Professional Documents

Culture Documents

Idea Optimal Home Energy Management Under Dynamic Electrical and Thermal Constraints

Uploaded by

Muhammad NaeemCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Idea Optimal Home Energy Management Under Dynamic Electrical and Thermal Constraints

Uploaded by

Muhammad NaeemCopyright:

Available Formats

Copyright (c) 2011 IEEE. Personal use is permitted.

For any other purposes, permission must be obtained from the IEEE by emailing pubs-permissions@ieee.org.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication.

IEEE TRANSACTION ON INDUSTRIAL INFORMATICS - SPECIAL SECTION ON SMART GRID 1

Optimal Home Energy Management under

Dynamic Electrical and Thermal Constraints

Francesco De Angelis, Matteo Boaro, Danilo Fuselli, Stefano Squartini, IEEE Senior Member,

Francesco Piazza, IEEE Member, and Qinglai Wei, IEEE Member

AbstractThe optimization of energy consumption, with con-

sequent costs reduction, is one of the main challenges in present

and future Smart Grid. Of course this has to occur keeping

the living comfort for the end-user unchanged. In this work an

approach based on the Mixed-Integer Linear Programming

paradigm, able to provide an optimal solution in terms of tasks

power consumption and management of renewable resources,

is developed. The proposed algorithm yields an optimal task

scheduling under dynamic electrical constraints, ensuring at the

same time the thermal comfort according to the user needs. On

purpose, a suitable thermal model based on heat-pump usage has

been considered in the framework. Some computer simulations

using real data have been performed and obtained results conrm

the efciency and robustness of the algorithm, also in terms of

achievable money saving.

Index TermsOptimal Home Energy Management, Energy

and Task scheduling, Mixed-Integer Linear Programming, Dy-

namic Residential Scenarios, Thermal Comfort, Smart Grid.

I. INTRODUCTION

S

MART grid of the future will provide a better energy

management reducing its waste and including renewable

resources both in local and wide areas [1][9]. To reach

this goal Computational Intelligence (CI) can be applied to

smart grid in many ways [10][12] using different techniques

like Articial Neural Networks (ANN) [14], [15], Fuzzy

Logic systems [16], [17], Evolutionary Computation [18], [19],

Dynamic Programming [20][22]. The attention in this paper

is focused on the micro-grid level, in which on the demand

side management a customer can achieve energy management

[23][25]. Both in a domestic and residential scenarios the

challenge consists in providing an optimal scheduling of the

tasks to be fullled considering both the deadlines imposed

by the user and the conditions related to energy and cost

characterizing the working horizon. The term task denotes in

this context the work done by an electrical appliance within a

certain time period.

During the years, several techniques have been developed to

accomplish energy or task scheduling: deterministic methods

[26], Particle Swarm Optimization [27], [28], Fuzzy Algo-

rithms [29], Articial Neural Networks [30], and also Dynamic

Programming techniques [31][34], but they all consider task

and energy scheduling separately. In this paper a Mixed-

Integer Linear Programming (MILP) approach that provides

F. De Angelis, M. Boaro, D. Fuselli, S. Squartini and F. Piazza are with

Dipartimento di Ingegneria dellInformazione, Universit` a Politecnica delle

Marche, Ancona, Italy.

Q. Wei is with the State Key Laboratory of Management and Control for

Complex Systems, Institute of Automation, Chinese Academy of Sciences,

Beijing, China.

jointly an optimal task and energy scheduling for smart homes

is proposed. Obviously a joint scheduling can give high perfor-

mances results because both the energy and the task aspect are

optimized concurrently, differently from a simple scheduling

operation, in which just a single aspect is considered. The

present work moves from the results obtained in [35] and new

features are proposed and included within the optimization

procedure in order to make it effectively operating in realistic

smart home scenarios. Such features regards both the task

management issue and the possibility to suitably cope with

the user thermal requirements.

About tasks, they can have predetermined inactivity period

for example during sleeping period if they are noisy; also

linked tasks are considered in the algorithm in order to

consider cycle-works (e.g. washing machine), so a sequence

made of sub-tasks is considered with a dened order among

themselves. Furthermore a based on priority policy has been

realized, so the system discards the processes with low priority

whenever it can not supply all the load demand. Differently

from [35], the supposed residential scenario is composed

by more storage systems and renewable energy sources, and

plug-in vehicles (PHV) are included within the optimization

procedure: electric vehicle can be considered as a storage

system, from which energy can be used to meet the load

demand, under some customer specics and bounds.

Regarding the thermal aspects of the scenario, many proce-

dures have been adopted in order to optimize the thermody-

namic behaviour of a house, given some comfort requirements

and a heating model [36], [37]. Until now no attempt has been

made to optimize the home energy management considering

the electrical and thermal constraints in a unique framework:

in this work both the electrical and thermal aspects are solved

concurrently within the same optimization algorithm. Another

relevant difference from [35] is that also a dynamic procedure

has been realized with success to face real-case optimization

problems, both in domestic and residential environment. Con-

sidering all the features listed, the automatic system has to

take decisions in order to nd the best solution in terms of

costs and renewable available energy, knowing task parameters

and respecting the electrical, thermal and temporal constraints

decided by the customer.

Here is the outline of the paper: the analytical issues of the

implemented algorithm are discussed in Section II, whereas

the related operational aspects, for the static and dynamic case

studies, are pointed out in Section III. Section IV deals with

the conducted computer simulations whereas Section V draws

the work conclusions.

Copyright (c) 2011 IEEE. Personal use is permitted. For any other purposes, permission must be obtained from the IEEE by emailing pubs-permissions@ieee.org.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication.

IEEE TRANSACTION ON INDUSTRIAL INFORMATICS - SPECIAL SECTION ON SMART GRID 2

II. THE PROPOSED ALGORITHM

The implemented algorithm is based on the Mixed-Integer

Linear Programming (MILP) paradigm, which represents an

evolution of the standard linear programming (LP): the

mathematical theory is explained in detail in [39], [40].

A. Notation

The list of used notation is reported as follows.

