Professional Documents

Culture Documents

Homework

Uploaded by

JudluzOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

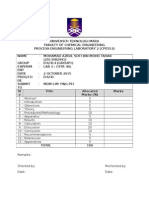

Homework

Uploaded by

JudluzCopyright:

Available Formats

4.

12 The production of carbon disulfide from methane and sulfur vapor can be carried out homogeneously or with a sold catalyst. Also, some solid materials act as poison, retarding the reaction. The following data were obtained on a flow basis at a constant temperature of 625C and with an initial reactants ratio of 1 mole of CH4 to 2 moles of sulfur vapor (considered as S2). The first set of data was obtained with the reactor empty (effective volume 67.0 cm3), and the second set was obtained the packing the reactor with a granular material (7 mesh) which reduced the void volume to 362 cm3.

Set 1

Run 1 2 3 1 2

Feed rate, gmol/h CH4 S2 0.417 0.834 0.238 0.476 0.119 0.238 0.119 0.238 0.178 0.357

Production of CS2, gmol/h 0.0531 0.0391 0.0312 0.0204 0.0220

Conversion of methane 0.127 0.164 0.262 0.171 0.123

Was the granular material acting as a catalyst or as a poison in this case? 5.19 Pure gaseous A at about 3atm and 30C (120 mmol/liter) is fed into a 1 liter mixed flow reactor at various flow rates. There it decomposes, and the exit concentration of A is measured for each flow rate. From the following data find a rate equation to represent the kinetics of the decomposition of A. Assume that reactant A alone affects the rate. vo, liter/min CA, mmol/liter 0.06 30 0.48 60 1.5 80 8.1 105

5.25 The aqueous decomposition of A is studied in an experimental mixed flow reactor. The results in Table P5.25 are obtained in steady-state runs. To obtain 75% conversion of reactant in a feed, CA0=0.8 mol/liter, what holding time is needed in a plug flow reactor? Concentration of A, mol/liter In Feed 2.00 2.00 2.00 1.00 1.00 0.48 0.48 0.48 Holding Time. see In Exit Stream 0.65 0.92 1.00 0.56 0.37 0.42 0.28 0.20 300 240 250 110 360 24 200 560

6.20 Reactant A decomposes with stoichiometry A-> R and with rate dependent only on CA. The following data on this aqueous decomposition are obtained in a mixed flow reactor: T, sec 14 25 29 30 29 27 24 19 15 12 20 CA0 200 190 180 170 160 150 140 130 120 110 101 CA 100 90 80 70 60 50 40 30 20 10 1

Determine which setup, plug flow, mixed flow, or any two-reactor combination gives minimum T for 90% conversion of a feed consisting of CA0=100. Also find this T minimum. If a two-reactor scheme is found to be optimum, give CA between stages and T for each stage. 4.6 Dibutyl phthalate (DBP), a plasticizer, has a potential market of 12 million lb/yr (AIChE Student Contest Problem) and is to be produced by reaction of n-butanol with monobutyl phthalate (MBP). The reaction follows an elementary rate law and is catalyzed by H2SO4 (Figure P4-6). A stream containing the stream enters the reactor. The concentration of MBP in the stream entering the reactor is 0.2 lbmol/ft3, and the molar feed rate of butanol is five times that of MBP. The specific reaction rate at 100F is 1.2 ft3/lbmol.h. There is a 1000 gallon CSTR and associated peripheral equipment available for use in this project for 30 days a year (operating 24 h/day) a) Determine the exit conversion in the available 1000 gallon reactor if you were to produce 33% os the share (i.e., 4 million lb/yr) of the predicted market. (Ans.: X=0.33) b) How might you increase the conversion for the same FAO? For example, what conversion would be achieved if a second 1000-gal CSTR were placed either in series or in parallel with the CSTR? (X2= 0.55 (series)) c) For the same temperature as part a), what CSTR volume would be necessary to achieve a conversion of 85% for a molar feed rate of MBP of 1 lbmol/min? d) If possible, calculate the tubular reactor volume necessary to achieve 85% conversion, when the reactor is oblong rather than cylindrical, with a major-to-minor axis ratio of 1.3:1.0. There are no radial gradients in either concentration or velocity. If it is not possible to calculate V and explain. e) How would your results for parts a) and b) change if the temperatures were raised to 150F where k is now 5.0 ft3/lbmol.h but the reaction is reversible with KC=0.3?

