Professional Documents

Culture Documents

Basics of 3-Phase Induction Motor (Part 3)

Uploaded by

vijaydev75Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basics of 3-Phase Induction Motor (Part 3)

Uploaded by

vijaydev75Copyright:

Available Formats

8/5/12

Basics of 3-phase Induction Motor (part 3) | EEP

electrical-engineering-portal.com http://electrical-engineering-portal.com/basics-of-3phase-induction-motor-3

Basics of 3-phase Induction Motor (part 3)

Toshiba three-phase induction motor nameplate

Continued fro second part Basics of 3-phase Induction Motor (part 2) Technical data to be specified by purchaser before purchasing a 3 phase induction motor:

Site Conditions

No. 1. 2. 3. 4. Technical data to be specified General data about ambient temperature and altitude: Area Classification: Temperature Class: Gas Group:

1/10

Data

electrical-engineering-portal.com/basics-of-3-phase-induction-motor-3

8/5/12

Basics of 3-phase Induction Motor (part 3) | EEP

5.

Type of Protection:

Basic Data

No. 1. Technical data to be specified Supply System: Data 415V 3 Ph 50 Hz

2. 3.

Neutral: Cooling method (Any one of the below): TENV Totally Enclosed, Non-Ventilated/ TEFC Totally Enclosed, Fan Cooled/TETC Totally Enclosed, Tube Cooled/ TEAAC Totally enclosed, Air to Air cooled /CACA Totally Enclosed, Air circuit machine with air cooler/CACW Totally Enclosed, Air circuit machine, water cooled air cooler. Degree of Enclosure Protection: Continuous Rating: Service Factor: Synchronous Speed: Insulation Class: Max. Permitted Temp Rise: Class 77 Deg Celsius

4. 5. 6. 7. 8. 9.

10.

Direction of Rotation (Any one of the below): CW/CCW/Bi-Dir. Method of Starting: Winding Connection:

2/10

11. 12.

electrical-engineering-portal.com/basics-of-3-phase-induction-motor-3

8/5/12

Basics of 3-phase Induction Motor (part 3) | EEP

13.

Neutral Terminals req.:

14.

Shaft Orientation (Any one of the below): Horizontal/Vertical Mounting: Foot/Flange Slide Rails Required:

15. 16.

17. 18.

Heater Required: Heater Voltage: (Motors rated below 37 kW shall employ 24V AC direct winding)

19. 20. 21.

Drain Required: Breather Required: Maximum Noise Level: 85dB (A) at 1m

22. 23.

GD2 (Pump + Coupling) = Winding temperature monitoring: 1. RTDs Required: 2. Thermocouples Req.: 3. No. per Winding:

24.

Bearing temp monitoring: 1. RTDs Required: 2. Thermocouples Req.: 3. No. per bearing:

electrical-engineering-portal.com/basics-of-3-phase-induction-motor-3

3/10

8/5/12

Basics of 3-phase Induction Motor (part 3) | EEP

25.

Differential CTs: If yes then: 1.

Differential CT's

Required CT Ratio: 2. Accuracy Class: 3. CT Arrangement:

26.

Cable Type: 1. Motor: 2. Heater: 3. Winding RTD: 4. Bearing Sensor: 5. CT:

27. 28. 29. 30.

Heater Terminal Box Entry: RTD/Thermocouple Terminal Box Entry: CT Terminal Box Entry: Motor Starter Protective System (Any one of the below ):Fuses+Contactor+OLR/ Circuit Breaker with overload, earth fault, undercurrent, Phase Unbalance, under voltage, Stall, Limit No. of Starts, over current Prospective System Fault Current: 50 kA (RMS SYM.)

31.

32.

