Professional Documents

Culture Documents

NMPC 3 Dof Helicopter

Uploaded by

Sohibul HajahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NMPC 3 Dof Helicopter

Uploaded by

Sohibul HajahCopyright:

Available Formats

MultiCraft

International Journal of Engineering, Science and Technology Vol. 2, No. 10, 2010, pp. 9-19

INTERNATIONAL JOURNAL OF ENGINEERING, SCIENCE AND TECHNOLOGY www.ijest-ng.com

2010 Multicraft Limited. All rights reserved

Model predictive control of a 3-DOF helicopter system using successive linearization

Yujia Zhai1*, Mohamed Nounou1, Hazem Nounou2, Yasser Al-Hamidi3

1. Chemical Engineering Program, Texas A&M University at Qatar, Education City, Doha, QATAR 2. Electrical and Computer Engineering Program, Texas A&M University at Qatar, Education City, Doha, QATAR 3. Mechanical Engineering Program, Texas A&M University at Qatar, Education City, Doha, QATAR *Corresponding Author: email: yujia.zhai@qatar.tamu.edu, Tel. +974-4423-0558, Fax. +974-4423-0011

Abstract Helicopter dynamics are in general nonlinear, time-varying, and may be highly uncertain. Traditional control schemes such as proportionalintegralderivative (PID) control, linear quadratic regulator (LQR), and eigen-structure assignment are usually not effective when a linearized model is used and the helicopter moves away from the design trim point. This paper presents a nonlinear model predictive control (NMPC) method to control the elevation and travel of a three degree of freedom (DOF) laboratory helicopter using successive linearization to approximate the internal model of the system. The developed algorithm is evaluated by simulation, and its performance is compared with that achieved by linear model predictive control (LMPC). Keywords: nonlinear systems, helicopter dynamics, MIMO systems, model predictive control, successive linearization 1. Introduction Helicopters have severe nonlinearities and open-loop unstable dynamics as well as significant cross-coupling between their control channels, which make the control of such multiple-input multiple-output (MIMO) systems a challenging task. Conventional approaches to helicopter flight control involve linearization of these nonlinear dynamics about a set of pre-selected equilibrium conditions or trim points within the flight envelop (Kim, 1993). Based on the obtained linear models, classical singleinput single-output (SISO) techniques with a PID controller are widely used (Reiner et al, 1995; Kim et al, 1997; Lee et al., 2005). Of course, this approach will require multi-loop controllers, which makes their design inflexible and difficult to tune. Hence, the MIMO controller design approaches have received more and more attention. For example, successful implementation of LQR design for a helicopter system has been presented in (Apkarian, 1998). Also, Koo et al (1998) used dynamical sliding mode control to stabilize the altitude of a nonlinear helicopter model in vertical flights. Later, neural network based inverse control of an aircraft system was presented in (Prasad et al, 1999). More MIMO control approaches for helicopter maneuver are presented in (SiraRamirez et al., 1994; Mahony et al., 2004; Marconi et al., 2007, Tao et al., 2010). In the past two decades, model predictive control (MPC) has been widely used in industrial process control (Lee et al., 1994; Ricker et al., 1995; Qin et al., 2003; Dua et al., 2008). With the development of modern micro-processors, it has been possible to solve the optimization problems associated with MPC online effectively, which makes MPC applicable to systems with fast dynamics (Wang et al., 2010; Zhai et al., 2010). Many researchers utilized linear MPC to control helicopter systems (Witt et al, 2007; Maia et al., 2008). However, as the linearized model is valid only for small perturbations from its equilibrium or trim point, the control performance can degrade severely if the helicopter does not operate around the design trim point. In this paper, a nonlinear model predictive control based on successive linearization (MPCSL) of the nonlinear helicopter model is applied to a laboratory helicopter system to achieve acceptable performance over a wide flight envelope. The performance of the applied control technique is illustrated and compared to that of LMPC by comparing the steady state error, rise time, and overshoot. This paper is organized as follows. First the dynamical model of a laboratory helicopter system is presented, followed by a description of the applied successive linearization based NMPC used to control the elevation and travel of the helicopter. Then, simulation results are presented to illustrate the effectiveness of the proposed control algorithm. Finally, conclusions are drawn in the last section.

