Professional Documents

Culture Documents

United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0257940 A1

Uploaded by

gowdas2011Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0257940 A1

Uploaded by

gowdas2011Copyright:

Available Formats

US 20120257940Al

(19)

United States

Gowda et al.

(12) Patent Application Publication (10) Pub. No.: US 2012/0257940 A1

(43) Pub. Date: Oct. 11, 2012

(54) (75)

CUTTER ASSEMBLY

Publication Classi?cation

Inventors:

Sharath Shankare GoWda,

(51)

Bangalore (IN); Krishna Prasad

Vangipuram Ramaswamy, Bangalore (IN); Shivanna, Bangalore (IN)

Int. Cl. B23C 5/22 B23C 3/00 B23P 11/00

(2006.01) (2006.01) (2006.01)

(52)

US. Cl. ......... .. 409/131; 407/47; 407/48; 29/525.01

(57)

ABSTRACT

(73) Assignee: (21) Appl. No.: (22) Filed: (30)

KENNAMETAL INC., Latrobe, PA (US)

13/438,893

Apr. 4, 2012

The present disclosure provides a cutter assembly (100), said

cutter assembly (100) comprises a back plate (101) adapted to

mount on a machine spindle, Wherein said back plate (101)

having stepped portion (201) on its surface. The stepped portion (201) of the back plate (101) comprises plurality of oblong slots (202) and locating surfaces (203) at predeter

mined locations in its outer circumference. A cutter ring (102) adapted mount on outer circumference of the stepped portion

Foreign Application Priority Data

Apr. 6, 2011 (IN) ......................... .. 1163/CHE/2011

(201) of the back plate (101) and a fastening members (103) to connect said cutter ring (102) With the back plate (101).

103

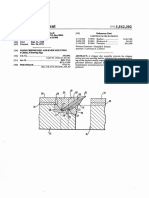

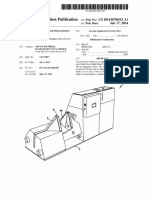

Patent Application Publication

Oct. 11, 2012 Sheet 1 0f 7

US 2012/0257940 A1

FIG. 1

Patent Application Publication

Oct. 11, 2012 Sheet 2 0f 7

US 2012/0257940 A1

101

204

205

103

FIG. 2

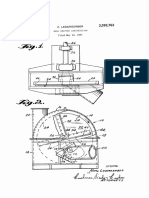

Patent Application Publication

Oct. 11, 2012 Sheet 3 0f 7

US 2012/0257940 A1

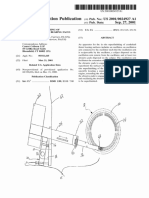

102

301 302

FIG. 3

100

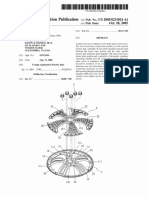

Patent Application Publication

Oct. 11, 2012 Sheet 4 0f 7

US 2012/0257940 A1

205

FIG. 4

Patent Application Publication

Oct. 11, 2012 Sheet 5 of7

US 2012/0257940 A1

204

100

Patent Application Publication

Oct. 11, 2012 Sheet 6 0f 7

US 2012/0257940 A1

Patent Application Publication

Oct. 11, 2012 Sheet 7 0f 7

US 2012/0257940 A1

FIG. 7

US 2012/0257940 A1

Oct. 11, 2012

CUTTER ASSEMBLY FIELD OF THE INVENTION

(103) in the bayonet slots (301); and tightening the fastening

members (103) to secure the cutter ring (102) against the back

plate (101).

BRIEF DESCRIPTION OF THE DRAWINGS

[0001]

The present disclosure relates to a milling cutter,

[0007]

and more particularly to a split type milling cutter that can be

disassembled into plurality of mating parts.

