 2JonathanDavidDeLosSantosAdornoNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- t-41 ps#1Document1 paget-41 ps#1pavel35No ratings yet

- td-01 02 PsDocument18 pagestd-01 02 Pspavel35100% (1)

- TroubleshootingDocument3 pagesTroubleshootingpavel35No ratings yet

- Heater and Air Conditioner SystemsDocument1 pageHeater and Air Conditioner Systemspavel35No ratings yet

- On-Board Diagnostic (Air Bag System)Document7 pagesOn-Board Diagnostic (Air Bag System)pavel35No ratings yet

- Immobilizer SystemDocument16 pagesImmobilizer Systempavel35No ratings yet

- On-Board Diagnostic (Immobilizer System)Document5 pagesOn-Board Diagnostic (Immobilizer System)pavel35No ratings yet

- Air Bag SystemDocument9 pagesAir Bag Systempavel35No ratings yet

- Body Electrical SystemDocument2 pagesBody Electrical Systempavel35No ratings yet

- Audio: Speaker Installation Note Double CabDocument3 pagesAudio: Speaker Installation Note Double Cabpavel35No ratings yet

- Audio: Warning and Indicator System, AudioDocument1 pageAudio: Warning and Indicator System, Audiopavel35No ratings yet

- Warning and Indicator SystemDocument4 pagesWarning and Indicator Systempavel35No ratings yet

- Wiper and WasherDocument3 pagesWiper and Washerpavel35No ratings yet

- Exterior Lighting SystemDocument12 pagesExterior Lighting Systempavel35No ratings yet

- Power SystemDocument4 pagesPower Systempavel35No ratings yet

- s-51 55 PsDocument5 pagess-51 55 Pspavel35No ratings yet

- Engine: Special ToolsDocument35 pagesEngine: Special Toolspavel35No ratings yet

- Troubleshooting (Power Window System)Document7 pagesTroubleshooting (Power Window System)pavel35No ratings yet

- Troubleshooting (Keyless Entry System)Document7 pagesTroubleshooting (Keyless Entry System)pavel35No ratings yet

- ST 01 PsDocument1 pageST 01 Pspavel35No ratings yet

- Seat BeltDocument4 pagesSeat Beltpavel35No ratings yet

- Body Shell (Stretch Cab - 4 Door)Document2 pagesBody Shell (Stretch Cab - 4 Door)pavel35No ratings yet

- Headliner, Floor CoveringDocument2 pagesHeadliner, Floor Coveringpavel35No ratings yet

- Dashboard and ConsoleDocument4 pagesDashboard and Consolepavel35No ratings yet

- Bucket Seat: 1 Connector 2 Cover 3 Front Seat Installation NoteDocument7 pagesBucket Seat: 1 Connector 2 Cover 3 Front Seat Installation Notepavel35No ratings yet

- Window GlassDocument6 pagesWindow Glasspavel35No ratings yet

- Rear Window Defroster: Lead of The Circuit Tester PushDocument1 pageRear Window Defroster: Lead of The Circuit Tester Pushpavel35No ratings yet

- Compact Temperature Switch For The Process Industry Model TCSDocument5 pagesCompact Temperature Switch For The Process Industry Model TCSمحمد فرحاتNo ratings yet

- Subsation BOQDocument22 pagesSubsation BOQNagendra Prasad chaudharyNo ratings yet

- ABB-Fireman Switch PDFDocument4 pagesABB-Fireman Switch PDFhandaomeNo ratings yet

- Scamp™ : Scaled, Compensated, and Multi-Point Flowmeter Signal ConditionerDocument20 pagesScamp™ : Scaled, Compensated, and Multi-Point Flowmeter Signal ConditionerSarge ChisangaNo ratings yet

- Iot Project - Part2Document39 pagesIot Project - Part2NXTEN sportsNo ratings yet

- ADC Hardware Control Panels Ref g7Document49 pagesADC Hardware Control Panels Ref g7Techne PhobosNo ratings yet

