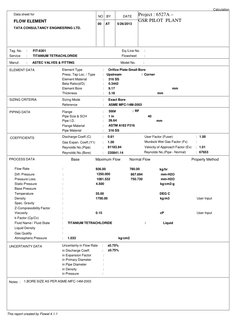

Calculation Data sheet for NO 00 BY AT DATE 5/26/2013

FLOW ELEMENT

TATA CONSULTANCY ENGINEERING LTD.

Project : 6527A GSR PILOT PLANT

Tag. No. Service Manuf.

: : :

FIT-6301 TITANIUM TETRACHLORIDE ASTEC VALVES & FITTING Element Type Press. Tap Loc. / Type Element Material Beta Ratio(d/D) Element Bore Thickness Sizing Mode Reference

Eq./Line No. Flowsheet Model No.

: : :

ELEMENT DATA

: Orifice Plate-Small Bore : Upstream / Corner : 316 SS : 0.3442 : 9.17 : 3.18 mm : : : : : : : : : : : Exact Bore ASME MFC-14M-2003 300# 1 in 26.64 316 SS 0.61 1.00 81183.94 235841.14 / RF 40 mm

mm

SIZING CRITERIA

PIPING DATA

Flange Pipe Size & SCH Pipe I.D. Flange Material Pipe Material Discharge Coeff.(C) Gas Expan. Coeff.(Y1) Reynolds No.(Pipe) Reynolds No.(Bore)

ASTM A182 F316 User Factor (Fuser) Murdock Wet Gas Factor (Fx) Velocity of Approach Factor (Ev) Reynolds No.(Pipe - Normal) : 1.00 : : 1.01 : 67653

COEFFICIENTS

PROCESS DATA Flow Rate Diff. Pressure Pressure Loss Static Pressure Base Pressure Temperature Density Spec. Gravity Z-Compressibility Factor Viscosity k-Factor (Cp/Cv) Fluid Name / Fluid State Liquid Density Gas Quality Atmospheric Pressure UNCERTAINTY DATA : : : : : : : : : : : : : : :

Base

Maximum Flow

936.00 1250.000 1081.532 4.500 35.00 1700.00

Normal Flow

780.00 867.694 750.720 kg/hr mm-H2O mm-H2O kg/cm2-g DEG C kg/m3

Property Method

User Input

0.15 TITANIUM TETRACHLORIDE /

cP Liquid

User Input

1.033 : : : : : : :

kg/cm2 0.75% 0.75%

Uncertainty in Flow Rate in Discharge Coeff. in Expansion Factor in Primary Diameter in Pipe Diameter in Density in Pressure

Notes :

1.BORE SIZE AS PER ASME-MFC-14M-2003

This report created by Flowel 4.1.1

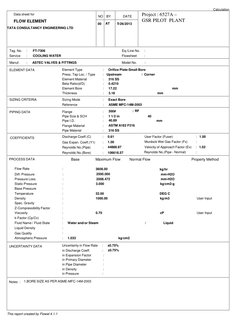

�Calculation Data sheet for NO 00 BY AT DATE 5/26/2013

FLOW ELEMENT

TATA CONSULTANCY ENGINEERING LTD

Project : 6527A GSR PILOT PLANT

Tag. No. Service Manuf.

: : :

FT-7306 COOLING WATER ASTEC VALVES & FITTINGS Element Type Press. Tap Loc. / Type Element Material Beta Ratio(d/D) Element Bore Thickness Sizing Mode Reference

Eq./Line No. Flowsheet Model No.

: : :

ELEMENT DATA

: Orifice Plate-Small Bore : Upstream / Corner : 316 SS : 0.4210 : 17.22 : 3.18 mm : : : : : : : : : : : Exact Bore ASME MFC-14M-2003 300# 1 1/2 in 40.89 316 SS 0.61 1.00 44888.97 106618.57 / RF 40 mm

mm

SIZING CRITERIA

PIPING DATA

Flange Pipe Size & SCH Pipe I.D. Flange Material Pipe Material Discharge Coeff.(C) Gas Expan. Coeff.(Y1) Reynolds No.(Pipe) Reynolds No.(Bore)