10

Zhai et al. / International Journal of Engineering, Science and Technology, Vol. 2, No. 10, 2010, pp. 9-19

2. Helicopter system dynamics It is economical for both industrial and academic research to investigate the effectiveness of an advanced control system before putting it into practical application. The research presented in this paper is based on a mathematical model of a 3-DOF laboratory helicopter system from Quanser Consulting, Inc. The 3-DOF helicopter consists of a base upon which an arm is mounted. The arm carries the helicopter body on one end and a counter weight on the other end. The arm can pitch about an elevation axis as well as swivel about a vertical (travel) axis. Encoders that are mounted on these axes allow measuring the elevation and travel of the arm. The helicopter body is mounted at the end of the arm and is free to swivel about a pitch axis. The pitch angle is measured via a third encoder (Apkarian, 1998). Due to hardware restrictions, the movement range of the elevation and pitch angles are constrained within [-1, +1] rad (Ishitobi et al., 2010). Two DC motors with propellers mounted on the helicopter body can generate a force proportional to the voltages applied to the DC motors. The force generated by the propellers can cause the helicopter body to lift off the ground. The purpose of the counterweight is to reduce the power requirements on the motors. The helicopter experimental system is shown in Figure 1 (Quanser, 2010).

Figure 1: Laboratory Helicopter from Quanser Consulting, Inc. The system dynamics can be described by the following highly nonlinear state model (Apkarian, 1998):

& = F ( x ) + [G1 ( x ), G2 ( x )]u x

where

(1)

x=

u=[ Vf

& & & Vb ]

T

G2 ( x ) = [0

& p cos + p sin + p & 2 3 1 & F (x ) = & p5 cos + p6 sin + p7 & & p9 T G1 ( x ) = [0 p4 cos 0 p8 0 p10 sin ]

p4 cos 0 p8 0

p10 sin ]

11

Zhai et al. / International Journal of Engineering, Science and Technology, Vol. 2, No. 10, 2010, pp. 9-19

p1 = [ (M f + M b )gLa + M c gLc ] J p3 = J p5 = ( M f + M b )gLh J

p2 = [ (M f + M b )gLa tan a + M c gLc tan c ] J p4 = K m La J p6 = (M f + M b )gLh tan h J

a = tan 1{(Ld + Le ) La }

p7 = J p9 = J

c = tan 1{Ld Lc }

p8 = K m Lh J p10 = K m La J

h = tan 1{Le Lh }

and, the symbols used in the above model are described in Table 1. Table 1. Notation and units used in the laboratory helicopter model Symbols Unit Degree Degree Degree Volt kg kg m m m m m m/s

2

Description Elevation angle Pitch angle Travel angle Voltages applied to the front and back motor Mass of the front section of the helicopter, and mass of the rear section Mass of the count-weight The length of pendulum for the elevation axis The distance from the pivot point to the counter-weight The distance from the pivot point to the helicopter body The length of pendulum for pitch axis The distance from the pitch axis to either motor Gravitational acceleration Moment of inertia about the elevation, pitch and travel axes Coefficient of viscous friction about the elevation, pitch and travel axes

V f , Vb M f , Mb Mc Ld Lc La Le Lh g

J J J

kg m2 kg m /s

2

In this research, a model predictive control algorithm with successive linearization is investigated for the control of the elevation and travel in the helicopter system by manipulating the voltages applied to the front and back motors. Therefore, elevation angle, , and travel angle, , are chosen as the controlled variables, i.e.,

y = [ ]

(2)

and the two voltages, V f and Vb , are chosen as the manipulated variables, i.e.,

u = [V f

Vb ]

(3)

