Professional Documents

Culture Documents

2300 Series PDF

2300 Series PDF

Uploaded by

hendrabudimanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2300 Series PDF

2300 Series PDF

Uploaded by

hendrabudimanCopyright:

Available Formats

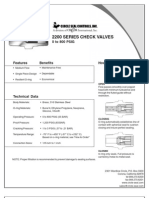

2300 SERIES CHECK VALVES

0 to 10,000 PSIG

Features

Designed For High Pressure Service Resilient O-ring Single-Piece Design

Benefits

Less Susceptible to Contamination Damage

How It Works

Zero Leakage at Normal Back Pressure Automatic Compensation for Wear Cushioned, Quiet Closing OPEN Flow passes smoothly over poppet head with minimum turbulence.

Technical Data

Body Materials: Aluminum, Brass, 303 Stainless Steel, or 17-4PH Stainless Steel Buna N, Ethylene Propylene, Neoprene, Teflon and Viton Aluminum Brass 303 S.S 17-4PH S.S Proof Pressure: Aluminum Brass 303 S.S. 17-4PH S.S. Aluminum Brass 303 S.S. 17-4PH S.S. 0 to 5,000 PSIG (345 BAR) (For Temp. under 250 F) 0 to 5,000 PSIG (345 BAR) 0 to 7,500 PSIG (517 BAR) 0 to 10,000 PSIG (690 BAR) 7,500 PSIG (517 BAR) 7,500 PSIG (517 BAR) 11,250 PSIG (776 BAR) 15,000 PSIG (1034 BAR) 12,500 PSIG (862 BAR) 12,500 PSIG (862 BAR) 18,750 PSIG (1293 BAR) 25,000 PSIG (1724 BAR) CLOSING O-ring automatically establishes line of contact with conical seat to cushion closing and insure perfect sealing.

O-ring Materials:

Operating Pressure:

CLOSED O-ring only seals. Full pressure is carried by metal-to-metal seat. Increasing pressure increases sealing efficiency.

Rated Burst Pressure:

Temperature Range:

-100 F to +400 F (-74 C to +204 C) Based on o-ring material, see How to Order 1/8 inch to 1 inch 2301 Wardlow Circle, P.O. Box 3300 Corona, California 92878 tel 909.270.6200 fax 909.270.6201 www.circle-seal.com sales@circle-seal.com

Connection Size:

NOTE: Proper filtration is recommended to prevent damage to sealing surfaces.

2300 SERIES CHECK VALVES

0 to 10,000 PSIG End Connection & Dimensions

PP - FEMALE / FEMALE PIPE

(inches)

Alternate Round Stock Configuration

F Dia.

Dash No. 1PP 2PP 3PP 4PP 6PP

Pipe Size 1/8" 1/4" 3/8" 1/2" 3/4"

B. Hex. .625 .813 1.000 1.250 1.500

C 1.50 2.00 2.35 2.89 3.30

F .59 .77 .95 1.19 1.43

G .31 .41 .50 .56 .69

B Across Flats G C G

MM - MALE / MALE PIPE

Dash No. 2MM 3MM 4MM 6MM 8MM

Pipe Size 1/4" 3/8" 1/2" 3/4" 1"

B. Hex. .625 .813 1.000 1.250 1.500

C 1.82 2.21 2.75 3.03 3.67

E .60 .61 .79 .80 .99

F Dia. .59 .77 .95 1.19 1.43

B Across Flats

F Dia.

G .31 .41 .50 .56 .69

G C

MP - MALE / FEMALE PIPE

Dash No. 1MP 2MP 3MP 4MP 6MP

Pipe Size 1/8" 1/4" 3/8" 1/2" 3/4"

B. Hex. .625 .813 1.000 1.250 1.500

C 1.46 1.67 2.07 2.56 2.88

E .40 .60 .61 .79 .80

F Dia. .59 .77 .95 1.19 1.43

B Across Flats

G .31 .41 .50 .56 .69

F Dia. E C G

2300 SERIES CHECK VALVES

0 to 10,000 PSIG

End Connection & Dimensions

(inches) (continued)

Dash No. 2PM 3PM 4PM

PM - FEMALE / MALE PIPE Pipe B F Size Hex. C E Dia. 1/4" .813 1.93 .60 .77 3/8" 1.000 2.26 .61 .95 1/2" 1.250 2.89 .79 1.19

B Across Flats

G .41 .50 .56

G

F Dia. E C

BB - FEMALE / FEMALE TUBE Dash Pipe B E No. Size Hex. C Dia. 4BB 1/4" .688 2.00 .66 6BB 3/8" .813 2.40 .77 8BB 1/2" 1.250 3.34 1.19 10BB 5/8" 1.250 3.53 1.19 12BB 3/4" 1.500 4.15 1.43

B Across Flats

E Dia.

