Professional Documents

Culture Documents

Condensation Calculation for Dubai Airport Building

Uploaded by

wado11Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Condensation Calculation for Dubai Airport Building

Uploaded by

wado11Copyright:

Available Formats

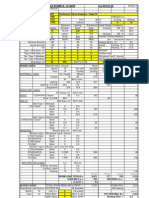

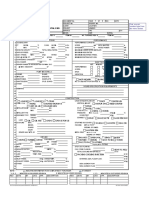

Proj. No.

:D0052

Project No.

DESIGN CALCULATION

Sheet No.

SHEET

Mechanical & Industrial Department

D0052

CAIRO - EGYPT

Date

3-Jan-17

Computed by

1 of 2

Subject Condensation Calculation - Highest Relative Humidity

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Thermal

Resistivity km/W

Inside Air

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 24C and 50%rh

and outside conditions of 16C and 81%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

5.33

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1492.6-1473)/1.92E+10

Gt

=

1.02E-09 Kg/m2s

where mv is the rate of vapour mass transfer per unit area

Pvi is the inside vapour pressure @ 24 C & 50% rh

1 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

3-Jan-17

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - Highest Relative Humidity

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Pvo is the outside vapour pressure @ 16C and 81%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

(24-16)/5.33

1.50 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

Vapour

Saturated Vapour

Differ Result*

Pressure(calculated) Pa Pressure(Pa) From

ence

pv2= Saturated Water Tables Pa

pv1-mvG1

t1

t2

t3

t4

t5**

t6**

t7**

Pv2

Pv3

Pv4

Pv5

pv6

pv7

pv8

=

=

=

=

=

=

=

23.82

23.35

22

21.77

16.6

16.48

16.21

=

=

=

=

=

=

=

1490

1489

1484

1481

1476

1474

1473

2985

2985

2645

2645

1938

1938

1818

1495

1496

1161

1164

462

464

345

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 12.7 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

** Although the result is positivepressure difference,the difference is very low which indicates a risk

of condensation .

2 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

3 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

4 of 40

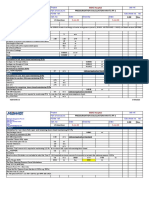

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

3-Jan-17

Computed by

1 of 2

Subject Condensation Calculation - Highest Dew Point Temperature

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Thermal

Resitivity km/W

Inside Air

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Sound Insulation

Air Gap (1)

Plaster Board

0.05

6.25

50.00

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 24C and 50%rh

and outside conditions of 30.5C and 70%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

5.33

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1492.6-2972)/1.92E+10

Gt

-7.71E-08

Kg/m2s

5 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - Highest Dew Point Temperature

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 24C and 50%rh

Pvo is the outside vapour pressure @ 30.5C and 70%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

(24-30.5)/5.33

-1.22 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

t6

t7

=

=

=

=

=

=

=

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

24.15 Pv2

=

1686 Tables

2985

24.53 Pv3

=

1763

3169

25.6 Pv4

=

2148

3363

25.82 Pv5

=

2379

3363

30 pv6

=

2780

4246

30.11 pv7

=

2895

4246

30.33 pv8

=

2972

4246

Differ Result*

ence

Pa

1299

1406

1215

984

1466

1351

1274

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

6 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

(Thermal Resisitivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

7 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

8 of 40

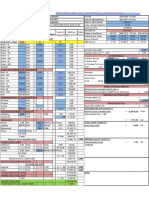

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

3-Jan-17

Computed by

1 of 2

Subject Condensation Calculation - Highest Dry Bulb Temperature

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivity

Thickness

&Thermal

m

Conductivity is

assumed to be

similar to:

Thermal

Resistivity km/W

Inside Air

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 46C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistance (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

5.33

(N s/kg)

where Rt is the total thermal resistance of the structure

mv

Pvi-Pvo

(1322-2928.3)/1.92E+10

Gt

-8.37E-08

Kg/m2s

9 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

3-Jan-17

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - Highest Dry Bulb Temperature