ASTM A182 F316 User Factor (Fuser) Murdock Wet Gas Factor (Fx) Velocity of Approach Factor (Ev) Reynolds No.(Pipe - Normal) : 1.00 : : 1.02 :

COEFFICIENTS

PROCESS DATA Flow Rate Diff. Pressure Pressure Loss Static Pressure Base Pressure Temperature Density Spec. Gravity Z-Compressibility Factor Viscosity k-Factor (Cp/Cv) Fluid Name / Fluid State Liquid Density Gas Quality Atmospheric Pressure UNCERTAINTY DATA : : : : : : : : : : : : : : :

Base

Maximum Flow

3608.00 2500.000 2008.472 3.000 32.00 1000.00

Normal Flow

kg/hr mm-H2O mm-H2O kg/cm2-g DEG C kg/m3

Property Method

User Input

0.70 Water and/or Steam /

cP Liquid

User Input

1.033 : : : : : : :

kg/cm2 0.75% 0.75%

Uncertainty in Flow Rate in Discharge Coeff. in Expansion Factor in Primary Diameter in Pipe Diameter in Density in Pressure

Notes :

1.BORE SIZE AS PER ASME-MFC-14M-2003

This report created by Flowel 4.1.1

�Calculation Data sheet for NO 00 BY AT DATE 5/26/2013

FLOW ELEMENT

TATA CONSULTANCY ENGINEERING LTD

Project : 6527A GSR PILOT PLANT

Tag. No. Service Manuf.

: : :

FT-7201 AICI 3 ASTEC VALVES & FITTINGS Element Type Press. Tap Loc. / Type Element Material Beta Ratio(d/D) Element Bore Thickness Sizing Mode Reference

Eq./Line No. Flowsheet Model No.

: : :

ELEMENT DATA

: Orifice Plate-Small Bore : Upstream / Flange : Hastelloy C : 0.4355 : 16.61 : 3.18 mm : : : : : : : : : : : Exact Bore ASME MFC-14M-2003 300# 1.5" 38.14 Duplex SS Duplex SS 0.61 0.98 241111.35 553663.04 / RF / XS mm

mm

SIZING CRITERIA

PIPING DATA

Flange Pipe Size & SCH Pipe I.D. Flange Material Pipe Material Discharge Coeff.(C) Gas Expan. Coeff.(Y1) Reynolds No.(Pipe) Reynolds No.(Bore)

COEFFICIENTS

User Factor (Fuser) Murdock Wet Gas Factor (Fx) Velocity of Approach Factor (Ev) Reynolds No.(Pipe - Normal)

: 1.00 : : 1.02 :

PROCESS DATA Flow Rate Diff. Pressure Pressure Loss Static Pressure Base Pressure Temperature Density Spec. Gravity Z-Compressibility Factor Viscosity k-Factor (Cp/Cv) Fluid Name / Fluid State Liquid Density Gas Quality Atmospheric Pressure UNCERTAINTY DATA : : : : : : : : : : : : : : :

Base

Maximum Flow

261.00 2500.000 1975.986 2.000 240.00 6.25

Normal Flow

kg/hr mm-H2O mm-H2O kg/cm2-g DEG C kg/m3

Property Method

User Input

0.01 1.4000 AICI3 /

cP Gas

User Input User Input

1.033 : : : : : : :

kg/cm2 0.82% 0.75% 0.33%

Uncertainty in Flow Rate in Discharge Coeff. in Expansion Factor in Primary Diameter in Pipe Diameter in Density in Pressure

Notes :

1.BORE SIZE AS PER ASME-MFC-14M-2003

This report created by Flowel 4.1.1

�Calculation Data sheet for NO 00 BY AT DATE 5/26/2013

FLOW ELEMENT

TATA CONSULTANCY ENGINEERING LTD

Project : 6527A GSR PILOT PLANT:

Tag. No. Service Manuf.

: : :

FT-3402 OXYGEN ASTEC VALVES & FITTINGS Element Type Press. Tap Loc. / Type Element Material Beta Ratio(d/D) Element Bore Thickness Sizing Mode Reference

Eq./Line No. Flowsheet Model No.