Indices:

t temporal slot

i task

j house

m storage system

k air ow

Parameters:

houses number of houses

tasks number of tasks

s items number of storage items

flows number of valid ows

T time horizon (number of temporal slots)

Ts

j,i,t

bit equal to 1 when task is on, 0 otherwise

Te

j,i,t

bit equal to 1 when task is off, 0 otherwise

T

start

j,i

earliest starting time decided by the user

T

end

j,i

latest ending time decided by the user

T

j,i

task execution time

T

s,off

start slot for inactivity period

T

e,off

end slot for inactivity period

P

j,i

power consumption (W)

SL

m,t

storage level (Wh)

SL

m,MIN

minimum storage level (Wh)

SL

m,MAX

maximum storage level (Wh)

Pc

m,t

electrical charge (W)

Pd

m,t

electrical discharge (W)

m

efciency

C

t

electricity cost ($cent/kWh)

Cmb storage item maintenance cost ($cent/kWh)

Cs

t

selling price ($cent/kWh)

Stot

t

total renewable resources (W)

S

j,i,t

renewable energy to task (W)

Sst

m,t

renewable energy to storage item (W)

Sex

t

renewable energy exported to grid (W)

Shp

j,t

renewable energy to heat pump (W)

j,k

energy/air-ow ratio (Wh/Kg)

continuous air ow from heat pump (Kg/h)

j,k

discrete air ow from heat pump (Kg/h)

b

j,k,t

bit for validating only one ow at each slot t

c air heat capacity at constant pressure at 273 K

hp

heat pump temperature (

C)

i

indoor temperature (

C)

o

outdoor temperature (

C)

target temperature (

C)

i

initial indoor temperature (

C)

MIN

minimum temperature (

C)

MAX

maximum temperature (

C)

heat

target temperature in heating case (

C)

cool

target temperature in cooling case (

C)

L1 house length (m)

L2 house width (m)

L3 house height (m)

roof pitch (degrees)

k

l

house loss factor ()

M

air

air mass in the house (Kg)

L thick of walls or windows (m)

thermal conductivity ()

A area covered by walls or windows (m

2

)

B. Cost function

The cost function used here is equivalent to the one reported

in [35]. It can be shown indeed that, if the same electrical

devices are considered, one can be derived from the other

by means some simple algebra calculations. The difference

just stands on the way to organize the various terms within

the function, which in authors opinion, results to be more

accessible and facilitate the reader understanding. Moreover,

taking into account the innovative contribution of this work,

the terms related to the thermal model are included in the

present cost function and not in the one proposed in [35].

From these premises it follows that the cost function to be

minimized is:

Q =

T

t=1

_

houses

j=1

_

tasks

i=1

_

w

j,i,t

P

j,i

S

j,i,t

_

C

t

_

+

+

sitems

m=1

_

_

Pc

m,t

m

Sst

m,t

_

C

t

Pd

m,t

m

(C

t

Cmb)

_

+

Sex

t

Cs

t

+

_

flows

k=1

(

j,k

j,k

b

j,k,t

) Shp

j,t

_

C

t

_

(1)

where w

j,i,t

= w

j,i,t1

+Ts

j,i,t

Te

j,i,t

is a bit that shows

if the i-th task of j-th house is on or off. The total renewable

energy Stot

t

is divided into the four parts S

j,i,t

, Sst

m,t

, Sex

t

and Shp

j,t

(devoted to task execution, storage systems, grid

and heat pump respectively) to have a clear view of all energy

ows dealt by the optimization algorithm. In this way all these

quantities can be monitored before and after the scheduling,

thus facilitating the understanding of how the overall amount

of renewable energy is used within the optimization horizon.

C. Task constraints

Starting and ending time for each task:

T

end

j,i

Tj,i

tT

start

j,i

Ts

j,i,t

= 1

T

end

j,i

tT

start

j,i

+Tj,i

Te

j,i,t

= 1 j, i

(2)

Continuity for each task:

Ts

j,i,t

= Te

j,i,t+Tj,i

j, i, T

start

j,i

t T

end

j,i

T

j,i

(3)

Copyright (c) 2011 IEEE. Personal use is permitted. For any other purposes, permission must be obtained from the IEEE by emailing pubs-permissions@ieee.org.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication.

IEEE TRANSACTION ON INDUSTRIAL INFORMATICS - SPECIAL SECTION ON SMART GRID 3

On/off for each task in every temporal slot:

w

j,i,t

= w

j,i,t1

+Ts

j,i,t

Te

j,i,t

j, i, 1 t T (4)

Some tasks must be off during some slots (e.g.: during

sleeping period):

T

e,off

=T

s,off

(T1)1

Ts

j,i,t

= 0 for some j and i

(5)

Consecutive tasks (k-th task is done before i-th task for

the j-th house, e.g. washing machine cycles):

M

t=T

start

j,i

Ts

j,i,t

+ (M T

start

j,i

+ 1)Te

j,k,M+1

M+

T

start

j,i

+1, i = k j, T

start

j,i

M T

end

j,i

T

j,i

(6)

D. Storage system constraints

Storage level for each item in the system:

SL

m,MIN

SL

m,t

SL

m,MAX

1 t T (7)

Electricity stored in a storage item at time t:

SL

m,t

= SL

m,t1

+Pc

m,t

m

Pd

m,t

m

1 t T

(8)

Final electricity stored must be greater or equal to a well

dened quantity:

SL

m,t

SL

m,END

t = T (9)

Charge and discharge rate can not exceed the electrical

charge and discharge limits:

Pc

m,t

Pc

m,MAX

Pd

m,t

Pd

m,MAX

1 t T

(10)

The storage item can discharge a smaller or equal quantity

to load only when at least one task is on:

1 t T

houses

j=1

_

tasks

i=1

(w

j,i,t

P

j,i

S

j,i,t

)+

+

flows

k=1

(

j,k

j,k

b

j,k,t

) Shp

j,t

_

sitems

m=1

Pd

m,t

(11)

E. Energy constraints

The four elements into which the total renewable energy

is splitted must satisfy the following contraint (1 t

T):

houses

j=1

_tasks

i=1

S

j,i,t

+Shp

j,t

_

+

sitems

m=1

Sst

m,t

+Sex

t

Stot

t

(12)

Imported energy from the grid can not exceed a certain

maximum allowed value E

MAX

:

j, 1 t T

numtask

i=1

(w

j,i,t

P

j,i

S

j,i,t

)+

+

sitems

m=1

(Pc

m,t

Sst

m,t

Pd

m,t

)+

+

flows

k=1

(

j,k

j,k

b

j,k,t

) Shp

j,t

E

MAX

(13)

Renewables for a task can not exceed the task power:

w

j,i,t

P

j,i

S

j,i,t

0 i, j, 1 t T (14)

Renewable energy for storage can not exceed the storage

system charge:

Pc

m,t

Sst

m,t

0 m, 1 t T (15)

Renewable energy can not exceed the heater consump-

tion:

flows

k=1

(

j,k

j,k

b

j,k,t

) Shp

j,t

0 j, t (16)

F. Thermal model and constraints

The heat balance model of a house is based on the following

formulas, based and derived from [41][43]:

dQ

hp

dt

= c (

hp

i

) (17)

dQ

loss

dt

= k

l

(

i

o

) (18)

where (17) is the heating or cooling energy deriving from heat

pump and (18) is the lost energy. So the indoor temperature

variation is:

d

i

dt

=

1

M

air

c

_

dQ

hp

dt

dQ

loss

dt

_

(19)

M

air

is evaluable thanks to the house geometry. In fact,

computing the volume of the house and knowing the air

density, indoor air mass can be determined as shown in

Section IV. Furthermore k

l

in (18) can be analyzed with an

electric approach, considering all the windows and the walls

in the house as equivalent resistances that satisfy:

R =

L

A

(20)

So a global averaged equivalent resistance is considered:

R

eq

=

1

N

N

i=1

R

i

=

1

k

l

(21)

MILP accepts only constraints consisting of equalities or in-

equalities composed by linear relationship between unknowns,

so to avoid multiplication of them it is necessary to approx-

imate equation (17) considering an averaged value between

the target temperature

and the indoor temperature

i

at the

beginning of optimization, so the (17) becomes:

dQ

hp

dt

= c

_

hp

i

2

_

(22)

It can be shown that this approximation involves a small

negligible error for the indoor temperature. So, according

Copyright (c) 2011 IEEE. Personal use is permitted. For any other purposes, permission must be obtained from the IEEE by emailing pubs-permissions@ieee.org.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication.