BACKGROUND OF THE INVENTION

The novel features and characteristic of the disclo

sure are set forth in the appended claims. The disclosure itself, hoWever, as Well as a preferred mode of use, further objectives

and advantages thereof, Will best be understood by reference

[0002] The conventional large diameter milling cutters are heavy and it is very dif?cult to handle such type of heavy milling cutters at the customer shop ?oor. It is desired to have

a neW milling adaptation system so that cutter becomes light and easy to handle at customer shop ?oor.

to the folloWing detailed description of an illustrative embodiment When read in conjunction With the accompany ing ?gures. One or more embodiments are noW described, by

Way of example only, With reference to the accompanying ?gures Wherein like reference numerals represent like ele

ments and in Which:

[0003] The existing split design milling cutter comprise of

a back plate, Which is mounted onto the spindle and a cutter

[0008]

FIG. 1 illustrates the perspective vieW of the cutter

ring With inserts mounted, Which Will be secured to the back plate. The customer still ?nds it dif?cult to mount cutter ring onto the back plate because of close tolerance betWeen the cutter ring and the back plate. Even a slight tilt in the axis due to Weight of cutter ring Will make the entry of cutter ring into the back plate di?icult. This is because entire circumferential locating face of back plate comes in contact With the inner face of the cutter ring. Sometimes, the cutter ring gets stuck in misaligned position affecting cutter run out (both axial and

assembly.

[0009] FIG. 2 illustrates the back plate of the present dis

closure. [0010] FIG. 3 illustrates the cutter ring of the present dis closure. [0011] FIG. 4 illustrates the sectional vieW of the cutter

assembly in mounting/dismounting position.

[0012] FIG. 5 illustrates the enlarged vieW of position of the drive tenon and the locating surface in mounting/dismounting

radial).

[0004] Further, the existing split design milling cutter com

prises tWo drive tenons Which are required for torque trans

position.

[0013] FIG. 6 illustrates the sectional vieW of the cutter

assembly in Working position.

[0014] FIG. 7 illustrates the enlarged vieW of the position of the drive tenon and the locating surface in Working position. [0015] The ?gures depict embodiments of the disclosure

for purposes of illustration only. One skilled in the art Will

mission. Hence, the positioning of the cutter ring on to the backplate is still dif?cult. It involves lot of hardWare like pins, springs and single central cap screW for clamping cutter ring to ?xture. Operator is required to alWays align arroW marks of the back plate and the cutter ring for proper mounting.

readily recogniZe from the folloWing description that altema

tive embodiments of the structures and methods illustrated

[0005] In addition, the locating surface of the existing split design milling cutter is fully cylindrical. The minimum clear

ance betWeen the locating surfaces of cutter ring and ?xture is 15 microns and maximum clearance is 35 microns, making mounting dif?cult in case of a slight tilt of cutter ring While

herein may be employed Without departing from the prin ciples of the disclosure described herein.

DETAILED DESCRIPTION OF THE INVENTION

mounting.

SUMMARY OF THE INVENTION

[0016]

In the folloWing detailed description, reference is

made to the accompanying ?gures, Which form a part hereof.

In the ?gures, similar symbols typically identify similar com

ponents, unless context dictates otherWise. The illustrative

[0006]

Accordingly the present disclosure provides for a

cutter assembly (100) comprising; a back plate (101) adapted

to mount on a machine spindle (C), Wherein said back plate

embodiments described in the detailed description, ?gures,

and claims are not meant to be limiting. Other embodiments

(101) having stepped portion (201) on its surface; Which comprises plurality of oblong slots (202) and locating sur

faces (203) at predetermined locations in its outer circumfer

ence; a cutter ring (102) adapted to mount on outer circum

ference of the stepped portion (201) of the back plate (101);

and a fastening members (103) to connect said cutter ring

(102) With the back plate (101), and also provides a method of assembling a cutter assembly (100) comprises acts fastening

a back plate (101) on the machine spindle (C), Wherein said

may be utiliZed, and other changes may be made, Without departing from the spirit or scope of the subject matter pre sented herein. It Will be readily understood that the aspects of the present disclosure, as generally described herein, and illustrated in the ?gures, can be arranged, substituted, com bined, and designed in a Wide variety of different con?gura tions, all of Which are explicitly contemplated and make part

of this disclosure. [0017] This disclosure is draWn inter-alia, to a milling cut ter. More particularly, embodiments of the disclosure relates to the split type milling cutters that can be disassembled into

back plate (101) having stepped portion (201) on its surface; Which comprises plurality of oblong slots (202) and locating

surfaces (203) at predetermined locations in its outer circum

plurality of mating parts.

