Professional Documents

Culture Documents

IKO Features and Maintenance Free Series

IKO Features and Maintenance Free Series

Uploaded by

Vikram BorkhediyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IKO Features and Maintenance Free Series

IKO Features and Maintenance Free Series

Uploaded by

Vikram BorkhediyaCopyright:

Available Formats

Gentle to The Earth

Nippon Thompson Co., Ltd. is working to develop global environment-friendly products. It is committed to developing products that make its customer's machinery and equipment more reliable, thereby contributing to preserving the global environment. This development stance manifests well in the keyword "Oil Minimum".

Gentle to The Earth

Our pursuit of Oil Minimum has led to the creation of proprietary family of lubricating parts as "C-Lube".

TheC-LubeSeries not only keeps products maintenance-free for long by giving them an optimal and minimal amount of a lubricant for an extended period of time but also contributes greatly to preserving the global environment.

The "Interchangeable" is a result of our consideration to the environment and radical pursuit of elimination of material and inventory waste.

Interchangeable is a collective name of "systems of products selection from users' perspective" which allows free interchange and replacement totally retaining the accuracy and preload of slide units and track rails.

The integration of maintenance free and advanced interchangeable system with C-Lube is the "Free & Interchangeable".

10

Features of Maintenance Free Series

Gentle to The Earth

U.S. PATENTED C-Lube Linear Way ML

No. 7677804 7252435 6729761 6712511 5435649

Ecology specication

5435649

Reducing usage of lubrication oil

Maintenance free

Endures running over 20,000 km without oil feeding!

Linear Way L

No. 7258486 6517244 6176617 6082899 5967667

Ecology

Consumption of precious oil resource is minimized! And elimination of oil feeder and its piping reduces the initial cost!

Compactness

The space consuming oil feeder is eliminated to save the space!

C-Lube Linear Way ME

No. 7748905 7677804 6729761 6712511 5564188 5374126 5356223 5324116

Linear Way E

No. 6176617 5967667 5356223 5324116 7677804 5564188 5374126

C-Lube Linear Way MH

No. 7832929 7762723 7748905 7677804 6729761 5435649 6176617 5967667 5564188 5374126 8123408 8113714 8033730 7997800 7950852 7832930 7458721 7458720 6766897 6461045 7927016 7862234 7832930 6712511 5564188 5374126

Linear Way H

No. 7677804 6517244 6461045 6250805 6176617 6880975 6851857 6517244 6461045 6309107 6176617 6082899 7780356 7534042 7458721 7458720 5800064 7341378 5967667 5800064 5622433 5564188 6082899 5967667 5622433 5564188 5374126 5967667 5435649

Contributes to reduction of total cost and environmental loads!!

Oil usage reduction effect

Troublesome lubrication maintenance process is reduced!!

Distance equivalent to halfway around the globe

Freedom of machine designing is expanded for user!!

Efcient use of space

C-Lube Linear Way MUL

No. No.

Linear Way U

No.

Linear Way F

C-Lube Linear Roller Way Super MX

No. No. 5564188 5374126

Linear Roller Way Super X

No. 6176617 No. 5464288 5374126 5306089

Oil

11

12

Features of Maintenance Free Series

Features Features of of C-Lube C-Lube Linear Linear Way Way and and C-Lube C-Lube Linear Linear Roller Roller Way Way

Gentle to The Earth

Original Original and and world's world's rst rst

structure with [C-Lube]

C-Lube Linear Way C-Lube Linear Roller Way

The aquamarine end plate is the symbol of maintenance free.

Long period maintenance free is realized with oil impregnated with C-Lube only !!

Maintenance free

This endures running over 20,000 km without oil feeding with lubrication oil in the C-Lube only. Furthermore, grease is pre-packed in the slide unit so long period maintenance free can be realized.

Durability test result

Linear Way LWL9 C-Lube Linear Way ML9

No C-Lube

No grease

4.9 km lubrication shortage damage Running of 86,000 km without failure Running of 46,000 km without failure Running of 89,000 km without failure Running of 71,000 km without failure Running of 56,000 km without failure

0

C-Lube Linear Way ME25 C-Lube Linear Roller Way MXG45

Maintenance free is achieved until the end of device life !