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 46C and 29%rh

Gt is the total vapour resistance (N s/kg)

q

tai-tao

Rt

22-46/5.33

-4.50 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistance of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

Vapour

Saturated Vapour

Differ Result*

Pressure(calculated) Pa Pressure(Pa) From

ence

pv2= pv1-mvG1

Saturated Water Tables Pa

t1

t2

t3

t4

t5

t6

t7

Pv2

Pv3

Pv4

Pv5

pv6

pv7

pv8

=

=

=

=

=

=

=

22.54

23.95

27.89

28.7

44.21

44.56

45.37

=

=

=

=

=

=

=

1531

1615

2033

2284

2719

2845

2928

2810

2985

3782

4008

9110

9593

9593

1279

1370

1749

1724

6391

6748

6665

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

10 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

11 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

12 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.1insulation)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 80C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

1.92E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

5.33

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-13749)/1.92E+10

Gt

-6.47E-07

Kg/m2s

13 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.1insulation)

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 80C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-80/5.33

-10.9 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

t6

t7

=

=

=

=

=

=

=

23.3

26.7

36.24

38.2

75.68

76.52

78.48

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

2940

2810

Pv3

=

3587

3567

Pv4

=

6824

5947

Pv5

=

8765

6632

pv6

=

12131

40236

pv7

=

13102

41938

pv8

=

13749

45524

Differ Result*

ence

Pa

-130

-20

-877

-2133

28105

28836

31775

Cond.

Cond.

Cond.

Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

14 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

15 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

16 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.15insulation)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.15

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 80C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

2.07E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

7.06

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-13749)/2.07E+10

Gt

-6.00E-07

Kg/m2s

17 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.15insulation)

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 80C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-80/7.06

-8.2 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

t6

t7

=

=

=

=

=

=

=

23

25.55

32.76

34.24

76.74

77.37

78.85

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

2823

2810

Pv3

=

3423

3363

Pv4

=

6425

5034

Pv5

=

9126

5323

pv6

=

12248

41938

pv7

=

13149

41938

pv8

=

13749

45524

Differ Result*

ence

Pa

-13

-60

-1391

-3803

29690

28789

31775

Cond.

Cond.

Cond.

Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

18 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

19 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

20 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.2insulation)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.20

0.01

0.30

0.02

34.48

7.69

0.18

4.00

0.06

30.00

520.00

5.00

50.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 80C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding

2.22E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Ventilated Air Gap + Exterior Cladding + Outside Air

8.78

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-13749)/2.22E+10

Gt

-5.60E-07

Kg/m2s

21 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 80C (0.2insulation)

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 80C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-80/8.78

-6.6 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

t6

t7

=

=

=

=

=

=

=

22.79

24.86

30.65

31.84

77.38

77.89

79.08

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

2721

2810

Pv3

=

3281

3169

Pv4

=

6080

4496

Pv5

=

9439

4759

pv6

=

12350

41938

pv7

=

13189

43700

pv8

=

13749

45524

Differ Result*

ence

Pa

89

-112

-1584

-4680

29588

30511

31775

No Cond.

Cond.

Cond.

Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

22 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

(Thermal Resistivity x Thickness)+Air Gap+Ventilated Air Gap+Outside Air

23 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

24 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

3-Jan-17

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 70C (0.1insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.00

0.00

34.48

7.69

0.00

0.00

0.06

30.00

520.00

0.00

0.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 70C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier

1.67E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Outside Air

5.07

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-9047)/1.67E+10

Gt

-4.63E-07

Kg/m2s

25 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 70C (0.1insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 70C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-70/5.07

-9.5 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

=

=

=

=

=

23.13

26.09

34.39

36.09

68.7

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

2478

2810

Pv3

=

2941

3363

Pv4

=

5254

5324

Pv5

=

6642

5947

pv6

=

9047

29873

Differ Result*

ence

Pa

332

422

70

-695

20826

No Cond.

No Cond.

No Cond.

Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

26 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

27 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

28 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

D0052

3-Jan-17

Sheet No.