Surge Protection Required:

4/10

electrical-engineering-portal.com/basics-of-3-phase-induction-motor-3

8/5/12

Basics of 3-phase Induction Motor (part 3) | EEP

Motor view

Technical data to be specified by manufacturer before selling a 3 phase induction motor

No. 1. 2. 3. 4. 5. 6. 7. 8. 9. Technical data to be specified Standard: Full Load Current (FLC): Starting Current: Efficiency (100/75/50%): Power Factor (100/75/50%): Power Factor (Starting): Full Load Torque (FLT): Starting Torque: Minimum Accelerating Torque (Motor & Load) @ 80%Volts: % FLT % FLT Data

electrical-engineering-portal.com/basics-of-3-phase-induction-motor-3

5/10

8/5/12

Basics of 3-phase Induction Motor (part 3) | EEP

10.

Pull-Out Torque:

% FLT at %SLIP

11.

Locked Rotor Withstand Time: 100% Volts: Hot: sec 80% Volts: Hot: sec Cold: sec Cold: sec

12.

Run-Up Time (Motor & Load): 100% Volts: Hot: sec 80% Volts: Hot: sec Cold: sec Cold: sec

13. 14. 15. 16.

Insulation Class & Temp Rise above Design Ambient: Maximum No. of Successive Starts: Max. No. of Starts in 1 Hour: Rotor Resistance (ac) @ 20C (Locked Rotor / Rated Load) pu Motor VA

17.

Rotor Reactance @ 20C pu Motor VA (Locked Rotor / Rated Load) Stator Resistance (ac) @ 20C (Locked Rotor / Rated Load) pu Motor VA

18.

19.

Stator Reactance @ 20C pu Motor VA (Locked Rotor / Rated Load) Stator Leakage Reactance @ 20C (Locked Rotor / Rated Load) Magnetizing Resistance @ 20C Magnetizing Reactance @ 20C pu Motor VA

20.

21. 22.

pu Motor VA pu Motor VA

electrical-engineering-portal.com/basics-of-3-phase-induction-motor-3

6/10

8/5/12

Basics of 3-phase Induction Motor (part 3) | EEP

23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34.

Torque / Speed Characteristic Current / Speed Characteristic Heating Time Constant: Cooling Time Constant: Bearing Type: Ball/Roller/Sleeve/Antifriction Lubrication: Oil/Grease Oil/Grease Cooling System: Rotor End float: Rotor End-Play: Rotor Air Gap: +mm +mm mm -mm -mm

Moment of Inertia GD (Motor & Load): kgm Referred to motor (including gearbox where applicable) Weight of Motor: kg Noise Level: dB @ m

35.

What precautions are to be taken while designing of foundation of rotating machines (Here 3 Phase induction motor)?

General 1. Description of driving and driven machinery,

electrical-engineering-portal.com/basics-of-3-phase-induction-motor-3 7/10

8/5/12

Basics of 3-phase Induction Motor (part 3) | EEP

2. Operating speed or speed ranges, 3. Number and arrangement of cylinders, 4. Distance between axis of main shaft of the machine and the top face of foundation, 5. Maximum rated output, 6. Gear box ratio where applicable, and 7. Maximum operating temperature in the bases of the machine.

For Static Design 1. A detailed loading diagram comprising plan, elevation and section showing details of communication and point of all loads on foundation. 2. A detailed drawing showing the position and size of mounting feet and details of holding down bolts.

For Dynamic Design 1. Details of out of balance forces and couples shall be given, together with associated frequencies for all possible modes of vibration for driving and driven machinery. These include the following: a) External forces, b) External primary couples, c) External secondary couples, and d) Harmonic torques. 2. Mass moments of inertia of driving and driven machine about three principal axes shall be indicated. 3. Additional information relating to specific machines, as given below, shall be provided where necessary: a) Loads due to dynamic short circuit conditions, and b) Loads due to an abnormal sudden stoppage. 4. Where it is found necessary to use anti-vibration mountings, the type and positions be indicated.

Data on Ground and Site Conditions

The following soil data shall be known: 1. Soil profile and soil characteristics up to a depth at least three times the expected mean plan dimension of the foundation which can be taken as the square root of the expected area, or hard strata. 2. Soil investigation to the extent necessary in accordance with IS: 1892-1979 and for

electrical-engineering-portal.com/basics-of-3-phase-induction-motor-3 8/10

8/5/12

Basics of 3-phase Induction Motor (part 3) | EEP

the determination of dynamic properties of soil in accordance with IS: 5249-1977. 3. The relative position of the water table below ground at different times of the year.