IEEE TRANSACTION ON INDUSTRIAL INFORMATICS - SPECIAL SECTION ON SMART GRID 4

to the thermal comfort chosen by the customer, the thermal

constraints are the following:

i

MIN

,

i

MAX

,

heat

or

i

cool

with 1 t T. Since common

air-air heat pump works with a discrete number of air ows,

from the continuous quantity we consider only a discrete

number of admittable values

k

. For this reason in the thermal

model we have the following kind of mapping:

t

flows

k=1

(

k

k

b

k,t

) 1 t T (23)

where b

k,t

is a binary variable which make valid only one

ow value for each temporal slot t, according to the following

constraint:

flows

k=1

b

j,k,t

1 j, 1 t T (24)

Finally our system is modelled, and minimizing the cost

function means minimizing the costs and optimizing the

available energy: the combined energy and task scheduling is

obtained according to the electrical and thermal requirements.

III. OPERATIVE CASES STUDY

A. The Static Case Study

By using the proles of electricity price, temperature and

renewable energy production, and the electrical or thermal

constraints dened by the user over the working horizon, the

algorithm nds the best energy and task scheduling for the

scenario. The proposed cost function (1) is analytically derived

from the function proposed in [35], but in this work it is

written in other way to focus on the different power ows of

renewable energy and to provide a more readible an intuitive

formula. In the algorithm four terms about renewable energies

are considered: S for load demand, Sst for storage system,

Sex to sell to the grid or Shp for the heat pump.

Differently from [35], more storage systems can be included

in the scenario and in the optimization procedure, and a

scheme based on a priority policy is realized to face every

kind of situation: if the system can not supply all the load

demand, this means mathematical solution can not be found

and the convergence can not be reached, then MILP algorithm

restarts discarding step by step the lowest priority task until the

best scheduling is obtained, according to the specic scenario.

Some task features have been added to improve perfor-

mances of [35] in a real case: consequentiality and inactivity.

Tasks can be inactive in some periods chosen by the user

because some of them can be noisy during sleeping period.

With regard to the consequentiality, unlike [35] we consider

more complex task behaviours, because one process can be

splitted in more sub-tasks in order to consider work cycles

(e.g. washing machine or dishwasher) in the correct order

using (6). Also more plug-in vehicles can be considered in the

scenario: electric vehicles can be used as storage systems when

they are connected to the automatic system, so the algorithm

considers these as temporary storage systems, according to

some constraints decided by the end user (e.g. time availability,

stored energy level).

In addition to all these features, differently from a simple

heat storage system like in [35], here a thermal house model

(analytically shown in Section II-F) is considered with all the

comfort constraints decided by the end user, so a complete

optimization framework is realized, including both electrical

and thermal constraints in order to meet the load demand

and the customer comfort, both for domestic and residential

environment (group of houses that share the same system

storages and renewable sources).

B. The Dynamic Case Study

The dynamic optimization can be seen as an external struc-

ture built upon MILP static case. In fact whenever a change in

the scenario occurs (new tasks or conguration modications),

static MILP is recomputed: old constraints are traduced and

added with the new conditions, and both electrical and thermal

tasks parameters are put in a general list in order to trace the

whole states of the processes from the beginning to the end.

As represented in the ow diagram in Fig. 1, when an interrupt

occurs, the system updates all the previous tasks, traces the

amount of time for which a task operated in the past, deletes

from the task list the completed ones, new tasks or plugin

vehicles are eventually added with their parameters, and MILP

algorithm recomputes the new scheduling for the new scenario.

System Running

Start optimization procedure

Interrupt

Update task list

Add/Remove task(s) or plug-in vehicle

YES

NO

Scheduling

Fig. 1. Flow diagram of the system in dynamic case with interrupt

Obviously the algorithm maintains consequentiality of the

tasks and all the constraints related to the electric and thermal

parts between sequential schedules: if a task has been already

started in the previous optimization procedure, now it is forced

to operate for the remaining time slots in order to nish

the process, so the time-continuity and operability between

various MILP algorithms are guaranteed because every time

new equivalent groups of constraints are considered. The

procedure includes also a dynamic work-horizon to allow

completion of tasks, so the necessary longest process duration

is used to launch the script: the work-horizon can be extended

automatically whenever new tasks need it, or can be simply

decreased step by step if the customer is not interested to

Copyright (c) 2011 IEEE. Personal use is permitted. For any other purposes, permission must be obtained from the IEEE by emailing pubs-permissions@ieee.org.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication.

IEEE TRANSACTION ON INDUSTRIAL INFORMATICS - SPECIAL SECTION ON SMART GRID 5

have new optimizations in future. For this dynamic automatic

system, an interrupt occurs when:

schedulable or not-schedulable tasks are added;

a critic task is switched on;

a critic task is switched off;

plug-in vehicle is connected;

plug-in vehicle is disconnected;

forecasted scenario proles change;

the optimization horizon changes.

Whenever one of these seven conditions occurs, there is a

new scheduling. We thus divide tasks in three categories:

schedulable, not-schedulable and critic.

A task is schedulable when the system can choose the process-

ing time: Te

i

Ts

i

> T

i

i. The admitted interval of time

is decided by the user, but obviously the algorithm chooses

when it is more convenient, performing both energy and task

scheduling.

A task is not-schedulable when the system can not locate

its execution within the working horizon, because the task

is constrained to operate exactly in a specic temporal range:

Te

i

Ts

i

= T

i

i, in this case the algorithm performs only

energy scheduling, because the processing window of the task

is already xed by the user.

A task (e.g. television) is critic when the system does not know

the amount of the related execution time, because it depends

on the customer behaviour. The system considers this kind

of task like always on during the working horizon T, so it

performs only energy scheduling and not task scheduling.

Furthermore when a plug-in vehicle is connected, a new

system storage is available in the scenario, so it can be used

to supply the load as well to recharge itself; and if the plug-

in vehicle is disconnected, then the automatic system must

consider the changing in the scenario and restart the opti-

mization procedure, with all the aspects updated. Regarding

the thermal aspect of the problem, the optimization procedure

restarts when there is a not-negligible difference between the

forecasted and real temperature proles. Moreover when the

optimization horizon changes, a refresh of all the parameters

of the system that may vary in time occurs: in this way the

working horizon for the algorithm can be extended in order to

continue task and energy scheduling operations in time, and

new forecasted and more accurate data can be used for the

next scheduling to reach a greater precision especially in the

use of renewable energy.

