Professional Documents

Culture Documents

Competency STD Worksheet (ACRO)

Competency STD Worksheet (ACRO)

Uploaded by

Robin RubinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Competency STD Worksheet (ACRO)

Competency STD Worksheet (ACRO)

Uploaded by

Robin RubinaCopyright:

Available Formats

I.

Identify and Clarify the Essential Task or Function Report to Control Room Engineer, unsafe and abnormal conditions within the plant premises. Measurement of Success o The supervisor confirmed the unsafe and abnormal conditions. o The Safety officer assessed the unsafe conditions. o Maintenance personnel started to address the abnormal conditions in the workplace. II. Identify and Clarify the Essential Task or Function Collect and submit coal samples to Laboratory. Measurement of Success o The coal samples are submitted to the Laboratory in-charge at 0500H, 1300H, and 2100H daily. o The laboratory in-charge reports the coal analysis to Control Room Engineer. III. Identify and Clarify the Essential Task or Function Collect and submit bottom ash and fly ash samples to Laboratory. Measurement of Success o The bottom ash and fly ash samples are submitted to the Laboratory in-charge at 0700H every Tuesdays and Thursdays. o The laboratory in-charge reports the bottom ash and fly ash analysis to Shift Superintendent. IV. Identify and Clarify the Essential Task or Function

Collects and evaluates actual data and information from local equipment. Measurement of Success o Log sheets are completely filled up. o Log sheets are filled up within the predetermined hour. V. Identify and Clarify the Essential Task or Function Assist remote start-up of SAF, IDF, PAF, FAB and BFP. Note: Task is broken down below. A. Identify and Clarify the Essential Task or Function Check lubrications and equipment status, line up valves and switches then secure area for start-up. Measurement of Success o Checked by supervisor and/or by absence of mishap due to incompletion of duties. o Checklist. B. Identify and Clarify the Essential Task or Function Inform Control Room Engineer of the completion of lining up, and clearance to operate in remote. Measurement of Success o Checked by supervisor and/or by absence of mishap due to incompletion of duties. C. Identify and Clarify the Essential Task or Function

Stand by for remote start-up. Measurement of Success o Presence of Auxiliary Operator near the equipment. D. Identify and Clarify the Essential Task or Function Observe and look for abnormalities and report it immediately to Control Room Engineer, or report to CRE that the started-up equipment is running at normal when no abnormalities are detected. Measurement of Success o Auxiliary operator has communicated to control room immediately. o Absence of mishap due to incompletion of duties. o Checklist. VI. Identify and Clarify the Essential Task or Function Clean and inspect all filters and strainers when DPT is high or as scheduled and replace if necessary. Measurement of Success o Proper execution of the Procedure XXXX. VII. Identify and Clarify the Essential Task or Function Local Start-up of Compressor System. Note: Task is broken down below. A. Identify and Clarify the Essential Task or Function

Check lubrications and compressor status, line up valves and switches then secure area for start-up. Measurement of Success o Checked by supervisor and/or by absence of mishap due to incompletion of duties. o Checklist. B. Identify and Clarify the Essential Task or Function Ask permission from Control Room Engineer to locally start the compressor. Measurement of Success o Reflected on the Control room logbook. C. Identify and Clarify the Essential Task or Function Observe and look for abnormalities and immediately stop compressor if necessary. Measurement of Success o Checklist. D. Identify and Clarify the Essential Task or Function Coordinate with Control Room Engineer about compressor and plant/Instrument air system pressure status and ask clearance to leave compressor house. Measurement of Success o Checklist.

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Synerquest Breastfeeding PolicyDocument2 pagesSynerquest Breastfeeding PolicyRobin RubinaNo ratings yet

- A Proposed Flood Mitigation Plan at Desta Homes Subdivision, Atlag, Malolos, BulacanDocument25 pagesA Proposed Flood Mitigation Plan at Desta Homes Subdivision, Atlag, Malolos, BulacanSherry Gesim100% (1)

- Prelim Exam in Stat.Document4 pagesPrelim Exam in Stat.MICHELLE DE LOS REYES100% (1)

- Synerquest Team of Experts 2013Document2 pagesSynerquest Team of Experts 2013Robin RubinaNo ratings yet

- Bosh, CoshDocument3 pagesBosh, CoshRobin Rubina50% (4)

- Advances in Drillpipe Fatigue ManagementDocument1 pageAdvances in Drillpipe Fatigue ManagementFares NaceredineNo ratings yet

- NIH BSL-3 SpecificationsDocument21 pagesNIH BSL-3 SpecificationsRobin RubinaNo ratings yet

- COSH Course OutlineDocument4 pagesCOSH Course OutlineRobin Rubina100% (1)

- Concept Paper 1Document10 pagesConcept Paper 1Lemuel CondesNo ratings yet

- Extra Curricular Activities: Its Perceived Effect On Students' PerformanceDocument17 pagesExtra Curricular Activities: Its Perceived Effect On Students' PerformanceLester VerianNo ratings yet

- DO 18A Checklist of RequirementsDocument2 pagesDO 18A Checklist of RequirementsRobin RubinaNo ratings yet

- Value Chain AnalysisDocument10 pagesValue Chain AnalysisSohong ChakrabortyNo ratings yet