SHEET

Mechanical & Industrial Department

Date

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 70C (0.15insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

MG

Checked by

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.15

0.01

0.00

0.00

34.48

7.69

0.00

0.00

0.06

30.00

520.00

0.00

0.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 70C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier

1.82E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Outside Air

6.80

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-9047)/1.82E+10

Gt

-4.24E-07

Kg/m2s

29 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

Subject Condensation Calculation - 70C (0.15insulation) (Ventilation Effect)

Building Concourse 2 - Dubai International Airport

where mv is the rate of vapour mass transfer per unit area

MG

Checked by

TZ

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 70C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-70/6.8

-7.1 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

=

=

=

=

=

22.85

25.05

31.25

32.52

69

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

2383

2810

Pv3

=

2808

3169

Pv4

=

4930

4496

Pv5

=

6840

5034

pv6

=

9047

29873

Differ Result*

ence

Pa

427

361

-434

-1806

20826

No Cond.

No Cond.

Cond.

Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

30 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

31 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

32 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

MG

Subject Critical Condensation Calculation - 60C (0.1insulation) (Ventilation EffecChecked by

Building Concourse 2 - Dubai International Airport

TZ

Approved by

MK

Data

Layer

Vaopur

Assumed

Resistivety

Thickness

&Thermal

m

Conductivety is

assumed to be

similar to:

Inside Air

Thermal

Resisitivity

km/W

Vapour

Resistivity

GNs/Kg m

0.12

Interior Panels

Plaster Board

0.05

6.25

50.00

Sound Insulation

Air Gap (1)

Ins. Fiberboard

0.05

1.00

17.54

0.18

20.00

5.00

0.10

0.01

0.00

0.00

34.48

7.69

0.00

0.00

0.06

30.00

520.00

0.00

0.00

Rigid Insulation

Vapour Barrier

Ventilated Air Gap

Exterior Cladding

Outside Air

Hardboard

Plaster

The calculation is based on inside conditions of 22C and 50%rh

and outside conditions of 60C and 29%rh

Calculation of Heat Flow Rate and Vapour Mass Transfer Rate

Gt

(Vapour Resistivity x Thickness)

Gt

Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier

1.67E+10

(N s/kg)

where Gt is the total vapour resistence (N s/kg)

Rt

Rt

=

=

Inside Air +(Thermal Resistivity x Thickness)+Air Gap+Outside Air

Inside Air + Interior Panels + Sound Insulation + Air Gap + Rigid Insulation +

Vapour Barrier + Outside Air

5.07

(N s/kg)

where Rt is the total thermal resistence of the structure

mv

Pvi-Pvo

(1322-5784)/1.67E+10

Gt

-2.67E-07

Kg/m2s

33 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

Date

D0052

3-Jan-17

Sheet No.

CAIRO - EGYPT

Computed by

1 of 2

MG

Subject Critical Condensation Calculation - 60C (0.1insulation) (Ventilation EffecChecked by

Building Concourse 2 - Dubai International Airport

TZ

where mv is the rate of vapour mass transfer per unit area

Approved by

MK

Pvi is the inside vapour pressure @ 22C and 50%rh

Pvo is the outside vapour pressure @ 70C and 29%rh

Gt is the total vapour resistence (N s/kg)

q

tai-tao

Rt

22-60/5.07

-7.5 W/m2

where q is the rate of flow of heat per unit area

tai is the inside air temp.

tao is the outside air temp.

Rt is the total thermal resistence of the structure

=

Calculation of Temperature And Vapour Pressure at Each Layer

Temperature (C)

t1=tai-qRsi

t1

t2

t3

t4

t5

=

=

=

=

=

22.9

25.24

31.81

33.15

59

Vapour

Saturated Vapour

Pressure(calculated) Pa Pressure(Pa) From

pv2= pv1-mvG1

Saturated Water

Tables

Pv2

=

1990

2810

Pv3

=

2257

3169

Pv4

=

3593

4759

Pv5

=

4395

5034

pv6

=

5784

19039

Differ Result*

ence

Pa

820

912

1166

639

13255

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

Outside Dew Point 24 C

* No condensation occurs when saturation vapour pressure is greater than the calculated vapour pressure.