- XI-921 NEW Service Manual 22mar2011Document52 pagesXI-921 NEW Service Manual 22mar2011Novy adi syaputra 93No ratings yet

- Plywood ScooterDocument7 pagesPlywood ScooterJim100% (4)

- Peugeot Partner Tepee Diesel 1.6 HDi Fault CodesDocument27 pagesPeugeot Partner Tepee Diesel 1.6 HDi Fault CodesGerman Alejandro Casanova BriceñoNo ratings yet

- SSRGB SSR Celduc PDFDocument27 pagesSSRGB SSR Celduc PDFdejanr111No ratings yet

- NTFAST Fire Contractors Guide Book 2016Document41 pagesNTFAST Fire Contractors Guide Book 2016userNo ratings yet

- Aconis 2000 Pms PDFDocument53 pagesAconis 2000 Pms PDFtralala78% (9)

- Doosan DX140LC, DX180LC Electrical Wiring DiagramsDocument129 pagesDoosan DX140LC, DX180LC Electrical Wiring DiagramsEngAbdelrahman Khames100% (3)

- 03 MiniatureCircuitBreakers LV10 042023 EN 202306011432240991Document98 pages03 MiniatureCircuitBreakers LV10 042023 EN 202306011432240991Wellington Otavio de SouzaNo ratings yet

- Solar Battery Charger CircuitDocument36 pagesSolar Battery Charger CircuitGeorge M JacobNo ratings yet

- Wiring Diagram for SA.2 and SQ.2 ActuatorsDocument2 pagesWiring Diagram for SA.2 and SQ.2 Actuatorscosmin1975100% (4)

- Digital Diagnosis Simulation Program: - 6-SPEED ATDocument20 pagesDigital Diagnosis Simulation Program: - 6-SPEED ATJuvenal Alfredo Huerta ZoluagaNo ratings yet

- Aes 503 PSP KaDocument35 pagesAes 503 PSP KaPatrascu Gabriel100% (1)

- 020 FDCIO181-2 A6V10214492 A enDocument7 pages020 FDCIO181-2 A6V10214492 A enmaztonny SPVNo ratings yet

- CASE IH MAXXUM 130 TRACTOR Service Repair Manual PDFDocument120 pagesCASE IH MAXXUM 130 TRACTOR Service Repair Manual PDFjfjksekdmeik0% (2)

- SSP 272 Phaeton ObpsDocument27 pagesSSP 272 Phaeton Obpsภูเก็ต เป็นเกาะNo ratings yet

- Report On Metro North InjuryDocument18 pagesReport On Metro North InjurymbrackenburyNo ratings yet

- Controlador Llama Siemens Lga PDFDocument12 pagesControlador Llama Siemens Lga PDFPaolo CruzNo ratings yet

- Mirrors: SectionDocument33 pagesMirrors: SectionАндрей НадточийNo ratings yet

- Teleco CatalogDocument48 pagesTeleco CatalogstuartxiNo ratings yet

- DP-H Series User's Manual: by DSC-Electronics Germany Georgstraße 36 53111 BonnDocument58 pagesDP-H Series User's Manual: by DSC-Electronics Germany Georgstraße 36 53111 Bonnljuul74No ratings yet

- Mahr Digimar 817 CLM Height Measuring Instrument 3759019 - ManualDocument152 pagesMahr Digimar 817 CLM Height Measuring Instrument 3759019 - ManualVallik TadNo ratings yet

- General Specifications: Model DY Vortex Flowmeter Model DYA Vortex Flow ConverterDocument44 pagesGeneral Specifications: Model DY Vortex Flowmeter Model DYA Vortex Flow ConverterYoyok WiratmoNo ratings yet

- Afb Manual As Rs s7 A003Document60 pagesAfb Manual As Rs s7 A003Ulices MezaNo ratings yet

- Manual Ats ZenithDocument18 pagesManual Ats ZenithGILBERTOPERDOMONo ratings yet