You might also like

- Distillation Aspen HysysDocument66 pagesDistillation Aspen HysysCzarina MasicatNo ratings yet

- Dubai Healthcare Providers DirectoryDocument30 pagesDubai Healthcare Providers DirectoryBrave Ali KhatriNo ratings yet

- Formal 17 12 04 PDFDocument184 pagesFormal 17 12 04 PDFJose LaraNo ratings yet

- HealthFlex Dave BauzonDocument10 pagesHealthFlex Dave BauzonNino Dave Bauzon100% (1)

- Tut1 2016 QDocument5 pagesTut1 2016 QAbhishek SardaNo ratings yet

- Examples and exercises – Reactor designDocument19 pagesExamples and exercises – Reactor designtehbear0% (1)

- Lead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RDocument189 pagesLead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RluizdasilvaazevedoNo ratings yet

- Chemical Reaction Engineering Exercise One 2022Document4 pagesChemical Reaction Engineering Exercise One 2022Matone MafologelaNo ratings yet

- Kinetics Probset (LE4)Document4 pagesKinetics Probset (LE4)Jewls HatudNo ratings yet

- Assignment Aspen PlusDocument8 pagesAssignment Aspen PlusVinayak PathakNo ratings yet

- Intermediate Accounting Testbank 2Document419 pagesIntermediate Accounting Testbank 2SOPHIA97% (30)

- Reactor Exercises 2013Document19 pagesReactor Exercises 2013RafiHunJian100% (2)

- Financial ManagementDocument21 pagesFinancial ManagementsumanNo ratings yet

- Lab CSTRDocument24 pagesLab CSTRNurtasha Atikah50% (2)

- Sec of Finance Purisima Vs Philippine Tobacco Institute IncDocument2 pagesSec of Finance Purisima Vs Philippine Tobacco Institute IncCharlotte100% (1)

- Lab Report CSTR 40LDocument26 pagesLab Report CSTR 40LAnonymous NyvKBW33% (3)

- Domestic Water Consumption in ChennaiDocument18 pagesDomestic Water Consumption in Chennaimaaz0% (1)

- CSTR 40L LAB EXPERIMENTDocument18 pagesCSTR 40L LAB EXPERIMENTSaber Minato Azrul100% (2)

- Books 2738 0Document12 pagesBooks 2738 0vinoohmNo ratings yet

- Reactor EnggDocument75 pagesReactor EnggarunperthNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Chapter 5 Octave Solutions ManualDocument34 pagesChapter 5 Octave Solutions Manualniquee9ner100% (3)

- CRE Chap 6Document16 pagesCRE Chap 6Chrysler Kane Depnag80% (5)

- Lab 2 ReportDocument9 pagesLab 2 Reportsherub wangdiNo ratings yet

- Tutorial 2 QuestionDocument3 pagesTutorial 2 Questionnur hidayatiNo ratings yet

- Revision QuestionsDocument12 pagesRevision QuestionsLiew Wen Xuan0% (2)

- Optimize reactor production with these sample chemistry questionsDocument8 pagesOptimize reactor production with these sample chemistry questionsMaame Efua Neizer100% (1)

- AsdfghjklDocument4 pagesAsdfghjklJV CustodioNo ratings yet

- Sample Exams Problems CHE 402Document3 pagesSample Exams Problems CHE 402Ricardo VelozNo ratings yet

- Chemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Document6 pagesChemical Reactors - Problems of Reactor Association 47-60: (Exam Jan'09)Alfredo ZuñigaNo ratings yet

- Cre-II EndtermDocument2 pagesCre-II Endtermbt21cme061No ratings yet

- Production of ethylene glycol from a semibatch reactorDocument3 pagesProduction of ethylene glycol from a semibatch reactorJose David D SNo ratings yet

- 2010 ChE 471 HW 8 FinalDocument4 pages2010 ChE 471 HW 8 FinalSiti HannaNo ratings yet

- Dibutyl PhthalateDocument1 pageDibutyl PhthalatebebsybiswezNo ratings yet

- 3 - Prob PFR 11-12 23-35 English-1Document4 pages3 - Prob PFR 11-12 23-35 English-1Biniyam haileNo ratings yet

- Assignment 3Document4 pagesAssignment 3Yi Hong LowNo ratings yet

- Simulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017Document5 pagesSimulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017ajali1957No ratings yet

- FDFSDDocument9 pagesFDFSDdvpNo ratings yet

- 10.37 first midterm problemsDocument2 pages10.37 first midterm problemsfayaz5uin1234No ratings yet

- CHE3044F Reactor Design Tutorial ProblemsDocument4 pagesCHE3044F Reactor Design Tutorial ProblemsnmhatityeNo ratings yet

- Practice Problem Set 1Document2 pagesPractice Problem Set 1oprudra2000No ratings yet

- Department of Chemical Engineering, Iit Delhi Reactor Sizing Problems Assignment-2Document2 pagesDepartment of Chemical Engineering, Iit Delhi Reactor Sizing Problems Assignment-2ShubhamGuptaNo ratings yet

- ChE 125 LE - 04 PDFDocument1 pageChE 125 LE - 04 PDFJojie-Ann AlabarcaNo ratings yet

- CRE IdocxDocument8 pagesCRE IdocxParth DesaiNo ratings yet

- Partial ExamDocument1 pagePartial ExamFranco CamachoNo ratings yet

- CSTR cascade experimentDocument14 pagesCSTR cascade experimentDEEPSHIKA DUTTANo ratings yet

- Worksheet On Chapter 6Document4 pagesWorksheet On Chapter 6fikadubiruk87No ratings yet

- Cro Tut8Document13 pagesCro Tut8Ernst SmitNo ratings yet

- Temperature, °C: SolutionDocument18 pagesTemperature, °C: Solutionمحمد حلمي هاريريNo ratings yet

- Assignment 4Document5 pagesAssignment 4Yi Hong LowNo ratings yet

- Chemical Reaction Engineering Assignment with Kinetic Data AnalysisDocument3 pagesChemical Reaction Engineering Assignment with Kinetic Data AnalysisJanaki Devi Parrat0% (1)

- Flow Reactors Assignment Problems 5 & 6Document1 pageFlow Reactors Assignment Problems 5 & 6DechenPemaNo ratings yet

- 2 - Prob Batch 11-12 14-22 EnglishDocument3 pages2 - Prob Batch 11-12 14-22 EnglishAbiola AjiginniNo ratings yet

- Gazi University Chemical Reaction Engineering ProblemsDocument4 pagesGazi University Chemical Reaction Engineering ProblemsJerson Mendoza CNo ratings yet

- Something Related To Catalysts.Document2 pagesSomething Related To Catalysts.Deepro BhattacharyaNo ratings yet

- 619PT304Document4 pages619PT304arpit gargNo ratings yet

- EgyE 201 Assignment On Energy Conversion SystemsDocument2 pagesEgyE 201 Assignment On Energy Conversion SystemsAngel de DiosNo ratings yet

- HW 2 K 1606Document7 pagesHW 2 K 1606Primus OngNo ratings yet

- Introduction To Chemical Reactor Engineering - Problems PDFDocument75 pagesIntroduction To Chemical Reactor Engineering - Problems PDFJojie-Ann Alabarca100% (1)