34 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

35 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

Result*

No Cond.

No Cond.

No Cond.

No Cond.

No Cond.

36 of 40

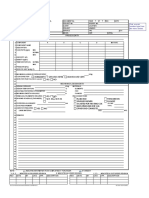

Proj. No. :D0052

Project No.

DESIGN CALCULATION

SHEET

Mechanical & Industrial Department

CAIRO - EGYPT

D0052

Sheet No.

Date

3-Jan-17

Computed by

1 of 2

Subject Ventilation Air Required - Not To Exceed 60C

Building Concourse 2 - Dubai International Airport

Checked by

TZ

MG

Approved by

MK

Heat Gain To The Ventilated Air Gap:

Q = U A T

Where

Q is the heat gain to the ventilated air gap in W

U is the overall heat transfer coeffient in W/m 2k

A is the area in m2

T is the temperature difference in Kelvin

Q = (3.85)(6.25)(353.15-333.15)

481

W

=

1642.615

BTU/hr

Ventilation air required:

Q = cfm(1.08)T

Where

Q is the heat gain to the ventilated air gap in BTU/hr

cfm is the required ventilation air

T is the temperature difference in Fahrenheit

1648.615 = cfm(1.08)(176-140)

cfm =

42

=

20 l/s

=

30 l/s

(For Safety)

Therefore ventilation air requird is 5 l/s for each 1 m 2

Area through which air flow = 4*2.5*0.03/2

= 0.15 /2 = 0.075 m2

Velocity =

=

0.03/.075

0.4 m/s

80 ft/min

For air to enter

37 of 40

Proj. No. :D0052

Project No.

DESIGN CALCULATION

Mechanical & Industrial Department

CAIRO - EGYPT

Subject Ventilation Air Required - Not To Exceed 60C

Building Concourse 2 - Dubai International Airport

SHEET

D0052

Sheet No.

Date

3-Jan-17

Computed by

1 of 2

Checked by

TZ

MG

Approved by

MK

38 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

39 of 40

Proj. No. :D0052

3-Jan-17

Computed by

MG

Approved by

MK

40 of 40

You might also like

- Heat y Thermodynamics Zemansky Solutions Bing PDFDocument5 pagesHeat y Thermodynamics Zemansky Solutions Bing PDFBhat Jasim0% (5)

- Condensation CalculationDocument40 pagesCondensation Calculationbinhjuki100% (2)

- AHU Fresh AirDocument2 pagesAHU Fresh AirSvetla Nikolova100% (1)

- RTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20Document1 pageRTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20alvinchuanNo ratings yet

- M'Sia Fire Stair Pressurization SampleDocument10 pagesM'Sia Fire Stair Pressurization Samplenim_gourav1997No ratings yet

- KRUGER - S - Q - KVN20-AL-123G - R01 - CC H9BC Binh Duong - KANDENKODocument4 pagesKRUGER - S - Q - KVN20-AL-123G - R01 - CC H9BC Binh Duong - KANDENKODo MinhNo ratings yet

- LV Motor Data SheetDocument4 pagesLV Motor Data Sheetwado11No ratings yet

- Chiller SystemDocument37 pagesChiller SystemAmit100% (1)

- Cooling Load CalculationDocument32 pagesCooling Load CalculationHenry San PedroNo ratings yet

- StairCase Press-Eclipse - (Printed 29.01.2020) PDFDocument3 pagesStairCase Press-Eclipse - (Printed 29.01.2020) PDFmhmdjdgmailcomNo ratings yet

- Air Conditioning System: Pan Humidifier Load Calculation Building Room1Document1 pageAir Conditioning System: Pan Humidifier Load Calculation Building Room1psn_kylmNo ratings yet

- Ventilation Heat Load SheetDocument61 pagesVentilation Heat Load SheetAnonymous BJ9omONo ratings yet

- Heat Load Estimation MS1525 DesignDocument10 pagesHeat Load Estimation MS1525 Designhans weemaesNo ratings yet