Frequency ratio

Wherever possible the natural frequency of the foundation soil-system shall be higher than the highest disturbing frequency and the frequency ratios shall not be normally less than 0.4.Where this is not possible, the natural frequency of the foundation-soil system shall be kept lower than the lowest disturbing frequency. The frequency ratios in such cases shall not be lower than 1.50. While the above criteria shall be applied to all possible modes of vibration, it may be permitted to operate machines closer to the resonance in certain modes of vibration provided the resulting amplitudes do not exceed the permissible limit. Even though machine may be balanced, minor disturbing forces can occur due to manufacturing tolerances and other causes, for sensitive installations, the frequencies arising from these may have to be considered.

Permisible Amplitudes

Limitations of Vibration Amplitude to Avoid Damage to Machinery This shall be specified by the manufacturer and shall in no cases be exceeded. Where no specific limit has been stated by the manufacturer, it may be taken that foundation satisfying the following amplitude criteria shall provide a satisfactory base for machinery. Limitations of Vibration Amplitude to Avoid Damage to Machinery the damage in neighboring buildings due to resonance will be negligible if the amplitude vibration of the foundation is less than 200 microns at frequencies below 20 Hz, where the disturbing frequency exceed 20 Hz, a lower amplitude may be necessary for certain installations. Limitation of Vibration Amplitude to Avoid Discomfort of Persons for low speed machines, it is unlikely that foundations which satisfy the previous point will produce vibrations of sufficient amplitude to be disturbing to persons. In special cases where there are particular reasons to avoid discomfort to personnel Limitations of Amplitude to Avoid Settlement for most soil types, foundations for low speed machines designed to limiting amplitude of 200 microns will not suffer undue settlement due to dynamic loads. In case of some soils like loose sands and silts in conjunction with high water table, there is a possibility of significant settlement to occur. In all such cases, it shall be preferable to consolidate the soil underneath the foundation. Anti-Vibration Mountings Where it is found to be impracticable to design a foundation consisting of a simple concrete block resting on the natural soils to give satisfactory dynamic characteristics, it may be possible to reduce the transmitted vibrations to acceptable levels by means of

electrical-engineering-portal.com/basics-of-3-phase-induction-motor-3 9/10

8/5/12

Basics of 3-phase Induction Motor (part 3) | EEP

anti-vibration mounting. Depending upon the nature of the machinery and the installation, the anti-vibration mounting may be used: a) Between machinery and foundation, and b) Between a foundation block and a supporting system.

Free vibration analysis

Free vibration analysis shall be carried out to calculate the natural frequencies and mode shapes of the foundation. The highest natural frequency calculated should be at least 10 percent higher than the operating frequency of the machine. Damping may be neglected for the purpose of free vibration analysis.

Frequency criteria

The following frequency criteria shall be checked: The fundamental natural frequency shall be at least 20perccnt away from the machine operating speed. That is, fn < 0.8 fm or fn > 1.2 fm Where fn = fundamental natural frequency of the foundation, and fm = operating speed of the machine. However, it is preferable to maintain a frequency separation of 50 percent.

Conclusion The foundation of any rotating electrical machine operating at 50 Hz should be such that the natural frequency of vibration is either less than 40 Hz or greater than 60 Hz.