[0018] One embodiment of the present disclosure provides

a cutter assembly. Said cutter assembly comprises; a back

ference; inserting plurality of fastening members (103) into

holes (401) provided on the back plate (101) for guiding a cutter ring (102); mounting the cutter ring (102) on the

plate (101) adapted to mount on a machine spindle (C),

stepped portion (201) of the back plate (101), Wherein said cutter ring (102) has plurality of bayonet slots (301) for pass ing the fastening members (103); rotating the cutter ring (102)

in predetermined direction to lock the fastening members

Wherein saidbackplate (101) having steppedportion (201) on its surface; Which comprises plurality of oblong slots (202)

and locating surfaces (203) at predetermined locations in its

outer circumference; a cutter ring (102) adapted to mount on

US 2012/0257940 A1

Oct. 11, 2012

outer circumference of the stepped portion (201) of the back plate (101); and a fastening members (103) to connect said

cutter ring (102) With the back plate (101).

[0019] In one embodiment of the present disclosure, the

[0032] In one embodiment of the present disclosure, the cutter ring (102) is rotated in the direction opposite to the direction of cutting to lock the fastening members (103) in the

bayonet slots (301).

[0033] One embodiment of the present disclosure provides

a method of milling using a cutter assembly. [0034] FIG. 1 in an exemplary embodiment illustrates the

oblong slots (202) are provided betWeen the locating surfaces (203), tangentially around circumference of the stepped por

tion (201).

[0020] In one embodiment of the present disclosure, the

oblong slots (202) are provided for mounting of the cutter ring (102) onto the back plate (101).

[0021] In one embodiment of the present disclosure, the locating surface (203) maintains a localiZed contact With the

cutter assembly (100) according to the present disclosure. Said cutter assembly (100) comprises a back plate (101)

mounted on the machine spindle (C) to support and drive a

cutter ring 102) along With the machine spindle (C). A cutter

ring (102) of circular shape With inserts mounted on the outer circumference, having its outer diameter adapted to mount on

cutter ring (102) at Working position.

[0022] In one embodiment of the present disclosure, at least one drive tenon (204) is provided on the back plate (101). [0023] In one embodiment of the present disclosure, the fastening members (103) are selected from the group com prising socket head cap screWs, threaded bolts, hex lobular

screWs or any fasteners Would also serve the purpose.

to the back plate (101). Plurality of fastening members (103)

are provided in the cutter assembly (100) to fasten the cutter

ring (102) to the back plate (101).

[0035] In one embodiment of the present disclosure, the fastening members (103) are selected from the group com

prising; socket head cap screWs, threaded bolts, hex lobular

screWs or any fastener Would also serve the purpose.

[0024]

In one embodiment of the present disclosure, the

back plate (101) is provided With) socket head cap screWs (103) to couple With the cutter ring (102).

[0025] In one embodiment of the present disclosure, the

[0036] In one embodiment of the present disclosure, the socket head cap screWs (103) made of head portion (103a) and the base portion (10319) to engage With bayonet slots

(301) for easy mounting/dismounting of the cutter ring (102) With the back plate (101).

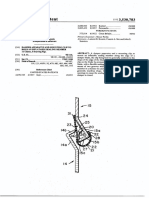

[0037] FIG. 2 in an exemplary embodiment illustrates the

cutter ring (102) comprises plurality of bayonet slots (301) to accommodate the fastening members (103).

[0026] In one embodiment of the present disclosure, the

back plate (101) according to the present disclosure. The back plate (101) is used to ?x to the machine spindle (C) and forms

bayonet slots (301) comprises hole (301b) to pass head por tions (10311) of the fastening member (103) and hole (30111) to accommodate base portions (10319) of the fastening member

butting surface for the cutter ring (102). The back plate (101)

comprises stepped portion (201). The stepped portion (201)

of the back plate (101) is the locating portion of cutter ring (102). The locating portion has a locating surface (203) to provide localiZed contact of the back plate (101) With the

cutter ring (102) during Working and to ensure goodradial run

(103).

[0027] In one embodiment of the present disclosure, the

cutter ring (102) comprises plurality of tenon slots (302) at

predetermined locations to make contact With the drive tenon

(204).

[0028] The present disclosure is also relation With the method of assembling a cutter assembly (100) comprises acts fastening a back plate (101) on the machine spindle (C),

out. Plurality of oblong slots (202) are provided tangentially around the circumference of the stepped portion (201) for ensuring no contact of locating surface (203) during mount

ing and dismounting of the cutter ring (102) on to the back plate (101). The oblong slots (202) help to mount the cutter ring (102) easily onto the back plate (101) Which is mounted on the machine spindle (C).