- Lift Well Pressurization Calculation Pasanger Liftwell No. 1-6 Tower-7 (3rd Basment To 14th Floor)Document1 pageLift Well Pressurization Calculation Pasanger Liftwell No. 1-6 Tower-7 (3rd Basment To 14th Floor)Akash SaxenaNo ratings yet

- Heat Load Calculation KTM MCHDocument16 pagesHeat Load Calculation KTM MCHnike_y2k0% (1)

- Stair Case-01 Pressurisation Calculation: 3.3 7.255 2.56 64.78 2.2 1.1 - 6.6 Walls (Tight) Door Frame (Single Leaf)Document7 pagesStair Case-01 Pressurisation Calculation: 3.3 7.255 2.56 64.78 2.2 1.1 - 6.6 Walls (Tight) Door Frame (Single Leaf)Shabeer HamzaNo ratings yet

- FireSmoke Control Stair PressurizationDocument10 pagesFireSmoke Control Stair PressurizationAshokNo ratings yet

- FAHU Cooling Load and Condensate RatesDocument4 pagesFAHU Cooling Load and Condensate RatesSundar DAACNo ratings yet

- Cooling and dehumidifying heat load estimateDocument149 pagesCooling and dehumidifying heat load estimateHenry San PedroNo ratings yet

- PRICE - Air Distribution GuideDocument5 pagesPRICE - Air Distribution Guidenvenkat.narayan100% (1)

- Technical Handbook Air CurtainsDocument13 pagesTechnical Handbook Air Curtainsaca111111No ratings yet

- Staircase Pressurization SPV BuildingDocument2 pagesStaircase Pressurization SPV BuildingNandan RajeNo ratings yet

- Genetics Pharma Dehumidifying Load Input Sheet: 1 BlisteringDocument1 pageGenetics Pharma Dehumidifying Load Input Sheet: 1 Blisteringirfanbaig36No ratings yet

- SPF Stair Case FanDocument2 pagesSPF Stair Case FanAla ShakerNo ratings yet

- Stairwell pressurization design calculation sheetDocument3 pagesStairwell pressurization design calculation sheetMohd Najeeb Ali FathaanNo ratings yet

- Halton Design Guide enDocument54 pagesHalton Design Guide enimtiyaz94No ratings yet

- Geothermal HVAC: Shifting Performance Risk From Buyer To SellerDocument5 pagesGeothermal HVAC: Shifting Performance Risk From Buyer To SellerKagitha TirumalaNo ratings yet

- Cooling Tower CalculationeditedDocument3 pagesCooling Tower CalculationeditedMark LouieNo ratings yet

- Staircase pressurization calculationDocument4 pagesStaircase pressurization calculationAbdul Sami100% (1)

- HVAC ComparisonDocument283 pagesHVAC Comparisonmilindskulkarni2005@yahoo.co.in100% (1)

- Humidification Calculation ImtiyazDocument2 pagesHumidification Calculation Imtiyazimtiyaz94No ratings yet

- DAR Stair Case PressurizationDocument16 pagesDAR Stair Case PressurizationfebousNo ratings yet

- Engineering Bulletin CDQ Desiccant DehumidificationDocument28 pagesEngineering Bulletin CDQ Desiccant DehumidificationsdvitkoNo ratings yet

- Atrium Natural Smoke CalculationsDocument5 pagesAtrium Natural Smoke CalculationsRamiAl-fuqahaNo ratings yet

- Drain Pipe Work of Indoor UnitDocument24 pagesDrain Pipe Work of Indoor UnitMiguel AbuegNo ratings yet

- Heat Load Class 100KDocument20 pagesHeat Load Class 100KIsrael MuhiNo ratings yet

- Food Court's Kitchens VentilationsDocument1 pageFood Court's Kitchens VentilationsSudhir KulkarniNo ratings yet

- Load Check FiguresDocument1 pageLoad Check FiguresArshavin Watashi WaNo ratings yet

