Professional Documents

Culture Documents

X795

Uploaded by

Casey RybackOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

X795

Uploaded by

Casey RybackCopyright:

Available Formats

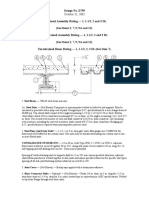

Design No.

X795

September 26, 2003 Ratings 1, 1-1/2, 2, 3 and 4 Hr

1. Steel Column, Steel Pipe or Steel Tube Wide flange steel column (W) or steel circular pipe (SP) or steel square or rectangular tube (ST) or min sizes as shown in the table below. 2. Spray-Applied Fire Resistive Materials* Applied by mixing with water and spraying in more than one coat to the thicknesses shown below, to steel surfaces which are clean and free of dirt, loose scale and oil. Min avg and min ind density of 40 and 36 lbs per cu ft, respectively. For method of density determination, see Design Information Section, Sprayed Material. The min thickness of Spray-Applied Fire Resistive Materials required for various fire resistance ratings of contours sprayed or boxed wide flange columns are shown in the table below: The thickness of Spray-Applied Fire Resistive Materials to be applied to all surfaces of the column (Item 1) required for rating periods of 1 h, 1-1/2 h, 2 h, 3 h, 4 h may be determined by the equation: h= R 1.05 (W/D) + 0.61 Where: h=Spray-Applied Fire Resistive Materials thickness in the range 0.25-3.875 in. R=Fire resistance rating in hours (1-4 h) D=Heated perimeter of steel column in inches W=Weight of steel column in lbs per foot W/D=0.33 to 6.62 As an alternate to the equation, the min thickness of Spray-Applied Fire Resistive Materials required for various fire resistance ratings of contours sprayed or boxed wide flange columns are shown in the table below: Column Size In. W6x9 W6x12 W6x16 W8x28 W10x49 W21x73 W12x106 W14x233 W14x730 Min Thkns In. 1 Hr 1-1/16 1 13/16 3/4 11/16 11/16 9/16 5/16 5/16 1-1/2 Hr 1-7/16 1-3/8 1-1/4 1-3/16 7/8 7/8 7/8 1/2 5/16 2 Hr 1-1/2 1-1/2 1-1/2 1-3/8 1-1/8 1-1/8 1-1/8 9/16 5/16 3 Hr 2-1/4 2-1/4 2-1/4 2 1-9/16 1-9/16 1-9/16 7/8 3/8 4 Hr 3 3 2-15/16 2-1/2 1-15/16 1-15/16 1-15/16 1-1/4 9/16

The hourly rating of the structural member is dependent upon the ratio of A/P and the thickness of Spray-Applied Fire Resistive Materials, where A is the cross sectional area of the pipe or tube and P is the heated perimeter. The A/P ratio of a circular pipe is determined by: A/P pipe= t(d-t) d Where: d=the outer diameter of the pipe (in.) t=the wall thickness of the pipe (in.) The A/P ratio of a rectangular or square tube is determined by: A/P tube= t(a+b-2t) a+b Where: a=the outer width of the tube (in.) b=the outer length of the tube (in.) t=the wall thickness of the tube (in.)

The thickness of Spray-Applied Fire Resistive Materials for ratings of 3/4, 1, 1-1/2, 2, 3 and 4 h of a steel pipe or tube can be determined by the equation: h= R-0.2 4.43 (A/P) Where: R=the hourly rating (hrs) h=the thickness of Spray-Applied Fire Resistive Materials, minimum 1.4 in., maximum 3-7/8 in. As an alternate to the equation, the min thickness of Spray-Applied Fire Resistive Materials required for various fire resistance ratings of contour sprayed steel pipes or tubes are shown on the table below: Column Size In. ST 4x4x3/16 in. ST 4x4x5/16 in. ST 4x4x3/8 in. ST 4x4x1/2 in. ST 20x20x3/4 in. ST 20x20x1 in. ST 20x20x1-1/12 in. ST 20x20x1-3/4 in. ST 32x32x1-1/4 in. ST 32x32x1-1/2 in. ST 32x32x1-3/4 in. ST 32x32x2 in. ST 36x24x1/2 in. SP 4x0.237 in. SP 6x0.432 in. SP 6x0.864 in. SP 8x0.322 in. SP 10x0.5 in Min Thkns In. 1 Hr 1 5/8 9/16 7/16 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 3/8 13/16 1/2 1/4 5/8 3/8 1-1/2 Hr 1-7/16 1-1/16 7/8 11/16 3/8 5/16 1/4 1/4 1/4 1/4 1/4 1/4 5/8 1-3/8 3/4 3/8 1 5/8 2 Hr 1-13/16 1-7/16 1-1/4 15/16 9/16 7/16 5/16 5/16 3/8 5/16 1/4 1/4 7/8 1-13/16 1-1/16 9/16 1-5/16 7/8 3 Hr 2-9/16 2-3/16 1-7/8 1-7/16 7/8 11/16 1/2 7/16 9/16 1/2 7/16 3/8 1-5/16 2-5/8 1-5/8 7/8 2-1/16 1-3/8 4 Hr 3-5/16 2-15/16 2-9/16 2 1-3/16 15/16 5/8 9/16 3/4 5/8 9/16 1/2 1-3/4 3-1/2 2-3/16 1-3/16 2-13/16 1-13/16