[0038] In one embodiment of the present disclosure, the

Wherein saidback plate (101) having steppedportion (201) on its surface; Which comprises plurality of oblong slots (202)

and locating surfaces (203) at predetermined locations in its

outer circumference; inserting plurality of fastening members (103) into holes (401) provided on the back plate (101) for

guiding a cutter ring (102); mounting the cutter ring (102) on

back plate (101) is provided With drive tenon (204) at prede

termined location for transmitting required torque to the cut ter ring (102) for its operation. The drive tenon (204) can be

the stepped portion (201) of the backplate (101), Wherein said cutter ring (102) has plurality of bayonet slots (301) for pass ing the fastening members (103); rotating the cutter ring (102)

in predetermined direction to lock the fastening members

provided on the locating surface (203) of the back plate (101)

or at any predetermined peripheral location of the back plate (101). More than one drive tenon (204) can be provided if more torque is required. [0039] FIG. 3 in an exemplary embodiment illustrates the cutter ring (102) according to the present disclosure. The cutter ring (102) having inserts mounted on its outer circum ference has the outer diameter matching With the diameter of

(103) in the bayonet slots (301); and tightening the fastening

members (103) to secure the cutter ring (102) against the back

plate (101).

[0029] In one embodiment of the present disclosure, gap is

created betWeen the back plate (101) and the cutter ring (102) during mounting/dismounting of cutter ring (102) on to the

the back plate (101). A cutter ring (102) comprises a milled hole (1 04) up to predetermined extent matching With the outer

back plate (101).

[0030] In one embodiment of the present disclosure, a drive

circumference of the stepped portion (201) for mounting the

cutter ring (102) on to the back plate (101). The cutter ring

(102) further comprises plurality of bayonet slots (301) for

easy mounting/dismounting of the cutter ring (102) and to

tenon (204) is provided on the back plate (101) for transmit

ting the torque.

[0031] In one embodiment of the present disclosure, plu rality of tenon slots (3 02) are provided in the cutter ring (102)

at predetermined locations to accommodate the drive tenon

support the cutter ring (102) during cutting. [0040] In addition, the cutter ring (102) comprises plurality

of tenon slots (302) for drive tenon (204) engagement and to

(204).

facilitate easy mounting/dismounting of the cutter ring (102) With the back plate (101).

US 2012/0257940 A1

Oct. 11, 2012

[0041]

In one embodiment of the present disclosure, the

bayonet slots (301) provided on the cutter ring comprises tWo holes (301a and 3011)), wherein the hole (30119) is having

diameter slightly more than the diameter of the head portion

(10311) of the socket head cap screW (103) to ensure easy

[0047] In one embodiment of the present disclosure, the cutter ring (102) is mounted on to the stepped portion (201) of

the back plate (101). During mounting, the head portion

(10311) of the socket cap head screWs (103) enters into hole

mounting/dismounting of the cutter ring (102) With the back

(30119) of the bayonet slots (301). After mounting, the cutter ring (102) is rotated in predetermined direction such that the

base portion (10319) of the socket head cap screW (103) rests

plate (101). The hole (30111) of the bayonet slot (301) has

diameter less than the diameter of (30119) to accommodate the base portion (10319) of the socket head cap screW (103) for

in the hole (30111) of the bayonet slot (301). [0048] During dismounting of the cutter ring (102), the

socket head cap screWs (103) are loosened and the cutter ring

locking the cutter ring (102) With the back plate (101) during

Working. The cutter ring (102) is placed on the back plate

(101) With head portions (103a) aligned With the hole (1031)). After placing the cutter ring (102), the cutter ring (102) is

rotated to move the base portions (10319) in to the hole (301a). After this, the cap screWs (103) are tightened to ?rmly mount the cutter ring (102) on the back plate (101). NoW the cutter

(1 02) is rotated in the direction of cutting. Then the cutter ring (102) is dismounted from the back plate (101).

[0049] In one embodiment of the present disclosure, the same back plate (101) can be used for both left hand and right hand cutters and the cutting directions of left hand and right

hand cutters are counter clock Wise and clock Wise respec

ring (102) is in Working position.

