Professional Documents

Culture Documents

ESPECIFICACIÓN DE E317lLT1-1

Uploaded by

Nj Nelson Javier0 ratings0% found this document useful (0 votes)

6 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageESPECIFICACIÓN DE E317lLT1-1

Uploaded by

Nj Nelson JavierCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

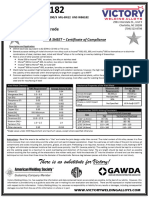

U.S. ALLOY CO.

317LT1-1 dba Washington Alloy

7010-G Reames Rd.

Flux Cored Wire Charlotte, NC 28216

www.weldingwire.com

Quality Management System

in accordance with

ISO 9001

Cert # 05-R0925

ALLOY DESCRIPTION AND APPLICATION;

E317LT1-1 is a flux-cored wire for single or multi-pass welds on stainless

steels. E317LT1-1 is noted for its low spatter generation, excellent bead shape and appearance and ease of

slag removal. It has very good deposit efficiency when used for flat and fillet welds of medium and heavy

thickness plates. It has been designed to be used with 100% CO2 shield gas. E317LT-1 provides weld

deposits with optimum ferrite content as its austenitic structure resulting in low susceptibility to cracking. The

extra low carbon content of E317LT-1 provides excellent resistance to inter- granular corrosion and stress

corrosion cracking caused by carbide precipitation. E317LT-1 also provides excellent resistance to pitting

corrosion due to its higher Molybdenum content compared to 316LT-1. Used extensively in the fabrication of

AISI type 317 stainless steel structures, pressure vessels, and tanks in dairy, pulp and paper, textile dyeing,

refinery and chemical equipment. The extra low carbon content reduces carbide precipitation. E317LT-1 can

be used to weld stainless steels of similar compositions when welds are required to meet higher resistance

requirements. One key advantage of E317LT-1 is its excellent resistance to pitting corrosion in chlorine

environments. It is also used for pollution control equipment where the corrosive attack is too severe for

E316LT-1 filler metal. E317LT0-1/-4 may be more fluid giving a flat to concave bead profile.

TYPICAL WELDING PROCEDURES; DCEP

Wire Diameter Wire Speed (ipm) Amps Volts Electrical Stickout CO2 (cfh)

0.045” 215-550 140-380 23-35 1/2-1” 35-50

1/16” 125-615 150-410 24-36 5/8-1.25 ” 35-50

Procedures may vary with change in position, base metals, filler metals, equipment and other changes.

CHEMISTRY (%) for Undiluted WELD METAL & PROPERTIES

AWS Requirements) Typical (AWS Requirements) Typical

Carbon 0.04 0.03 Molybdenum 3.00-4.00 3.59

Manganese 0.5-2.5 1.78 Phosphorus 0.04 0.024

Silicon 1.00 0.65 Sulfur 0.03 0.018

Chromium 18.0-21.0 18.95 Nickel 12.0-14.0 13.30

AWS Requirements As Welded

Tensile Strength (psi) 75,000 min. 88,600

Yield Strength (psi) N/A 76,750

Elongation 15% min. 34%

Iron balance and all single values are maximum percentages unless noted

AVAILABLE SIZES: TSF 317LT

Other sizes available – please inquire

SPECIFICATIONS; ANSI/AWS A5.22 E317LT0-1/-4 or E317LT1-1/-4

ASME SFA 5.22 E317LT0-1/-4 or E317LT1-1/-4

ASME F-6 , A-8

T0 = flat and horizontal: T1 = all position: -1 is for 100% CO2; -4 = 75-80 Ar /CO2

EAST COAST GULF COAST WEST COAST

7010-G Reames Rd 4755 Alpine Drive #100A 8535 Utica Ave

Charlotte, NC 28216 Stafford, TX 77477 Rancho Cucamonga, CA 91730

Tel (888) 522-8296 Tel (877) 711-9274 Tel (800)830-9033

Fax (704)598-6673 Fax (281)313-6332 Fax (909)291-4586 11-2016 DC

Warehouse Distribution Center – Portland, Oregon Head Office – Puyallup,

Washington Alloy Company believes that all information and data given is correct. Use this information to assist in making your

own evaluations or decisions and this information should not be mistaken as an expressed or implied warranty. U.S. ALLOY CO.

assumes no liability for results or damages incurred from the use of any information contained herein, in whole or in part.