ARABIAN VERMICULITE INDUSTRIES Type Z-146. Investigated for exterior use. W R GRACE & CO - CONN CONSTRUCTION PRODUCTS DIV Type Z-146. Investigated for exterior use. GRACE KOREA INC Type Z-146. Investigated for exterior use. 3. Metal Lath (Optional for contour application) 3.4 lbs per sq yd galv or painted expanded steel lath. Lath shall be lapped 1 in. and tied together with No. 18 SWG galv steel wire spaced vertically 6 in. O.C. *Bearing the UL Classification Mark

You might also like

- Design No. X790: BXUV.X790 Fire-Resistance Ratings - ANSI/UL 263Document4 pagesDesign No. X790: BXUV.X790 Fire-Resistance Ratings - ANSI/UL 263souravrobinNo ratings yet

- Tablas Weldolets, ThredoletsDocument44 pagesTablas Weldolets, ThredoletsIng TelloNo ratings yet

- Y710Document2 pagesY710RimNo ratings yet

- BXUV.Y708 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQ For Pyrocrete 239Document3 pagesBXUV.Y708 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQ For Pyrocrete 239mohammed6474No ratings yet

- Design No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263Document3 pagesDesign No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263EngTamerNo ratings yet

- CatalogDocument7 pagesCatalogFelipe A. Gutiérrez M.No ratings yet

- Design No. D916: April 25, 2002Document8 pagesDesign No. D916: April 25, 2002dleechuyNo ratings yet

- Design No. D759: October 31, 2003Document9 pagesDesign No. D759: October 31, 2003souravrobinNo ratings yet

- Section: United Structural WorksDocument1 pageSection: United Structural WorksRajender Reddy RamidiNo ratings yet

- Style 38 CouplingsDocument4 pagesStyle 38 CouplingscristobalmonoNo ratings yet

- VibrationControl CATALOGO SOPORTES PDFDocument12 pagesVibrationControl CATALOGO SOPORTES PDFMilena Lemus FonsecaNo ratings yet

- Fluid Tech-Info enDocument17 pagesFluid Tech-Info enadhityaNo ratings yet

- Design No. D782: BXUV.D782 Fire-Resistance Ratings - ANSI/UL 263Document5 pagesDesign No. D782: BXUV.D782 Fire-Resistance Ratings - ANSI/UL 263EngTamerNo ratings yet

- Zap DataSheet RevDDocument2 pagesZap DataSheet RevDnmihai73No ratings yet

- A Pi Ring Joint Flange DataDocument2 pagesA Pi Ring Joint Flange DataSusin LimNo ratings yet

- McKinney Pricebook 2012 With AddendumDocument278 pagesMcKinney Pricebook 2012 With AddendumSecurity Lock DistributorsNo ratings yet

- X854Document10 pagesX854RimNo ratings yet

- Baja StructuralDocument18 pagesBaja StructuralIin HarwiNo ratings yet

- Tightener Idler Catalog (Powerdrive - Com)Document8 pagesTightener Idler Catalog (Powerdrive - Com)PowerDriveNo ratings yet

- Steel BookDocument477 pagesSteel BookAKSHEYMEHTANo ratings yet

- American SteelBook 2Document472 pagesAmerican SteelBook 2MiguelRagasNo ratings yet

- BYBU - XR731 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq - GCP-AVICOTE Z-156PC PDFDocument5 pagesBYBU - XR731 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq - GCP-AVICOTE Z-156PC PDFCIAKNo ratings yet

- Steel BookDocument468 pagesSteel BookFabian PorrasNo ratings yet

- Design No. D925: BXUV.D925 Fire-Resistance Ratings - ANSI/UL 263Document9 pagesDesign No. D925: BXUV.D925 Fire-Resistance Ratings - ANSI/UL 263EngTamerNo ratings yet

