Professional Documents

Culture Documents

NME-101/201: Basic Manufacturing Processes L T P (2 0 0)

Uploaded by

Ravi KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NME-101/201: Basic Manufacturing Processes L T P (2 0 0)

Uploaded by

Ravi KumarCopyright:

Available Formats

NME-101/201: Basic Manufacturing Processes

Unit-I Engineering Materials

L T P [2 0 0]

Materials and Civilization, their socio economic impact. Engineering Materials their classification and applications. 1 Metals & Alloys: Properties and Applications Mechanical Properties of Materials: Strength, elasticity, plasticity, stiffness, malleability, ductility, brittleness, malleability, toughness, hardness, resilience, hardness, machine ability, formability, weld ability. Elementary ideas of fracture fatigue & creep. 2 Steels and Cast Irons: Carbon steels, their classification based on percentage of carbon as low, mild, medium & high carbon steel, their properties & applications. Wrought iron. Cast iron. Alloy steels: stainless steel, tool steel. 2 Alloys of Non Ferrous Metals: Common uses of various non-ferrous metals (Copper, Zink, Tin, Magnesium, Lead, Aluminum etc.) & alloys and its composition such as Cu-alloys: Brass, Bronze, Alalloys. 2 Unit-II Basic Metal Forming & Casting Processes. Forming Processes: Basic metal forming operations & uses of such as: Forging, Rolling, Wire & Tubedrawing/making and Extrusion, and their uses. Press-work: Die & Punch assembly, cutting and forming, its applications. Hot-working versus cold-working 4 Casting: Pattern: Materials, types and allowances. Type and composition of Molding sands and their desirable properties. Mould making with the use of a core. Gating system. Casting defects & remedies. Cupola Furnace. Die-casting and its uses. 3 Unit-III Machining and Welding Operations and their Applications Machining: Basic principles of Lathe-machine and operations performed on it. Basic description of machines and operations of Shaper-Planer, Drilling, Milling & Grinding. 4 Welding: Introduction, classification of welding processes. Gas-welding, types of flames and their applications. Electric-Arc welding. Resistance welding. Soldering & Brazing processes and their uses. 3 Unit-IV Misc. Topics/ Processes Heat Treatment Processes: Introduction to Heat- treatment of carbon steels: annealing, normalizing, quenching, tempering and case-hardening. Manufacturing Establishment: Plant location. Plant layoutits types. Types of Production. Production versus Productivity. 1 Non-Metallic Materials: Common types & uses of Wood, Cement-concrete, Ceramics, Rubber, Plastics and Composite-materials. 3 Misc. Processes: Introduction to Galvanizing and Electroplating. 1 Reference Books: 1. 2. 3. 4. Processes and Materials of Manufacture, Lindberg, PHI Manufacturing Engineering And Technology, Kalpakjian and Schmid, Pearson Manufacturing Processes, Kalpakjian and Schmid, Pearson Manufacturing Processes, H. N .Gupta, R. C. Gupta, Arun Mital, New Age

15

You might also like

- Lecturer in Production EngineeringDocument7 pagesLecturer in Production EngineeringGanesh MalayathNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- ME104 Manufacturing Process: Suggested ReadingsDocument1 pageME104 Manufacturing Process: Suggested ReadingsAditya KumarNo ratings yet

- Manufacturing Processes (K.U Syllabus)Document1 pageManufacturing Processes (K.U Syllabus)shalom_pklNo ratings yet

- Engineering MaterialDocument2 pagesEngineering Materialultimatestatus2279No ratings yet

- ME3392 SyllabusDocument2 pagesME3392 Syllabusmanoj1316kumar_63152No ratings yet

- PHRE 415 - Metallurgy and Workshop PracticesDocument2 pagesPHRE 415 - Metallurgy and Workshop Practicesasphaltnoob8No ratings yet

- Engineering Materials PDFDocument24 pagesEngineering Materials PDFPradeepkumarKatgiNo ratings yet

- 46595-261231-302061 A Welding TechnologyDocument2 pages46595-261231-302061 A Welding TechnologyVijay Kumar DodaiNo ratings yet

- Mech SyllabusDocument25 pagesMech SyllabusPratham JainNo ratings yet

- Manufacturing Processes - 1: Subject Code:3ME05 Semester - 3Document9 pagesManufacturing Processes - 1: Subject Code:3ME05 Semester - 3anon_736570908No ratings yet

- Me8351 Manufacturing Technology-I SyllabusDocument1 pageMe8351 Manufacturing Technology-I SyllabusAnonymous ZB6qyhD6No ratings yet

