Professional Documents

Culture Documents

Alloy

Uploaded by

enemesio_85Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alloy

Uploaded by

enemesio_85Copyright:

Available Formats

Alloy 112 Coated Electrodes

WASHINGTON ALLOYS Quality Management System is Certified to ISO 9001:2008 Cert # 05-R0925

U.S. ALLOY CO.

dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216 www.weldingwire.com

Alloy 112 is a nickel-chromium molybdenum flux-coated electrode designed for shielded metal-arc welding of lnconel 625 or 601, for high strength welds on 9% nickel steels and for overlaying carbon steel. Alloy 112 is also used for joining dissimilar combinations of steels or stainless steels to nickel-iron chromium alloys such as Incoloy 800 or 801. More common uses of Alloy 112 include the nuclear industry where it is used for pressure vessel superheaters, steam separators and tube plates. This electrode is commonly used in cryogenic installations; chemical and petrochemical applications; and for heat treatment and case hardening industrial furnace parts. More specific uses include joining Inconel 625, 718, X-750, AL6XN, 254SMo and 706 to 9% nickel steels; for welding Incoloy 825 to carbon steel, stainless steel and low alloy steel; for joining Inconel 625, Monel K500, Incoloy 800 and 825 to Inconel 706, 718 and X-750; and for joining Incoloy 825, and 800. Alloy 112 is found where temperatures range from cryogenic to 1000F (540C) and base metals in UNS N06625 such as ASTM B443, B444, and B446.

TYPICAL WELDING PROCEDURES; DCEP Diameter Amps 3/32 70-95 5/32 130-175 Diameter 1/8 3/16 Amps 100-135 175-210

Electrodes larger than 1/8(3.2mm) may be limited to flat and horizontal positions

Procedures may vary with change in position, base metals, filler metals, equipment and other changes.

When welding vertical reduce amperage 10-20% AWS CHEMISTRY REQUIREMENTS (%) & TYPICAL WELD METAL STRENGTHS;

Carbon Manganese Iron Phosphorus Sulphur Silicon Copper Nickel + Co 0.10 max 1.00 max 7.00 max 0.03 max 0.02 max 0.75 max 0.50 max 55.0 min. Molybdenum Tensile Strength (psi) Yield Strength (psi) Elongation Niobium (or Cb) + Tantalum Cobalt max if specified Chromium Titanium 8.0-10.0 110,000 60,000 30% 3.15-4.15 0.12 20.0-23.0 0.40 max

AVAILABLE SIZES:

TN NI-112 = 3/32, 1/8, 5/32, 3/16

SPECIFICATIONS; ANSI/AWS A5.11 ASME SFA 5.11

EAST COAST 7010-G Reames Rd Charlotte, NC 28216 Tel (888) 522-8296 Fax (704)598-6673

ENiCrMo-3 ENiCrMo-3 ; F-43

WEST COAST 8535 Utica Ave Rancho Cucamonga, CA 91730 Tel(800)830-9033 Fax (909)291-4586

GULF COAST 4755 Alpine Drive #100A Stafford, TX 77477 Tel (877) 711-9274 Fax (281)313-6332

Warehouse Distribution Center Dayton, Ohio

Head Office Puyallup, Washington

Washington Alloy Company believes that all information and data given is correct. Use this information to assist in making your own evaluations or decisions and this information should not be mistaken as an expressed or implied warranty. U.S. ALLOY CO. assumes no liability for results or damages incurred from the use of any information contained herein, in whole or in part.

You might also like

- Alloy 625 Wire & Rod: U.S. Alloy CoDocument1 pageAlloy 625 Wire & Rod: U.S. Alloy CowinstonsequeiraNo ratings yet

- Aluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Document1 pageAluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Valli RajuNo ratings yet

- Aluminium 1100Document2 pagesAluminium 1100Anup DalalNo ratings yet

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraNo ratings yet

- Welding of Copper and Its AlloysDocument30 pagesWelding of Copper and Its Alloysaj87_goswami100% (2)

- ROYAL 8016 B2 (AWS:SFA 5.5, E 8016 B2) : ApplicationsDocument1 pageROYAL 8016 B2 (AWS:SFA 5.5, E 8016 B2) : Applicationssviluppi____No ratings yet