Such a dynamic extension has been implemented, so the

optimization algorithm can offer solutions step by step, when-

ever a scenario changes in terms of own characteristics. This

results in an overall optimal task and energy scheduling with

remarkable reliability and robustness capabilities, especially in

dynamic and not predictable real cases.

IV. COMPUTER SIMULATIONS

In this section dynamic simulations in one house environ-

ment are presented: the scenario is composed of a photovoltaic

system (equipped with panels having total area A

pv

= 15 m

2

and efciency

pv

= 0.2), one storage system and one heat

pump (air-air type), whose parameters are shown respectively

in Tab. I and Tab. II. Because of the difculty of nding a

complete set of data from a unique source, the solar irradiation

prole I

t

is taken from [44], the outdoor temperature prole

from [45] and the electricity cost from [46], ensuring that there

is temporal coherence in all these considered data.

Algorithm coding and simulations have been carried out in

MATLAB (R2007b - Version 7.5) on a Sony VAIO VGN-

FE31M Intel Core 2 Duo laptop with the following HW

characteristics: T5600 Processor, Supports Enhanced Intel

Speedstep Technology, 1.83 GHz, RAM 1 GB/GO DDR2

(SDRAM) 533 MHz, NVIDIA Geforce Graphic Card Go 7600

with dedicated 128 MB/Mo VRAM.

In performed simulations, the maximum energy that can be

acquired from the grid is 5 kW, the energy selling price is

2.14 dollar cent/kWh and the maintenance cost is Cmb =

0.01 $cent/kWh. According to [47] we can compute the PV

output power as P

pv

= I

t

pv

A

pv

. Moreover, since the

resolution time used in simulations is one hour, Wh and W

agree so we can consider the same unit of measurement both

for energy and power parameters. For the sake of clarity,

the labels used in the following Tables are here listed and

explained:

means that the task must be off

means that the task can be on

means that the task is on

ID denotes an identication number (for tasks and stor-

age systems)

is the storage system efciency

Cp is the maximum capacity of the storage system

Ch

r

is the storage system charge rate (W)

Dh

r

is the storage system discharge rate (W)

SL

0

, SL

e

, SL

min

and SL

max

are the initial, nal,

minimum and maximum state of charge, respectively (W)

R

heat pump

is the amount of renewable energy used for

the heat pump (W)

R

task

is the amount of renewable energy used for tasks

(W)

R

store

is the amount of renewable energy used for the

storage system charge (W)

R

sell

is the amount of renewable energy sold to grid (W)

R

tot

is total amount of renewable energy (W)

En

cost

is the electricity price (cents/kWh)

I

en

is the power acquired from the grid (W)

Load is the actual load demand (W)

TABLE I

STORAGE SYSTEM PARAMETERS

ID SL

0

SLe SL

min

SLmax Cp Chr Dhr

kW

1 100% 2 1 0.5 4.5 5 2 2

Both for heating and cooling cases, an heat pump with 4

different functioning levels is chosen, in order to represent the

most common device of this type. The heat pump parameters

Copyright (c) 2011 IEEE. Personal use is permitted. For any other purposes, permission must be obtained from the IEEE by emailing pubs-permissions@ieee.org.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication.

IEEE TRANSACTION ON INDUSTRIAL INFORMATICS - SPECIAL SECTION ON SMART GRID 6

TABLE II

HEAT PUMP PARAMETERS

Air flow rate (Kg/h) Power (W) (Wh/Kg)

Heating

426 400 1066

690 891 775

868 1550 560

1148 2080 551

Cooling

488 450 1086

690 920 750

868 1500 579

1148 1740 659

are shown in Tab. II, where for each valid value of air

ow rate and power the value is reported, that is the

relationship which binds the air ow and the consumption.

For the simulations we consider a specic house model, whose

geometry and parameters are reported in Tab. III.

TABLE III

HOUSE GEOMETRY AND PARAMETERS

House parameters V alue Unit

House length (L1) 30 m

House width (L2) 10 m

House height (L3) 4 m

Roof pitch () 40 degrees

Number of windows 6

Height of windows 1 m

Width of windows 1 m

Thick of windows 0.1 m

Thick of walls 0.2 m

Thermal coefficient of windows 2808 J/(hrm

C)

Thermal coefficient of walls 136.8 J/(hrm

C)

Considering the values reported in Tab III, the volume of the

house is computed in the following way:

V

house

= L1 L2 L3 + tan

_

180

_

L1 L2 (25)

So, the inside air mass can be calculated with the formula

M

air

= V

house

air

, where

air

is the air density at sea

level (1.225 kg/m

3

). Using windows and walls parameters

shown in Tab. III, the equivalent house resistance R

eq

can be

computed thanks to (20) and (21) formulas.

In order to face both the heating and cooling cases, two

different simulations are executed with the same scenario

but with different outdoor temperatures (summer and winter).

In Tab. IV we propose the initial scenario for the entire

simulation. Regarding the ID numbers, the rst digit refers

to the process number, and the second digit to the subtask

number; for storage systems just one digit is enough.

For the initial scenario in Tab. IV we consider processes

(washing machine, dishwasher) that can be seen as a sequence

of sub-tasks with a specic order among themselves. After the

rst scheduling we suppose that two interrupts occur in the

simulation as reported in Tab. V. With the rst interrupt we

TABLE IV

TASKS AND USER CONSTRAINTS

Tstart T

end

Tasks P

(W)

ID T

(hour)

Wash machine 8:00 13:00 3 800 11 1

1000 12 1

900 13 1

Cooker oven 9:00 13:00 1 1500 21 2

Dishwasher 14:00 17:00 2 1000 31 1

2000 32 1

suppose that the customer comes back home at 12:00 (slot s5

in Tab. VIII), so PHV can be charged or used until 16:00 (slot

s8 in Tab. IX) to meet partially the load demand. Furthermore

with the second interrupt TV and PC are powered on from

17:00 (slot s10 in Tab. X) onwards.

TABLE V

INTERRUPTS TABLE

ID Type Tstart T

end

Tasks P

(W)

T

(hour)

PHV 2 12:00 16:00

4

TV 41 critic 17:00

1 200

PC 51 critic 17:00

1 150

The plug-in vehicle (PHV) is integrated in the scenario

conguration as a storage system, and its parameters are

reported in Table VI.

TABLE VI

PHV PARAMETERS

ID SL

0

SLe SL

min

SLmax Cp Chr Dhr

kW

2 100% 3 6 2 9 10 2 2

Let us consider 8 a.m as starting time (rst temporal slot s1)

and for the rst simulation the outdoor temperature in Illinois

(US) on the third day of December 2011 (data set taken from

[45]): all the rst simulation results in Watt are reported (for

each slot s1, s2, etc.) in Tables VIII, IX and X.