- Calculating cooling load for a battery roomDocument2 pagesCalculating cooling load for a battery roomMohammed IqbalNo ratings yet

- Determine cooling coil and reheater outputs for office AC systemDocument4 pagesDetermine cooling coil and reheater outputs for office AC systemRashel Hasan100% (1)

- Documents Room DY Auto Heat Load RaphaDocument18 pagesDocuments Room DY Auto Heat Load RaphaShaikh TauseefNo ratings yet

- Hvac-Dbr - R6Document29 pagesHvac-Dbr - R6adkNo ratings yet

- Heat Gain CalculationsDocument17 pagesHeat Gain CalculationsPrabu RajaNo ratings yet

- Value Engineering of Car Park Ventilation SystemDocument8 pagesValue Engineering of Car Park Ventilation SystemmitasyahuNo ratings yet

- HVAC Thermal Load EstimatingDocument28 pagesHVAC Thermal Load EstimatingIntisar Ali SajjadNo ratings yet

- Sizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerDocument5 pagesSizing calculations for BFW pumps, FD, SA and ID fans for 50,000 kg/hr boilerMati Dalam Penantian CintamuNo ratings yet

- Acmv Technical ReportDocument10 pagesAcmv Technical Reportarun kurlanNo ratings yet

- Elevator Lobby Pressurization 1Document2 pagesElevator Lobby Pressurization 1Mohamed MonamNo ratings yet

- Dr. Fixit Newcoat 105 1 PDFDocument3 pagesDr. Fixit Newcoat 105 1 PDFmohdrashidNo ratings yet

- Coil Selection FormatDocument6 pagesCoil Selection FormatTanveer AzizNo ratings yet

- Duct Metal Take-Off SheetDocument2 pagesDuct Metal Take-Off SheetpratheeshNo ratings yet

- Machinery Room Ventilation Analysis ToolDocument48 pagesMachinery Room Ventilation Analysis ToolDon Quijote de la ManchaNo ratings yet

- Cooling Load Estimatin Prg1Document7 pagesCooling Load Estimatin Prg1Calvin HobbesNo ratings yet

- K-Flex Calculation Based On Ambient Temperature 30°C, RH 75% & H 11 (Final)Document1 pageK-Flex Calculation Based On Ambient Temperature 30°C, RH 75% & H 11 (Final)Ah BengNo ratings yet

- Staircase Pressurization Calculation SheetDocument4 pagesStaircase Pressurization Calculation SheetTariq AsgharNo ratings yet

- Cooling Unit. Off Coil Temp Room Temp PDFDocument5 pagesCooling Unit. Off Coil Temp Room Temp PDFSundar Ramasamy100% (1)

- Android Kitchen Exhaust Calculation On AndroidDocument5 pagesAndroid Kitchen Exhaust Calculation On AndroidPraveen SagayarajNo ratings yet

- Condensate Drain Calculation - Split Units PDFDocument1 pageCondensate Drain Calculation - Split Units PDFAltaf KhanNo ratings yet

- AHU Dimentions: Design Calculation SheetDocument5 pagesAHU Dimentions: Design Calculation SheetAbdelfatah NewishyNo ratings yet

- Engine Room Ventilation - Necesar AerDocument1 pageEngine Room Ventilation - Necesar AerBirshopulosNo ratings yet

- Project energy analysis and HVAC load calculationDocument4 pagesProject energy analysis and HVAC load calculationgurramviswaNo ratings yet

- HVAC - Overview of Space Heating Systems PDFDocument68 pagesHVAC - Overview of Space Heating Systems PDFFredie UnabiaNo ratings yet

- Condensation calculations for building envelopeDocument22 pagesCondensation calculations for building envelopelutfi awn100% (1)

- Datasheet For RMU Rev 0Document4 pagesDatasheet For RMU Rev 0wado11No ratings yet

- Cathodic Protection Specification for Pipelines and TanksDocument7 pagesCathodic Protection Specification for Pipelines and Tankswado11No ratings yet

- Diesel fuel storage tank data sheetDocument2 pagesDiesel fuel storage tank data sheetwado11No ratings yet

