Professional Documents

Culture Documents

4340 Chrome-Moly Welding Wire and Rod Spec Sheet

Uploaded by

Pankaj Kumbhare0 ratings0% found this document useful (0 votes)

26 views1 pageThis document provides information about 4340 chrome-moly welding wire and rod from U.S. Alloy Co., including:

1) 4340 is a chromium-molybdenum alloy used for welding heat-treatable steels like 4340 and 4330, requiring preheat and possibly post-weld heat treatment.

2) Typical gas metal arc welding procedures are provided for various wire diameters and voltages.

3) Typical gas tungsten arc welding procedures and filler wire sizes are also listed for different material thicknesses.

Original Description:

Original Title

4340 Wire for Low Alloy Steels

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information about 4340 chrome-moly welding wire and rod from U.S. Alloy Co., including:

1) 4340 is a chromium-molybdenum alloy used for welding heat-treatable steels like 4340 and 4330, requiring preheat and possibly post-weld heat treatment.

2) Typical gas metal arc welding procedures are provided for various wire diameters and voltages.

3) Typical gas tungsten arc welding procedures and filler wire sizes are also listed for different material thicknesses.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views1 page4340 Chrome-Moly Welding Wire and Rod Spec Sheet

Uploaded by

Pankaj KumbhareThis document provides information about 4340 chrome-moly welding wire and rod from U.S. Alloy Co., including:

1) 4340 is a chromium-molybdenum alloy used for welding heat-treatable steels like 4340 and 4330, requiring preheat and possibly post-weld heat treatment.

2) Typical gas metal arc welding procedures are provided for various wire diameters and voltages.

3) Typical gas tungsten arc welding procedures and filler wire sizes are also listed for different material thicknesses.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

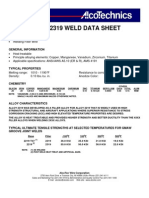

U.S. ALLOY CO.

4340 Chrome-Moly dba Washington Alloy

7010-G Reames Rd.

Welding Wire and Rod Charlotte, NC 28216

www.weldingwire.com

Quality Management System

in accordance with

ISO 9001:2000

Cert # 05-R0925 ALLOY DESCRIPTION AND APPLICATION;

4340 is a Chromium-molybdenum low alloy wire that will produce

a dense, heat-treatable deposit. This alloy is used to weld AISI/SAE 4340 and 4330 and

other heat-treatable alloys or base metals needing flame hardening. Preheat and inter-pass

recommended and may also need followed by post heat treating.

(1)

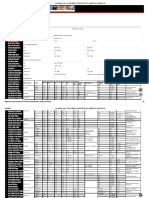

TYPICAL GMAW WELDING PROCEDURES; DCEP Short Circuit 98Ar/2% O2

Wire Diameter Wire Speed (ipm) Amps Volts Travel speed (ipm) (cfh) 75/25

0.023 80-350 30-85 14-19 10-15 20-25

0.030 110-340 40-130 15-20 12-24 20-25

0.035 100-520 60-235 16-25 11-40 20-30

0.045 70-270 90-290 18-23 12-22 25-35

(1)

Spray 0.035 320-600 160-300 23-26 11-22 25-35

(1)

0.045 170-550 170-375 23-29 12-21 25-35

(1)

1/16” 175-350 275-475 25-31 9-19 25-35

TYPICAL GTAW WELDING PROCEDURES; DCEN with EWTh-2 truncated conical tip

Filler Wire Size Tungsten Amps Volts Gas Cup Size Argon (cfh) Base thickness

1/16” 1/16” 100-160 12 3/8” 20 1/16-3/32”

1/16-3/32” 3/32” 120-250 12 3/8” 20 1/8- 3/16”

1/8” 1/8” 150-300 12 1/2” 25 1/4-1/2”

Procedures may vary with change in position, base metals, filler metals, equipment and other

changes.