: : :

ELEMENT DATA

: Orifice Plate-Small Bore : Upstream / Corner : 316 SS : 0.3088 : 8.23 : 3.18 mm : : : : : : : : : : : Exact Bore ASME MFC-14M-2003 300# 1 in 26.64 316 SS 0.61 1.00 40450.28 131009.38 / RF 40S mm

mm

SIZING CRITERIA

PIPING DATA

Flange Pipe Size & SCH Pipe I.D. Flange Material Pipe Material Discharge Coeff.(C) Gas Expan. Coeff.(Y1) Reynolds No.(Pipe) Reynolds No.(Bore)

ASTM A182 F316 User Factor (Fuser) Murdock Wet Gas Factor (Fx) Velocity of Approach Factor (Ev) Reynolds No.(Pipe - Normal) : 1.00 : : 1.00 :

COEFFICIENTS

PROCESS DATA Flow Rate Diff. Pressure Pressure Loss Static Pressure Base Pressure Temperature Density Spec. Gravity Z-Compressibility Factor Viscosity k-Factor (Cp/Cv) Fluid Name / Fluid State Liquid Density Gas Quality Atmospheric Pressure UNCERTAINTY DATA : : : : : : : : : : : : : : :

Base

Maximum Flow

64.00 1000.000 890.339 11.000 25.00 15.50

Normal Flow

kg/hr mm-H2O mm-H2O kg/cm2-g DEG C kg/m3

Property Method

User Input

0.02 1.3947 oxygen /

cP Gas

User Input Ideal Gas Method

1.033 : : : : : : :

kg/cm2 0.75% 0.75% 0.03%

Uncertainty in Flow Rate in Discharge Coeff. in Expansion Factor in Primary Diameter in Pipe Diameter in Density in Pressure

Notes :

1.BORE SIZE AS PER ASME-MFC-14M-2003

This report created by Flowel 4.1.1

�Calculation Data sheet for NO 00 BY AT DATE 5/26/2013

FLOW ELEMENT

TATA CONSULTANCY ENGINEERING LTD

Project : 6527A GSR PILOT PLANT

Tag. No. Service Manuf.

: : :

FT-3401 STEAM ASTEC VALVES & FITTINGS Element Type Press. Tap Loc. / Type Element Material Beta Ratio(d/D) Element Bore Thickness Sizing Mode Reference

Eq./Line No. Flowsheet Model No.

: : :

ELEMENT DATA

: Orifice Plate-Small Bore : Upstream / Flange : 316 SS : 0.3226 : 8.60 : 6.35 mm : : : : : : : : : : : Exact Bore ASME MFC-14M-2003 300# 1 in 26.64 316 SS 0.60 0.99 39891.30 123645.23 / RF 40S mm

mm

SIZING CRITERIA

PIPING DATA

Flange Pipe Size & SCH Pipe I.D. Flange Material Pipe Material Discharge Coeff.(C) Gas Expan. Coeff.(Y1) Reynolds No.(Pipe) Reynolds No.(Bore)

ASTM A182 F316 User Factor (Fuser) Murdock Wet Gas Factor (Fx) Velocity of Approach Factor (Ev) Reynolds No.(Pipe - Normal) : 1.00 : : 1.01 :

COEFFICIENTS

PROCESS DATA Flow Rate Diff. Pressure Pressure Loss Static Pressure Base Pressure Temperature Density Spec. Gravity Z-Compressibility Factor Viscosity k-Factor (Cp/Cv) Fluid Name / Fluid State Liquid Density Gas Quality Atmospheric Pressure UNCERTAINTY DATA : : : : : : : : : : : : : : :

Base

Maximum Flow

61.00 2500.000 2202.464 11.000 300.00 4.68

Normal Flow

kg/hr mm-H2O mm-H2O kg/cm2-g DEG C kg/m3

Property Method

User Input

0.02 1.4000 Water and/or Steam /

cP Gas

User Input User Input

1.033 : : : : : : :

kg/cm2 0.75% 0.75% 0.08%

Uncertainty in Flow Rate in Discharge Coeff. in Expansion Factor in Primary Diameter in Pipe Diameter in Density in Pressure

Notes :

1.BORE SIZE AS PER ASME-MFC-14M-2003

This report created by Flowel 4.1.1

�Calculation Data sheet for NO 00 BY AT DATE 5/26/2013

FLOW ELEMENT

TATA CONSULTANCY ENGINEERING LTD

Project : 6527A GSR PILOT PLANT

Tag. No. Service Manuf.