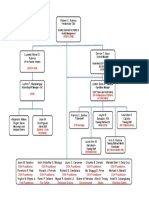

- Synerquest Table of Organization (As of Aug 31, 2015)Document1 pageSynerquest Table of Organization (As of Aug 31, 2015)Robin RubinaNo ratings yet

- Synerquest Anti-TB PolicyDocument2 pagesSynerquest Anti-TB PolicyRobin RubinaNo ratings yet

- Synerquest Sexual Harrassment PolicyDocument5 pagesSynerquest Sexual Harrassment PolicyRobin RubinaNo ratings yet

- Hepab Dole PPDocument4 pagesHepab Dole PPRobin RubinaNo ratings yet

- Synerquest 2013 Updated Profile Ver2Document10 pagesSynerquest 2013 Updated Profile Ver2Robin RubinaNo ratings yet

- Emergency Disaster KitDocument2 pagesEmergency Disaster KitRobin RubinaNo ratings yet

- Sample HEALTHDocument8 pagesSample HEALTHRobin RubinaNo ratings yet

- Profile of COSH TrainersDocument2 pagesProfile of COSH TrainersRobin RubinaNo ratings yet

- Profile of EPR TrainersDocument2 pagesProfile of EPR TrainersRobin RubinaNo ratings yet

- RCRubina Brief Profile 2013Document2 pagesRCRubina Brief Profile 2013Robin RubinaNo ratings yet

- Loans and Advances at HDFC Bank PaperDocument7 pagesLoans and Advances at HDFC Bank PaperSarah FatimaNo ratings yet

- Patterns of Expenditure of Older People in Rural IndonesiaDocument5 pagesPatterns of Expenditure of Older People in Rural IndonesiaInternational Journal of Business Marketing and ManagementNo ratings yet

- Marketing Research - Hair PDFDocument35 pagesMarketing Research - Hair PDFMaureen Lim QuizonNo ratings yet

- DPA Course Description1Document2 pagesDPA Course Description1Mark Juan AbelonNo ratings yet

- A Process For Creating The Business Case For UX ProjectsDocument4 pagesA Process For Creating The Business Case For UX Projectsparesh_dhakeNo ratings yet

- Actual Self Image Ideal Self Image and The Relation Between Satisfaction and Destination Loyalty 2167 0269.1000102Document11 pagesActual Self Image Ideal Self Image and The Relation Between Satisfaction and Destination Loyalty 2167 0269.1000102Anupama KujurNo ratings yet

- Metlit-06 Usulan Penelitian (B) - Dr. Dr. Tjhin WIguna, SPKJ (K)Document34 pagesMetlit-06 Usulan Penelitian (B) - Dr. Dr. Tjhin WIguna, SPKJ (K)Laurencia LenyNo ratings yet

- Basics of EVM PartI-Eleanor HauptDocument0 pagesBasics of EVM PartI-Eleanor HauptCristhiams Jesus Mendez PintoNo ratings yet

- Ni 43 101 Final 2013Document272 pagesNi 43 101 Final 2013Berg Huaripata GoicocheaNo ratings yet

- Crosstab & Chi-Square Test in SPSSDocument7 pagesCrosstab & Chi-Square Test in SPSSSajjad Hossain ShuvoNo ratings yet

- Mint Business Newspaper - A New Path AheadDocument20 pagesMint Business Newspaper - A New Path Aheadketan-ray-8621No ratings yet

- Statistics For Managers Using Microsoft Excel: 4 EditionDocument42 pagesStatistics For Managers Using Microsoft Excel: 4 EditionNadia Dwi JayantiNo ratings yet

- Conceptual FrameworkDocument2 pagesConceptual FrameworkOnycha SyNo ratings yet

- Use Traffic Conflicts Technique (TCT) To Evaluate Serious Intersections in DamascusDocument2 pagesUse Traffic Conflicts Technique (TCT) To Evaluate Serious Intersections in DamascusIng AnnaNo ratings yet

- MA 4303 Practise QuestionsDocument7 pagesMA 4303 Practise QuestionsAtul Gautam100% (1)

- Strategic Marketing: Unit 5Document48 pagesStrategic Marketing: Unit 5Bitha AnojNo ratings yet

- Tribute To Paul HessDocument13 pagesTribute To Paul HessBillPrantyNo ratings yet

- The U&A and UAIDocument6 pagesThe U&A and UAIlalaNo ratings yet

- Interpreting Results From Rasch Analysis 2. Advanced Model Applications and The Data-Model Fit AssessmentDocument15 pagesInterpreting Results From Rasch Analysis 2. Advanced Model Applications and The Data-Model Fit Assessmentj AlgarishiNo ratings yet

- NCR Reported by NCR Issued To: Non-Conformance ReportDocument2 pagesNCR Reported by NCR Issued To: Non-Conformance ReportRahul SundarNo ratings yet

- International Journal of Managing Value and Supply Chains (IJMVSC)Document22 pagesInternational Journal of Managing Value and Supply Chains (IJMVSC)William ScottNo ratings yet

- Epidemiological Triad or Epidemiological Triangle Model: Levels of Disease PreventionDocument8 pagesEpidemiological Triad or Epidemiological Triangle Model: Levels of Disease PreventionkennethNo ratings yet

- SHRM PDFDocument8 pagesSHRM PDFKaran UppalNo ratings yet

- Topics On Library Research PaperDocument6 pagesTopics On Library Research Papervvgnzdbkf100% (1)