You might also like

- USA 316L-17 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 316L-17 Coated Electrode: Alloy Description and ApplicationKaliyaperumal DhanapalNo ratings yet

- Aluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Document1 pageAluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Valli RajuNo ratings yet

- 253 MA Flux-Cored Wire: Alloy Description and ApplicationDocument1 page253 MA Flux-Cored Wire: Alloy Description and ApplicationGuilherme AugustoNo ratings yet

- Stainless Steel Flux Cored Tig: Alloy Description and ApplicationDocument1 pageStainless Steel Flux Cored Tig: Alloy Description and ApplicationNGUYEN VINHNo ratings yet

- 8018-B2L Low-Alloy Steel Electrode: Cert # 05-R0925Document1 page8018-B2L Low-Alloy Steel Electrode: Cert # 05-R0925Ehab AhmedNo ratings yet

- 9015-B9, 9018-B9 Low-Alloy Steel Electrode: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page9015-B9, 9018-B9 Low-Alloy Steel Electrode: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216m s sankar raoNo ratings yet

- 71t 1cDocument1 page71t 1cSuthan M RNo ratings yet

- USA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Nhien ManNo ratings yet

- USA 309L-16 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 309L-16 Coated Electrode: Alloy Description and ApplicationRaju ChaudharyNo ratings yet

- 1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Ilham Alwi KhunaefiNo ratings yet

- 7018 Wa - Alloy 2Document1 page7018 Wa - Alloy 2Khaled A MarashliNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- 4340 Chrome-Moly Welding Wire and Rod Spec SheetDocument1 page4340 Chrome-Moly Welding Wire and Rod Spec SheetPankaj KumbhareNo ratings yet

- 4140 Electrode PDFDocument1 page4140 Electrode PDFweerasinghekNo ratings yet

- 410 Welding Wire and RodDocument1 page410 Welding Wire and RodJenderalKancilNo ratings yet

- Ca 15Document2 pagesCa 15naraen9790579455No ratings yet

- Alloy 625 Wire & Rod: U.S. Alloy CoDocument1 pageAlloy 625 Wire & Rod: U.S. Alloy CowinstonsequeiraNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- Снимок экрана 2024—03—25 в 20.29.12Document10 pagesСнимок экрана 2024—03—25 в 20.29.127hb7zdthg9No ratings yet

- SS 309 All PropertiesDocument1 pageSS 309 All Propertiessharafudheen_sNo ratings yet

- 110S-1 Alloy Steel Welding Wire Data SheetDocument1 page110S-1 Alloy Steel Welding Wire Data SheetjavadmohammadiNo ratings yet

- Silverbraze 50ni2 BAg-24 AMS 4788 TDSDocument2 pagesSilverbraze 50ni2 BAg-24 AMS 4788 TDSChandrajeet ShelkeNo ratings yet

- ER4043Document1 pageER4043Luis Fidel Ramírez LópezNo ratings yet

- Applications: TYPE: Basic (Lime)Document1 pageApplications: TYPE: Basic (Lime)Tran van VuongNo ratings yet

- SOW 09380SB2T SpecSheetDocument2 pagesSOW 09380SB2T SpecSheetAi NayNo ratings yet

- AlloyDocument1 pageAlloyenemesio_85No ratings yet

- Aluminum A380Document4 pagesAluminum A380syuepiNo ratings yet

- L1_34385_en__U_UTP-AF-ROBOTIC-352_fde_enDocument1 pageL1_34385_en__U_UTP-AF-ROBOTIC-352_fde_enl.raickNo ratings yet