- 1 - Prob Kinet 11-12 1-13 EnglishDocument4 pages1 - Prob Kinet 11-12 1-13 EnglishYenNo ratings yet

- Tutorial For Chapter 23Document9 pagesTutorial For Chapter 23Thurgah VshinyNo ratings yet

- Problem As Cat Al Is Is 2018Document10 pagesProblem As Cat Al Is Is 2018Victor Daniel Martínez CarreteroNo ratings yet

- Chapter 2Document16 pagesChapter 2Awat MuhammadNo ratings yet

- Problem set for batch and continuous reactor kineticsDocument4 pagesProblem set for batch and continuous reactor kineticsThalia RodriguezNo ratings yet

- Allyl CDocument15 pagesAllyl CTengku Mohd Imran0% (1)

- CHEE 321: Chemical Reaction Engineering: Module 3: Isothermal Reactor DesignDocument16 pagesCHEE 321: Chemical Reaction Engineering: Module 3: Isothermal Reactor DesignPranav NakhateNo ratings yet

- Assignment 2 Reactor Design Single ReactionDocument4 pagesAssignment 2 Reactor Design Single ReactionNitin MauryaNo ratings yet

- Nanoporous Catalysts for Biomass ConversionFrom EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- HPE Alletra 6000-PSN1013540188USENDocument4 pagesHPE Alletra 6000-PSN1013540188USENMauricio Pérez CortésNo ratings yet

- CaseHistoriesOnTheApplication of Vacuum PreloadingDocument25 pagesCaseHistoriesOnTheApplication of Vacuum PreloadingvaishnaviNo ratings yet

- Mechanical PropertiesDocument30 pagesMechanical PropertiesChristopher Traifalgar CainglesNo ratings yet

- Iqvia PDFDocument1 pageIqvia PDFSaksham DabasNo ratings yet

- Article 4Document31 pagesArticle 4Abdul OGNo ratings yet

- SIWES Report Example For Civil Engineering StudentDocument46 pagesSIWES Report Example For Civil Engineering Studentolayinkar30No ratings yet

- Vitamin D3 5GDocument7 pagesVitamin D3 5GLuis SuescumNo ratings yet

- EE3331C Feedback Control Systems L1: Overview: Arthur TAYDocument28 pagesEE3331C Feedback Control Systems L1: Overview: Arthur TAYpremsanjith subramani0% (1)

- Hilti X-HVB SpecsDocument4 pagesHilti X-HVB SpecsvjekosimNo ratings yet

- Market Participants in Securities MarketDocument11 pagesMarket Participants in Securities MarketSandra PhilipNo ratings yet

- Duct Design ChartDocument7 pagesDuct Design ChartMohsen HassanNo ratings yet

- Bid Document PDFDocument125 pagesBid Document PDFAzharudin ZoechnyNo ratings yet

- The Non Technical Part: Sample Interview Questions For Network EngineersDocument5 pagesThe Non Technical Part: Sample Interview Questions For Network EngineersblablaNo ratings yet

- AP Statistics - 2014-2015 Semester 1 Test 3Document4 pagesAP Statistics - 2014-2015 Semester 1 Test 3Camden BickelNo ratings yet

- 2016 04 1420161336unit3Document8 pages2016 04 1420161336unit3Matías E. PhilippNo ratings yet

- JRC Wind Energy Status Report 2016 EditionDocument62 pagesJRC Wind Energy Status Report 2016 EditionByambaa BattulgaNo ratings yet

- GSM Multi-Mode Feature DescriptionDocument39 pagesGSM Multi-Mode Feature DescriptionDiyas KazhiyevNo ratings yet

- Duty Entitlement Pass BookDocument3 pagesDuty Entitlement Pass BookSunail HussainNo ratings yet

- Literature Review 5Document4 pagesLiterature Review 5api-463653994No ratings yet

- PNW 0605Document12 pagesPNW 0605sunf496No ratings yet