At each interrupt (highlighted as the underlined and bold col-

umn in the tables) the automatic system recomputes the static

MILP updating both electrical and thermal old constraints with

the new ones. Furthermore it takes decisions in order to nd

the best solution in terms of costs and renewable available

energy, respecting the new electrical, thermal and temporal

constraints decided by the customer. It must be noticed that

continuity between different schedulings is maintained and

previous temporal constraints are updated and still valid for

the next optimization stage.

As shown in the tables, the optimization procedure makes

the tasks on when it is more convenient in terms of renewable

energy or electricity cost, and the scheduling proles consists

of distributed tasks over the time (within the admitted range).

Copyright (c) 2011 IEEE. Personal use is permitted. For any other purposes, permission must be obtained from the IEEE by emailing pubs-permissions@ieee.org.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication.

IEEE TRANSACTION ON INDUSTRIAL INFORMATICS - SPECIAL SECTION ON SMART GRID 7

2 4 6 8 10 12 14 16 18

4

6

8

10

12

14

16

18

20

22

24

26

Temporal Slots

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Target temperature

Outdoor temperature

Indoor temperature (with optimizer)

Upper bound temperature

Indoor temperature (without optimizer)

Fig. 2. Temperature proles: heating case, 3

rd

December 2011, Illinois (US)

Tab. X clearly shows that critic tasks are considered always

on during the working horizon: the system does not know the

amount of the related processing times, because these tasks

depend on the customer behaviour. This whole simulation can

be extended to a building scope, in which more apartments

share the same renewable sources, but different local tasks

must be accomplished: some related simulation results are not

reported for the sake of conciseness.

Regarding the temperature proles, Fig. 2 shows that user

constraints are respected, so the thermal comfort chosen by

the customer is satised in terms of valid temperature range

(minimum and maximum values). The indoor temperature

prole that appears in Fig. 2 seems to be smaller than the

minimum valid value in certain temporal slots: this depends on

the approximation introduced with (22) in the thermal model

of the house in order to make linear all the thermal constraints

for the optimization procedure in MILP. Anyway the greatest

error is about 0.5

C, and for this reason it does not affect the

fulllment of the requirements. In Fig. 2 and Fig. 3 also the

indoor temperature in the case without optimization is plotted:

there are some differences with the case with optimization, but

the trend is the same. If we compute the Mean Square Error

(MSE) among the indoor and target temperatures for both the

cases, we verify that not only the performance index is similar,

but it is even better in terms of thermal constraints in the MILP

optimized case, like shown in Tab. VII.

TABLE VII

MSE COMPARISON [

C

2

]

Functionality MSE

(with optimizer)

MSE

(without optimizer)

Heating 3.3048 3.3897

Cooling 22.5843 23.1488

Considering the imported and exported energy towards the

grid, dynamic MILP optimization procedure provides a total

cost of 0.69 $. If MILP optimization and the storage system are

missing, the tasks start in the rst valid slot for the customer

(according to the available maximum load) and all the renew-

ables are sold to the grid; furthermore there is no optimization

for the house heating too, and only a thermostat controls

the heat pump just whenever the temperature measured with

sensors is below the target temperature; regarding the plug-in

vehicle a case in which it is always charged with the maximum

2 4 6 8 10 12 14 16 18

8

10

12

14

16

18

20

22

24

26

28

30

Temporal slots

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Target temperature

Outdoor temperature

Indoor temperature (with optimizer)

Lower bound temperature

Indoor temperature (without optimizer)

Fig. 3. Temperature proles: cooling case, 10

th

August 2011, Illinois (US)

charge rate is considered: in this case the total cost is 1.39 $.

So, using dynamic procedure a cost reduction of 50.4 % is

achieved.

In addition to the heating case, also the cooling case has

been simulated: we consider the same scenario described

before but the outdoor temperature is taken from Illinois (US)

on the tenth day of August 2011 [45]. Without reporting the

results in detail, the dynamic procedure provides a total cost of

0.57 $, and without the MILP optimization the cost is 1.19 $,

so a cost reduction of 52.1 % is achieved also in this case.

It is clear that also in summer periods the MILP procedure

provides an optimal task, energy and thermal scheduling,

offering the indoor temperature comfort within the temperature

range established by the customer, as shown in Fig. 3. In

both addressed case studies, the required time for the entire

algorithm computation is about 1.28 s, which is indeed a small

value if compared with the typical 1-hour time resolution of

the simulated scenario.

V. CONCLUSIONS

In this work a MILP based energy management system for

smart home scenarios has been described and evaluated. The

optimization framework is general enough to deal with real

situations in which renewable energy sources, electrical stor-

age systems and domestic thermal model have been suitably

integrated in order to provide a given comfort level according

to the customer needs. The proposed algorithm always nds

out the best solution according to the imposed constraints; it

also includes a policy priority to yield exible optimization

scheduling. Moreover it is able to work not only in static but

also in dynamic cases maintaining the task continuity and the

thermal comfort between consequent schedulings.

Some computer simulations have been performed on pur-

pose and related results allowed the authors to positively con-

clude about the effectiveness of the idea and its suitability in

presence of time-variant conditions, also from a pure monetary

perspective. Moreover, the computational time required by

the optimization algorithm is negligible with respect to time

resolution of 1-hour used in the simulated scenario (as in most

contributions in the literature): this property allows the user

having a relevant exibility in selecting both longer working

horizons and lower time resolution values.

Copyright (c) 2011 IEEE. Personal use is permitted. For any other purposes, permission must be obtained from the IEEE by emailing pubs-permissions@ieee.org.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication.