References:

1. NEMA MG-1. 2. Industrial Power Engineering and Application Hand Book by K C Agarwaal. 3. Industrial Power System Hand Book by Shoaib Khan. 4. Theory and Calculation of Alternating Current Phenomena by Charles Proteus Steinmetz 5. Motor protection relay (MM30) manual from L&T

electrical-engineering-portal.com/basics-of-3-phase-induction-motor-3

10/10

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Ecodial enDocument3 pagesEcodial envijaydev75No ratings yet

- ABB XLPE Cable Systems Users Guide Rev 3Document28 pagesABB XLPE Cable Systems Users Guide Rev 3vijaypshindeNo ratings yet

- GALAXY 40P - Service Manual - 141205 - MEDIENDocument89 pagesGALAXY 40P - Service Manual - 141205 - MEDIENARMANDOROSASNo ratings yet

- Testing and Commissioning of MetalClad SwitchgearDocument4 pagesTesting and Commissioning of MetalClad Switchgearvijaydev75100% (1)

- Wire Fuse and SwitchDocument47 pagesWire Fuse and SwitchMacy RiegoNo ratings yet

- TCM HandbookDocument109 pagesTCM Handbookvijaydev75No ratings yet

- Guidelines To Visual Inspection of Electrical Installations - EEPDocument5 pagesGuidelines To Visual Inspection of Electrical Installations - EEPvijaydev75No ratings yet

- Electrical Thumb Rules You MUST Follow (Part 1)Document4 pagesElectrical Thumb Rules You MUST Follow (Part 1)vijaydev75100% (2)

- UK Electrical Industry British Standards BSDocument19 pagesUK Electrical Industry British Standards BSvijaydev75100% (1)

- Electrical Thumb Rules You MUST Follow (Part 4)Document4 pagesElectrical Thumb Rules You MUST Follow (Part 4)vijaydev75No ratings yet

- Fuel - Consumption - Chart - Standard Diesel EngineDocument1 pageFuel - Consumption - Chart - Standard Diesel EngineCaptIsqanNo ratings yet

- Electrical Thumb Rules You MUST Follow (Part 3) : Size of Capacitor For Power Factor CorrectionDocument4 pagesElectrical Thumb Rules You MUST Follow (Part 3) : Size of Capacitor For Power Factor Correctionvijaydev75No ratings yet

- Electrical Thumb Rules You MUST Follow (Part 2)Document2 pagesElectrical Thumb Rules You MUST Follow (Part 2)vijaydev75100% (1)

- CCTVDocument22 pagesCCTVvijaydev75No ratings yet

- The Role of Circuit Breakers in LVMV Power SystemsDocument5 pagesThe Role of Circuit Breakers in LVMV Power Systemsvijaydev75No ratings yet

- Safety Clearance Recommendations For TransformerDocument6 pagesSafety Clearance Recommendations For Transformervijaydev75No ratings yet

- Electrical Engineering Portal - Com Calculating Lightning Strike DistanceDocument2 pagesElectrical Engineering Portal - Com Calculating Lightning Strike Distancevijaydev75No ratings yet

- Electrical Safety Standards For LVMVHV Part2Document13 pagesElectrical Safety Standards For LVMVHV Part2vijaydev75No ratings yet

- Assemblies of Switchgear and Control Panels Part 1Document6 pagesAssemblies of Switchgear and Control Panels Part 1vijaydev75No ratings yet

- Inspection of Voltage Drop in ConductorsDocument2 pagesInspection of Voltage Drop in Conductorsvijaydev75No ratings yet

- Basics of 3-Phase Induction Motor (Part 2) - EEPDocument4 pagesBasics of 3-Phase Induction Motor (Part 2) - EEPvijaydev75No ratings yet

- 2 Unit 2 Hardware Design - DigitalDocument51 pages2 Unit 2 Hardware Design - DigitalAyush SinghNo ratings yet

- Manual For Fluke 438Document18 pagesManual For Fluke 438Main hoon LaHorE -LaHoreEeE Fun & FactsNo ratings yet

- Mpe Installation, Use and Maintenance ManualDocument56 pagesMpe Installation, Use and Maintenance ManualapeirotanNo ratings yet

- Tamil Dubbed Frozen Movies Free Download 720pDocument4 pagesTamil Dubbed Frozen Movies Free Download 720pSaranyaNo ratings yet

- Instrumentation and Measurements BE-56 A&B Fall 2020: Instructor: LT Dr. Col Humayun Zubair KhanDocument35 pagesInstrumentation and Measurements BE-56 A&B Fall 2020: Instructor: LT Dr. Col Humayun Zubair Khanahmad khanNo ratings yet