*1

C-Lube integrated High-speed at 240 m/min No grease C-Lube integrated High acceleration / deceleration 26G No grease C-Lube integrated Load of 0.09C No grease C-Lube integrated Load of 0.1C No grease C-Lube integrated Load of 0.1C No grease

20 000km

40 000

60 000

80 000

100 000

*1.

Typical device life is assumed. Re-greasing may be necessary depending on use conditions.

Traveling distance km

Ecology

As lubrication oil in C-Lube is supplied by the amount necessary to maintain lubrication performance of the rolling guide, the consumption of lubrication oil is reduced and lubrication performance is maintained even when it run for a long period.

Oil supply test result

Lubrication oil supply amount wt%

100 80 60 40 20

No pre-packed grease No applied load ML9 ML12 ML15

Ecology specication reducing usage of lubrication oil!

20 000km

40 000

60 000

80 000

100 000

Traveling distance km

C-Lube integrated

Lubrication oil is carried through circulation of rolling elements

The lubrication oil is supplied directly to the rolling elements, not to the track rail. When rolling elements make contact with the capillary lubricating element integrated with the circulation path of slide unit rolling elements, the lubrication oil is supplied to surfaces of rolling elements and carried to the loading area through circulation of rolling elements. This results in adequate lubrication oil being properly maintained in the loading area and lubrication performance will last for a long time.

Compact

As C-Lube Linear Way and C-Lube Linear Roller Way are integrated with lubrication part C-Lube, their slide units are not long unlike types with external lubrication parts. Replacement of conventional parts is easy free from constraints of mounting space and stroke length.

External lubrication parts

Linear way using conventional lubrication parts C-Lube Linear Way

Lubrication oil is directly supplied to surfaces of the rolling elements

The surface of capillary lubricating element is always covered with the lubrication oil. Lubrication oil is continuously supplied to the surface of rolling elements by surface tension in the contact of capillary lubricating element surface and rolling elements. On the surface of capillary lubricating element with which the rolling elements make contact, new lubrication oil is always supplied from the other sections.

Compact design taking into account compactness!

Cylindrical rollers C-Lube Cylindrical rollers

Cylindrical rollers

Smooth

Lubrication oil lm Surface tension

Frictional resistance test result

Frictional resistance N

3.0

ML9 standard preload

Track

rail

Slide u

nit stro

ke dire

ction

C-Lube

Capillary

C-Lube

C-Lube Linear Way and C-Lube Linear Roller Way do not generate slide resistance unlike lubrication parts external to the slide unit that make contact with the track rail. Driving force follow-up property is superior and energy is saved by improvement of accuracy and reduction of friction loss.

2.0

1.0

50

100

150

Light and smooth motion is achieved!

13

Travelling distance mm

14

Features of Interchangeable Specication

Ultimate Interchangeable pursuit of elimination

Accuracy interchangeability

Three accuracy classes are available! Height variation can be controlled with multiple assembled sets!

system by radical of any waste

Short delivery products

Separate delivery of slide unit and track rail!

Unit interchangeability

Many type of slide units are available! Every slide unit is interchangeable with the same track rail!

High accuracy of the device can be maintained in the multiple-use environment!!

It is easily added or replaced!!

You may order what you need by any quantity at any time!!

Q Q

I dropped the linear way unit by mistake, and the unit is damaged. Can I replace it?

Dropped

A A

Sounds great!

Unit interchangeability

If you use Linear way of Interchangeable specication, you may need to replace only slide unit.

Q Q

Calculated accuracy cannot be achieved after assembly of the device?

Accuracy not improved

Fine accuracy

Accuracy interchangeability, preload interchangeability

How do you like to use accuracy higher by one class or higher preload type? As accuracy of the interchangeable products is controlled strictly by parts, setting can be modied.

Oh, dear! It's going to be late

Please modify my accuracy

I need to increase the rigidity of the unit because of sudden specication change.

I want to be long type...

Power up

I carelessly forgot to arrange some parts, but I need them urgently. Can it be delivered soon?

If late...

Unit interchangeability

The rigidity can be improved easily by increasing the unit length.

Sounds great!

Short delivery available

Interchangeable parts are available for short delivery, they can be delivered quickly with our perfect inventory system. Slide unit and track rail can be ordered individually.

Need more rigidity

I forgot to arrange

15

16

Features of Interchangeable Specification

Free combination is enabled for model, accuracy, preload!!

