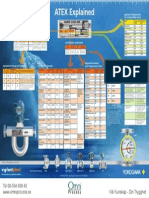

ATEX Explained

N200

KEMA 02 ATEX 2183 X II 2G Ex d [ib] IIC T6T3 or Ex de [ib] IIC T6T3 II 2D Ex tD A21 IP6x T150C

WARNING

WAIT 15 MIN. AFTER POWER-DISCONNECTION BEFORE OPENING THE ENCLOSURE.

see: Instruction Manual

PS is the max. pressure at room temperature TS are the process temperature limits

Ignition Temperatures for Combustible Dusts

Dusts Aluminium Coal dust (lignite) Flour Grain dust Typical Ignition Temp. (C) Cloud Layer 590 380 490 510 420 530 420 700 810 460 490 >450 225 340 300 320 >450 (melts) >450 570 435 460

0344

ATEX Marking

0344

DIODE SAFETY BARRIER Um : 250Vac/dc TEMP. CLASS ENCLOSURE: IP67 T6 T5 T4 T3 PROCESS TEMP. 65 80 115 150C SEE CERTIFICATE FOR DATA

Made in Germany by ROTA YOKOGAWA, Rheinstrae 8, D-79664 Wehr

22-5479.31/C

Methyl cellulose Phenolic resin

II

CE marking & Specific Defines suitability Defines suitability number of marking of Equipment Equipment of use of Group II of use of Group II notified body explosive Groups Category equipment in equipment in responsible for protection gas atmospheres dust atmospheres production

Certification Code (Gas)

Ex

Explosion protected equipment

Polythene PVC Soot Starch Sugar

d [ ib ]

Protection Concepts

IIC

Gas Groups

T6...T3

Temperature Classification

Equipment Group and Category

Gas Zone Dust Zone Equipment Category Group Hazardous Area Characteristics

Present continuously or long periods or frequently (>1000 hours/year) Likely to occur in normal operation occasionally (>10 <1000 hours/year) Not likely to occur in normal operation or infrequently and for short periods (<10 hours/year)

Protection Concept

Description Intrinsic safety 'ia' Intrinsic safety 'ib' Type - n

(Energy limitation)

Apparatus Groups and Temperature Class

Suitable zones Gas Dust 0, 1, 2 1, 2 2 1, 2 1, 2 2 EN Standard Gas Dust EN 61241-11 EN 61241-11 Concept of protection Limit the energy of sparks and surface temperatures Gas/Vapour class Acetic Acid Acetone Acetylene Ammonia Butane Contain the explosion, quench the flame Cyclohexane Ethanol (ethyl alcohol) Ethylene Hydrogen Kerosene EN 61241-4 EN 61241-18 EN 61241-18 Keep the flammable gas out Methane (natural gas)

(non-mining)

Temperature Classification

T-Class Hazards which will not ignite below

IP Protection Class

First Digit Solids 0 No protection 1 Protected against solids 2 Protected against solids

objects over 12mm (e.g. fingers) objects over 50mm (e.g. accidental touch by hands)

Equipment Code Gas Dust Ex ia Ex ib Ex nL Ex d Ex q Ex nC Ex p Ex ma Ex mb Ex o Ex nR Ex nP Ex e Ex nA Ex tD Ex pD Ex ma/D Ex mb/D Ex iaD Ex ibD

Apparatus Group llA llA llC llA llA llA llA llB llC llA llA llA

Temperature Class T1 T1 T2 T1 T2 T3 T2 T2 T1 T3 T1 T2 T2 T1 T2 T2 T3 T1 T1

Second Digit Fluids 0 No protection 1 Protected against

vertically falling drops of water

0 1 2

20 21 22

1 2 3

II II II

20,21,22 EN 50020/39* (EN 60079-11) 21,22 EN 50020/39* (EN 60079-11) EN 60079-15 EN 50018* (EN 60079-1) EN 50017* (EN 60079-5) EN 60079-15 21,22 20 21,22 EN 50016* EN 60079-2 EN 50028* (EN 60079-18) EN 50028* (EN 60079-18) EN 50015* (EN 60079-6) EN 60079-15 EN 60079-15 EN 60079-7 EN 60079-15 20,21,22

T1 T2 T3 T4 T5 T6

450C 300C 200C 135C 100C 85C

2 Protected against direct

sprays up to 15 from the vertical sprays up to 60 from the vertical

Flameproof protection Sand / powder (quartz) filling Type - n

(Enclosed break)

3 Protected against solids

objects over 2.5mm (e.g. tools and wires)

3 Protected against direct 4 Protected against sprays 5 Protected against low

4 Protected against solids

objects over 1mm (e.g. tools, wires, small wires) limited ingress (no harmful deposit)

from all directions limited ingress permitted pressure jets if water from all directions limited ingress permitted jets of water e.g. for use on shipdecks limited ingress permitted of temporary immersion between 15cm and 1m. Duration of test 30 min. periods of immersion under pressure

5 Protected against dust

Pressurized protection Encapsulation Encapsulation ROTAMASS Oil immersion Type - n

(Restricted breathing)

1, 2 0, 1, 2 1, 2 1, 2 2 2 1, 2 2

Methanol

(methyl alcohol)

Equipment T class approval is based on use in an ambient of -20C to +40C unless otherwise stated (ie. T amb. = 35C). The T-Class on the equipment states that the equipment will not provide an ignition capable surface hotter than the temperature represented by the stated T-Class. Therefore equipment to be installed in hazardous areas where the hazard has temperature class T6 must not get hotter than 85C. For equipment in hazardous areas, the higher the T-Number the less hot the surface temperature will get.

6 Totally protected

against dust

6 Protected against strong

Methyl ethyl ketone llB

(MEK)

7 Protected against effects

Propane Propan-1-ol

(n-propyl alcohol)

llA llB llA

8 Protected against long

Propan-2-ol

(iso-propyl alcohol)

Type - n

(Pressurisation)

Tetrahydrofuran (THF) llB No arcs, sparks or hot surfaces Toluene Xylene llA llA

Increased safety Type - n

(Non-sparking)

RAMC

Enclosure

EN 61241-1

Protection by enclosure

* Soon to be replaced by standard in bracket

www.yokogawa.com/eu

Other ATEX certified devices: RAMC RAKD digitalYEWFLO ADMAG AXF SE ADMAG AXF RXF

YOKOGAWA EUROPE B.V., Databankweg 20, 3821 AL Amersfoort, THE NETHERLANDS

Tel 08-564 808 40 www.omniprocess.se

Vr Kunskap - Din Trygghet