- Truss 0402Document35 pagesTruss 0402Mihai RaducuNo ratings yet

- Grating AceroGrillDocument9 pagesGrating AceroGrillRafaelNo ratings yet

- Truss 0402Document35 pagesTruss 0402Cos_sensNo ratings yet

- Sch80ctech SDL80C TDocument9 pagesSch80ctech SDL80C Thumberto.aranguiz2715No ratings yet

- Rail Chart: Nominal Weight Per Yard Type of Rail Dimensions in Inches Section Designation HT BW HW W HD FD BD EDocument5 pagesRail Chart: Nominal Weight Per Yard Type of Rail Dimensions in Inches Section Designation HT BW HW W HD FD BD ECarlos A. RocaNo ratings yet

- Design No. N852: BXUV.N852 Fire-Resistance Ratings - ANSI/UL 263Document5 pagesDesign No. N852: BXUV.N852 Fire-Resistance Ratings - ANSI/UL 263EngTamerNo ratings yet

- Peso de CablesDocument5 pagesPeso de Cablesrlexl6darvNo ratings yet

- Bus Bar Ampacity Table Ampacities of Copper Bus Bars Alloy Uns C11000Document6 pagesBus Bar Ampacity Table Ampacities of Copper Bus Bars Alloy Uns C11000edalzurcNo ratings yet

- BTC Gate ValvesDocument26 pagesBTC Gate ValvesCamilo Sanchez VanegasNo ratings yet

- Fittings Flanges SpecsDocument8 pagesFittings Flanges SpecsMajed AdamNo ratings yet

- Design No. N782: BXUV.N782 Fire-Resistance Ratings - ANSI/UL 263Document6 pagesDesign No. N782: BXUV.N782 Fire-Resistance Ratings - ANSI/UL 263EngTamerNo ratings yet

- Ampacity Chart For Copper Bus Bar DesignDocument2 pagesAmpacity Chart For Copper Bus Bar DesignfaberromeroNo ratings yet

- Ampacity Chart For Copper Bus Bar DesignDocument2 pagesAmpacity Chart For Copper Bus Bar DesignfaberromeroNo ratings yet

- Fire Dampers: Construction and SpecificationsDocument7 pagesFire Dampers: Construction and SpecificationsAmr Adeeb Abd-ElaahNo ratings yet

- Raccordi A Inserto Forgiato PDFDocument3 pagesRaccordi A Inserto Forgiato PDFpeppino di capriNo ratings yet

- Seamless Welded Fittings: A B K DV E F GDocument8 pagesSeamless Welded Fittings: A B K DV E F Gmdasifkhan2013100% (1)

- API 650 Tank Nozzle Stand OutDocument5 pagesAPI 650 Tank Nozzle Stand Outgplese0No ratings yet

- ASTM.F994 Penetration ConnectionsDocument6 pagesASTM.F994 Penetration Connectionsnkpong849005No ratings yet

- Straightening Vane Assembly Isometric View of Vane: Vane and Spool Piece DimensionsDocument1 pageStraightening Vane Assembly Isometric View of Vane: Vane and Spool Piece Dimensionsaamirtec301No ratings yet

- 12 Allowable Pipe Span Formulas and TablesDocument10 pages12 Allowable Pipe Span Formulas and TablesSeungmin Paek91% (11)

- Taper Bushing InstallationDocument6 pagesTaper Bushing InstallationatenciajNo ratings yet

- 150T Bin Design ReportDocument3 pages150T Bin Design Reportgopalakrishnannrm1202No ratings yet

- ThyssenKrupp Drilling CatálogoDocument16 pagesThyssenKrupp Drilling Catálogoflasher_for_nokiaNo ratings yet

- Pipe Threads-What Is The Limit PDFDocument15 pagesPipe Threads-What Is The Limit PDFMohamed RafeekNo ratings yet

- BYBU - XR701 Fire Resistance Ratings - ANSI/UL 1709Document2 pagesBYBU - XR701 Fire Resistance Ratings - ANSI/UL 1709FPA InspectorNo ratings yet

- Tex-417-A, Unit Weight, Yield, and Air Content (Gravimetric) of ConcreteDocument9 pagesTex-417-A, Unit Weight, Yield, and Air Content (Gravimetric) of ConcreteJoe A. CagasNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168From EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Tests of Creosoted Timber, Paper No. 1168No ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Ansi B77.1-2011Document190 pagesAnsi B77.1-2011Casey RybackNo ratings yet