Interchangeable specication has realized the incomparable high interchangeability by severely managing the dimensions of slide unit and track rail with the background of unique high processing technology. This feature allows independent handling of slide unit and track rail, thus allowing you to select free combination and to order any products for any volume at any necessary time.

Ultimate interchangeable system

Requirements of ;

Interchangeable specication

Interchangeable specification realizes ;

Wish to prepare for a sudden design change Wish to select freely the combination of high accuracy and preload Slide unit and track rail are separately handled Free combination of slide unit and track rail can be selected Compactness-independent storing of slide units and track rails

Accuracy interchangeability

Three accuracy classes of Ordinary, High and Precision class are provided, to support even high traveling accuracy purposes. In addition, as height variation of multiple assembled sets is managed with high accuracy, you may use parallel track rails at ease.

Standard setting up to precision

Wish to improve the rigidity and life of machines Wish to improve the accuracy of machines Wish to replace the slide unit immediately The number of slide units is in short Wish to replace the track rail immediately The length of track rail is not sufcient Wish to store only the slide units in stock for emergency

p l e H Sor

Slide unit Track rail

t u o d te

Set condition

Tolerances of dimensions H and N Variation of dimensions H and N in 1 set Parallelism in operation of the C surface to A surface Parallelism in operation of the D surface to B surface

N

D B

Select the products as many as you wish.

It allows the accuracy improvement of units without design changes!

Corresponding to parallel arrangement of multiple assembled sets as standard

Variation of dimensions H of multiple assembled sets is specied

Preload interchangeability

The high accuracy dimensions management utilizing the simple structure achieved the interchangeability of preloaded slide units. It supports the applications requiring the rigidity of one higher rank.

Light preload

Take

over

Unit interchangeability

A wide variety of slide unit models with different sectional shape and length are provided, for free replacement on the same track rail.

High preload setting is possible thanks to high accuracy dimensions control

Interchangeability of track rail

Track rail

High carbon Stainless steel-made Butt-jointing steel-made track rail track rail track rails

Standard preload

Slide unit

Interchangeability of slide unit

Slide unit shape

Flange type mounting from bottom Flange type mounting from top Block type mounting from top Compact block type mounting from top

Rigidity is necessary after all!

Track rail

It allows the rigidity improvement of units without design changes!

Maintenance free is achieved only by replacing the slide unit!

Length of slide unit

Short unit Standard unit Long unit Extra long unit

By replacing the interchangeable linear way or linear roller way slide unit with C-Lube Linear Way or C-Lube Linear Roller Way slide unit, maintenance free is achieved while using the same track rail.

Free selection is possible for slide units and track rails!

17 18

Features of Linear Way Series

's excellent features realized by contact in two-row raceways

Two-row four-point contact type simple structure

adopts two-row four-point contact type for every Linear Way series. Thanks to our design know how and production technologies having been fostered for long time, high accuracy and smooth motion is realized in the micro series. In addition, load in every direction can be received evenly and therefore stable high accuracy and rigidity can be achieved even in applications where load has Simple two-row four-point variable direction and size or Four-point contact structure contact structure complex load is applied.

a simple structure by four-points

Interchangeable

The simple structure of four-contact in two-row raceway yields small manufacturing errors or accuracy measurement errors, allowing the maintenance of each raceway in the high dimensions accuracy.

This technology realizes interchangeable specication and high interchangeable system in every series!

Track rail

Slide unit Measurement of way accuracy

As the ball is stabilized during track groove measurement, measurement of high accuracy and precise preload management are possible.

Variety of models and size variations

Essential for micro sizing!

Micro Linear Way L realized by simple structure

Micro linear way L for further needs of miniaturization produced by original small sizing technology Wide variety of track rail width from 1 mm to 6 mm is available and high accuracy of micro positioning mechanism is realized.

A wide variety of models and sizes, such as super miniature size of only 1 mm track rail width, is provided for your selection to meet each requirement.

Series Model Size Track rail width

Min Max

C-Lube Linear Way ML Linear Way L C-Lube Linear Way ME Linear Way E C-Lube Linear Way MH Linear Way H

ML LWL ME LWE MH LWH LWF MUL LWU

7 models 13 sizes 20 models 18 sizes 18 models 21 models 15 models 6 sizes 6 sizes 9 sizes

5 42 mm 1 42 mm 15 45 mm 15 45 mm 8 45 mm 8 85 mm 33 90 mm 25 30 mm 25 130 mm

25 models 12 sizes 4 models 1 models 3 models 7 sizes 2 sizes 8 sizes

Track rail width

Linear Way F C-Lube Linear Way MUL Linear Way U

World's smallest size!

