Professional Documents

Culture Documents

Stainless Steel Flux Cored Tig: Alloy Description and Application

Uploaded by

NGUYEN VINHOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stainless Steel Flux Cored Tig: Alloy Description and Application

Uploaded by

NGUYEN VINHCopyright:

Available Formats

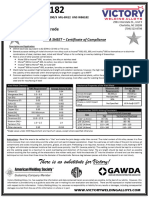

U.S. ALLOY CO.

STAINLESS STEEL dba Washington Alloy

7010-G Reames Rd.

Flux Cored Tig Charlotte, NC 28216

www.weldingwire.com

Quality Management System

in accordance with

ISO 9001:2000

Cert # 05-R0925

ALLOY DESCRIPTION AND APPLICATION;

These flux cored rods are primarily used for the root pass on piping where backing and

purging gas may not be possible or desirable. This rod should be used as a basic tig rod

on DCEN, however caution is advised due to the easily removable slag covering that

must be removed prior to addition welding.

TYPICAL GTAW WELDING PROCEDURES; DCEN 100% Argon

Wire Diameter Amps Volts

2.2mm (.087”) 100-250 12-13

Procedures may vary with change in position, base metals, filler metals, equipment and other

changes.

TYPICAL UNDILUTED METAL CHEMISTRY (%) per AWS A5.22;

Chemistry

Grade 1) Intended Use

C Cr Ni Mo

R308L 0.03 18.0-21.0 9.0-11.0 0.50 Welding of 18Cr & 8Ni such as 304, 304L

R309L 0.03 22.0-25.0 12.0-14.0 0.50 Welding of carbon steel to austenitic stainless

R316L 0.03 17.0-20.0 11.0-14.0 2.0-3.0 Primarily use on 316 or 316L

R347 2) 0.08 18.0-21.0 9.0-11.0 0.50 Primarily use on 347

1) All grades has the following : Mn=0.50-2.5, Si=1.2, P=0.04, S=0.03 Cu=0.50 Single values are maximum

2) R347 also has Cb+Ta =8xCmin. -1.0 max.

Grade Tensile Strength, minimum Elongation Percent, minimum

R308L 75,000 35

R309L 75,000 30

R316L 70,000 30

R347 75,000 30

AVAILABLE SIZES: TST 308LT1-5 = Rods of 2.2mm x 915mm

TST 309LT1-5 = Rods of 2.2mm x 915mm

TST 316LT1-5 = Rods of 2.2mm x 915mm

TST 347LT1-5 = Rods of 2.2mm x 915mm

SPECIFICATIONS: Washington Alloy per AWS for stainless flux cored rods chemistry only

EAST COAST GULF COAST WEST COAST

7010-G Reames Rd 4855 Alpine Drive #190 8535 Utica Ave

Charlotte, NC 28216 Stafford, TX 77477 Rancho Cucamonga, CA 91730

Tel (888) 522-8296 Tel (877) 711-9274 Tel(800)830-9033

Fax (704)598-6673 Fax (281)313-6332 Fax (909)291-4586

9-2008 DC

Washington Alloy Company believes that all information and data given is correct. Use this information to assist in making your

own evaluations or decisions and this information should not be mistaken as an expressed or implied warranty. U.S. ALLOY CO.

assumes no liability for results or damages incurred from the use of any information contained herein, in whole or in part.

.

You might also like

- USA 316L-17 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 316L-17 Coated Electrode: Alloy Description and ApplicationKaliyaperumal DhanapalNo ratings yet

- ESPECIFICACIÓN DE E317lLT1-1Document1 pageESPECIFICACIÓN DE E317lLT1-1Nj Nelson JavierNo ratings yet

- USA 309L-16 Coated Electrode: Alloy Description and ApplicationDocument1 pageUSA 309L-16 Coated Electrode: Alloy Description and ApplicationRaju ChaudharyNo ratings yet

- 71t 1cDocument1 page71t 1cSuthan M RNo ratings yet

- 8018-B2L Low-Alloy Steel Electrode: Cert # 05-R0925Document1 page8018-B2L Low-Alloy Steel Electrode: Cert # 05-R0925Ehab AhmedNo ratings yet