TYPICAL WELD CHEMISTRY (%)& WELD METAL PROPERTIES; 100%Ar (GTAW)

PWHT: completely annealed

Carbon 0.35 welded post weld re-heat treated

Manganese 0.85 oil quenched at 1600°F then

Silicon 0.50 Tempered at 1150° F 950° F

Phosphorus 0.011 Tensile Strength (psi) 200,000 289,000

Sulfur 0.014 Yield Strength (psi) 168,000 250,000

Chromium 0.78

Nickel 1.80

Molybdenum 0.25

AVAILABLE SIZES: TU 4340 = Spools and rods of

Vacuum melted, Flux cored and Metal core alloys also available

SPECIFICATIONS; AISI/SAE 4340

EAST COAST GULF COAST WEST COAST

7010-G Reames Rd 4855 Alpine Drive #190 8535 Utica Ave

Charlotte, NC 28216 Stafford, TX 77477 Rancho Cucamonga, CA 91730

Tel (888) 522-8296 Tel (877) 711-9274 Tel(800)830-9033 1-2008 DC

Fax (704)598-6673 Fax (281)313-6332 Fax (909)291-4586

Warehouse Distribution Center – Dayton, Ohio Head Office – Puyallup, Washington

Washington Alloy Company believes that all information and data given is correct. Use this information to assist in making your

own evaluations or decisions and this information should not be mistaken as an expressed or implied warranty. U.S. ALLOY CO.

assumes no liability for results or damages incurred from the use of any information contained herein, in whole or in part.

You might also like

- Welding Handbook v68Document390 pagesWelding Handbook v68Bryan Brito100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Magnet 4 DocDocument4 pagesMagnet 4 DocMIS NURUL IMAN JakbarNo ratings yet

- Fastener BasicsDocument2 pagesFastener BasicsDigvijay Singh IINo ratings yet

- Duplex Stainless Steels: Properties and Welding TechniquesDocument25 pagesDuplex Stainless Steels: Properties and Welding Techniqueskdsenipah6667No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Is 3075Document12 pagesIs 3075rajeevkumarrajeevNo ratings yet

- En1092 Flange StandardDocument70 pagesEn1092 Flange Standardmubs997100% (3)

- DT & NDTDocument46 pagesDT & NDTThulasi RamNo ratings yet

- Material Grade Comparison TableDocument6 pagesMaterial Grade Comparison TableGhazali Zuberi100% (3)

- Pneumatic Sheet Metal Cutting MachineDocument24 pagesPneumatic Sheet Metal Cutting MachineMyneni Sriram70% (10)

- Workshop ManualDocument113 pagesWorkshop ManualAkash JainNo ratings yet

- Asme Section Ii A Sa-414 Sa-414m PDFDocument4 pagesAsme Section Ii A Sa-414 Sa-414m PDFdavid perezNo ratings yet

- Final Examination #1: Open Book Questions (1 50)Document29 pagesFinal Examination #1: Open Book Questions (1 50)kiho sung100% (1)

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- 110S-1 Alloy Steel Welding Wire Data SheetDocument1 page110S-1 Alloy Steel Welding Wire Data SheetjavadmohammadiNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- 410 Welding Wire and RodDocument1 page410 Welding Wire and RodJenderalKancilNo ratings yet

- USA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Nhien ManNo ratings yet

- 1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Ilham Alwi KhunaefiNo ratings yet

- SS 309 All PropertiesDocument1 pageSS 309 All Propertiessharafudheen_sNo ratings yet

- 71t 1cDocument1 page71t 1cSuthan M RNo ratings yet

- 4140 Electrode PDFDocument1 page4140 Electrode PDFweerasinghekNo ratings yet

- 7018 Wa - Alloy 2Document1 page7018 Wa - Alloy 2Khaled A MarashliNo ratings yet

- USA 309L-16 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 309L-16 Coated Electrode: Alloy Description and ApplicationRaju ChaudharyNo ratings yet

- 9015-B9, 9018-B9 Low-Alloy Steel Electrode: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page9015-B9, 9018-B9 Low-Alloy Steel Electrode: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216m s sankar raoNo ratings yet

- Stainless Steel Flux Cored Tig: Alloy Description and ApplicationDocument1 pageStainless Steel Flux Cored Tig: Alloy Description and ApplicationNGUYEN VINHNo ratings yet