High accuracy even with the smallest size of 1 mm*!

*Track rail width of 1 mm

Even the smallest size of 1 mm can be securely mounted and xed**!

**Tapped rail specication

Micro Linear Way L

Even the smallest size of 1 mm can ensure stable operation!

LWL1

19

LWL1 can be used for further super miniaturization

of machines and devices with free-minded thinking.

1N=0.102kgf=0.2248lbs. 1mm=0.03937inch

20

Features of Linear Roller Way Series

Ultimate high performance produced by world's

Super high load capacity

The Linear Roller Way Super X has a large contact area with the way and a number of cylindrical roller with excellent load capacity, which allows to achieve larger load rating.

rst roller guide structure of

Super high rigidity

The rigidity of linear motion rolling guide signicantly affects properties of machines and devices to be incorporated. The Linear Roller Way Super X achieves high rigidity as a number of small cylindrical rollers with smaller elastic deformation relative to load than that of balls are incorporated in the slide unit.

Comparison of basic dynamic load rating

600 000

Comparison of basic static load rating

900 000

Comparison of elastic deformation

30 MX25Roller type MH25Ball type 20

Basic dynamic load rating N

Basic static load rating N

500 000

Roller typeMX and LRX Ball typeMH and LWH

800 000 700 000 600 000 500 000 400 000 300 000 200 000

Roller typeMX and LRX Ball typeMH and LWH

400 000

Displacement

10 12 15 20 25 30 35 45 55 65 85 100

Inertia F=ma

25

300 000

15

200 000

10

100 000 100 000 0 10 12 15 20 25 30 35 45 55 65 85 100 0

5 000

10 000

15 000

20 000

Size

Size

Load N

Size smaller by one size than the ball type can be used!

Well-balanced high rigidity is realized in every direction!

Long life

Roller TypeMXG45 Ball TypeMHG45

Same size

C = 124 000 N C0 = 223 000 N C = 95 200 N C0 = 114 000 N

CBasic dynamic load rating N C0Basic static load rating N LLife km PApplied load N

Roller type has large basic dynamic load rating C and long life due to the different "index"!

Life calculation example

Roller Type

Ball type

Applied load In case of 10000 N

C L=50( P)

10/3

C L=50( P)

L 220 000 km

21

L 43 000 km

Signicant increase!

1N=0.102kgf=0.2248lbs. 1mm=0.03937inch

22

Features of Linear Roller Way Series

Vibration characteristics

The Linear Roller Way Super X has high rigidity relative to ball types of the same size, so deformation amount is low relative to repeated uctuating load, natural frequency is high and vibration damping time is short.

Impulse hammer Acceleration pickup

Half amplitude

Corresponding to compactication

Vibration damping curve in downward vibration (Half amplitude)

250

Roller type with signicantly higher load capacity than the ball type. The Linear Roller Way Super X allows for downsizing from many size variations for compactication of devices.

Compliance x 10-9 m/N

200 MX15Roller type 150 MH15Ball type 100

To make the device needs to be more compact while maintaining the load capacity

To make the device needs to be compact while maintaining the load capacity

For example, when

Jig

Xe-2f t

0

XInitial amplitude f0Natural frequency Damping ratio t Time

LWH55B

Ball Typeis used

To increase the load capacity with the same size

To make the device needs to be more compact while maintaining the load capacity

MXN45

Roller Type

MX45

Roller Type

MX55

Roller Type

MXN55

Roller Type

Bed

50

Vibration damping curve

0 0 0.01 0.02 0.03 0.04 0.05

Positioning time can be shortened!

Time s

Same size

Downsizing Same size Same size

Allows accurate positioning with excellent frictional characteristic

The Linear Roller Way Super X prevents skew of cylindrical roller and achieves smooth motion by adopting unique retaining method to accurately guide cylindrical roller ends with retaining plate. The Linear Roller Way Super X has good response characteristics to micro-feeding and allows for accurate positioning, thanks to small frictional resistance against preload and load and excellent frictional characteristics relative to plain guides and ball type linear motion rolling guide.