- Datasheet For AC UPS Rev 0Document4 pagesDatasheet For AC UPS Rev 0wado11No ratings yet

- Design Calculation Sheet: Booster PumpsDocument2 pagesDesign Calculation Sheet: Booster PumpsAhmadNo ratings yet

- FDD - FPS - 007 - Cost ControlDocument3 pagesFDD - FPS - 007 - Cost Controlwado11No ratings yet

- Generator Exhaust Pipe Diameter Calculations: Marina Towers L9959Document4 pagesGenerator Exhaust Pipe Diameter Calculations: Marina Towers L9959febousNo ratings yet

- METRIC FLOW CHART for UPVC PIPESDocument2 pagesMETRIC FLOW CHART for UPVC PIPESwado11No ratings yet

- Dif-Oo15-Int-Ed-0003 PCV Rev 0Document3 pagesDif-Oo15-Int-Ed-0003 PCV Rev 0wado11No ratings yet

- Datasheet For RMU Rev 0Document4 pagesDatasheet For RMU Rev 0wado11No ratings yet

- Dif-0015-Int-Ed-0025 Flame Det Rev 0Document10 pagesDif-0015-Int-Ed-0025 Flame Det Rev 0wado11No ratings yet

- F. Instrumentation ItemsDocument2 pagesF. Instrumentation Itemswado11No ratings yet

- FDD - FPS - 010 - Project CloseoutDocument4 pagesFDD - FPS - 010 - Project Closeoutwado11No ratings yet

- VECO ENGINEERING LTD. STATIC MIXER DATADocument1 pageVECO ENGINEERING LTD. STATIC MIXER DATAwado11100% (1)

- Veco Engineering Ltd. Equipment Data Sheet: Centrifugal FanDocument9 pagesVeco Engineering Ltd. Equipment Data Sheet: Centrifugal Fanwado11No ratings yet

- Veco Engineering Ltd. Equipment Data Sheet: Expansion JointDocument2 pagesVeco Engineering Ltd. Equipment Data Sheet: Expansion Jointwado11No ratings yet

- Solar Panelpanel Design (22.8.12)Document12 pagesSolar Panelpanel Design (22.8.12)Battinapati ShivaNo ratings yet

- SEO-OPTIMIZED TITLEDocument3 pagesSEO-OPTIMIZED TITLEwado11No ratings yet

- Burner - Api 560Document3 pagesBurner - Api 560wado11No ratings yet

- Duct Pressure Drop Calculator - Bok - HQ - Ventilation - Eaf-1 - Eor WestDocument12 pagesDuct Pressure Drop Calculator - Bok - HQ - Ventilation - Eaf-1 - Eor Westwado11No ratings yet

- Burner - Api 560Document3 pagesBurner - Api 560wado11No ratings yet

- Transportation CalculationsDocument11 pagesTransportation Calculationswado11No ratings yet

- Static Pressure Calculator r3Document3 pagesStatic Pressure Calculator r3arshi_yusufNo ratings yet

- Teksan Hybrid Power Systems ENG Low ResDocument6 pagesTeksan Hybrid Power Systems ENG Low Reswado11No ratings yet

- BMS PresentationDocument23 pagesBMS Presentationwado11No ratings yet

- Head Loss Calculation - Fire Hydrant Sys..Temporary ReiserDocument15 pagesHead Loss Calculation - Fire Hydrant Sys..Temporary ReiserEngFaisal AlraiNo ratings yet

- Duct Pressure Drop Calculator - Bok - HQ - Ventilation - Eaf-1 - Eor WestDocument12 pagesDuct Pressure Drop Calculator - Bok - HQ - Ventilation - Eaf-1 - Eor Westwado11No ratings yet

- ASHRAE Terminology - Complete ListDocument297 pagesASHRAE Terminology - Complete Listwado11No ratings yet

- ASHRAE Terminology - Complete ListDocument298 pagesASHRAE Terminology - Complete Listwado11No ratings yet