- 7018 Wa - Alloy 2Document1 page7018 Wa - Alloy 2Khaled A MarashliNo ratings yet

- 4340 Chrome-Moly Welding Wire and Rod Spec SheetDocument1 page4340 Chrome-Moly Welding Wire and Rod Spec SheetPankaj KumbhareNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- USA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Nhien ManNo ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- 9015-B9, 9018-B9 Low-Alloy Steel Electrode: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page9015-B9, 9018-B9 Low-Alloy Steel Electrode: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216m s sankar raoNo ratings yet

- 4140 Electrode PDFDocument1 page4140 Electrode PDFweerasinghekNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- SS 309 All PropertiesDocument1 pageSS 309 All Propertiessharafudheen_sNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- 410 Welding Wire and RodDocument1 page410 Welding Wire and RodJenderalKancilNo ratings yet

- 110S-1 Alloy Steel Welding Wire Data SheetDocument1 page110S-1 Alloy Steel Welding Wire Data SheetjavadmohammadiNo ratings yet

- 253 MA Flux-Cored Wire: Alloy Description and ApplicationDocument1 page253 MA Flux-Cored Wire: Alloy Description and ApplicationGuilherme AugustoNo ratings yet

- Aluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Document1 pageAluminum Bronze A2 Welding Wire and Rod: Cert # 05-R0925Valli RajuNo ratings yet

- 1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Document1 page1100 Aluminum Welding Wire: Dba Washington Alloy 7010-G Reames Rd. Charlotte, NC 28216Ilham Alwi KhunaefiNo ratings yet

- Alloy 6005A: We Are AluminumDocument2 pagesAlloy 6005A: We Are AluminumLeo PardNo ratings yet

- AWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsDocument56 pagesAWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsFakhar WindratamaNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Elettrodo Per Alluminio e Sue Leghe AWS A5.3 - E4043 (Selectarc - Eurosald Mod. AL105)Document1 pageElettrodo Per Alluminio e Sue Leghe AWS A5.3 - E4043 (Selectarc - Eurosald Mod. AL105)Eraldo MigliavaccaNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- CHF101 Flux Wire ComboDocument1 pageCHF101 Flux Wire ComboImmalatulhusnaNo ratings yet

- Pinnacle Alloys ENiCrFe 3 12.16Document2 pagesPinnacle Alloys ENiCrFe 3 12.16satnamNo ratings yet

- Duplex SSDocument2 pagesDuplex SSsjk_akolNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- Revofil R308Lt: Stainless Filler MetalDocument1 pageRevofil R308Lt: Stainless Filler MetalAris WicaksonoNo ratings yet

- 5183 Aluminum Welding WireDocument1 page5183 Aluminum Welding Wiresank79No ratings yet

- SAW Fluxes Stainless and Heat Resistant Steels: Basicity To BoniszewskiDocument3 pagesSAW Fluxes Stainless and Heat Resistant Steels: Basicity To BoniszewskiSungJun ParkNo ratings yet

- Aws Er70sDocument4 pagesAws Er70smanofNo ratings yet

- KST 309LDocument1 pageKST 309LTharman SupramaniamNo ratings yet

- Welding Instructions For Toolholders: Material Microalloyed Heat-Treatable Steel 34Mncrb4+TiDocument1 pageWelding Instructions For Toolholders: Material Microalloyed Heat-Treatable Steel 34Mncrb4+TiVetriselvan ArumugamNo ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Class: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageDocument2 pagesClass: Er410 Aws: A5.9: Request A Quotedata Sheetmaterial Safety Sheetback To Products PageAditya PrajasNo ratings yet

- SAw Wire MedDocument1 pageSAw Wire MedvahidNo ratings yet

- CHS29 9Document1 pageCHS29 9sulis setiawanNo ratings yet

- OK 67.70 ESAB 309moDocument1 pageOK 67.70 ESAB 309moSadashiva sahooNo ratings yet

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinNo ratings yet

- CHF101 CHW S16 PDFDocument1 pageCHF101 CHW S16 PDFImmalatulhusnaNo ratings yet

- S-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDDocument6 pagesS-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDSergio AlejandroNo ratings yet