MXDL25 and MXDG45 T3 preload frictional resistance

Test portion Preload Velocity Lubrication Extra long unit MXDL25 Long unit MXDG45 T3 preload 0.6 m/min C-Lube integrated, with grease

50

C = 95 400 N C0 = 159 000 N

Same load capacity

C = 95 400 N C0 = 159 000 N

C = 113 000 N C0 = 121 000 N

Load capacity increased

C = 148 000 N C0 = 248 000 N

Same load capacity

C = 148 000 N C0 = 248 000 N

Downsizing

Downsizing

Same size

Downsizing

Frictional resistance N

40 30 20 10 0

MXDL25 MXDG45

High follow-up property is ensured even for micro-feeding!

Downsizing and increased load capacity!

0 100 200 300

Roller type with large increase of load capacity!

Compatible ball type and mounting dimensions

The Linear Roller Way Super X has mounting dimensions compatible with the ball type Linear Way H. Replacement with roller type is possible without signicant design change to machine or device.

Distance mm

High running accuracy

Optimal design based on analysis of re-circulation behavior of cylindrical roller circulation realizes smooth and quiet motion. In addition, load is applied to many cylindrical rollers and therefore the micro deection during running is minimized. Extra long unit is optimal for applications requiring higher running accuracy. (For details, see page-29)

500

Roller Type

Ball type

C-Lube Linear Roller Way Super MX

C-Lube Linear Way MH

246

Flange type

308

MX

Block type

MH, MHT

Deection amount during running

unit: m

MXDG30 T3 preload

0.12 0.12

Competitor's super high accuracy long type

Stable running accuracy is achieved!

MXD

MHD

MXDG30 is equivalent to competitor's super high accuracy long type

23

Downsizing and increased load capacity are possible!

Compact block type

MXS

MHS

1N=0.102kgf=0.2248lbs. 1mm=0.03937inch

24

Models and Size Variations

A variety of models and size variations

Ball Type Miniature Series Ball Type Compact Series

C-Lube Linear Way ML Linear Way L

Thanks to the structure with two rows of balls to contact with the way at four points, stable accuracy and rigidity can be achieved even in applications where load has variable direction and size or complex load is applied, despite its very small body.

C-Lube Linear Way ME Linear Way E Low Decibel Linear Way E

Versatile linear motion rolling guide achieved utility pursuing compactness in every aspect just like lower, narrower, and shorter. Low decibel types with resin separator to prevent direct contact between balls are also available.

Standard type

Wide type

Length of slide unit

Short

ML LWL

MLF LWLF

C No symbol G

Extra long Standard

Standard type

Size 1, 2, 3, 5, 7, 9, 12, 15, 20, 25

Flange type mounting from bottom

Flange type mounting from top

Block type mounting from top

Length of slide unit

Short

Wide type 4, 6, 10, 14, 18, 24, 30, 42

ME LWE

MET LWET

MES LWES

C No symbol G

Standard

Size 15, 20, 25, 30, 35, 45

Long

Long

Micro Linear Way L

As the lineup of track rail width from 1 mm to 6 mm is available, i.e. standard and long, you can select an optimal linear bushing for the specications of your machine and device. For LWL1, world's smallest size is realized: track rail width of 1 mm, slide unit width of 4 mm and assembly height of 2.5 mm.

Ball Type High Rigidity Series

C-Lube Linear Way MH Linear Way H

Linear motion rolling guide having a maximum load rating among ball type units by incorporating a large-diameter ball. Stable accuracy and rigidity can be achieved even in applications where load with variable direction and size and complex load are applied.

Standard type

Wide type

LWL1

4 2.5 4.2 4 3.2

LWL2

6 4

LWL3

8 4

LWLF4

10 4.5

LWLF6

12

Sectional shape

Original size

unit: mm

Short Length of slide unit

original size

Flange type mounting from bottom MH LWH

Flange type 1 mounting from top MHT LWHT

Block type Compact block type mounting from top mounting from top MHD MHS LWHD LWHS

Length of slide unit

Short

C No symbol

Standard

Standard

Long

G Standard rail specication Tapped rail specication Tapped rail specicationmounting from lateral Solid rail specication

Extra long

L Size

Track rail model

Note 1 Some models may be mounted from bottom.