For such dynamical system with severe nonlinearities, the direct MIMO control is challenging; however, this challenge can be overcome using successive linearization as described in the next sections. 3. NMPC using successive linearization Ishitobi et al. (2010) have shown that the nonlinear model described in Section 2 captures the essential dynamic behavior of a laboratory helicopter, and therefore, it is used in this work to describe the Quanser laboratory helicopter system and to design the

12

Zhai et al. / International Journal of Engineering, Science and Technology, Vol. 2, No. 10, 2010, pp. 9-19

MPCSL scheme. At every instance, the nonlinear model is linearized at the current state and the control input. Then, the obtained linear model is used in MPC. This successive linearization makes the predictive model represent the latest operating condition of the helicopter. In addition, if compared with conventional MPC, the use of a linearized model reduces the computational effort in solving the MPC optimization problem significantly, and makes the developed control algorithm more realistic to meet the requirement of a real-time control system. The remainder of this section describes the MPCSL algorithm in more detail. 3.1. Model Linearization The nonlinear system in section 2 can be written as:

& = f ( x , u ) x n x u n u x

and,

(4)

y = g (x, u )

ny

(5)

where n x , nu and n y are the dimensions of state vector, manipulated variables and controlled variables, respectively. The equations (4) and (5) can be linearized as follows:

& f ( x0 , u0 ) + A( x x0 ) + B (u u0 ) x

(6) (7)

y g ( x0 , u0 ) + C ( x x0 ) + D (u u0 )

where,

A= C=

f x g x

, B=

x 0 ,u0

f u g u

x0 ,u0

, D=

x0 ,u0

x0 ,u0

are matrices of the appropriate sizes. At a given time sample,

x0 and u0 represent the current state and control vectors,

0 0 0 1 p7 0 0 0 0 0 0 0 0 0 0 0 0 1 p9

respectively. Using equations (1), (6), (7), these system matrices can be obtained as follows:

0 p sin + p cos 2 1 0 A= 0 0 0

1 p3 0 0 0 0

p4 sin (V f + Vb ) 0 p5 sin + p6 cos 0 p10 cos (V f + Vb ) 0 p4 cos 0 p8 0 p10 sin

0 p cos 4 0 B= p8 0 p10 sin

13

Zhai et al. / International Journal of Engineering, Science and Technology, Vol. 2, No. 10, 2010, pp. 9-19

1 0 0 0 0 0 C= 0 0 0 0 1 0

0 0 D= 0 0

After linearization, the linearized model is discretized and the discrete model is used in MPC as described next. 3.2 MPC algorithm The diagram below depicts the structure used by the model predictive controller.

Figure 2: The structure of model predictive controller As shown in Figure 2, once the model has been obtained, it can be used as an internal model of a predictive controller. The model generates predictions of future process outputs over a specified prediction horizon, which are then used to minimize the following MPC objective criterion:

minuk

s.t.,

i =1

T eT k = 0,1,L, M 1 y , iQe y , i + j =1 u j Ru j , M

(8)

uL uk uU uk = u (tk ) = u (t ) , t [t0 , tP ] e y ,i = yi ri , i [1, P ] u j = u j + 1 u j

R n u n u are the weighting matrices n for the output error and the control signal changes respectively, and ne = P n y , nu = M nu . rk e is the output

where M and P are the control and prediction horizons respectively, Q

ne ne

and

reference vector at tk , and uL , uU are constant vectors determining the input constraints as element-by-element inequalities (Al Seyab et al, 2008). By minimizing the objective function in equation (8), the MPC algorithm generates a sequence of control inputs uk and k = 0,1, L , M 1 , as illustrated in Figure 3 (Qin et al., 2003).