: : :

FIT-8402 HCL ASTEC VALVES & FITTINGS Element Type Press. Tap Loc. / Type Element Material Beta Ratio(d/D) Element Bore Thickness Sizing Mode Reference

Eq./Line No. Flowsheet Model No.

: : :

ELEMENT DATA

: Orifice Plate-Small Bore : Upstream / Corner : Hastelloy C : 0.0493 : 1.31 : 3.18 mm : : : : : : : : : : : Exact Bore ASME MFC-14M-2003 300# 1 in 26.64 Duplex SS Duplex SS 0.64 1.00 71.46 1449.88 / RF 40 mm

mm

SIZING CRITERIA

PIPING DATA

Flange Pipe Size & SCH Pipe I.D. Flange Material Pipe Material Discharge Coeff.(C) Gas Expan. Coeff.(Y1) Reynolds No.(Pipe) Reynolds No.(Bore)

COEFFICIENTS

User Factor (Fuser) Murdock Wet Gas Factor (Fx) Velocity of Approach Factor (Ev) Reynolds No.(Pipe - Normal)

: 1.00 : : 1.00 : 64

PROCESS DATA Flow Rate Diff. Pressure Pressure Loss Static Pressure Base Pressure Temperature Density Spec. Gravity Z-Compressibility Factor Viscosity k-Factor (Cp/Cv) Fluid Name / Fluid State Liquid Density Gas Quality Atmospheric Pressure UNCERTAINTY DATA : : : : : : : : : : : : : : :

Base

Maximum Flow

7.00 250.000 249.225 0.030 35.00 1030.00

Normal Flow

6.30 201.274 200.649 kg/hr mm-H2O mm-H2O kg/cm2-g DEG C kg/m3

Property Method

User Input

1.30 HCL /

cP Liquid

User Input

1.033 : : : : : : :

kg/cm2 0.75% 0.75%

Uncertainty in Flow Rate in Discharge Coeff. in Expansion Factor in Primary Diameter in Pipe Diameter in Density in Pressure

Notes :

1.BORE SIZE AS PER ASME-MFC-14M-2003 2.PLEASE CHECK THE PROCESS PARAMETERS.BETA IS NOT IN LIMIT.

Reynolds Number Is Smaller Than Specified by: ASME MFC-14M-2003 Method

This report created by Flowel 4.1.1

�Calculation Data sheet for NO 00 BY AT DATE 5/26/2013

FLOW ELEMENT

TATA CONSULTANCY ENGINEERING LTD

Project : 6527A GSR PILOT PLANT

Tag. No. Service Manuf.

: : :

FIT-8401 HCL H2 ASTEC VALVES & FITTINGS Element Type Press. Tap Loc. / Type Element Material Beta Ratio(d/D) Element Bore Thickness Sizing Mode Reference

Eq./Line No. Flowsheet Model No.

: : :

ELEMENT DATA

: Orifice Plate-Small Bore : Upstream / Corner : Hastelloy C : 0.2110 : 5.62 : 3.18 mm : : : : : : : : : : : Exact Bore ASME MFC-14M-2003 300# 1 in 26.64 Duplex SS Duplex SS 0.61 0.97 10324.11 48929.43 / RF 40 mm

mm

SIZING CRITERIA

PIPING DATA

Flange Pipe Size & SCH Pipe I.D. Flange Material Pipe Material Discharge Coeff.(C) Gas Expan. Coeff.(Y1) Reynolds No.(Pipe) Reynolds No.(Bore)

COEFFICIENTS

User Factor (Fuser) Murdock Wet Gas Factor (Fx) Velocity of Approach Factor (Ev) Reynolds No.(Pipe - Normal)

: 1.00 : : 1.00 : 9378

PROCESS DATA Flow Rate Diff. Pressure Pressure Loss Static Pressure Base Pressure Temperature Density Spec. Gravity Z-Compressibility Factor Viscosity k-Factor (Cp/Cv) Fluid Name / Fluid State Liquid Density Gas Quality Atmospheric Pressure UNCERTAINTY DATA : : : : : : : : : : : : : : :