Size 8, 10, 12, 15, 20, 25, 30, 35, 45, 55, 65, 85

25

1N=0.102kgf=0.2248lbs. 1mm=0.03937inch

26

Models and Size Variations

A variety of models and size variations

Ball Type Wide Type Series

Roller Type

Linear Way F

As wide track rail is used and the distance between the load points is long, this is a linear motion rolling guide suitable to single-row use due to the structure resistant to across-the-width moment load. It is also resistant to complex load.

C-Lube Linear Roller Way Super MX Linear Roller Way Super X

Linear motion rolling guide that has achieved the highest level of performance in all characteristics utilizing the roller's superior characteristic, such as rigidity, load capacity, running accuracy and vibration damping property. With extra long unit with the maximum slide unit length, load capacity and rigidity are improved and running performance with super high accuracy is realized.

Flange type mounting from top / bottom

Flange type mounting from top / bottom

Block type mounting from top

Length of slide unit

Standard No symbol

Flange type mounting from top / bottom

1 MX 1 LRX

Block type mounting from top

Compact block type mounting from top

Low section ange type mounting from top

Low section block type mounting from top

LWFH

LWFF

LWFS

MXD LRXD

MXS LRXS

MXN

MXNS

LWFH LWFF LWFS

Size 40,60,90 33,37,42,69 33,37,42

Note 1 Size 20 series allows only for mounting from top and model mounting from bottom is MXH and LRXH.

C

Short

Length of slide unit No symbol G

Standard Long

L

Extra long

Size 10, 12, 15, 20, 25, 30, 35, 45, 55, 65, 85, 100

Ball Type U-Shaped Track Rail Series

C-Lube Linear Way MUL Linear Way U

Linear motion rolling guide of the structure with way inside the track rail of U-shaped section and slide unit therein. With the U-shaped track rail, rigidity against the track rail moment load and torsion is signicantly improved.

Four-row roller guide of world's smallest size Track rail width of 10 mm

Small type MUL LWUL

Standard type LWU

Length of slide unit Standard No symbol Size MUL 25, 30 LWUL 25, 30 LWU 40, 50, 60, 86, 100, 130

Super high rigidity Super high load capacity High running performance Excellent frictional characteristics

Stainless steel made

LRXD10SL

1N=0.102kgf=0.2248lbs. 1mm=0.03937inch

27

28

Models and Size Variations

Features of extra long unit

C-Lube Linear Roller Way Super MX

Length of slide unit is

C-Lube Linear Way MH

Length of slide unit is

1.4 to 1.5 times longer

1.6 times longer

Further improvement of running accuracy Load capacity and rigidity are signicantly improved!!

Load capacity of machine or device is improved

than that of standard unit

than that of standard unit

Long unit

1.2 to

1.3 time

Long unit

1.2 to 1.3

times

As its basic dynamic load rating and basic static load rating are larger than those of Long type by 122% and 129%, respectively, life and margin safety of machine or device are improved.

Comparison of basic dynamic load rating Comparison of basic static load rating

MH(T, D) G

MX (D,S) G MXN (S) G

Increased to 158% relative to standard unit! Increased to 122% relative to long unit!

Increased to 181% relative to standard unit! Increased to 129% relative to long unit!

(In case of MXL45)

1400 000

Standard unit

MX (D,S) MXN (S)

Basic dynamic load rating

600 000 500 000 400 000 300 000 200 000 100 000 0

Basic static load rating N

1.4 to 1.5

times

Standard unit

1.6 time

s

800 000 700 000

(In case of MXL45)

Short unit Standard unit Long unit Extra long unit Short unit Standard unit Long unit Extra long unit

MH(T,D)

1200 000 1000 000 800 000 600 000 400 000 200 000 0

Extra long unit Extra long unit

MH(T,D) L

Size 20

Size 25

Size 30

Size 35

Size 45

Size 55

Size 65

Size 85

Size 20

Size 25

Size 30

Size 35

Size 45

Size 55

Size 65

Size 85

MX (D,S) L MXN (S) L

Super accurate feeding mechanism is realized

As running accuracy is as low as a half of that of long unit, feeding mechanism with super high accuracy can be realized.

423 mm

Running deection m

500

mm

420

mm

Contributing to improvement of machine or device rigidity

Elastic deformation relative to load is small in comparison with long unit, device rigidity is improved, accuracy is improved, and resonance can be avoided.