14

Zhai et al. / International Journal of Engineering, Science and Technology, Vol. 2, No. 10, 2010, pp. 9-19

Figure 3: Manipulated variable profile Then, only the first element in this control sequence is implemented and the whole procedure is repeated at next sampling instant. In this research, the internal model used by the model predictive controller is a linear model that is obtained by linearizing the nonlinear helicopter model at each sampling instant. Therefore, the optimization problem above is a standard quadratic programming problem (QP) which can be solved by any modern QP solvers. Given the medium size of optimization problem in this application, the active set method is used here to efficiently solve this online optimization problem (Fletcher, 2000; Nocedal et al., 2006). 4. Simulated Example In this example, the MPCSL control algorithm described earlier is applied to the nonlinear helicopter model using MATLAB/SIMULINK. The voltages V f and Vb of the two motors are assumed to be changeable in the range 0V ,5V . The

nominal values of the physical constants in the helicopter test-bed are as follows (Ishitobi, et al., 2010):

J = 0.86kg m 2 , J = 0.044kg m 2

J = 0.82kg m 2 ,

La = 0.62m , Lc = 0.44m , Ld = 0.05m , Le = 0.02m , Lh = 0.177m , M f = 0.69kg , M b = 0.69kg , M c = 1.69kg , K m = 0.5N / V , g = 9.81m / s 2 ,

= 0.001kg m 2 / s , = 0.001kg m 2 / s , = 0.005kg m 2 / s ,

In this simulation, the reference signals for the elevation and travel angles are changed between 20 to 20 to simulate the demands given by the pilot as shown in Figures 4, and 5. Also, the sampling time and simulation time used are 0.1 and 200 seconds, respectively.

o o

20 reference signal for elevation angle (degree) 15 10 5 0 -5 -10 -15 -20 -25

20

40

60

80 100 120 time(second)

140

160

180

200

Figure 4: Reference signal for the elevation angle

15

Zhai et al. / International Journal of Engineering, Science and Technology, Vol. 2, No. 10, 2010, pp. 9-19

20 reference signal for travel angle (degree) 15 10 5 0 -5 -10 -15 -20 0 20 40 60 80 100 120 time(second) 140 160 180 200

Figure 5: Reference signal for the travel angle In order to show the advantages of the MPCSL method when used to control this helicopter system, the control results are compared with those of LMPC, which is well tuned using the linearized model at the helicopter hovering condition, i.e., = 0 0 0 . The design parameters used in these two MIMO approaches are given in Table 2.

] [

Table 2: Design parameters used in LMPC and MPCSL Initial Condition & = & = 0 , V = 1.8865 , V = 1.9366 & = = = = f b P M Q R 10(MPCSL); 20(LMPC) 5(MPCSL); 5(LMPC) 10*IP (MPCSL); 10*IP(LMPC) 0.01*IM(MPCSL); 0.01*IM(LMPC)

The simulation results for the MPCSL and LMPC are shown in Figures 6 and 7, and the corresponding voltage signals applied to the rotors are shown in Figures 8 and 9.

16

Zhai et al. / International Journal of Engineering, Science and Technology, Vol. 2, No. 10, 2010, pp. 9-19

20 15 10 elevation (degree) 5 0 -5 -10 -15 -20 -25

Ref. Trajectory LMPC MPCSL

20

40

60

80 100 120 time(second)

140

160

180

200

Figure 6: Control simulation results for the elevation angle

25 20 15 10 travel (degree) 5 0 -5 -10 -15 -20 0 20 40 60 80 100 120 time(second) 140

Ref. Trajectory LMPC MPCSL

160

180

200

Figure 7: Control simulation results for the travel angle

17

Zhai et al. / International Journal of Engineering, Science and Technology, Vol. 2, No. 10, 2010, pp. 9-19

5 4.5 4 voltage on front rotar (volt) 3.5 3 2.5 2 1.5 1 0.5 0 0 20 40 60 80 100 120 time(second) 140 160

LMPC MPCSL

180

200

Figure 8: Voltage applied on the front rotor

4.5 4 3.5 voltage on back rotar (volt) 3 2.5 2 1.5 1 0.5 0 0 20 40 60 80 100 120 time(second) 140 160

LMPC MPCSL

180

200

Figure 9: Voltage applied on the back rotor

18

Zhai et al. / International Journal of Engineering, Science and Technology, Vol. 2, No. 10, 2010, pp. 9-19