- Ultrasonic Thickness Gauge NOVOTEST UT-1М-IPDocument4 pagesUltrasonic Thickness Gauge NOVOTEST UT-1М-IPAGNEL V VARKEYNo ratings yet

- A30 (Sm-A305n) BY-SAI MOBILE SOLUTION PDFDocument32 pagesA30 (Sm-A305n) BY-SAI MOBILE SOLUTION PDFabivecueNo ratings yet

- ImpedancematchingDocument17 pagesImpedancematchingRamya RNo ratings yet

- CL-1000 UV Crosslinker ManualDocument22 pagesCL-1000 UV Crosslinker ManualMinghan YongNo ratings yet

- DS - TE6502 - GB - 7296 - Thermocouples For Additional ThermowellDocument7 pagesDS - TE6502 - GB - 7296 - Thermocouples For Additional ThermowellThomasFrenchNo ratings yet

- Figure 2.15 Triggering A Silicon-Controlled: Aircraft Electrical and Electronic Systems 42Document20 pagesFigure 2.15 Triggering A Silicon-Controlled: Aircraft Electrical and Electronic Systems 42Jhony BhatNo ratings yet

- Digital Signal Processing: EC303: September 22 2020Document35 pagesDigital Signal Processing: EC303: September 22 2020V Prakash SinghNo ratings yet

- Ak111 (Three Phases, 50&60hz)Document8 pagesAk111 (Three Phases, 50&60hz)Christian Rivera FloverNo ratings yet

- Measurement of Vibration & Axial DisplacementDocument6 pagesMeasurement of Vibration & Axial DisplacementSatNo ratings yet

- 2step - e 759 5 05.2.3dnDocument128 pages2step - e 759 5 05.2.3dnMarcelo HANo ratings yet

- Sound Amplification SystemDocument8 pagesSound Amplification SystemSrushti KitukaleNo ratings yet

- VSX 1020 K - Brochure PDFDocument2 pagesVSX 1020 K - Brochure PDFJULIUSNo ratings yet

- 627G Wheel Tractor-Scraper Electrical System: Machine Harness Connector and Component LocationsDocument4 pages627G Wheel Tractor-Scraper Electrical System: Machine Harness Connector and Component LocationsMauricio BellidoNo ratings yet

- TIP110, T IP115: Darlington TransistorsDocument5 pagesTIP110, T IP115: Darlington Transistorsمحمدعبدالخالق العلوانيNo ratings yet

- The Laplace TransformDocument22 pagesThe Laplace Transformindrayadi2009No ratings yet

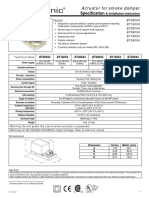

- Specification: Actuator For Smoke DamperDocument2 pagesSpecification: Actuator For Smoke Dampermartin saadNo ratings yet

- Group Delay As I Understand It by JOHN ORAMDocument2 pagesGroup Delay As I Understand It by JOHN ORAMDávid BaltaváriNo ratings yet

- S310 Serise: 200V Class 0.4 1.5KW (0.88 2.9KVA)Document71 pagesS310 Serise: 200V Class 0.4 1.5KW (0.88 2.9KVA)Sdiri OùMaimàNo ratings yet

- Evolution of C-Si: PV Cell TechnologiesDocument52 pagesEvolution of C-Si: PV Cell TechnologiesFábio VelôzoNo ratings yet

- Brochure - Daker - DK - Plus - GB - 10 KVADocument6 pagesBrochure - Daker - DK - Plus - GB - 10 KVASwat Guratai by javed Javed iqbalNo ratings yet

- Design Examples Using The ToolboxDocument23 pagesDesign Examples Using The Toolboxrajeevjain09No ratings yet

- DO880Document4 pagesDO880sitaNo ratings yet

- Starter Pinion TestDocument2 pagesStarter Pinion TestbejoythomasNo ratings yet