Base

Maximum Flow

7.20 1000.000 947.354 0.030 35.00 0.95

Normal Flow

6.54 816.334 773.353 kg/hr mm-H2O mm-H2O kg/cm2-g DEG C kg/m3

Property Method

User Input

0.01 1.4036 HCL H2 /

cP Gas

User Input Ideal Gas Method

1.033 : : : : : : :

kg/cm2 0.84% 0.75% 0.38%

Uncertainty in Flow Rate in Discharge Coeff. in Expansion Factor in Primary Diameter in Pipe Diameter in Density in Pressure

Notes :

1.BORE SIZE AS PER ASME-MFC-14M-2003

This report created by Flowel 4.1.1

�Calculation Data sheet for NO 00 BY AT DATE 5/26/2013

FLOW ELEMENT

TATA CONSULTANCY ENGINEERING LTD

Project : 6527A GSR PILOT PLANT

Tag. No. Service Manuf.

: : :

FIT-8202 HYDROGEN ASTEC VALVES & FITTINGS Element Type Press. Tap Loc. / Type Element Material Beta Ratio(d/D) Element Bore Thickness Sizing Mode Reference

Eq./Line No. Flowsheet Model No.

: : :

ELEMENT DATA

: Orifice Plate-Small Bore : Upstream / Corner : 316 SS : 0.0721 : 1.92 : 3.18 mm : : : : : : : : : : : Exact Bore ASME MFC-14M-2003 300# 1 in 26.64 316 SS 0.62 0.99 573.56 7951.76 / RF 40 mm

mm

SIZING CRITERIA

PIPING DATA

Flange Pipe Size & SCH Pipe I.D. Flange Material Pipe Material Discharge Coeff.(C) Gas Expan. Coeff.(Y1) Reynolds No.(Pipe) Reynolds No.(Bore)

ASTM A182 F316 User Factor (Fuser) Murdock Wet Gas Factor (Fx) Velocity of Approach Factor (Ev) Reynolds No.(Pipe - Normal) : 1.00 : : 1.00 : 528

COEFFICIENTS

PROCESS DATA Flow Rate Diff. Pressure Pressure Loss Static Pressure Base Pressure Temperature Density Spec. Gravity Z-Compressibility Factor Viscosity k-Factor (Cp/Cv) Fluid Name / Fluid State Liquid Density Gas Quality Atmospheric Pressure UNCERTAINTY DATA : : : : : : : : : : : : : : :

Base

Maximum Flow

0.40 250.000 248.403 0.030 35.00 0.80

Normal Flow

0.37 210.807 209.459 kg/hr mm-H2O mm-H2O kg/cm2-g DEG C kg/m3

Property Method

User Input

0.01 1.4036 hydrogen (normal) /

cP Gas

Lucas Viscosity Eqn. Ideal Gas Method

1.033 : : : : : : :

kg/cm2 0.76% 0.75% 0.09%

Uncertainty in Flow Rate in Discharge Coeff. in Expansion Factor in Primary Diameter in Pipe Diameter in Density in Pressure

Notes :

1.BORE SIZE AS PER ASME-MFC-14M-2003 2.PLEASE CHECK THE PROCESS PARAMETERS.BETA RATIO IS NOT IN LIMIT.

Reynolds Number Is Smaller Than Specified by: ASME MFC-14M-2003 Method

This report created by Flowel 4.1.1

�Calculation Data sheet for NO 00 BY AT DATE 5/26/2013

FLOW ELEMENT

TATA CONSULTANCY ENGINEERING LTD

Project : 6527A GSR PILOT PLANT

Tag. No. Service Manuf.

: : :

FIT-8201 TIC4 H2 ASTEC VALVES & FITTINGS Element Type Press. Tap Loc. / Type Element Material Beta Ratio(d/D) Element Bore Thickness Sizing Mode Reference

Eq./Line No. Flowsheet Model No.