It can be seen from the Figures 6 and 7 that when the helicopter is operating in a wide range of its flight envelope, the tracking performance of LMPC looks acceptable; however, large overshoot is not avoidable due to the inaccuracy of the internal model used in prediction. Also, compared with LMPC, the MPCSL approach results in smaller overshoot and shorter settling time for both the elevation and travel angles, which is a considerable improvement in performance. This is shown in Tables 3, 4, and 5, which compare the tracking mean absolute errors (MAE), percent overshoot, and settling time (using a band of 2% of the total change in the controlled variables), for the two control algorithms. Table 3: MAE for elevation and travel control MAE (degree) LMPC MPCSL Elevation 0.4114 0.2122 Travel 0.9346 0.5909

Table 4: Overshoot for elevation and travel control Percentage Overshoot LMPC MPCSL Elevation 7.5% 0% Travel 25% 5.3%

Table 5: Settling time for elevation and travel control Settling Time (seconds) LMPC MPCSL Elevation 7.5 1.1 Travel 8.9 6.4 5. Conclusion This paper presents a nonlinear model predictive control method that is based on successive linearization to control the elevation and travel of a laboratory helicopter system. The performance of the developed algorithm is illustrated and compared to that of linear model predictive control, and the results show a considerable improvement for the developed algorithm in term of tracking error, overshoot and settling time. Acknowledgements The authors would like to gratefully acknowledge the financial support of Qatar National Research Fund (QNRF). References

Al Seyab R.K. and Cao Y., 2008. Nonlinear system identification for predictive control using continuous time recurrent neural networks and automatic differentiation. Journal of Process Control. Vol. 18, pp. 568-581. Apkarian J., 1998. 3D Helicopter experiment manual. Canada: Quanser Consulting. Dua P., Kouramas K., Dua V. and Pistikopoulos E.N., 2008. MPC on a chip Recent advances on the application of multi-parametric modelbased control, Computer & Chemical Engineering, Vol. 32, No. 4-5, pp. 754-765. Fletcher R., 2000. Practical optimization method, Wiley, ISBN: 0471494631. Garcia C.E. and Morshedi A.M., 1984. Quadratic programming solution of dynamic matrix control. Proc. Am. Contr. Conf., San Diego. Ishitobi M., Nishi M. and Nakasaki K., 2010. Nonlinear adaptive model following control for a 3-DOF tandem-rotor model helicopter. Control Engineering Practice, doi: 10.1016/j.conengprac.2010.03.017. Kim B.S., 1993. Nonlinear flight control using neural networks. Ph.D. Dissertation, Georgia Institute of Technology, Atlanta, GA, December Kim B.S. and Calise A.J., 1997. Nonlinear flight control using neural networks, Journal of Guidance Control Dynam. Vol. 20, No. 1, pp. 26-33. Koo T.J. and Sastry S., 1998. Output tracking control design of a helicopter model based on approximate linearization. In proceedings of the 37th IEEE conference on decision and control (pp. 3596-3601). Lee S., Ha C. and Kim B.S., 2005. Adaptive nonlinear control system design for helicopter robust command augmentation. Aerospace Science and Technology, Vol. 9, pp. 241-251. Lee, J.H., and Ricker N.L., 1994. Extended Kalman filter based nonlinear model predictive control. Ind. Engng Chem. Res. Vol. 33, pp. 15301541. Mahony R. and Hamel T., 2004. Robust trajectory tracking for a scale model autonomous helicopter. International Journal of Robust and Nonlinear Control, Vol. 14, No. 12, pp. 1035-1059.

19

Zhai et al. / International Journal of Engineering, Science and Technology, Vol. 2, No. 10, 2010, pp. 9-19