- Syllabus PtamDocument1 pageSyllabus PtamDhana MuruganNo ratings yet

- SyllabusDocument2 pagesSyllabusDhana MuruganNo ratings yet

- SyllabusDocument2 pagesSyllabusDhana MuruganNo ratings yet

- Mett.7th SemDocument9 pagesMett.7th SemLokesh DahiyaNo ratings yet

- EME Module 2Document31 pagesEME Module 2Yashaswini AnandNo ratings yet

- Syllabus For 3 Years Diploma in Mechanical EngineeringDocument24 pagesSyllabus For 3 Years Diploma in Mechanical EngineeringPratham JainNo ratings yet

- Sixth Semester: Teaching Scheme Credits 4 ObjectivesDocument15 pagesSixth Semester: Teaching Scheme Credits 4 ObjectivesNitin RautNo ratings yet

- Ms&e FD&MDocument2 pagesMs&e FD&Mnetwing2009No ratings yet

- Mf5103 Advances in Casting and Welding: For Syllabus, Question Papers, Notes & Many MoreDocument2 pagesMf5103 Advances in Casting and Welding: For Syllabus, Question Papers, Notes & Many MoreNandha Gopal SenthilnathanNo ratings yet

- (G.Idy8%: CircularDocument16 pages(G.Idy8%: CircularROHAN SINHANo ratings yet

- MT 010 601 Non Ferrous Physical MetallurgyDocument2 pagesMT 010 601 Non Ferrous Physical Metallurgyവിഷ്ണു സിNo ratings yet

- Manufacturing EngineeringDocument3 pagesManufacturing EngineeringRavichandran GNo ratings yet

- MP SyllabusDocument1 pageMP SyllabusRAMAKANT RANANo ratings yet

- MEC304 Production Process - I 4: Coursecommon To Mech/AutoDocument1 pageMEC304 Production Process - I 4: Coursecommon To Mech/AutoHoney SinghNo ratings yet

- FGHFGHFDocument2 pagesFGHFGHFJob ShortsNo ratings yet

- Production TechnologyDocument5 pagesProduction TechnologyAparnaa MoorthyNo ratings yet

- 4.1 Materials and MetallurgyDocument16 pages4.1 Materials and MetallurgyVijayKumarNo ratings yet

- 14phdme002 Advanced Materials and ProcessingDocument1 page14phdme002 Advanced Materials and ProcessingRing MasterNo ratings yet

- Manufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Document2 pagesManufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Madduri HemantNo ratings yet

- Elements of Matallurgy & Materials ScienceDocument2 pagesElements of Matallurgy & Materials Sciencebhati_mukesh89No ratings yet

- Ase102:Aerospace Materials and Processes: Session 2019-20 Page:1/1Document1 pageAse102:Aerospace Materials and Processes: Session 2019-20 Page:1/1Yashwanth Krishna GampaNo ratings yet

- Syllabus For Foremen Gr. IIDocument4 pagesSyllabus For Foremen Gr. IIMohammed AseerNo ratings yet

- 11 Engineering MaterialsDocument20 pages11 Engineering MaterialsAbdul Hai MohammedNo ratings yet

- Metallurgy SyllabusDocument1 pageMetallurgy SyllabusSathrudhan ChoudharyNo ratings yet

- Material Tech Master File Cp01 - I SemDocument50 pagesMaterial Tech Master File Cp01 - I SemvinayakNo ratings yet

- Syllabus For The Trade of Fitter: First Semester (Semester Code No. FTR - 01) Duration: Six Month Week Trade Theory NoDocument8 pagesSyllabus For The Trade of Fitter: First Semester (Semester Code No. FTR - 01) Duration: Six Month Week Trade Theory NosidNo ratings yet

- EM SyllabusDocument2 pagesEM SyllabusABINASH PANDANo ratings yet

- Course No Course Title L P U ME 303 Production Techniques 3 0 3Document2 pagesCourse No Course Title L P U ME 303 Production Techniques 3 0 3zak3CHA8_No ratings yet

- ME8351 Manufacturing Technology I Syllabus Regulation 2017Document2 pagesME8351 Manufacturing Technology I Syllabus Regulation 2017Dr.S.Ravi CITNo ratings yet

- Mt-I Syllabus PDFDocument1 pageMt-I Syllabus PDFThenarasumohanveluNo ratings yet

- CTS FitterDocument14 pagesCTS FitterSahitya SaxenaNo ratings yet

- View Syllabus by IDDocument7 pagesView Syllabus by IDDamodar PrabhuNo ratings yet