- Silverbraze 50ni2 BAg-24 AMS 4788 TDSDocument2 pagesSilverbraze 50ni2 BAg-24 AMS 4788 TDSChandrajeet ShelkeNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Duplex Stainless Steels: Properties and Welding TechniquesDocument25 pagesDuplex Stainless Steels: Properties and Welding Techniqueskdsenipah6667No ratings yet

- Hot Rolled Structural Steel Plate Data SheetDocument2 pagesHot Rolled Structural Steel Plate Data SheetHugo RodriguezNo ratings yet

- Cellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499Document4 pagesCellulosic Electrodes: Brand AWS A/SFA 5.1/5.5 EN 499ashwini shuklaNo ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- 6010Document1 page6010mateo zamoraNo ratings yet

- Stainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16Document10 pagesStainless Steel Stick Electrodes: Aws E309-16 Aws E309Mo-16 Aws E309Mol-16ManuelNo ratings yet

- Duplex-Alloy-2205-Stress ValuesDocument5 pagesDuplex-Alloy-2205-Stress ValuesShiniNo ratings yet

- Kevinsteel SA 1210Document4 pagesKevinsteel SA 1210meisamNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Variable Displacement AC CompressorsDocument6 pagesVariable Displacement AC CompressorsNGUYEN VINHNo ratings yet

- ASME - IX - 2019 - Boiler - and - Pressure - Vessel (P-No. Listing)Document2 pagesASME - IX - 2019 - Boiler - and - Pressure - Vessel (P-No. Listing)NGUYEN VINHNo ratings yet

- MS-G-003 - General Method Statement For Horizontal PumpDocument19 pagesMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHNo ratings yet

- Nguyen Van Kien (FCAW)Document1 pageNguyen Van Kien (FCAW)NGUYEN VINHNo ratings yet

- En1092 Flange StandardDocument70 pagesEn1092 Flange Standardmubs997100% (3)

- JIS G34431 : 2007 EN Combined PDF LicenseDocument19 pagesJIS G34431 : 2007 EN Combined PDF LicenseNGUYEN VINHNo ratings yet

- Installation Method for Key Process EquipmentDocument54 pagesInstallation Method for Key Process EquipmentNGUYEN VINHNo ratings yet

- WEC-CM-MS-0...... Method Statement For Tower Crane InstallationDocument29 pagesWEC-CM-MS-0...... Method Statement For Tower Crane InstallationNGUYEN VINHNo ratings yet

- JIS Z 3212-2000 Covered Electrodes For High Tensile SteelDocument12 pagesJIS Z 3212-2000 Covered Electrodes For High Tensile SteelNGUYEN VINHNo ratings yet

- Welding Procedure PreparationDocument122 pagesWelding Procedure Preparationthe_badass1234100% (21)

- WEC-CM-MS-0...... Method Statement For Tower Crane InstallationDocument29 pagesWEC-CM-MS-0...... Method Statement For Tower Crane InstallationNGUYEN VINHNo ratings yet

- Installation Method for Key Process EquipmentDocument54 pagesInstallation Method for Key Process EquipmentNGUYEN VINHNo ratings yet

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONNo ratings yet

- TGX 308L 316L 309L 347Document2 pagesTGX 308L 316L 309L 347NGUYEN VINHNo ratings yet

- Ky Hieu Moi HanDocument16 pagesKy Hieu Moi HanNGUYEN VINHNo ratings yet

- Sapa Pipe and TubeTechnical Inserts June 2011Document10 pagesSapa Pipe and TubeTechnical Inserts June 2011mekag94No ratings yet

- NDT For QC Inspector: "Khuyeát Taät Haøn, Nguyeân Nhaân Vaø Caùch Khaéc Phuïc"Document41 pagesNDT For QC Inspector: "Khuyeát Taät Haøn, Nguyeân Nhaân Vaø Caùch Khaéc Phuïc"NGUYEN VINHNo ratings yet

- Flamethrower Using Isopropyl Alcohol and Butane LighterDocument3 pagesFlamethrower Using Isopropyl Alcohol and Butane LighterAymara Montilla GonzalezNo ratings yet

- The Breakpoint Experiment: Determining Chlorine Residual in WaterDocument3 pagesThe Breakpoint Experiment: Determining Chlorine Residual in Waterg_trifonov100% (2)