Maia M.H. and Galvao R.K.H., 2008. Robust constrained predictive control of a 3DOF helicopter model with external disturbances. ABCM Symposium Series in Mechatronics, Vol. 3, pp. 19-26. Marconi L. and Naldi R., 2007. Robust full degree of freedom tracking control of a helicopter. Automatica, Vol. 43, No. 11, pp. 1909-1920. Nocedal J. and Wright S.J., 2006. Numerical Optimization, Second Edition. Springer Series in Operations Research, Spring Verlag. Prasad J.V.R. and Calise A.J., 1999. Adaptive nonlinear controller synthesis and flight evaluation on an unmanned helicopter, IEEE International Conference on Control Application. Qin S.J. and Badgwell T.A., 2003. A survey of industrial model predictive control technology. Control Engineering Practice, Vol. 11, pp. 733764. Quanser, 2010. 3-DOF helicopter experiment manual - online version. Quanser Consulting Inc. Reiner J., Balas G.J. and Garrard W.L., 1995. Robust dynamic inversion for control of highly maneuverable aircraft, Journal of Guidance Control Dynam. Vol. 18, No. 1, pp. 18-24. Ricker N.L. and Lee J.H., 1995. Nonlinear model predictive control of the Tennessee Eastman Challenge process. Computers Chem. Engng, Vol. 19, No. 9, pp. 961-981. Sira-Ramirez H., Zribi M. and Ahmad S., 1994. Dynamical sliding mode control approach for vertical flight regulation in helicopters. IEE Proceeding Control Theory and Application, Vol. 141, No. 1, pp. 19-24. Tao C.W., Taur J.S. and Chen Y.C., 2010. Design of a parallel distributed fuzzy LQR controller for the twin rotor multi-input multi-output system. Fuzzy Sets and Systems, Vol. 161, No. 15, pp. 2081-2103. Witt J., Boonto S. and Werner H., 2007 Approximate model predictive control of a 3-DOF helicopter. Proceeding of the 46th IEEE conference on decision and control, New Orleans, LA, USA, Dec, 12-14. Wang Y. and Boyd S., 2010. Fast model predictive control using online optimization. IEEE Transactions on Control Systems Technology, Vol. 18, No. 2. Zhai Y.J., Yu D.W. , Guo H.Y. and Yu D.L., 2010. Robust air/fuel ratio control with adaptive DRNN model and AD tuning. Engineering Application of Artificial Intelligence, Vol. 23, pp. 283-289.

Biographical notes Dr. Yujia Zhai received his M.Sc and Ph.D. from University of Liverpoo and Liverpool John Moores University, UK, in 2004 and 2009, respectively. He is currently working as a post-doctoral researcher in the Chemical Engineering Program, Texas A&M University at Qatar. His research interests include Dynamical System Identification and Control, Artificial Neural network, Nonlinear Optimization, and Model Predictive Control Dr. Mohamed Nounou received his B.S. degree with honors (Magna Cum Laude) from Texas A&M University in 1995, and his M.S. and Ph.D. degrees from the Ohio State University in 1997 and 2000, respectively, all in Chemical Engineering. From 2000-2002, he worked for PDF Solutions, a consulting company for the semiconductor industry, in San Jose, CA. In 2002, he joined the department of Chemical and Petroleum Engineering at the United Arab Emirates University as an assistant professor. In 2006, he joined the Chemical Engineering Program at Texas A&M University at Qatar, where he is now an associate professor. Dr. Nounous research interests include process modeling and estimation, system biology, and intelligent control. He published more than forty refereed journal and conference papers and book chapters. Dr. Nounou served as an associate editor and in technical committees of several international journals and conferences. He is a member of the American Institute of Chemical Engineers (AIChE) and a senior member of the Institute of Electrical and Electronics Engineers (IEEE). Dr. Hazem Nounou received his B.S. degree with honors (Magna Cum Laude) from Texas A&M University in 1995, and the M.S. and Ph.D. degrees from Ohio State University in 1997 and 2000, respectively, all in Electrical Engineering. In 2001, he worked as a development engineer for PDF Solutions, a consulting firm for the semiconductor industry, in San Jose, CA, USA. Then, in 2001, he joined the Department of Electrical Engineering at King Fahd University of Petroleum and Minerals in Dhahran, Saudi Arabia as assistant professor. In 2002, he moved to the Department of Electrical Engineering at United Arab Emirates University, Al-Ain, United Arab Emirates. In 2007, he joined the Electrical and Computer Engineering Program at Texas A&M University at Qatar, where is he currently an associate professor. His areas of interest include intelligent and adaptive control, control of time-delay systems, system biology and system identification and estimation. He published more than forty refereed journal and conference papers. Dr. Nounou served as an associate editor and in technical committees of several international journals and conferences. He is a senior member of the Institute of Electrical and Electronics Engineers (IEEE). Yasser Al-Hamidi is currently working as a Technical Laboratory Coordinator in the Mechanical Engineering Program at Texas A&M University at Qatar since 2007. He is specialized in instrumentation, controls and automation. He worked as a Lab Engineer in the College of Engineering, University of Sharjah for seven years before joining TAMUQ. His other experiences include Laboratory Supervisor/Network Administrator at Ajman University of Science and Technology (Al Ain Campus), Maintenance Engineer at AGRINCO, Electrical Engineer at Ministry of Culture (National Theater Project, Damascus) and also as a Novel Network Supervisor (NetWare 3.12) in a medical and agricultural services company, Damascus. Yasser's professional interests include precision mechatronics, real-time control systems design, networked control systems.