- Ca 15Document2 pagesCa 15naraen9790579455No ratings yet

- 22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESDocument7 pages22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESNguyen Anh TuanNo ratings yet

- Duplex Stainless SteelDocument24 pagesDuplex Stainless SteeljeffreymacaseroNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperMADDI MADHAV.No ratings yet

- Electrical and Thermal Properties of ETP Copper C101/CW004ADocument2 pagesElectrical and Thermal Properties of ETP Copper C101/CW004APradeep KumarNo ratings yet

- RA151 28pgDocument31 pagesRA151 28pgpipedown456No ratings yet

- 409 Data SheetDocument2 pages409 Data SheetMatthieuNo ratings yet

- Super Duplex Stainless Steel: Excellent Engineering SolutionsDocument4 pagesSuper Duplex Stainless Steel: Excellent Engineering SolutionsTXUSNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- The Weldability of Steels Used in Jack-Up Drilling PlatformsDocument10 pagesThe Weldability of Steels Used in Jack-Up Drilling PlatformsAnat HershkovitzNo ratings yet

- Stainless Steel Grade 904LDocument5 pagesStainless Steel Grade 904LMadan YadavNo ratings yet

- Austral Wright Metals Incoloy 800 Product Data SheetDocument2 pagesAustral Wright Metals Incoloy 800 Product Data Sheetshashi_uit100% (1)

- Duplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Document6 pagesDuplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dell_RevanNo ratings yet

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456No ratings yet

- Alloy 6moDocument2 pagesAlloy 6moqshaath100% (1)

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- Utp 63Document1 pageUtp 63Eileen TylerNo ratings yet

- Ni base flux cored wireDocument1 pageNi base flux cored wireBBalopesabbNo ratings yet

- How To Weld Fully Austenitic Stainless SteelsDocument20 pagesHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNo ratings yet

- 421 - Domex 700 MCDocument2 pages421 - Domex 700 MClalamed21No ratings yet

- High Temperature Brazing AlloysDocument0 pagesHigh Temperature Brazing AlloysvkmsNo ratings yet

- Alloy 5556 Weld Data Sheet: Typical ApplicationsDocument2 pagesAlloy 5556 Weld Data Sheet: Typical Applicationsvishal bailurNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- COPPER-110: Nearest StandardDocument3 pagesCOPPER-110: Nearest StandardPS Pinturas pinturasNo ratings yet

- High-strength steel welding electrodeDocument6 pagesHigh-strength steel welding electrodefaridshabaniNo ratings yet

- AluminiumDocument48 pagesAluminiumGhiffariAwliyaMuhammadAshfaniaNo ratings yet

- AVESTA How To Weld Duplex SteelDocument20 pagesAVESTA How To Weld Duplex SteelGMacella100% (1)

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- AISI 1015: Digest DDocument2 pagesAISI 1015: Digest DGovinda RajNo ratings yet

- NSW Annual Seminar - Metals for BusbarsDocument19 pagesNSW Annual Seminar - Metals for BusbarsYuttapong SupattaravongNo ratings yet

- 904LDocument5 pages904LManish542No ratings yet

- Alloy 4643 welding dataDocument2 pagesAlloy 4643 welding databastosgabiNo ratings yet

- Dual Shield 7000a1Document1 pageDual Shield 7000a1Gokul RajanNo ratings yet

- Alform-Plate High-Strength Rev3 EnglDocument12 pagesAlform-Plate High-Strength Rev3 EnglTomáš BrtníkNo ratings yet

- Nichrome Alloys For HeatingDocument10 pagesNichrome Alloys For HeatingRajaram GanesanNo ratings yet

- C 18150Document2 pagesC 1815003sri03No ratings yet

- Analysis of Tig Welding Weldment and Defect Identification Using Non Destructive Testing NDTDocument48 pagesAnalysis of Tig Welding Weldment and Defect Identification Using Non Destructive Testing NDTRebecca KelleyNo ratings yet

- P91 MaterialDocument15 pagesP91 MaterialelrajilNo ratings yet

- Welding 9%ni SteelsDocument9 pagesWelding 9%ni SteelspmoinoNo ratings yet

- ESPECIFICACIÓN DE E317lLT1-1Document1 pageESPECIFICACIÓN DE E317lLT1-1Nj Nelson JavierNo ratings yet