IEEE TRANSACTION ON INDUSTRIAL INFORMATICS - SPECIAL SECTION ON SMART GRID 8

TABLE VIII

FIRST SCHEDULING

ID Priority Link P T s1 s2 s3 s4 s5 s6 s7 s8 s9 s10

Task 1 11 3 800 1

Task 2 12 3 after ID 11 1000 1

Task 3 13 3 after ID 12 900 1

Task 4 21 1 1500 2

Task 5 31 3 1000 1

Task 6 32 3 after ID 31 1200 1

Heat pump 891 891 400 891 400 400 400 400 400 0

Ch 1 0 0 0 0 0 851 0 0 212 0

Dh 1 885 528 44 0 43 0 18 544 0 0

SL 1 1115 587 543 543 500 1351 1333 788 1000 1000

R

task

0 0 828 270 857 0 1000 656 0 0

Rstore

0 0 0 0 0 851 0 0 212 0

R

sell

0 0 0 0 0 0 0 0 0 0

R

heat pump

6 363 0 891 400 400 191 400 400 0

Rtot

6 363 828 1161 1257 1251 1191 1056 612 0

Encost

6.58 5.70 5.61 5.60 6.12 5.99 5.09 5.37 5.53 6.53

Ien

0 0 1828 2230 0 0 191 0 0 0

Load 891 891 2700 3391 1300 400 1400 1600 400 0

TABLE IX

SCHEDULING AFTER THE FIRST INTERRUPT

ID Priority Link P T s5 s6 s7 s8 s9 s10 s11 s12 s13 s14

Task 1 13 3 900 1

Task 2 31 3 1000 1

Task 3 32 3 after ID 31 1200 1

Heat pump 400 400 400 0 400 400 400 400 400 400

Ch 1 0 0 1681 0 212 0 0 0 0 500

Dh 1 43 0 0 293 0 400 400 400 400 0

SL 1 500 500 2181 1888 2100 1700 1300 900 500 1000

Ch 2 2 0 851 2000 149

Dh 2 2 0 0 0 0

SL 2 2 3000 3851 5851 6000

R

task

857 0 0 907 0 0 0 0 0 0

Rstore

0 851 791 149 212 0 0 0 0 0

R

sell

0 0 0 0 0 0 0 0 0 0

R

heat pump

400 400 400 0 400 0 0 0 0 0

Rtot

1257 1251 1191 1056 612 0 0 0 0 0

Encost

6.12 5.99 5.09 5.37 5.53 6.53 6.66 6.74 6.97 4.72

Ien

0 0 3890 0 0 0 0 0 0 900

Load 1300 400 1400 1200 400 400 400 400 400 400

TABLE X

SCHEDULING AFTER THE SECOND INTERRUPT

ID Priority Link P T s10 s11 s12 s13 s14 s15 s16 s17 s18 s19

Task 1 41 5 200 9

Task 2 51 4 150 9

Heat pump 400 400 400 400 400 891 400 400 400 400

Ch 1 650 0 0 0 0 0 0 750 0 500

Dh 1 0 750 750 750 0 0 0 0 750 0

SL 1 2750 2000 1250 500 500 500 500 1250 500 1000

R

task

0 0 0 0 0 0 0 0 0 0

Rstore

0 0 0 0 0 0 0 0 0 0

R

sell

0 0 0 0 0 0 0 0 0 0

R

heat pump

0 0 0 0 0 0 0 0 0 0

Rtot

0 0 0 0 0 0 0 0 0 0

Encost

6.53 6.66 6.74 6.97 4.72 4.26 3.34 2.50 2.91 2.35

Ien

1400 0 0 0 750 1241 750 1500 0 900

Load 750 750 750 750 750 1241 750 750 750 400

Copyright (c) 2011 IEEE. Personal use is permitted. For any other purposes, permission must be obtained from the IEEE by emailing pubs-permissions@ieee.org.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication.

IEEE TRANSACTION ON INDUSTRIAL INFORMATICS - SPECIAL SECTION ON SMART GRID 9

Future efforts will be mainly targeted to improve the overall

optimization framework, specially from a thermal point of

view. In particular, a more complex thermal model which con-

siders the heat ows exchanged between multiple apartments

close to each other (as in a building) will be implemented.

Furthermore, the presence of a water heating system operated

by air-water heat pump will be included as well.

REFERENCES

[1] S. Chu and A. Majumdar. Opportunities and challenges for a sustainable

energy future. Nature, 488(7411):294-303, 08 2012.

[2] A. Ipakchi and F. Albuyeh, Grid of the Future, IEEE Power Energy

Magazine, vol. 7, no. 2, pp. 52 - 62, 2009.

[3] H. Farhangi, The Path of the Smart Grid, IEEE Power Energy Magazine,

vol. 8, no. 1, pp. 18-28, Jan./Feb. 2010.

[4] C. Cecati, G. Mokryani, A. Piccolo and P. Siano, An Overview on the

Smart Grid Concept, IECON 2010 - 36th Annual Conference on IEEE

Industrial Electronics Society, 7-10 Nov. 2010.

[5] J. Ekanayake, N. Jenkins, K. Liyanage, J. Wu, and A. Yokoyama. Smart

grid: technology and applications. Wiley, 2012.

[6] V. Gungor, D. Sahin, T. Kocak, S. Ergut, C. Buccella, C. Cecati, and

G. Hancke. Smart grid technologies: communication technologies and

standards. IEEE Transactions on Industrial Informatics, 7(4):529-539,

2011.

[7] M. Nehrir, C. Wang, K. Strunz, H. Aki, R. Ramakumar, J. Bing,

Z. Miao, and Z. Salameh. A review of hybrid renewable/alternative

energy systems for electric power generation: Congurations, control,

and applications. IEEE Transactions on Sustainable Energy, 2(4):392-

403, 2011.

[8] C. Cecati, C. Citro, A. Piccolo and P. Siano, Smart Operation of Wind

Turbines and Diesel Generators According to Economic Criteria, IEEE

Transaction on Industrial Electronincs, Vol. 58, No. 10, pp. 45144525,

2011.

[9] V. Calderaro, C. Hadjicostis, A. Piccolo, and P. Siano. Failure identi-

cation in smart grids based on petri net modeling. IEEE Transactions

on Industrial Electronics, 58(10):46134623, 2011.

[10] R. G. Harley and J. Liang, Computational Intelligence in Smart Grids,

Symposium Series on Computational Intelligence (SSCI): CIASG, 2011.

[11] G. K. Venayagamoorthy, Potentials and Promises of Computational In-

telligence for Smart Grids, Power and Energy Society General Meeting:

IEEE, 2009.

[12] P. Werbos. Computational intelligence for the smart grid-history, chal-

lenges, and opportunities. IEEE Computational Intelligence Magazine,

6(3):1421, 2011.

[13] R. Banos, F. Manzano-Agugliaro, F. Montoya, C. Gil, A. Alcayde,

and J. Gomez. Optimization methods applied to renewable and sus-

tainable energy: A review. Renewable and Sustainable Energy Reviews,

15(4):17531766, 2011.

[14] V. Miranda, A. Castro, and S. Lima. Diagnosing faults in power

transformers with autoassociative neural networks and mean shift. IEEE

Transactions on Power Delivery, 27(3):13501357, 2012.

[15] A. Bhattacharya and C. Chakraborty. A shunt active power lter with

enhanced performance using ann- based predictive and adaptive con-

trollers. IEEE Transactions on Industrial Electronics, 58(2):421428,

2011.

[16] M. Fazzolari, R. Alcala, Y. Nojima, H. Ishibuchi, and F. Herrera. A

review of the application of multi-objective evolutionary fuzzy systems:

Current status and further directions. IEEE Transactions on Fuzzy

systems. 2012.

[17] P. Dash, M. Biswal, Measurement and Classication of simultaneous

power signal patterns with an S-transform variant and Fuzzy Decision

Tree. IEEE Trans. on Industrial Informatics, in press, 2012.

[18] Y. del Valle, G. K. Venayagamoorthy, S. Mohagheghi, J. Hernandez and

R. G. Harley, Particle Swarm Optimization: Basic Concepts, Variants

and Applications in Power Systems, IEEE Transaction on Evolutionary

Computation, vol. 12, no. 2, pp. 171-195, Apr. 2008.

[19] A. Ela, M. Abido, and S. Spea. Differential evolution algorithm for

optimal reactive power dispatch. Electric Power Systems Research,

81(2):458464, 2011.