Load Load Measuring method

600

mm

Measuring position

0.2 0.1 0 -0.1 -0.2 30

Test conditions Test Extra long unit portion MXDL45 Preload T3 preload

300 mm

Deection amount 0.07 m

Comparison of elastic deformation under downward load

Comparison of elastic deformation under upward load

600 mm 463 mm

40

50

60

70

80

90

100

Rigidity increased to 155% relative to standard unit! Rigidity increased to 117% relative to long unit!

(With displacement of 10 m for Size 45)

45 40

Rigidity increased to 152% relative to standard unit! Rigidity increased to 113% relative to long unit!

(With displacement of 10 m for Size 45)

45 40

Traveling distance mm Running deection m

0.2

Displacement m

0 -0.1 -0.2 30

30 25 20 15 10 5 0 0 10 000 20 000 30 000 40 000

Displacement m

Test conditions Test Long unit portion MXDG45 Preload T3 preload

300 mm

Deection amount 0.12 m

0.1

35

MXD45 T3 preloadStandard unit MXDG45 T3 preloadLong unit MXDL45 T3 preloadExtra long unit

35 30 25 20 15 10 5 0 0

(standard unit) T3 preloadStandard unit MXD45 (longMXDG45 unit) T3 preloadLong unit (extra long unit) T3 preloadExtra long unit MXDL45

40

50

60

70

80

90

100

High accuracy running performance is realized ( ) without major change of machine or device design !

1

Traveling distance mm

10 000

20 000

30 000

40 000

Note1 Position of the slide unit mounting hole is changed.

Load N

Load N

29

1N=0.102kgf=0.2248lbs. 1mm=0.03937inch

30

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Michelson-Morley ExperimentDocument23 pagesMichelson-Morley ExperimentKamalakanth RvNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 16 Suspension 3Document37 pages16 Suspension 3Sunilkumar ReddyNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- E3022-15 Standard Practice For Measurement of Emission Characteristics and Requirements For LED UV-A Lamps Used in Fluorescent Penetrant and Magnetic Particle TestingDocument8 pagesE3022-15 Standard Practice For Measurement of Emission Characteristics and Requirements For LED UV-A Lamps Used in Fluorescent Penetrant and Magnetic Particle TestingAhmed Shaban KotbNo ratings yet

- Stamping Design GuidelineDocument13 pagesStamping Design GuidelineVikram Borkhediya100% (1)

- Owners Manual Activa 5G EnglishDocument83 pagesOwners Manual Activa 5G EnglishVikram Borkhediya50% (2)

- KKS ConceptDocument6 pagesKKS ConceptAmit Nigam100% (2)

- Automobile Body BuildingDocument4 pagesAutomobile Body BuildingVikram BorkhediyaNo ratings yet

- Effect of Creep Failure in Bolted Flanged JointsDocument17 pagesEffect of Creep Failure in Bolted Flanged JointsMarta ParaparNo ratings yet

- Optic Imaging PDFDocument435 pagesOptic Imaging PDFPriya Surya HarijantoNo ratings yet

- Astm d4332Document3 pagesAstm d4332許喬甯No ratings yet

- Guided Linear Motion Components & SystemsDocument44 pagesGuided Linear Motion Components & SystemsVikram BorkhediyaNo ratings yet

- Physical Science Grade 11 ExamDocument4 pagesPhysical Science Grade 11 ExamFatima Ybanez Mahilum-LimbagaNo ratings yet

- Patwari 2017 CutoffDocument66 pagesPatwari 2017 CutoffVikram BorkhediyaNo ratings yet

- Hero PleasureDocument4 pagesHero PleasureVikram BorkhediyaNo ratings yet

- Desub Mandual TbeltDocument141 pagesDesub Mandual TbeltVikram BorkhediyaNo ratings yet

- 218 ECAB4 D 01Document114 pages218 ECAB4 D 01Vikram BorkhediyaNo ratings yet

- Guide To Buying A HouseDocument57 pagesGuide To Buying A HouseVikram BorkhediyaNo ratings yet

- Sheetmetal Design GuidelinesDocument5 pagesSheetmetal Design GuidelinesVikram Borkhediya0% (1)

- Design Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyDocument5 pagesDesign Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyVikram BorkhediyaNo ratings yet

- Fundamentals of CastingDocument18 pagesFundamentals of CastingKasinathan JeevaNo ratings yet

- Mechanical Engineering SyllabusDocument3 pagesMechanical Engineering SyllabusVikram BorkhediyaNo ratings yet

- 2 - Design BasicsDocument26 pages2 - Design BasicsVikas TiwariNo ratings yet

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsDocument37 pagesDr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsVikram BorkhediyaNo ratings yet

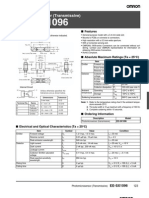

- OMRON Home SensorDocument4 pagesOMRON Home SensorVikram BorkhediyaNo ratings yet

- Dr. A. Aziz Bazoune: Mechanical Engineering DepartmentDocument36 pagesDr. A. Aziz Bazoune: Mechanical Engineering DepartmentVikram BorkhediyaNo ratings yet

- Thermal and Hydraulic Properties of RockDocument11 pagesThermal and Hydraulic Properties of RockaliNo ratings yet

- Centrifugal ChillersDocument16 pagesCentrifugal ChillersMortal Being100% (2)

- Indian Standard: Code of Practice For Composite ConstructionDocument28 pagesIndian Standard: Code of Practice For Composite Constructionvishnumani3011No ratings yet

- MEMB 333 Final ReportDocument51 pagesMEMB 333 Final ReportFikri AzimNo ratings yet

- Wind Speed in Sri Lanka PDFDocument15 pagesWind Speed in Sri Lanka PDFsandrock92100% (1)

- Gaugler, R. S. (1944) - U.S.A. Patent No. 2350348.Document5 pagesGaugler, R. S. (1944) - U.S.A. Patent No. 2350348.pathiNo ratings yet

- Shear Properties of Sandwich Core Materials: Standard Test Method ForDocument4 pagesShear Properties of Sandwich Core Materials: Standard Test Method ForCarlos Raul Caballero LeonNo ratings yet

- Rfqr211351 - Enquiry For DriveDocument34 pagesRfqr211351 - Enquiry For DriveyuwonoNo ratings yet

- Spin Crossover - Quo Vadis?Document11 pagesSpin Crossover - Quo Vadis?Tommy Chente MartinezNo ratings yet

- Vol19b 0925Document17 pagesVol19b 0925Walaa Hassan Salem Abd El KareemNo ratings yet

- JNXX Zmy81 Z NKNDocument11 pagesJNXX Zmy81 Z NKNNavya ShrivastavNo ratings yet

- Motion Class-IX (Physics) Solved Test Paper - 02Document5 pagesMotion Class-IX (Physics) Solved Test Paper - 02anshika tembhareNo ratings yet

- Finite Element Methods - l10Document13 pagesFinite Element Methods - l10Himanshu Jaiswal100% (1)

- Studies On Creep Crack Growth Using The F - Integral: Enyineering Frarrurr MechanicsDocument24 pagesStudies On Creep Crack Growth Using The F - Integral: Enyineering Frarrurr MechanicsTirupati TulasiNo ratings yet

- 3 Dof Thermodynamics TableDocument86 pages3 Dof Thermodynamics TableAliNo ratings yet

- U.S. Metar Observation ReportDocument43 pagesU.S. Metar Observation ReportAmirAli MohebbiNo ratings yet

- Flexible Displays Using TFT'SDocument16 pagesFlexible Displays Using TFT'SRaghavendra RaghavNo ratings yet

- Ce Correl Fluid Mechanics (A) : Situation 1Document2 pagesCe Correl Fluid Mechanics (A) : Situation 1Glenn Frey LayugNo ratings yet

- Bio 1410 F22 Exam 1 ReviewDocument2 pagesBio 1410 F22 Exam 1 ReviewGlory LuluNo ratings yet

- Active Materials and Intelligent StructuresDocument31 pagesActive Materials and Intelligent StructuresvincemugnaioNo ratings yet

- 01303610DTST60000 Exde06 53Document53 pages01303610DTST60000 Exde06 53jaleelNo ratings yet

- Physics LabsDocument2 pagesPhysics LabsLacramioara StoicaNo ratings yet

- Gamry - Poteniodynamic-and-Cyclic-PolarizationDocument3 pagesGamry - Poteniodynamic-and-Cyclic-PolarizationHenrique Ribeiro Piaggio CardosoNo ratings yet