G .24 .41 .56 .56 .69

G C

Valve Size Tube Pipe Cv (maximum)

4BB 1PP .31

Flow Rates 6BB 2PP 3PP .76 1.78

8BB; 10BB 12BB 4PP 6PP 2.82 5.11

2300 SERIES CHECK VALVES

0 to 10,000 PSIG How to Order 23 49 R 2PP 7

BASIC MODEL NUMBER 2300 Series O-RING MATERIAL, TEMPERATURE & CRACKING PRESSURE RANGE 62 - EPR -65 F to +300 F .5 1.5 PSIG 49 - Buna N -65 F to + 250 F 2 5 PSIG 59 - Buna N -65 F to + 275 F .5 1.5 PSIG 33 - Neoprene -40 F to + 240 F 2 5 PSIG 20 - Teflon -100 F to +400 F 5 PSIG 32 - Viton -20 F to +400 F .5 1.5 PSIG BODY MATERIAL A - 2024-T4/T351 Aluminum B - Brass R - 17-4 PH Stainless Steel T - 303 Stainless Steel LEAKAGE 2362, 2332, 2359 2333, 2349 2320 CRACKING PRESSURE Call out dash number if not standard* 7 - 7 PSIG CONNECTIONS P - Female Pipe, NPT M - Male Pipe, NPT B - Female Tube, AND10050 S - British Taper, Male Pipe X - British Taper, Female Pipe CONNECTIONS SIZES Pipe sizes in 1/8 increments Tube sizes in 1/16 increments

* Standard based on seal material. zero @ 1 psi to proof zero @ 3 psi to proof zero @ 75 psi to proof

*For cracking pressures less than standard, consult factory for leakage rates.

Viton is a registered trademark of DuPont Dow Elastomers. Teflon is a registered trademark of the DuPont Company.

Please consult Circle Seal Controls or your local distributor for information on special connections, lubricant, operating pressures and temperature ranges. NOTES: Vacuum service may require special lubricants. AND10050 connection not normally recommended for 10,000 psi service unless special fitting seals are used.

Special Cracking Pressures

Valves with special springs can be furnished to order. Minimum Cracking Pressure Available 0.5 psi Maximum Cracking Pressure Available 30 psi When ordering a cracking pressure less than the maximum indicated for a specific o-ring, indicate the exact maximum cracking pressure in the part number (i.e. 2349R-2PP-3). If higher cracking pressure than the maximum shown is desired, cracking pressure tolerance is 20%.

For Your Safety It is the sole responsibility of the system designer and user to select products suitable for their specific application requirements and to ensure proper installation, operation and maintenance of these products. Material compatibility product ratings and application details should be considered in the selection. Improper selection or use of products described herein can cause personal injury or property damage.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Office 365 Serial Key Plus Product KeyDocument3 pagesOffice 365 Serial Key Plus Product Keyhendrabudiman46% (13)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Day 2 Hazard Identification, Assesment & ControlDocument39 pagesDay 2 Hazard Identification, Assesment & Controlmike cams86% (7)

- Black & Decker The Complete Guide Maintain Your Pool & Spa Repair & Upkeep MadeDocument241 pagesBlack & Decker The Complete Guide Maintain Your Pool & Spa Repair & Upkeep Madealpinahu100% (8)

- Method Repair of Damaged Galvanized Coating For FencingDocument6 pagesMethod Repair of Damaged Galvanized Coating For FencinghendrabudimanNo ratings yet

- En - Fds Genlub TDXDocument6 pagesEn - Fds Genlub TDXhendrabudimanNo ratings yet

- Critchley Z MarkersDocument1 pageCritchley Z MarkershendrabudimanNo ratings yet

- Control of Nonconformance ProcedureDocument3 pagesControl of Nonconformance ProcedurehendrabudimanNo ratings yet

- Main Electrical Earthing Conductor Tag: As Required Under AS/NZS 3000:2007 Clause 5.5.1.3Document1 pageMain Electrical Earthing Conductor Tag: As Required Under AS/NZS 3000:2007 Clause 5.5.1.3hendrabudimanNo ratings yet

- Drager Flame 1300Document17 pagesDrager Flame 1300Mohan ArumugavallalNo ratings yet

- DM GL1002-2008r0 PSDDocument5 pagesDM GL1002-2008r0 PSDhendrabudimanNo ratings yet

- Attachment XXXDocument1 pageAttachment XXXhendrabudimanNo ratings yet

- Ultrasonic Vortex Flowmeter "Ultra Yewflo-Uyf200": KAWANO Takashi MATSUNAGA Yoshinori ANDOH Tetsuo Yasumatsu AkioDocument4 pagesUltrasonic Vortex Flowmeter "Ultra Yewflo-Uyf200": KAWANO Takashi MATSUNAGA Yoshinori ANDOH Tetsuo Yasumatsu AkiohendrabudimanNo ratings yet

- E-Z-Code: "Mr. Ouch" - NEMA Safety LabelsDocument1 pageE-Z-Code: "Mr. Ouch" - NEMA Safety LabelshendrabudimanNo ratings yet