: : :

ELEMENT DATA

: Orifice Plate-Small Bore : Upstream / Flange : 316 SS : 0.3969 : 10.58 : 3.18 mm : : : : : : : : : : : Exact Bore ASME MFC-14M-2003 300# 1 in 26.64 316 SS 0.61 0.98 51664.16 130163.58 / RF 40 mm

mm

SIZING CRITERIA

PIPING DATA

Flange Pipe Size & SCH Pipe I.D. Flange Material Pipe Material Discharge Coeff.(C) Gas Expan. Coeff.(Y1) Reynolds No.(Pipe) Reynolds No.(Bore)

ASTM A182 F316 User Factor (Fuser) Murdock Wet Gas Factor (Fx) Velocity of Approach Factor (Ev) Reynolds No.(Pipe - Normal) : 1.00 : : 1.01 : 46365

COEFFICIENTS

PROCESS DATA Flow Rate Diff. Pressure Pressure Loss Static Pressure Base Pressure Temperature Density Spec. Gravity Z-Compressibility Factor Viscosity k-Factor (Cp/Cv) Fluid Name / Fluid State Liquid Density Gas Quality Atmospheric Pressure UNCERTAINTY DATA : : : : : : : : : : : : : : :

Base

Maximum Flow

39.00 750.000 617.622 0.030 136.40 2.84

Normal Flow

35.00 598.521 492.838 kg/hr mm-H2O mm-H2O kg/cm2-g DEG C kg/m3

Property Method

User Input

0.01 1.4036 TIC4 H2 /

cP Gas

User Input Ideal Gas Method

1.033 : : : : : : :

kg/cm2 0.80% 0.75% 0.28%

Uncertainty in Flow Rate in Discharge Coeff. in Expansion Factor in Primary Diameter in Pipe Diameter in Density in Pressure

Notes :

1.BORE SIZE AS PER ASME-MFC-14M-2003

This report created by Flowel 4.1.1

�Calculation Data sheet for NO 00 BY AT DATE 5/26/2013

FLOW ELEMENT

TATA CONSULTANCY ENGINEERING LTD

Project : 6527A GSR PILOT PLANT

Tag. No. Service Manuf.

: : :

FIT-8101 TIC4 ASTEC VALVES & FITTINGS Element Type Press. Tap Loc. / Type Element Material Beta Ratio(d/D) Element Bore Thickness Sizing Mode Reference

Eq./Line No. Flowsheet Model No.

: : :

ELEMENT DATA

: Orifice Plate-Small Bore : Upstream / Flange : 316 SS : 0.3111 : 8.29 : 3.18 mm : : : : : : : : : : : Exact Bore ASME MFC-14M-2003 300# 1 in 26.64 316 SS 0.64 0.98 581.59 1869.73 / RF 40 mm

mm

SIZING CRITERIA

PIPING DATA

Flange Pipe Size & SCH Pipe I.D. Flange Material Pipe Material Discharge Coeff.(C) Gas Expan. Coeff.(Y1) Reynolds No.(Pipe) Reynolds No.(Bore)

ASTM A182 F316 User Factor (Fuser) Murdock Wet Gas Factor (Fx) Velocity of Approach Factor (Ev) Reynolds No.(Pipe - Normal) : 1.00 : : 1.00 : 533

COEFFICIENTS

PROCESS DATA Flow Rate Diff. Pressure Pressure Loss Static Pressure Base Pressure Temperature Density Spec. Gravity Z-Compressibility Factor Viscosity k-Factor (Cp/Cv) Fluid Name / Fluid State Liquid Density Gas Quality Atmospheric Pressure UNCERTAINTY DATA : : : : : : : : : : : : : : :

Base

Maximum Flow

36.00 750.000 662.326 0.030 136.40 5.88

Normal Flow

33.02 623.144 550.114 kg/hr mm-H2O mm-H2O kg/cm2-g DEG C kg/m3

Property Method

User Input

0.82 1.4036 TIC4 /

cP Gas

User Input Ideal Gas Method

1.033 : : : : : : :

kg/cm2 0.76% 0.75% 0.28% 0.09% 0.09%

Uncertainty in Flow Rate in Discharge Coeff. in Expansion Factor in Primary Diameter in Pipe Diameter in Density in Pressure

Notes :

1.BORE SIZE AS PER ASME-MFC-14M-2003

Reynolds Number Is Smaller Than Specified by: ASME MFC-14M-2003 Method

This report created by Flowel 4.1.1