- Alloy 4047 Weld Data SheetDocument2 pagesAlloy 4047 Weld Data SheetMarcoAntonioNo ratings yet

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- 8018-B2L Low-Alloy Steel Electrode: Cert # 05-R0925Document1 page8018-B2L Low-Alloy Steel Electrode: Cert # 05-R0925Ehab AhmedNo ratings yet

- ESPECIFICACIÓN DE E317lLT1-1Document1 pageESPECIFICACIÓN DE E317lLT1-1Nj Nelson JavierNo ratings yet

- 253 MA Flux-Cored Wire: Alloy Description and ApplicationDocument1 page253 MA Flux-Cored Wire: Alloy Description and ApplicationGuilherme AugustoNo ratings yet

- 6010Document1 page6010mateo zamoraNo ratings yet

- SOW 09380SB2T SpecSheetDocument2 pagesSOW 09380SB2T SpecSheetAi NayNo ratings yet

- Er70S-6 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-6 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- INDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Document6 pagesINDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Roberto AlvarezNo ratings yet

- Alloy 2319 welding data sheetDocument2 pagesAlloy 2319 welding data sheetSyam NathNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- Applications: TYPE: Basic (Lime)Document1 pageApplications: TYPE: Basic (Lime)Tran van VuongNo ratings yet

- USA 316L-17 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 316L-17 Coated Electrode: Alloy Description and ApplicationKaliyaperumal DhanapalNo ratings yet

- AWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsDocument56 pagesAWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsFakhar WindratamaNo ratings yet

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- 1100 Data SheetDocument1 page1100 Data SheetMuhammad Whisnu NugrahaNo ratings yet

- Pinnacle Alloys ENiCrFe 3 12.16Document2 pagesPinnacle Alloys ENiCrFe 3 12.16satnamNo ratings yet

- C7025 (英文) ver1 6Document11 pagesC7025 (英文) ver1 6顏健軒No ratings yet

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocument1 pageSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNo ratings yet

- ER4043Document1 pageER4043Luis Fidel Ramírez LópezNo ratings yet

- Ficha Tecnica ER-316LDocument1 pageFicha Tecnica ER-316LOscar ZavaletaNo ratings yet

- Typical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Document20 pagesTypical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Samuel LatumahinaNo ratings yet

- Cd-4Mcu: Alloy Data SheetDocument2 pagesCd-4Mcu: Alloy Data SheetFlowline PumpsNo ratings yet

- 817M40 PDFDocument2 pages817M40 PDFSamir ChaudharyNo ratings yet

- E7018 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7018 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Er70S-2 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-2 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Aluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Document1 pageAluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Valli RajuNo ratings yet

- Er 70s2 PDFDocument1 pageEr 70s2 PDFtaravindnagarajNo ratings yet

- Alloy 6005A: We Are AluminumDocument2 pagesAlloy 6005A: We Are AluminumLeo PardNo ratings yet

- 4140 Chrome-Moly Electrode: Alloy Description and ApplicationDocument1 page4140 Chrome-Moly Electrode: Alloy Description and ApplicationCarmenJuliaNo ratings yet

- Reaming Speeds and Feeds PDFDocument1 pageReaming Speeds and Feeds PDFWarrior TempurNo ratings yet

- Ca 15Document2 pagesCa 15naraen9790579455No ratings yet

- BOHLER FOX S EV 50-1 Stick ElectrodeDocument1 pageBOHLER FOX S EV 50-1 Stick ElectrodeKrishna Vacha100% (1)

- Factors of A Safe Residential Electrical InstallationDocument32 pagesFactors of A Safe Residential Electrical InstallationjporangecubeNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

- Midalloy ER80S-B6 Welding Wire Technical BulletinDocument1 pageMidalloy ER80S-B6 Welding Wire Technical Bulletinjoel cisnerosNo ratings yet

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification SheetShaneNo ratings yet

- Bohler Fox S Ev 50: Stick Electrode, Unalloyed BasicDocument1 pageBohler Fox S Ev 50: Stick Electrode, Unalloyed Basickiki270977No ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Codes and StandardsDocument10 pagesCodes and StandardsPankaj KumbhareNo ratings yet