[0042] FIG. 4 in an exemplary embodiment illustrates the

tively With respect to the spindle axis.

[0050] In one embodiment of the present disclosure, the

sectional vieW of the cutter assembly (100) in mounting/

bayonet slot (301) design is modi?ed in the cutter ring (102)

to use the same back plate (101) for both left hand and right

hand cutters.

dismounting position. In mounting/dismounting position the

locating surface (203) and the drive tenon (204) of the back plate (101) are Well inside the tenon slots (302) provided on the cutter ring (102).

[0043] FIG. 5 in an exemplary embodiment illustrates

[0051]

In one embodiment of the present disclosure, the

enlarged vieW of position of the drive tenon (204) and the

cutter ring (102) is rotated about 10-15 degrees opposite to the cutting direction till the engagement of the cutter ring (102) With the drive tenon (204).

[0052] In one embodiment of the present disclosure, the drive tenon (204) makes contact With butting surface of the tenon slots (302) to provide positive drive. In one embodi

locating surface (203) in mounting/dismounting position.

The locating surface (203) and the drive tenon (204) of the back plate (101) enters in to the tenon slots (302) of the cutter

ring (102) during mounting/dismounting of the cutter ring

(102) on to the back plate (101). This provides the clearance betWeen the cutter ring (102) and the back plate (101) for easy mounting/dismounting. The clearance (B) is clearly visible in

FIG. 5.

ment of the present disclosure, the back plate (101) provided

With plurality of holes (205) on its surface to mount the back

plate (101) on to the machine spindle. The holes (205) pro

vided on the back plate (101) are according to the industrial standards. [0053] In one embodiment of the present disclosure, the

[0044]

FIG. 6 in an exemplary embodiment illustrates the

sectional vieW of the cutter assembly (100) in Working posi tion. In Working position of the cutter assembly (100), locat ing surface (203) of the back plate (101) is in localiZed contact With the cutter rings (102) inner circumference to provide

good radial run out. Further, the drive tenon (204) is in contact With the Wall of the tenon slot (302) for transmitting the

backplate (101) comprises plurality of holes (401) for mount ing the fastening members (103).

Advantages

[0054] The present disclosure provides a cutter assembly Which can be disassembled into plurality of mating parts,

hence can be easily handled and less man poWer is required. [0055] The back plate of the present disclosure can be used

torque to the cutter ring (102).

[0045] FIG. 7 in an exemplary embodiment illustrates enlarged vieW of the position of the drive tenon (204) and the

locating surface (203) in Working position. During Working

position, the locating surface (203) of the back plate (101) is

in localiZed contact With the cutter ring (102) to ensure good radial run out. The drive tenon (204) Will butt against the butting surface of tenon slot (302) to transmit the torque

for both right hand and left hand milling cutters. Hence, the

cutter assembly is economical and consumes less lead time.

[0056]

The present disclosure provides a cutter assembly

Which can be easily mounted and dismounted to the machine

spindle.

[0057] The locating surfaces makes localiZed contact With the cutter assembly during Working to provide goodradial run

out. Hence life of the cutter assembly is enhanced.

required for cutting and to provide positive drive to the cutter

ring (102).

[0046] To assemble the cutter assembly on to a machine

spindle (C) falloWing steps are falloWed installing a ?xture on to the machine spindle (C) to secure the back plate (101). A cutter ring (102) is then mounted on to the back plate (101) Withplurality of socket head cap screWs (103). During mount ing, the locating surface (203) and the drive tenon (204) of the back plate (101) are designed to enter into the tenon slots (302) for easy mounting of the cutter ring (102). The cutter

EQUIVALENTS

[0058] With respect to the use of substantially any plural and/or singular terms herein, those having skill in the art can translate from the plural to the singular and/or from the sin gular to the plural as is appropriate to the context and/or

application. The various singular/plural permutations may be

expressly set forth herein for sake of clarity. [0059] It Will be understood by those Within the art that, in

ring (102) is placed on the backplate (101) With head portions (103a) aligned With the hole (3011)). Then the cutter ring is

rotated in predetermined direction to lock the cutter ring (102) With the back plate (101) and to make contact With the drive tenon (204). Then, tightening the cap screWs (103) to secure the cutter ring (102) With the back plate (101).

