MAXIMUM MATERIAL PRINCIPLE

1

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�MAXIMUM MATERIAL PRINCIPLE

Maximum material size refers to that limit of size of a feature, which results in the part containing the maximum amount of material. It is the maximum limit of size for an external feature, such as a shaft, or the minimum limit of size for an internal feature, such as a hole.

2

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�MAXIMUM MATERIAL CONDITION(MMC) Maximum material condition (MMC) is a condition wherein a geometrical tolerance applies when the feature is a everywhere at the maximum material size specified on the drawing, but greater geometrical variations are permitted as the feature size approaches the minimum material limit

3

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�VIRTUAL SIZE

Virtual size refers to the overall envelop of perfect form, within which the feature would just fit. For an external feature, such as a shaft, it is the maximum measured size plus the effect of actual form variations, such as straightness, flatness, or roundness. For an internal feature, such as a hole, it is the minimum measured size minus the effect of such form variations. Therefore it always lies beyond the least material size in a direction, which would include more material. The extreme virtual size, referred to as the virtual condition, is based on the maximum material size and the maximum permissible form variations, which are specified on the drawing.

4

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�LEAST MATERIAL CONDITION

This refers to that size of a feature which results in the part containing the minimum amount of material. Thus it is the minimum limit of size for an external feature and the maximum limit of size for an internal feature .

The phrase least material size is preferred than minimum material size to avoid confusion when maximum material is abbreviated to MM ,with the abbreviation of MMC

5

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�FEATURES OF SIZE

Features of size are features, which do have diameter or thickness. These may be cylinders, such as shafts and holes. They may also be slots, tabs, or rectangular or flat parts, where two parallel flat surfaces are considered to form a single feature

6

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�Tolerancing Features of Size

If freedom of assembly of mating parts is the chief criterion for establishing a geometrical tolerance for a feature of size, the least favorable assembly condition exists when the parts are made to the maximum material size. Further geometric variations can then be permitted, with out jeopardizing assembly, as the features approach their least material size .

7

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�MMC & VIRTUAL SIZES

8

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�MMC - EFFECT ON FORM VARIATIONS

9

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�MMC - EFFECT ON LOCATION

10

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

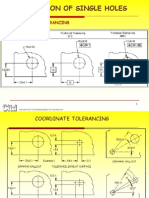

�MAXIMUM MATERIAL CONDITION(MMC)

APPLICATION OF SYMBOL If a geometrical tolerance is required to be modified on an MMC basis, it is specified on the drawing by including the symbol M immediately after the tolerance value in the feature control symbol

This permits the feature surface or surfaces to cross the maximum material boundary by the amount of the form tolerance. If it is required that the virtual size be kept within the maximum material boundary, the form tolerance must be specified as zero at MMC

11

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�MAXIMUM MATERIAL CONDITION(MMC)

APPLICATION WITH MAXIMUM VALUE

TOLERANCE WITH A MAXIMUM VALUE

It is some times necessary to ensure that the geometrical tolerance does not vary over the full range permitted by the size variations. For such applications a maximum limit may be applied to the geometrical tolerance, in addition to the tolerance permitted at the maximum material limit.

12

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�REGARDLESS OF FEATURE SIZE (RFS)

When MMC is not specified with a geometrical tolerance for a feature of size, no relationship is intended to exist between the feature size and the geometrical tolerance

13

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�MAXIMUM MATERIAL CONDITION

MEASUREMENT AND GAGING Features controlled by geometrical tolerances, to which MMC is not applied, can be checked only by individual measurements When a feature is controlled by a geometrical tolerance once modified on an MMC basis, the geometrical characteristic is best checked by means of a functional GO gage If the geometrical tolerance is zero at MMC, the boundary of perfect form will be the maximum material size boundary. The functional GO gage will then check both the maximum material size and the geometrical tolerance simultaneously. If the geometrical tolerance is other than zero at MMC, the feature must not cross the extreme virtual size boundary. In this case a functional GO gage can be used to check the geometrical characteristics only, and the limits of size are measured separately

14

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY

�MAXIMUM MATERIAL CONDITION SYMBOL

15

THE INSTITUTE FOR ENHANCEMENT OF TECHNOLOGY