- Testing Epoxy Resin Adhesive: Standard Method of Test ForDocument13 pagesTesting Epoxy Resin Adhesive: Standard Method of Test ForCasey Ryback100% (1)

- Testing Epoxy Resin Adhesive: Standard Method of Test ForDocument13 pagesTesting Epoxy Resin Adhesive: Standard Method of Test ForCasey Ryback100% (1)

- FRP Composites Grating ManualDocument10 pagesFRP Composites Grating ManualCasey Ryback33% (3)

- Naamm Manualwqrwqr 532 PDFDocument71 pagesNaamm Manualwqrwqr 532 PDFBok MortegaNo ratings yet

- Astm A 53 PDFDocument22 pagesAstm A 53 PDFminhyNo ratings yet

- MBG - 531-09 Metal Bar Grating ManualDocument36 pagesMBG - 531-09 Metal Bar Grating ManualCarlo Monsalve100% (1)

- Traces of Thiophene in Benzene by Spectrophotometry: Standard Test Method ForDocument4 pagesTraces of Thiophene in Benzene by Spectrophotometry: Standard Test Method ForCasey RybackNo ratings yet

- Solidification Point of Benzene: Standard Test Method ForDocument4 pagesSolidification Point of Benzene: Standard Test Method ForCasey RybackNo ratings yet

- D 3771 - 03 - Rdm3nzeDocument4 pagesD 3771 - 03 - Rdm3nzeCasey RybackNo ratings yet

- D 396 - 02Document6 pagesD 396 - 02David CazorlaNo ratings yet

- Ash From Petroleum Products: Standard Test Method ForDocument4 pagesAsh From Petroleum Products: Standard Test Method ForNelson GomesNo ratings yet

- Compressibility and Recovery of Gasket Materials: Standard Test Method ForDocument4 pagesCompressibility and Recovery of Gasket Materials: Standard Test Method ForGustavo MartínezNo ratings yet

- D 4522 - 04 - Rdq1mjiDocument2 pagesD 4522 - 04 - Rdq1mjiCasey RybackNo ratings yet

- ASTM D 86 Distillation of Petroleum Products at Atmospheric Pressure - 2004 PDFDocument24 pagesASTM D 86 Distillation of Petroleum Products at Atmospheric Pressure - 2004 PDFecsuperalNo ratings yet

- D 850 - 00 - Rdg1mc0wmaDocument6 pagesD 850 - 00 - Rdg1mc0wmaCasey RybackNo ratings yet

- Isobutyl Acetate (95 % Grade) : Standard Specification ForDocument2 pagesIsobutyl Acetate (95 % Grade) : Standard Specification ForCasey RybackNo ratings yet

- Solidification Point of Benzene: Standard Test Method ForDocument5 pagesSolidification Point of Benzene: Standard Test Method ForCasey RybackNo ratings yet

- Astm D 850-03 Distalation of Industrial Aromatic Hydrocarbons and Related Materials PDFDocument7 pagesAstm D 850-03 Distalation of Industrial Aromatic Hydrocarbons and Related Materials PDFGianinaRoncalChávezNo ratings yet

- D 850 - 99 - Rdg1mc05oueDocument6 pagesD 850 - 99 - Rdg1mc05oueCasey RybackNo ratings yet

- D 850 - 02 - Rdg1mc1sruqDocument8 pagesD 850 - 02 - Rdg1mc1sruqCasey RybackNo ratings yet

- D 850 - 02 - Rdg1mc0wmkuxDocument6 pagesD 850 - 02 - Rdg1mc0wmkuxCasey RybackNo ratings yet

- D 853 - 03 - Rdg1my0wmwDocument2 pagesD 853 - 03 - Rdg1my0wmwCasey RybackNo ratings yet

- D 6214 - 98 R03 - RdyymtqDocument4 pagesD 6214 - 98 R03 - RdyymtqCasey RybackNo ratings yet

- D 6140 - 97 - RdyxndatotcDocument3 pagesD 6140 - 97 - RdyxndatotcCasey RybackNo ratings yet

- D 6141 Â " 97 RDYXNDEDocument2 pagesD 6141 Â " 97 RDYXNDELeón SuárezNo ratings yet

- Solidification Point of Benzene: Standard Test Method ForDocument3 pagesSolidification Point of Benzene: Standard Test Method ForCasey RybackNo ratings yet

- D 6213 - 97 R03 - RdyymtmDocument4 pagesD 6213 - 97 R03 - RdyymtmCasey RybackNo ratings yet