- Size of BoltDocument1 pageSize of BolthendrabudimanNo ratings yet

- Terminal Blocks: NEMA TypeDocument24 pagesTerminal Blocks: NEMA TypehendrabudimanNo ratings yet

- CVH Series PDFDocument9 pagesCVH Series PDFhendrabudimanNo ratings yet

- Terminal Blocks: IEC TypeDocument20 pagesTerminal Blocks: IEC TypehendrabudimanNo ratings yet

- 2200 Series PDFDocument3 pages2200 Series PDFhendrabudimanNo ratings yet

- 2100 2800 Series PDFDocument2 pages2100 2800 Series PDFhendrabudimanNo ratings yet

- 100 Series PDFDocument2 pages100 Series PDFhendrabudimanNo ratings yet

- Bulletin 6060Document2 pagesBulletin 6060Muni SwamyNo ratings yet

- Material Safety Data Sheet: Vigoro Weed & Feedi 29-0-3Document9 pagesMaterial Safety Data Sheet: Vigoro Weed & Feedi 29-0-3Daniel WellsNo ratings yet

- FM 01 PDFDocument2 pagesFM 01 PDFLeonardo GlebisNo ratings yet

- House Service Cut-Out BrochureDocument6 pagesHouse Service Cut-Out BrochureDaniel GnanaselvamNo ratings yet

- Katalog Za Kancelariski MebelDocument21 pagesKatalog Za Kancelariski MebelbzdravevaNo ratings yet

- Intro To ScrumDocument40 pagesIntro To ScrumAvay KumarNo ratings yet

- Exoc Module 15 Network Troubleshooting PDFDocument86 pagesExoc Module 15 Network Troubleshooting PDFJeanNo ratings yet

- EC GATE 19 Questions-With-Solutions PDFDocument56 pagesEC GATE 19 Questions-With-Solutions PDFchiranjibaviNo ratings yet

- Carpigiani GB 110-220-330-440 REVISED 2-2-06Document38 pagesCarpigiani GB 110-220-330-440 REVISED 2-2-06zamaenter100% (1)

- T.H. - A Metamaterial That Can Make Use of Origami To Reduce ShockDocument1 pageT.H. - A Metamaterial That Can Make Use of Origami To Reduce ShockThejaswiniNo ratings yet

- The Effect of Gas Metal Arc Welding (GMAW) Processes On Different Welding Parameters - DoneDocument5 pagesThe Effect of Gas Metal Arc Welding (GMAW) Processes On Different Welding Parameters - DoneAsim AliNo ratings yet

- Carboline Southwest SFRM Specification 11-11-10Document8 pagesCarboline Southwest SFRM Specification 11-11-10Salman ShaikhNo ratings yet

- D 2172 - 01 RdixnziDocument13 pagesD 2172 - 01 RdixnziJhony CotaNo ratings yet

- Contoh CV HSEDocument3 pagesContoh CV HSECandra Wae Lah67% (3)

- Arun - Effect of Very Fine Particles On Concrete Made With Dune SandDocument23 pagesArun - Effect of Very Fine Particles On Concrete Made With Dune SandRejin100% (1)

- Engineering Mechanics (ME 105) Tutorial Sheet-4Document3 pagesEngineering Mechanics (ME 105) Tutorial Sheet-4baruaoleNo ratings yet

- Screwguard Rotair Altair: People. Passion. PerformanceDocument4 pagesScrewguard Rotair Altair: People. Passion. PerformanceAristideNo ratings yet

- VFP6FAQDocument14 pagesVFP6FAQPricope MihaNo ratings yet

- 7ceramics Manuf Process PPT Report7Document19 pages7ceramics Manuf Process PPT Report7Yohan ManaligodNo ratings yet

- Experiment No. 1 Familiarization With Laboratory Apparatus in General Chemistry ObjectiveDocument7 pagesExperiment No. 1 Familiarization With Laboratory Apparatus in General Chemistry ObjectiveCrisha GutierrezNo ratings yet

- Applied Physics in AnesthesiaDocument35 pagesApplied Physics in AnesthesiaKshitizma GiriNo ratings yet

- Step-By-Step Install Guide Moodle On Linux With Sclipo Live Web Class On Linux v1.4Document4 pagesStep-By-Step Install Guide Moodle On Linux With Sclipo Live Web Class On Linux v1.4Kefa RabahNo ratings yet

- Aspire 4352Document224 pagesAspire 4352Bryan LagosNo ratings yet

- Uen R 15170001Document42 pagesUen R 15170001Jari GoethuysNo ratings yet

- 62 ConfgDocument402 pages62 Confgringku2kNo ratings yet

- Friction and GravityDocument2 pagesFriction and GravityYahaira Cleigh Ruz YapNo ratings yet

- 526 89110kv-Sf6-Cb PDFDocument13 pages526 89110kv-Sf6-Cb PDFJafarov VuqarNo ratings yet