- Engineering Materials and Metallurgy SyllabusDocument2 pagesEngineering Materials and Metallurgy SyllabusSuganthiVasanNo ratings yet

- ME-402 Manufacturing Technology-I CR-3Document1 pageME-402 Manufacturing Technology-I CR-3Almedin HreljicNo ratings yet

- 7 MetallurgyDocument2 pages7 MetallurgyNarasimha Murthy InampudiNo ratings yet

- Chapter 1-IntroductionDocument6 pagesChapter 1-IntroductionG. Dancer GhNo ratings yet

- Manufacturing ProcessDocument1 pageManufacturing ProcessRonald Reagon20% (5)

- Me 2252 Manufacturing TechnologyDocument3 pagesMe 2252 Manufacturing TechnologyRamarajan YogeeswaranNo ratings yet

- Elective 7Document1 pageElective 7Other StuffNo ratings yet

- Lesson Plan: Page 1 of 6 Unit: I Branch: B.E. Mechanical Engg. Semester: IVDocument6 pagesLesson Plan: Page 1 of 6 Unit: I Branch: B.E. Mechanical Engg. Semester: IVDinesh Kumar RNo ratings yet

- Wk1 D4-5 (Workshop Materials)Document41 pagesWk1 D4-5 (Workshop Materials)Mel ParasNo ratings yet

- Construction Materials and Testing: "Metals"Document6 pagesConstruction Materials and Testing: "Metals"Aira Joy AnyayahanNo ratings yet

- Basic Manufacturing ProcessDocument1 pageBasic Manufacturing ProcessAshok PradhanNo ratings yet

- Engineering MetallurgyDocument2 pagesEngineering MetallurgyROOSSVELT PRABHU K A VNo ratings yet

- Material Science & MetallurgyDocument2 pagesMaterial Science & Metallurgysameer_m_daniNo ratings yet

- Me209 Mechanical Properties of Structural Materials PDFDocument4 pagesMe209 Mechanical Properties of Structural Materials PDFjishnuNo ratings yet

- Material Science & MetallurgyDocument2 pagesMaterial Science & MetallurgyBhavesh Pipaliya0% (1)

- Concept of Immiserising Growth of An Economy by Professor Jagdish Bhagwati-Explained! PDFDocument5 pagesConcept of Immiserising Growth of An Economy by Professor Jagdish Bhagwati-Explained! PDFRavi KumarNo ratings yet

- Driver Less CarDocument8 pagesDriver Less CarPrajakta Priya R0% (1)

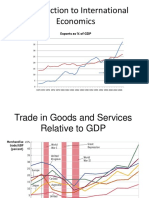

- Introduction To International Economics: Exports As % of GDPDocument21 pagesIntroduction To International Economics: Exports As % of GDPRavi KumarNo ratings yet

- Casting Processes CompleteDocument49 pagesCasting Processes CompleteRavi KumarNo ratings yet

- Eme-503: Manufacturing Science-Ii Unit-I A Metal Cutting and Machine ToolsDocument2 pagesEme-503: Manufacturing Science-Ii Unit-I A Metal Cutting and Machine ToolsRavi KumarNo ratings yet

- Linearity ExpectationDocument1 pageLinearity ExpectationRavi KumarNo ratings yet

- Gate 03292012Document1 pageGate 03292012Ravi KumarNo ratings yet

- Policy: Car-Scrapping Schemes: An Effective Economic Rescue Policy?Document8 pagesPolicy: Car-Scrapping Schemes: An Effective Economic Rescue Policy?Ravi KumarNo ratings yet

- ME 351 Course OutlineDocument1 pageME 351 Course OutlineRavi KumarNo ratings yet

- Graphite Structures in Cast Iron EnglishDocument1 pageGraphite Structures in Cast Iron EnglishsateeshkoriNo ratings yet

- Applications of ElectrolysisDocument3 pagesApplications of ElectrolysisShahidan Latif100% (1)

- Crankshaft 1Document14 pagesCrankshaft 1Shweta NarayanNo ratings yet

- Embrittlement of SteelsDocument26 pagesEmbrittlement of SteelsUlises Quintana CarhuanchoNo ratings yet

- Metallurgy Assignment - Rev - 3Document21 pagesMetallurgy Assignment - Rev - 3Maria CutajarNo ratings yet

- World Largest Gold and Copper Mine Reko Diq BalochistanDocument6 pagesWorld Largest Gold and Copper Mine Reko Diq BalochistanJavaid Ali ShahNo ratings yet