- D 6213 Â " 97 RDYYMTMTOTCDocument4 pagesD 6213 Â " 97 RDYYMTMTOTCLeón SuárezNo ratings yet

- D 6140 Â " 97 RDYXNDATUKVEDocument4 pagesD 6140 Â " 97 RDYXNDATUKVELeón SuárezNo ratings yet

- Kanban SystemDocument23 pagesKanban SystemSlamet Dwi HaryantoNo ratings yet

- Chapter 4 Process Description (Draft)Document4 pagesChapter 4 Process Description (Draft)ezraNo ratings yet

- Flat Products Made of Steel BS EN10028 - 2Document26 pagesFlat Products Made of Steel BS EN10028 - 2Javier OrnaNo ratings yet

- Certificado BSI FM 35435 2013Document4 pagesCertificado BSI FM 35435 2013Nestor Robles TorresNo ratings yet

- UOP Integration of Membranes For CO2 Removal Tech Paper PDFDocument15 pagesUOP Integration of Membranes For CO2 Removal Tech Paper PDFghasem_726990287No ratings yet

- Introduction To BlacksmithingDocument57 pagesIntroduction To BlacksmithingPC100% (3)

- Panzhihua Iron and Steel Facility, China: Blast Furnace Top Pressure Recovery TurbineDocument4 pagesPanzhihua Iron and Steel Facility, China: Blast Furnace Top Pressure Recovery TurbinePavan KumarNo ratings yet

- LSCM Group 2 Scientific Glass Case AnalysisDocument9 pagesLSCM Group 2 Scientific Glass Case Analysisshahbaaz syedNo ratings yet

- Optibelt SC PLUS BrochureDocument2 pagesOptibelt SC PLUS BrochurevietkhamNo ratings yet

- SpittelauDocument20 pagesSpittelauFranco PiaggioNo ratings yet

- MBa ProjectDocument2 pagesMBa Projectsahil100% (1)

- High Level Sand Reclamation by Means of Secondary Attrition - A Viable Alternative To Thermal ReclamationDocument14 pagesHigh Level Sand Reclamation by Means of Secondary Attrition - A Viable Alternative To Thermal ReclamationPradipto SahaNo ratings yet

- CFB Boilers IntroductionDocument37 pagesCFB Boilers IntroductionBernie_Garcia__9886No ratings yet

- Nanolite CLC Blocks PDFDocument2 pagesNanolite CLC Blocks PDFKrishna YarlagaddaNo ratings yet

- 01 A Malhotra - KBR PurifierTM Technology and Project Execution Options For Ammonia PlantsDocument15 pages01 A Malhotra - KBR PurifierTM Technology and Project Execution Options For Ammonia PlantsDerek MorseNo ratings yet

- 9485 & 926 Transfer Tapes: Product Data SheetDocument3 pages9485 & 926 Transfer Tapes: Product Data SheetvijaygalaxyNo ratings yet

- 6582-Specification Index - 7 Feb 2011Document4 pages6582-Specification Index - 7 Feb 2011kolli.99995891No ratings yet

- Machine SafeguardingDocument43 pagesMachine Safeguardingfaizijust4uNo ratings yet

- 3M Fiber BrochureDocument6 pages3M Fiber Brochuremujahaddad100% (1)

- Geometallurgy PDFDocument5 pagesGeometallurgy PDFEdythMarcaNo ratings yet

- Polymers and PlasticsDocument34 pagesPolymers and PlasticsDIENLUU150489No ratings yet

- CO2 Production PlantDocument4 pagesCO2 Production PlantRodrigo Lagos EscobarNo ratings yet

- Case Study 5Document5 pagesCase Study 5Mary Apple D. Cirpo100% (1)

- Writing Activity: My Skill Is WeldingDocument3 pagesWriting Activity: My Skill Is Weldingkevin araujoNo ratings yet

- Set No: 1: Code No: V3212/R07Document4 pagesSet No: 1: Code No: V3212/R07sanyasirao1100% (1)

- Soldering HandoutDocument5 pagesSoldering HandoutamrsheblksNo ratings yet

- Copper Tubes - ASTM B88Document4 pagesCopper Tubes - ASTM B88Jacques SwartNo ratings yet

- A Partial Look at Concrete - A Very Good BookDocument148 pagesA Partial Look at Concrete - A Very Good BookRajat HiraNo ratings yet

- Kreiselbrecher enDocument12 pagesKreiselbrecher enFranz Anggi KriboNo ratings yet

- Uhde Brochures PDF en 17Document20 pagesUhde Brochures PDF en 17geocottonNo ratings yet