Received October 2010 Accepted November 2010 Final acceptance in revised form December 2010

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- POH NAVAJO Pa-31Document438 pagesPOH NAVAJO Pa-31Mantenimiento CMA68475% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1D Kalman Filter - ShoudongDocument9 pages1D Kalman Filter - ShoudongSohibul HajahNo ratings yet

- Assessment Case Based Method Dan Project Based LearningDocument25 pagesAssessment Case Based Method Dan Project Based LearningSohibul HajahNo ratings yet

- Matrik Korelasi ISOvsIWAvsBANvsMBNQADocument63 pagesMatrik Korelasi ISOvsIWAvsBANvsMBNQASohibul HajahNo ratings yet

- RPARC Version 2018Document14 pagesRPARC Version 2018Sohibul HajahNo ratings yet

- GX Works3 Ver1 - Operating Manual SH (NA) - 081215-Y (12.19)Document802 pagesGX Works3 Ver1 - Operating Manual SH (NA) - 081215-Y (12.19)Sohibul Hajah100% (2)

- Sensor GasDocument8 pagesSensor GasSohibul HajahNo ratings yet

- Experiments in Princ by David E. L WWW Bookfind BizDocument321 pagesExperiments in Princ by David E. L WWW Bookfind BizSohibul HajahNo ratings yet

- Sensor Dan Transduser: Pengertian Dan Prinsip DasarDocument33 pagesSensor Dan Transduser: Pengertian Dan Prinsip DasarSohibul HajahNo ratings yet

- YaaaDocument354 pagesYaaaSohibul Hajah100% (1)

- World of MetalsDocument36 pagesWorld of Metalsnavanee2008No ratings yet

- Storace (2004) - Piecewise-Linear Approximation of Nonlinear Dynamical SystemsDocument13 pagesStorace (2004) - Piecewise-Linear Approximation of Nonlinear Dynamical SystemsSohibul HajahNo ratings yet

- MODEL MATCHING For NONLINEAR SYSTEMS Not Having The State Space RealizationDocument5 pagesMODEL MATCHING For NONLINEAR SYSTEMS Not Having The State Space RealizationSohibul HajahNo ratings yet

- Modeling Helicopter UAV: Carl ThibaultDocument12 pagesModeling Helicopter UAV: Carl ThibaultSohibul HajahNo ratings yet

- Extended Kalman Filter Based Speed Sensor Less PMSM Control With Load ReconstructionDocument16 pagesExtended Kalman Filter Based Speed Sensor Less PMSM Control With Load ReconstructionSohibul HajahNo ratings yet

- State Space A To NPGMV ControlDocument43 pagesState Space A To NPGMV ControlSohibul HajahNo ratings yet

- An Introduction To Nonlinear Model Predictive ControlDocument23 pagesAn Introduction To Nonlinear Model Predictive ControlSohibul HajahNo ratings yet