[20] S. Mohagheghi , G. K. Venayagamoorthy and R. G. Harley, Adaptive

critic design based neuro-fuzzy controller for a static compensator in a

multimachine power system. IEEE Transaction on Power Systems, vol.

21, no. 4, pp.1744 -1754 2006.

[21] G. Venayagamoorthy. Dynamic, stochastic, computational, and scalable

technologies for smart grids. IEEE, Computational Intelligence Maga-

zine, 6(3):22-35, 2011.

[22] G. Venayagamoorthy, D. Wunsch, R. Harley, J. Si, A. Barto, W. Powell,

and D. Wunsch. Applications of approximate dynamic programming in

power systems control. Handbook of learning and approximate dynamic

programming, IEEE Press, pages 479-515, 2012.

[23] P. Palensky and D. Dietrich, Demand Side Management: Demand Re-

sponse, Intelligent Energy Systems and Smart Loads, IEEE Transaxtion

on Industrial Informatics, vol. 7, no. 3, pp. 381-388, 2011.

[24] P. Siano, C. Cecati, H. Yu and J. Kolbusz, Real Time Operation of Smart

Grids via FCN Networks and Optimal Power Flow, IEEE Transaxtion

on Industrial Informatics, in press, 2012.

[25] T. Logenthiran, D. Srinivasan, and T. Shun. Demand side management

in smart grid using heuristic optimization. IEEE Transactions on Smart

Grid, 3(3):1244-1252, 2012.

[26] J. Zhu, Optimization of Power System Operation, Wiley-IEEE, 2009.

[27] M. A. A. Pedrasa, T. D. Spooner and I. F. MacGilland, Scheduling

of Demand Side Resources Using Binary Particle Swarm Optimization,

IEEE Transactions on Power Systems, 24(3):11731181, 2009.

[28] N. Gudi, L. Wang, V. Devabhaktuni and S. S. S. R. Depuru, Demand

Response Simulation Implementing Heuristic Optimization for Home

Energy Management, North American Power Symposium (NAPS), 2010.

[29] R. H. Liang and J. H. Liao, A Fuzzy-Optimization Approach for

Generation Scheduling with Wind and Solar Energy Systems, IEEE

Transactions on Power Systems,2007.

[30] Z. A. Vale, P. Faria, H. Morais, H. M. Khodr, M. Silva and P. Kadar,

Scheduling Distributed Energy Resources in an Isolated Grid - An

Articial Neural Network Approach, Power and Energy Society General

Meeting, IEEE, 2010.

[31] T. Huang and D. Liu. A self-learning scheme for residential energy

system control and management. Neural Computing and Applications,

pages 111, 2011.

[32] Fuselli, D., De Angelis, F., Boaro, M., Liu, D., Wei, Q., Squartini, S. and

Piazza, F., Optimal battery management with ADHDP in smart home

environments, Advances in Neural Networks - ISNN 2012, vol. 7367,

Part I, LNCS series, 2012.

[33] M. Boaro, D. Fuselli, F. Angelis, D. Liu, Q. Wei, and F. Piazza, Adaptive

dynamic programming algorithm for renewable energy scheduling and

battery management, Cognitive Computation, pp. 1-14, in press, 2012.

[34] H. Morais, P. K ad ar, P. Faria, Z. A. Vale and H. M. Khodr, Optimal

Scheduling of a Renewable Micro-Grid in an Isolated Load Area

Using Mixed-Integer Linear Programming, Renewable Energy - An

International Journal, 2009.

[35] D. Zhang, L. G. Papageorgiou, N. J. Samsatli and N. Shah, Optimal

Scheduling of Smart Homes Energy Consumption with Microgrid, The

First International Conference on Smart Grids, Green Communications

and IT Energy-aware Technologies, IEEE, 2011.

[36] J. Gustafsson, J. Delsing and J. van Deventer, Thermodynamic Sim-

ulation of a Detached House with District Heating Subcentral, IEEE

Systems Conference, Montreal, Canada, April 7-10, 2008.

[37] M. Va sak, A. Star ci c and A. Martin cevi c, Model Predictive Control of

Heating and Cooling in a Family House, MIPRO, Proceedings of the

34th International Convention, 2011.

[38] R. Blan, J. Cooper, K. Chao, S. Stan, and R. Donca. Parameter

identication and model based predictive control of temperature inside

a house. Energy and Buildings, 43(2):748758, 2011.

[39] J. Matou sek and B. G artner, Understanding and Using Linear Program-

ming, Springer, 2007.

[40] B. Korte and J. Vygen. Combinatorial optimization: theory and algo-

rithms, Vol. 21. Springer, 2012.

[41] E. Kazanavi cius, A. Mikuckas, I. Mikuckien e and J.

Ceponis, The

Heat Balance Model of Residential House, Information Technology and

Control, ISNN 1392, Vol. 35, No. 4, 2006.

[42] B. Qela and H. Mouftah, Simulation of a House Heating System Using

C# - An Energy Conservation Perspective, 23rd Canadian Conference

on Electrical and Computer Engineering (CCECE), 2010.

[43] S. Fux, A. Ashouri, M. Benz, and L. Guzzella. EKF based self-adaptive

thermal model for a passive house. Energy and Buildings, in press, 2012.

[44] National Renewable Energy Laboratory (NREL), San Francisco, Avail-

able: http://www.nrel.gov/rredc/ [01 June 2011].

[45] Meteorologisk institutt, Henrik Mohns Plass, Oslo, Norway, Available:

http://www.met.no/ [16 October 2011].

[46] ComEd, USA, Available: http://www.thewattspot.com [05 June 2011].

[47] T. Markvart, Solar Electricity, 2nd ed., New York, NY: Wiley, 2000.

Copyright (c) 2011 IEEE. Personal use is permitted. For any other purposes, permission must be obtained from the IEEE by emailing pubs-permissions@ieee.org.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication.

IEEE TRANSACTION ON INDUSTRIAL INFORMATICS - SPECIAL SECTION ON SMART GRID 10

Francesco De Angelis was born in Macerata, Italy,

on June 1987. He received the Bachelor Degree

in 2009 and the Master Degree with honours in

2012 in Electronic Engineering at Universit` a Po-

litecnica delle Marche, Ancona, Italy. He carried

out his MSc thesis at the Institute of Automation,

Chinese Academy of Sciences in Beijing, under the

supervision of Prof. Derong Liu and Prof. Francesco

Piazza. The work was about the development of

advanced algorithms and techniques for optimal en-

ergy management in smart home environments. He

is also author and coauthor of several peer-reviewed papers, and his current

research is focused on the development of complex algorithms and methods

for improving environmental pre-diagnosis and performance of industrial

processes in terms of energy requirements.

Matteo Boaro was born in Ancona, Italy on Febru-

ary 1987. He received his BSc degree in 2009

and his MSc in 2012, both in Electronic Engi-

neering from Universit` a Politecnica delle Marche

(UNIVPM), Ancona, Italy. His research interests are

focused on energy management and optimisation in

domestic environments, both from the electric and

thermal point of view.