- GK Technique (WWW - Admissionwar)Document41 pagesGK Technique (WWW - Admissionwar)Sahabur Rahman ShaonNo ratings yet

- Philippine Environmental Laws OverviewDocument34 pagesPhilippine Environmental Laws OverviewRadie ArnaldoNo ratings yet

- Effect of Nitrogen, Phosphorus and Potassium Fertilization On Growth, Yield and Quality of Pomegranate 'Kandhari'Document7 pagesEffect of Nitrogen, Phosphorus and Potassium Fertilization On Growth, Yield and Quality of Pomegranate 'Kandhari'Faten AbdallahNo ratings yet

- Main Groups in the Modern Periodic TableDocument4 pagesMain Groups in the Modern Periodic TableMohamed MohamedNo ratings yet

- Hospira VincristineDocument9 pagesHospira VincristineIvenks EeNo ratings yet

- Chemical Kinetics and ElectrochemistryDocument3 pagesChemical Kinetics and ElectrochemistryB NithuNo ratings yet

- Technical Data Sheet for AMPCO 18 Alloy Sand and Centrifugal CastingsDocument1 pageTechnical Data Sheet for AMPCO 18 Alloy Sand and Centrifugal CastingsS BHATTACHARYYANo ratings yet

- TDC For Plates - SA 516 65Document3 pagesTDC For Plates - SA 516 65Renny DevassyNo ratings yet

- Design Glass, Aluminum, Stainless SteelDocument36 pagesDesign Glass, Aluminum, Stainless Steely2kareinNo ratings yet

- SISTEM MODULAR: 964 SP BiologyDocument105 pagesSISTEM MODULAR: 964 SP BiologySifu KNo ratings yet

- Experiment 3Document4 pagesExperiment 3Mama ChoiiNo ratings yet

- Diffusion Lecture#2Document114 pagesDiffusion Lecture#2mm11_ned100% (1)

- Chengpeng Ma 2018Document14 pagesChengpeng Ma 2018Dr.V.K.Bupesh RajaNo ratings yet

- Differences Between A Thermostatic Expansion Valve and An Electronic Expansion ValveDocument4 pagesDifferences Between A Thermostatic Expansion Valve and An Electronic Expansion Valvexuyen tran100% (1)

- Class 1CJ1S01 (Pip PN01CJ1S01 - 2007)Document4 pagesClass 1CJ1S01 (Pip PN01CJ1S01 - 2007)Zvonko BešlićNo ratings yet

- Claretschool Ofzamboangacity: Teacher'S Learning Plan in Grade 8 ScienceDocument30 pagesClaretschool Ofzamboangacity: Teacher'S Learning Plan in Grade 8 ScienceLeonelyn Hermosa Gasco - CosidoNo ratings yet

- Trex 01192Document186 pagesTrex 01192OSDocs2012No ratings yet

- Dpr-Srikanth Reddy - Polyhouse With SubsidyDocument23 pagesDpr-Srikanth Reddy - Polyhouse With SubsidyGenesisGenesis75% (4)

- AlfaRex - TM20Document2 pagesAlfaRex - TM20Ridwan PramudyaNo ratings yet

- Indian Patent Law - RNPDocument40 pagesIndian Patent Law - RNPRishikesh ChakorNo ratings yet

- Casco Phil. Chemical Co. Inc. v. Gimenez G.R. No. L-17931Document2 pagesCasco Phil. Chemical Co. Inc. v. Gimenez G.R. No. L-17931fgNo ratings yet

- Preliminary Idea of Reaction MechanismDocument15 pagesPreliminary Idea of Reaction MechanismSiddhant SahNo ratings yet

- NM1 MassaDocument11 pagesNM1 MassaShandy ArmandoNo ratings yet

- Steam Jigging Boosts Batch Pan OutputDocument14 pagesSteam Jigging Boosts Batch Pan OutputnghiNo ratings yet

- Sbornik ZeomedcosDocument164 pagesSbornik ZeomedcosflashmonNo ratings yet

- WES - Company Profile R5-2018Document109 pagesWES - Company Profile R5-2018imtiyazNo ratings yet

- 9 Insan Sase Service Review Class: General Science No.2Document3 pages9 Insan Sase Service Review Class: General Science No.2Mahater Salic100% (1)