- IMDSDocument13 pagesIMDSJohn OoNo ratings yet

- 4 Contamination Control 2Document61 pages4 Contamination Control 2Vijay RajaindranNo ratings yet

- IA SeriesDocument20 pagesIA Seriessina20795No ratings yet

- SFF 8448Document8 pagesSFF 8448eleptonNo ratings yet

- While Start Drive Test Learning, You Must Know The Basic Things! These All Conotents Are at Introductory LevelDocument15 pagesWhile Start Drive Test Learning, You Must Know The Basic Things! These All Conotents Are at Introductory LevelRakesh SolankiNo ratings yet

- UAMDocument35 pagesUAMVishnu R PuthusseryNo ratings yet

- State of Patriot MissilesDocument13 pagesState of Patriot MissilesTaira Mai100% (1)

- Ufgs 33 52 43.13Document40 pagesUfgs 33 52 43.13Tendai Felex MadukeNo ratings yet

- Lube-Tech: Lubricants For Wind TurbinesDocument6 pagesLube-Tech: Lubricants For Wind TurbinesMC ANo ratings yet

- L19 External DiffusionDocument30 pagesL19 External DiffusionEga NabellaNo ratings yet

- Tools of BiotechnologyDocument10 pagesTools of Biotechnologyiamforu1No ratings yet

- Cfw300 Manual 1Document124 pagesCfw300 Manual 1maurilioNo ratings yet

- Role of QAQC Eng.Document38 pagesRole of QAQC Eng.arunkumar100% (2)

- Gsk980Tda Turning Machine CNC System: CharacteristicsDocument10 pagesGsk980Tda Turning Machine CNC System: CharacteristicsPramod YadavNo ratings yet

- 101.S-4501 Steamer Cyclone Cleaning ProcedureDocument6 pages101.S-4501 Steamer Cyclone Cleaning ProcedureTRONGKIMNo ratings yet

- Master Thesis: Tasuku KanedaDocument77 pagesMaster Thesis: Tasuku Kanedamkali345No ratings yet

- 545 ELP-ES-2011 - Catálogo de DisipadoresDocument24 pages545 ELP-ES-2011 - Catálogo de DisipadoresrichkidNo ratings yet

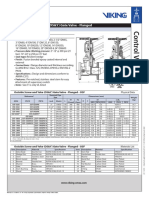

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesMark Louie GuintoNo ratings yet

- AY 2015-16cvbbnjDocument245 pagesAY 2015-16cvbbnjSyed Abdul AzizNo ratings yet

- Grid Synchronization of Power Converters Using Multiple Second Order Generalized IntegratorsDocument6 pagesGrid Synchronization of Power Converters Using Multiple Second Order Generalized IntegratorsJandfor Tansfg ErrottNo ratings yet

- Catalogo Bulldog Jgo Empacaduras Maquinas+Motores Todo en UnoDocument78 pagesCatalogo Bulldog Jgo Empacaduras Maquinas+Motores Todo en UnoAlexis SanchezNo ratings yet

- BC 20s HandbuchDocument173 pagesBC 20s HandbuchmanoharNo ratings yet

- Forged - Pipe - Fittings - ANSI - B-16.11 PDFDocument1 pageForged - Pipe - Fittings - ANSI - B-16.11 PDFImran KamalNo ratings yet

- Chapter - I: Hydro DriveDocument19 pagesChapter - I: Hydro Drivekuldeep ududholiraNo ratings yet

- BX-74 / BX-78: Sliding Gate Operator BX SeriesDocument24 pagesBX-74 / BX-78: Sliding Gate Operator BX SeriesStefce PetrovNo ratings yet

- Technical LetteringDocument12 pagesTechnical LetteringMaverick Timbol50% (2)

- Home,: A Solace To Which A Journey Is Never Too Long..Document25 pagesHome,: A Solace To Which A Journey Is Never Too Long..Duvonto RealtyNo ratings yet

- Investigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProDocument4 pagesInvestigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProEditor IJTSRDNo ratings yet

- ARO Pump ManualDocument8 pagesARO Pump Manualrazaq athabNo ratings yet