- Copper Alloy: Leaded Gun Metal Cusn5Zn5Pb5-CDocument1 pageCopper Alloy: Leaded Gun Metal Cusn5Zn5Pb5-CPankaj KumbhareNo ratings yet

- BronzeLG2LeadedGunmetalBronze PDFDocument2 pagesBronzeLG2LeadedGunmetalBronze PDFAnthonyNo ratings yet

- Phosphor Bronze To Bs 1400: Pb2Document1 pagePhosphor Bronze To Bs 1400: Pb2Suresh NairNo ratings yet

- 421 - Domex 700 MCDocument2 pages421 - Domex 700 MClalamed21No ratings yet

- Cushion Connector CompressedDocument2 pagesCushion Connector CompressedAndreeNo ratings yet

- Sprocket MartinDocument16 pagesSprocket MartinAnonymous hXUhpe7SNo ratings yet

- Titanium Nitride (Tin) : Physical Vapour Deposition (PVD) Process. The Coating Has High Hardness and LowDocument19 pagesTitanium Nitride (Tin) : Physical Vapour Deposition (PVD) Process. The Coating Has High Hardness and LowhadeNo ratings yet

- B 308 - B 308M - 02 Qjmwoc9cmza4tqDocument6 pagesB 308 - B 308M - 02 Qjmwoc9cmza4tqGalih PutraNo ratings yet

- D2 Tool SteelDocument1 pageD2 Tool SteelMarwan ShehataNo ratings yet

- Crosby - Hoist RingDocument3 pagesCrosby - Hoist RingYADAGIRI REDDYNo ratings yet

- A 663 - A 663M - 89 R00 - Qty2my9bnjyztqDocument3 pagesA 663 - A 663M - 89 R00 - Qty2my9bnjyztqAbram MejiaNo ratings yet

- Design and Specifying High Strength Corrosion Resistant Reinforcing SteelDocument38 pagesDesign and Specifying High Strength Corrosion Resistant Reinforcing SteelaljaycruzadoNo ratings yet

- Model: P255-Fully Stainless Steel Construction: Crimped-On-Ring Case Pressure GaugeDocument6 pagesModel: P255-Fully Stainless Steel Construction: Crimped-On-Ring Case Pressure GaugetaibkNo ratings yet

- 300 AS 3679.1 (Australia) : StandardsDocument2 pages300 AS 3679.1 (Australia) : StandardsFrank SunNo ratings yet

- H44X2-Check Valve-ValveDocument2 pagesH44X2-Check Valve-ValveAlvi SarowarNo ratings yet

- Roqtuf PDFDocument6 pagesRoqtuf PDFLeonidio CamposNo ratings yet

- Critical valve repair kits and sealsDocument30 pagesCritical valve repair kits and sealsFrendy RianNo ratings yet

- Aalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Document4 pagesAalco Metals LTD Stainless Steel 1.4542 17 4 PH 100Sergio CLNo ratings yet

- Kit Notes For Clyde Puffer Steam Cargo BoatDocument7 pagesKit Notes For Clyde Puffer Steam Cargo Boatn00113031No ratings yet

- Soal Non FerrousDocument5 pagesSoal Non FerrousPuja PradnyanaNo ratings yet

- Irst 19Document12 pagesIrst 19krischaeverNo ratings yet

- Jayee Screens BrochureDocument12 pagesJayee Screens BrochuresearchengineXNo ratings yet

- Long Span and High-Rise Steel ConstructionDocument89 pagesLong Span and High-Rise Steel Constructionကိုနေဝင်း100% (1)

- Duplex 2209 Weld Overlay by ESSC Process: Er. Manoj Kumar, Dr. Abhishek KambojDocument7 pagesDuplex 2209 Weld Overlay by ESSC Process: Er. Manoj Kumar, Dr. Abhishek KambojAyyappanSubramanianNo ratings yet

- Sa 105 PDFDocument10 pagesSa 105 PDFkumarNo ratings yet

- Different Casting Methods ExplainedDocument14 pagesDifferent Casting Methods ExplainedRamoji Aditya Chary100% (1)