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNo ratings yet

- Oxford Alloy 385-16 (E385)Document1 pageOxford Alloy 385-16 (E385)brunizzaNo ratings yet

- Astm A335 PDFDocument11 pagesAstm A335 PDFJACILDO SOARES CAVALCANTE100% (1)

- SAE - AMS 5659mv004Document9 pagesSAE - AMS 5659mv004Nilesh PatilNo ratings yet

- Mil H 25579Document22 pagesMil H 25579Senthil KumarNo ratings yet

- Duplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Document6 pagesDuplex Stainless Steel AL 2205™ Alloy: (UNS S31803 and S32205)Dell_RevanNo ratings yet

- Astm A513 PDFDocument20 pagesAstm A513 PDFpradelles89% (9)

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- 8-12-8 Fabrication of Piping PDFDocument7 pages8-12-8 Fabrication of Piping PDFasif rahimNo ratings yet

- Oxford Alloy 625T-1 (ENiCrMo3T1-1)Document1 pageOxford Alloy 625T-1 (ENiCrMo3T1-1)brunizzaNo ratings yet

- Metalloy 80N1 Gas-Shielded Metal-Cored Wire for Nickel-Molybdenum SteelsDocument2 pagesMetalloy 80N1 Gas-Shielded Metal-Cored Wire for Nickel-Molybdenum SteelsClaudia MmsNo ratings yet

- 4140 Chrome-Moly Electrode: Alloy Description and ApplicationDocument1 page4140 Chrome-Moly Electrode: Alloy Description and ApplicationCarmenJuliaNo ratings yet

- Welded Large Diameter Austenitic Steel Pipe For Corrosive or High-Temperature ServiceDocument7 pagesWelded Large Diameter Austenitic Steel Pipe For Corrosive or High-Temperature ServiceالGINIRAL FREE FIRENo ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- Sae Ams 5554F-2011Document5 pagesSae Ams 5554F-2011Mehdi MokhtariNo ratings yet

- Quality American Filler Metals ManufacturerDocument15 pagesQuality American Filler Metals ManufacturerbrunizzaNo ratings yet

- Alloy 4643 welding dataDocument2 pagesAlloy 4643 welding databastosgabiNo ratings yet

- How To Weld Fully Austenitic Stainless SteelsDocument20 pagesHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNo ratings yet

- Seamless Ferritic Alloy-Steel Pipe For High-Temperature ServiceDocument11 pagesSeamless Ferritic Alloy-Steel Pipe For High-Temperature Serviceist93993No ratings yet

- Sites Process Steelcastings Pages MaterialsDocument9 pagesSites Process Steelcastings Pages Materialschand_yelNo ratings yet

- A512-06 (2012) Standard Specification For Cold-Drawn Buttweld Carbon Steel Mechanical TubingDocument20 pagesA512-06 (2012) Standard Specification For Cold-Drawn Buttweld Carbon Steel Mechanical TubingChuthaNo ratings yet

- E309LT1Document1 pageE309LT1Edgar HornusNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Eng A Comparative S.c.chaudhariDocument8 pagesEng A Comparative S.c.chaudhariImpact JournalsNo ratings yet

- Sigmacover™ 456: Product Data SheetDocument6 pagesSigmacover™ 456: Product Data SheetscottNo ratings yet

- Investigation of Flow Inside An Axial-Flow PumpDocument16 pagesInvestigation of Flow Inside An Axial-Flow PumptafocanNo ratings yet

- Generador Electrico Aska - Apd75c-6Document4 pagesGenerador Electrico Aska - Apd75c-6Nj Nelson JavierNo ratings yet

- Postgraduate Prospectus 2021: World ChangersDocument35 pagesPostgraduate Prospectus 2021: World ChangersSKNo ratings yet

- Nursing Health History SummaryDocument1 pageNursing Health History SummaryHarvey T. Dato-onNo ratings yet

- EngM6 TB WebDocument161 pagesEngM6 TB WebNong BillNo ratings yet

- Internal and external factors affecting pricing decisionsDocument6 pagesInternal and external factors affecting pricing decisionsNguyễn YếnNo ratings yet