- Table of Mineral Abbreviations..New..Document3 pagesTable of Mineral Abbreviations..New..musticicekNo ratings yet

- Welding Procedures and Welding Qualiy Control For PipingDocument18 pagesWelding Procedures and Welding Qualiy Control For PipingImam BuchairiNo ratings yet

- ImportedfromGoogleNotebook MaterialScienceDocument97 pagesImportedfromGoogleNotebook MaterialScienceHarish PothepalliNo ratings yet

- 2.materials Technology Answered PDFDocument4 pages2.materials Technology Answered PDFOxbown9167% (6)

- Sudharshan Seneviratne 1995Document41 pagesSudharshan Seneviratne 1995darshanieratnawalliNo ratings yet

- MInerals in India PDFDocument25 pagesMInerals in India PDFThelonelyPrinceNo ratings yet

- Surface Hardening enDocument20 pagesSurface Hardening enSidney RileyNo ratings yet

- 13HMFDocument9 pages13HMFAnonymous 1Mk09KeNo ratings yet

- Multilateral Technology Level 4 UISDocument62 pagesMultilateral Technology Level 4 UISSebastian Otalora BarriosNo ratings yet

- The Sintering Process of Iron Ore FinesDocument5 pagesThe Sintering Process of Iron Ore FinesRanggaa RamandanaNo ratings yet

- Duplex Stainless Steel 3rd EditionDocument68 pagesDuplex Stainless Steel 3rd EditionPhani Sridhar Ch100% (3)

- Medieval Iron MakingDocument45 pagesMedieval Iron MakingEdvards Puciriuss100% (1)

- Heat Exchanger GasketDocument3 pagesHeat Exchanger GasketGurinder SinghNo ratings yet

- SS 1Document7 pagesSS 1xanshahNo ratings yet

- A Discussion: ON Magnetic SeparationDocument25 pagesA Discussion: ON Magnetic SeparationaghilifNo ratings yet

- 5086 Aluminum Plate SuppliersDocument10 pages5086 Aluminum Plate Supplierssanghvi overseas incNo ratings yet

- Standared SamplesDocument26 pagesStandared SamplesHazem DiabNo ratings yet

- Mineral Maps MacedoniaDocument14 pagesMineral Maps MacedoniamileNo ratings yet

- Effect of Repeated Weld Repairs....Document12 pagesEffect of Repeated Weld Repairs....Nicolás Toro ValenzuelaNo ratings yet

- 15 Cone 10 RecipesDocument10 pages15 Cone 10 RecipesInga NowakNo ratings yet

- New Metallic Materials-Al-Li AlloysDocument23 pagesNew Metallic Materials-Al-Li AlloyszorazhrNo ratings yet

- Mechanical MaterialsDocument80 pagesMechanical MaterialsDirkPons100% (3)

- Industrial MineralsDocument103 pagesIndustrial MineralsRamo Kiss100% (1)

- Is 1870 1965 EditDocument168 pagesIs 1870 1965 Editshravan.office11No ratings yet

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherFrom EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNo ratings yet

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedFrom EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedRating: 4.5 out of 5 stars4.5/5 (5)

- The Importance of Being Earnest: Classic Tales EditionFrom EverandThe Importance of Being Earnest: Classic Tales EditionRating: 4.5 out of 5 stars4.5/5 (44)

- The Inimitable Jeeves [Classic Tales Edition]From EverandThe Inimitable Jeeves [Classic Tales Edition]Rating: 5 out of 5 stars5/5 (3)

- The Book of Bad:: Stuff You Should Know Unless You’re a PussyFrom EverandThe Book of Bad:: Stuff You Should Know Unless You’re a PussyRating: 3.5 out of 5 stars3.5/5 (3)

- The Little Book of Big F*#k Ups: 220 of History's Most-Regrettable MomentsFrom EverandThe Little Book of Big F*#k Ups: 220 of History's Most-Regrettable MomentsNo ratings yet

- Sex, Drugs, and Cocoa Puffs: A Low Culture ManifestoFrom EverandSex, Drugs, and Cocoa Puffs: A Low Culture ManifestoRating: 3.5 out of 5 stars3.5/5 (1428)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtFrom EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtRating: 4 out of 5 stars4/5 (60)

- 1,001 Facts that Will Scare the S#*t Out of You: The Ultimate Bathroom ReaderFrom Everand1,001 Facts that Will Scare the S#*t Out of You: The Ultimate Bathroom ReaderRating: 3.5 out of 5 stars3.5/5 (48)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticFrom EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticRating: 3.5 out of 5 stars3.5/5 (10)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)