- Alloy 625 Spec SheetDocument3 pagesAlloy 625 Spec SheetLinnie McleodNo ratings yet

- Weldability of Cr-Mo SteelsDocument20 pagesWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- Metalloy 80N1 Gas-Shielded Metal-Cored Wire for Nickel-Molybdenum SteelsDocument2 pagesMetalloy 80N1 Gas-Shielded Metal-Cored Wire for Nickel-Molybdenum SteelsClaudia MmsNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- FaseDocument1 pageFaseenemesio_85No ratings yet

- Expancion JointsDocument1 pageExpancion Jointsenemesio_85No ratings yet

- Api510 PnumbersDocument14 pagesApi510 PnumbersBudy SinagaNo ratings yet

- Standards of Pressure PipingDocument3 pagesStandards of Pressure Pipingenemesio_85No ratings yet

- WPQ InfDocument1 pageWPQ Infenemesio_85No ratings yet

- 11201Document16 pages11201ChevronelleNo ratings yet

- Ultrasonic Phased Array Inspection For An PDFDocument19 pagesUltrasonic Phased Array Inspection For An PDFwiNo ratings yet

- Aoos Dfekfkeprkf Askjfrk AsseeDocument1 pageAoos Dfekfkeprkf Askjfrk Asseeenemesio_85No ratings yet

- Inf WpsDocument1 pageInf Wpsenemesio_85No ratings yet

- ISO 15156-3-2009 Technical Circular 1 2010-06-20Document12 pagesISO 15156-3-2009 Technical Circular 1 2010-06-20manuelazo78100% (2)

- Ultrasonido Por Arreglo de FasesDocument12 pagesUltrasonido Por Arreglo de Fasesenemesio_85No ratings yet

- ISO 15156-3-2009 Technical Circular 1 2010-06-20Document12 pagesISO 15156-3-2009 Technical Circular 1 2010-06-20manuelazo78100% (2)

- Ultra So NidosDocument89 pagesUltra So Nidosenemesio_85No ratings yet

- ISO 15156-3-2009 Technical Circular 1 2010-06-20Document12 pagesISO 15156-3-2009 Technical Circular 1 2010-06-20manuelazo78100% (2)

- AlloyDocument1 pageAlloyenemesio_85No ratings yet

- TALRUT InspectionDocument1 pageTALRUT Inspectionenemesio_85No ratings yet

- Ultrasonic Testing: Weld Inspection Using AWS D1.1Document65 pagesUltrasonic Testing: Weld Inspection Using AWS D1.1CLIFFORDPANo ratings yet

- Large Structure Inspection (LSI™) System: Pipelines Ship Hulls Storage Tanks Pressure VesselsDocument2 pagesLarge Structure Inspection (LSI™) System: Pipelines Ship Hulls Storage Tanks Pressure Vesselsenemesio_85No ratings yet

- ElectrodeDocument1 pageElectrodeenemesio_85No ratings yet

- Reporte Tq. CriogenicoDocument9 pagesReporte Tq. Criogenicoenemesio_85No ratings yet

- ANSI B31.3 Tratamiento TermicoDocument6 pagesANSI B31.3 Tratamiento Termicoenemesio_85No ratings yet

- Ucs 56Document1 pageUcs 56enemesio_85100% (1)

- Welding Positions For PipesDocument1 pageWelding Positions For Pipesenemesio_85No ratings yet

- Aws - Welding StandardDocument5 pagesAws - Welding Standardenemesio_85No ratings yet

- Welding PositionsDocument1 pageWelding Positionsenemesio_85No ratings yet

- Welding PositionsDocument1 pageWelding Positionsenemesio_85No ratings yet

- Practical Plate InspectionDocument8 pagesPractical Plate InspectionMohd Effiezool Yaser100% (1)

- ML 993360390Document37 pagesML 993360390enemesio_85No ratings yet

- Tuberias (Cedulas)Document21 pagesTuberias (Cedulas)enemesio_85No ratings yet

- Sound AttenuatorsDocument24 pagesSound Attenuatorsadeel_akhtarNo ratings yet

- DDNS Management System User's Manual V1.0 - 20120301Document7 pagesDDNS Management System User's Manual V1.0 - 20120301judapiesNo ratings yet

- Diesel Engine: Service Parts List ForDocument49 pagesDiesel Engine: Service Parts List ForIgnacio OsorioNo ratings yet