- Ideal Gas ProcessesDocument6 pagesIdeal Gas ProcessesKlydeJoseNo ratings yet

- Quick Installation Guide: RTH2300/RTH221Document40 pagesQuick Installation Guide: RTH2300/RTH221IBJSC.comNo ratings yet

- The Charles's LawDocument11 pagesThe Charles's LawRhoda Mari Quijoy DoriaNo ratings yet

- Air conditioning system comparisonDocument16 pagesAir conditioning system comparisonSachin MahatoNo ratings yet

- Pages From 0-Fan Coil Unit (Zamil) - 2Document1 pagePages From 0-Fan Coil Unit (Zamil) - 2Vic BayotNo ratings yet

- AHH Software EnglishDocument7 pagesAHH Software EnglishPshyu NbNo ratings yet

- PSU (PCB4) : B286/B289 Point To Point Block Diagram 1/2Document3 pagesPSU (PCB4) : B286/B289 Point To Point Block Diagram 1/2Phong DoanNo ratings yet

- Thermodynamics BasicsDocument19 pagesThermodynamics BasicsKelvin TohNo ratings yet

- HVAC Basics: Hvac - Heating, Ventilation, Air-ConditioningDocument20 pagesHVAC Basics: Hvac - Heating, Ventilation, Air-ConditioningAli GurselNo ratings yet

- ASHRAE 90.1 Prescriptive Wall Insulation RequirementsDocument2 pagesASHRAE 90.1 Prescriptive Wall Insulation RequirementsfresitoNo ratings yet

- HVAC Chapter 5: Applied PsychometricsDocument83 pagesHVAC Chapter 5: Applied PsychometricsLurking RogueNo ratings yet

- Air Conditioning BasicsDocument17 pagesAir Conditioning BasicsGnana Subramanian ArumugamNo ratings yet

- Thermochemistry QuizDocument2 pagesThermochemistry QuizAlgem Cris CrusisNo ratings yet

- Tugas Kimatkom 1Document5 pagesTugas Kimatkom 1stella jovitaNo ratings yet

- Syllabus MEEM2200 Fall2012Document3 pagesSyllabus MEEM2200 Fall2012chronsbonsNo ratings yet

- Ashrae Chart PDFDocument2 pagesAshrae Chart PDFNapoleon Low100% (2)

- 1 Thermodynamic Relations: 1.1 Relations For Energy PropertiesDocument24 pages1 Thermodynamic Relations: 1.1 Relations For Energy PropertiesSarthak100% (2)

- ASME Steam Tables - Compact Edition-American Society of Mechanical Engineers (2006)Document32 pagesASME Steam Tables - Compact Edition-American Society of Mechanical Engineers (2006)Jesús CbNo ratings yet

- Enthalpy - Thermodynamics Questions and Answers - SanfoundryDocument8 pagesEnthalpy - Thermodynamics Questions and Answers - SanfoundryBhardwaj Rajinder SippyNo ratings yet

- Thermodynamic Properties of R12Document12 pagesThermodynamic Properties of R12kupoo_99950% (2)

- 7.1.prob - Sheet Gas Power CyclesDocument3 pages7.1.prob - Sheet Gas Power CyclesAnonymous mXicTi8hB0% (1)

- Gas MixDocument2 pagesGas MixLena BshnaweNo ratings yet

- Thermodynamics key concepts and energy typesDocument29 pagesThermodynamics key concepts and energy typesLester Alfred M. Olasiman100% (1)

- Modul 1 Fungsi PDFDocument15 pagesModul 1 Fungsi PDFAzmaazniza AzanNo ratings yet

- Heat and Internal Energy SeatworkDocument1 pageHeat and Internal Energy SeatworkJonel RuleNo ratings yet

- Temperature and HeatDocument48 pagesTemperature and Heatalexzandrei.rara937No ratings yet

- ASHRAE Systems & Equipments 2008 SIDocument2 pagesASHRAE Systems & Equipments 2008 SINikki Ramsey33% (3)

- Refrigeration Midterm Exam ###Document3 pagesRefrigeration Midterm Exam ###Patience LastyNo ratings yet