- Eight Lane Vadodara Kim ExpresswayDocument11 pagesEight Lane Vadodara Kim ExpresswayUmesh SutharNo ratings yet

- Burnelli AircraftDocument51 pagesBurnelli Aircraftretread1100% (3)

- Buwis ButilDocument2 pagesBuwis ButilHelbert Agluba PaatNo ratings yet

- RGB PDFDocument35 pagesRGB PDFGestion Medios Zamba ColorsNo ratings yet

- Sri Bhavishya Educational AcademyDocument4 pagesSri Bhavishya Educational AcademyAnonymous A6Jnef04No ratings yet

- 279 Glenridge Avenue, St. Catharines ON, LST 3K3: "Agriculture and Irrigation Solutions". Contech Engineered SolutionsDocument52 pages279 Glenridge Avenue, St. Catharines ON, LST 3K3: "Agriculture and Irrigation Solutions". Contech Engineered Solutionsapi-251312018No ratings yet

- Jenkins Lab Guide: 172-172, 5th Floor Old Mahabalipuram Road (Above Axis Bank-PTC Bus Stop) Thuraipakkam Chennai 600097Document45 pagesJenkins Lab Guide: 172-172, 5th Floor Old Mahabalipuram Road (Above Axis Bank-PTC Bus Stop) Thuraipakkam Chennai 600097thecoinmaniac hodlNo ratings yet

- Connected Topological Spaces: Definition 3.1.1Document22 pagesConnected Topological Spaces: Definition 3.1.1WilmerAlexanderVivasNogueraNo ratings yet

- Xray Order FormDocument1 pageXray Order FormSN Malenadu CreationNo ratings yet

- DTMF Relay and Interworking On CUBE PDFDocument18 pagesDTMF Relay and Interworking On CUBE PDFEngin KartalNo ratings yet

- 2013 Course Structure BTech CSEDocument32 pages2013 Course Structure BTech CSEMankush JainNo ratings yet

- Learning and Teaching in The Clinical EnvironmentDocument4 pagesLearning and Teaching in The Clinical EnvironmentDaniel Alejandro Lozano MorenoNo ratings yet

- 0000 0000 0335Document40 pages0000 0000 0335Hari SetiawanNo ratings yet

- iGCSE Anthology English Language A and English LiteratureDocument25 pagesiGCSE Anthology English Language A and English LiteratureBubbleNo ratings yet

- Edu Mphil SyllabusDocument27 pagesEdu Mphil Syllabussollu786_889163149No ratings yet

- FulfillerDocument8 pagesFulfillermanojeil1No ratings yet

- Generator Honda EP2500CX1Document50 pagesGenerator Honda EP2500CX1Syamsul Bahry HarahapNo ratings yet

- FisheryDocument2 pagesFisheryKyle GalangueNo ratings yet

- Programme EnergyDocument9 pagesProgramme EnergyAbdulazizNo ratings yet

- Soal Bing XiDocument9 pagesSoal Bing XiRhya GomangNo ratings yet

- Assurance Question Bank 2013 PDFDocument168 pagesAssurance Question Bank 2013 PDFIan RelacionNo ratings yet

- The Dilemma of Recognition Experienced Reality of Ethnicised Politics in Rwanda and BurundiDocument192 pagesThe Dilemma of Recognition Experienced Reality of Ethnicised Politics in Rwanda and BurundiShenandoa LeãoNo ratings yet

- Class Will and TestamentDocument4 pagesClass Will and TestamentAllan Tomas33% (3)

- Accounting for Inventory Valuation Methods Research ProposalDocument66 pagesAccounting for Inventory Valuation Methods Research ProposalAyman Ahmed Cheema100% (1)

- Catch Up Friday 011153Document3 pagesCatch Up Friday 011153Vanessa Pond100% (6)

- Electrode ChemDocument17 pagesElectrode Chemapi-372366467% (3)