Danilo Fuselli was born in Recanati, Italy, on

August 1987. He has got the Master Degree with

honors in Electronic Engineering from Universit` a

Politecnica delle Marche, Italy, in 2012. His the-

sis work was achieved at Institute of Automation,

Chinese Academy of Science in Beijing, China

under the supervision of Prof. Derong Liu and Prof.

Francesco Piazza (October 2011 - March 2012).

Fuselli is author and coauthor of several international

conference papers and his current research interests

are in development and application of advanced

computational algorithms for energy problems in smart home environment,

with special attention on linear and complex systems optimization.

Stefano Squartini (Senior Member IEEE and Mem-

ber AES/ISCA) was born in Ancona, Italy, on 1976.

He got the Italian Laurea with honors in electronic

engineering from Polytechnic University of Marche

(UnivPM), Italy, in 2002. He got his PhD degree

(2005) and also a PostDoc fellowship (June 2006-

October 2007) at UnivPM. He currently works as

Assistant Professor in Circuit Theory at Department

of Information Engineering (UnivPM). He is one

of the founding members of the research group

3MediaLabs and he actively participated to various

(funded) regional, national and european projects on multimedia Digital Signal

Processing (DSP). He is author and coauthor of several international scientic

peer-reviewed articles. He is Associate Editor for IEEE Transactions on Neural

Networks and Learning Systems (since 2010) and part of the Cognitive

Computation Editorial Board (2011). His research interests are in the area

of digital signal processing and machine learning, with special focus on

speech/audio processing and energy management.

Francesco Piazza (Member IEEE) was born in Jesi,

Italy, on February 1957. He got the Italian Lau-

rea with honors in electronic engineering from the

University of Ancona, Italy, in 1981. From 1981 to

1983 he worked on image processing at the Physics

Department. In 1983 he worked at the Olivetti OSAI

software development center (Ivrea, Italy). In 1985

he joined the Department of Electronics and Auto-

matics of the University of Ancona. Currently he is

Full Professor of Electrical Science at the Universit` a

Politecnica delle Marche in Italy. He is author or

coauthor of more than 300 international papers. His current research interests

are in the areas of circuit theory and digital signal processing including

adaptive DSP algorithms and circuits, articial neural networks, speech and

audio processing.

Qingali Wei received the B.S. degree in automa-

tion, the M.S. degree in control theory and control

engineering, and the Ph.D. degree in control theory

and control engineering, from the Northeastern Uni-

versity, Shenyang, China, in 2002, 2005, and 2008,

respectively. From 20092011, he was a postdoctoral

fellow with State Key Laboratory of Management

and Control for Complex Systems, Institute of Au-

tomation, Chinese Academy of Sciences, Beijing,

China. He is currently an assistant research fellow

of the institute. His research interests include neural-

networks-based control, adaptive dynamic programming, optimal control,

nonlinear system and their industrial applications.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Second Periodical Test in Organization and Management SY 2018-2019Document3 pagesSecond Periodical Test in Organization and Management SY 2018-2019Merida BravoNo ratings yet

- 74 Series Logic ICsDocument6 pages74 Series Logic ICsanon-466841No ratings yet

- Finding Targets PDFDocument9 pagesFinding Targets PDFSteve TangNo ratings yet

- Manual HobartDocument39 pagesManual HobartВолодимир БроNo ratings yet

- Philips HD 9 User ManualDocument3 pagesPhilips HD 9 User ManualNdangoh DerekNo ratings yet

- IES OBJ Civil Engineering 2000 Paper IDocument17 pagesIES OBJ Civil Engineering 2000 Paper Itom stuartNo ratings yet

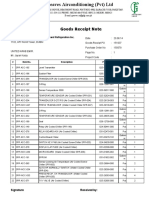

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocument4 pagesGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNo ratings yet

- Electro TechniquesDocument2 pagesElectro TechniquesPinkk DaisyfieldNo ratings yet

- Brp-Rotax Chassis Approval FormDocument3 pagesBrp-Rotax Chassis Approval Formdelta compNo ratings yet

- JCPS School Safety PlanDocument14 pagesJCPS School Safety PlanDebbie HarbsmeierNo ratings yet

- Empowerment Technology Lesson 4 PDFDocument18 pagesEmpowerment Technology Lesson 4 PDFqueenless eightyoneNo ratings yet

- Handbook On National Spectrum Management 2015Document333 pagesHandbook On National Spectrum Management 2015Marisela AlvarezNo ratings yet

- Sociology of Crimes and Ethics Suggested Answer "A"Document34 pagesSociology of Crimes and Ethics Suggested Answer "A"Bernabe Fuentes Jr.No ratings yet

- Drsent PT Practice Sba OspfDocument10 pagesDrsent PT Practice Sba OspfEnergyfellowNo ratings yet

- Dpb6013 HRM - Chapter 3 HRM Planning w1Document24 pagesDpb6013 HRM - Chapter 3 HRM Planning w1Renese LeeNo ratings yet

- SIMPLE PlaybookDocument12 pagesSIMPLE PlaybookMatt LylesNo ratings yet

- Concrete Casting - Pump Station ADocument13 pagesConcrete Casting - Pump Station ABright MuzaNo ratings yet

- Void Engineers (Convention: Mage The Ascension)Document6 pagesVoid Engineers (Convention: Mage The Ascension)Beth0% (1)

- MGNM801 Ca2Document19 pagesMGNM801 Ca2Atul KumarNo ratings yet

- GE Uno Downlight Backlit BLDocument2 pagesGE Uno Downlight Backlit BLChen KengloonNo ratings yet

- 19 Uco 578Document20 pages19 Uco 578roshan jainNo ratings yet

- Davis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersDocument8 pagesDavis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersAngeloNo ratings yet

- SQL - Day 2: Structured Query LanguageDocument10 pagesSQL - Day 2: Structured Query LanguageNight KingNo ratings yet

- How To Install 64 Bits IDES On 32 Bits OSDocument1 pageHow To Install 64 Bits IDES On 32 Bits OSMuhammad JaveedNo ratings yet

- Evidence MODULE 1 Evidence DefinitionDocument8 pagesEvidence MODULE 1 Evidence Definitiondave BarretoNo ratings yet

- Pascal Die Casting Machine SystemDocument20 pagesPascal Die Casting Machine Systemenascimento32No ratings yet

- Updated WorksheetDocument5 pagesUpdated WorksheetJohn Ramer Lazarte InocencioNo ratings yet

- Analysis Chart - Julie Taymor-ArticleDocument3 pagesAnalysis Chart - Julie Taymor-ArticlePATRICIO PALENCIANo ratings yet

- Group 4 - When Technology and Humanity CrossDocument32 pagesGroup 4 - When Technology and Humanity CrossJaen NajarNo ratings yet

- Configuring Hyper-V: This Lab Contains The Following Exercises and ActivitiesDocument9 pagesConfiguring Hyper-V: This Lab Contains The Following Exercises and ActivitiesMD4733566No ratings yet