- CHAPTER 2 4.0 Three Phase SystemsDocument41 pagesCHAPTER 2 4.0 Three Phase SystemsMUHAMMAD ALIFF DANIAL RAZMINo ratings yet

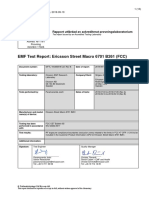

- EMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat ProvningslaboratoriumDocument13 pagesEMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat Provningslaboratoriumiogdfgkldf iodflgdfNo ratings yet

- Demo-C Tfin52 67Document5 pagesDemo-C Tfin52 67namank005No ratings yet

- 9040 - User ManualDocument236 pages9040 - User ManualWallie Billingsley77% (13)

- Bricks CalculationDocument3 pagesBricks CalculationAravindanNo ratings yet

- Quality Management Project On Quality Tools of "Ford Motors"Document6 pagesQuality Management Project On Quality Tools of "Ford Motors"Anuj SharmaNo ratings yet

- Military Standard for Circular Connector Insert ArrangementsDocument59 pagesMilitary Standard for Circular Connector Insert ArrangementsVadim RiabovNo ratings yet

- K1 RootingDocument20 pagesK1 RootingHassan BallouzNo ratings yet

- GE Con Perkins Más StamfordDocument2 pagesGE Con Perkins Más Stamfordjim perdigonNo ratings yet

- AMMONIUM SULPHATE, TECHNICAL SpecificationDocument10 pagesAMMONIUM SULPHATE, TECHNICAL Specificationbabji dudekulaNo ratings yet

- TMForumOpenAPIs EnablingAZeroIntergrationAPIeconomyDocument30 pagesTMForumOpenAPIs EnablingAZeroIntergrationAPIeconomyjdaoukNo ratings yet

- Detailed Lesson Plan in Science IVDocument12 pagesDetailed Lesson Plan in Science IVAgnes DumlaoNo ratings yet

- Sintesis Biodiesel Melalui Transesterifikasi Minyak Goreng Bekas Berbasis Katalis Heterogen Cao Dari Limbah Cangkang Telur AyamDocument6 pagesSintesis Biodiesel Melalui Transesterifikasi Minyak Goreng Bekas Berbasis Katalis Heterogen Cao Dari Limbah Cangkang Telur Ayamkarim kasmudinNo ratings yet

- Physics Exit 3q1718 .Document16 pagesPhysics Exit 3q1718 .Mikaella Tambis0% (1)

- Robohawks Team HandbookDocument11 pagesRobohawks Team Handbookapi-376756259No ratings yet

- Manual WkhtmltopdfDocument5 pagesManual WkhtmltopdfGeorge DiazNo ratings yet

- Project-BOQ - (Excluding VUP, LVUP)Document127 pagesProject-BOQ - (Excluding VUP, LVUP)Shivendra KumarNo ratings yet

- Wacker Silres Ren - 60 - Silicone Resin Solution For Medium Solids or High Solids Heat ResistancDocument3 pagesWacker Silres Ren - 60 - Silicone Resin Solution For Medium Solids or High Solids Heat ResistancJameel AhsanNo ratings yet

- ZI-Manual en PDFDocument56 pagesZI-Manual en PDFhaphapNo ratings yet

- Thermal Arc 161 STL 201 Ts Inverter Welder SM PDFDocument96 pagesThermal Arc 161 STL 201 Ts Inverter Welder SM PDFduyNo ratings yet

- Çimsa Eco White TDS (EN)Document1 pageÇimsa Eco White TDS (EN)Babu NysemereNo ratings yet

- RDSS L2 Pert Chart - PKG-04 - Joynagar.... 21082023Document5 pagesRDSS L2 Pert Chart - PKG-04 - Joynagar.... 21082023sourish69No ratings yet

- User Interface DesignDocument6 pagesUser Interface DesignpoojaqNo ratings yet

- M103C 10/11 Meter Maximum Beam AntennaDocument9 pagesM103C 10/11 Meter Maximum Beam AntennaRádio Técnica AuroraNo ratings yet

- G100-G102-Chassis-Manual #1Document151 pagesG100-G102-Chassis-Manual #1Daihatsu Charade BanjarnegaraNo ratings yet

- 319918Document4 pages319918Daniel BilickiNo ratings yet