general, terms used herein, and especially in the appended claims (e.g., bodies of the appended claims) are generally

intended as open terms (e.g., the term including should be interpreted as including but not limited to, the term

US 2012/0257940 A1

Oct. 11, 2012

having should be interpreted as having at least, the term

includes should be interpreted as includes but is not lim

-continued

Referral numeral

103a 103b

104

ited to, etc .). It Will be further understood by those Within the

art that if a speci?c number of an introduced claim recitation

Description

Head portion of the fastening member Base portion of the fastening member

milled hole on the cutter ring

is intended, such an intent Will be explicitly recited in the claim, and in the absence of such recitation no such intent is present. For example, as an aid to understanding, the folloW

ing appended claims may contain usage of the introductory

phrases at least one and one or more to introduce claim recitations. However, the use of such phrases should not be construed to imply that the introduction of a claim recitation by the inde?nite articles a or an limits any particular

201 202 203

204

stepped portion on back plate Oblong slots Locating surface

Drive tenon

205

Holes on the back plate

301

301a and 301b 302 401

Bayonet slots

Holes ofthe tenon slots Tenon slots Holes on the back plate to mount the fastening members

claim containing such introduced claim recitation to inven tions containing only one such recitation, even When the same claim includes the introductory phrases one or more or at

least one and inde?nite articles such as a or an (e.g., a and/ or an should typically be interpreted to mean at least

one or one or more); the same holds true for the use of

B C

Clearance between cutter ring and the back plate Machine spindle

de?nite articles used to introduce claim recitations. In addi tion, even if a speci?c number of an introduced claim recita

1. A cutter assembly comprising:

a back plate adapted to mount on a machine spindle, said

tion is explicitly recited, those skilled in the art Will recogniZe

that such recitation should typically be interpreted to mean at least the recited number (e.g., the bare recitation of tWo recitations, Without other modi?ers, typically means at least

tWo recitations, or tWo or more recitations). Furthermore, in those instances Where a convention analogous to at least one

back plate having a stepped portion including a plurality of oblong slots and locating surfaces at predetermined

locations on an outer circumference of the stepped por

tion;

a cutter ring adapted to be mounted on the outer circum

ference of the stepped portion of the back plate; and

at least one fastening member to connect said cutter ring

of A, B, and C, etc. is used, in general such a construction is

intended in the sense one having skill in the art Would under

With the back plate (101).

2. The cutter assembly as claimed in the claim 1, Wherein

stand the convention (e.g., a system having at least one of A, B, and C Would include but not be limited to systems that have A alone, B alone, C alone, A and B together, A and C

the oblong slots are provided betWeen the locating surfaces

tangentially around circumference of the stepped portion.

3. The cutter assembly as claimed in the claim 1, Wherein

together, B and C together, and/or A, B, and C together, etc.).

In those instances Where a convention analogous to at least one of A, B, or C, etc. is used, in general such a construction is intended in the sense one having skill in the art Would understand the convention (e. g., a system having at least one ofA, B, or C Would include but not be limited to systems that

the oblong slots are provided for mounting of the cutter ring onto the back plate.

4. The cutter assembly as claimed in the claim 1, Wherein the locating surfaces maintains a localiZed contact With the

cutter ring at Working position.

5. The cutter assembly as claimed in the claim 1, Wherein at least one drive tenon is provided on the back plate. 6. The cutter assembly as claimed in the claim 1, Wherein the at least one fastening member is selected from the group comprising a socket head cap screW, a threaded bolt, and a hex

lobular screW.

have A alone, B alone, C alone, A and B together, A and C

together, B and C together, and/or A, B, and C together, etc.).

It Will be further understood by those Within the art that

virtually any disjunctive Word and/or phrase presenting tWo

or more alternative terms, Whether in the description, claims,

or draWings, should be understood to contemplate the possi

bilities of including one of the terms, either of the terms, or both terms. For example, the phrase A or B Will be under stood to include the possibilities of A or B or A and B.

[0060] While various aspects and embodiments have been disclosed herein, other aspects and embodiments Will be apparent to those skilled in the art. The various aspects and

embodiments disclosed herein are for purposes of illustration and are not intended to be limiting, With the true scope and

spirit being indicated by the folloWing claims.

REFERRAL \] [ lMERALS

7. The cutter assembly as claimed in claim 1, Wherein the back plate is provided With socket head cap screWs to couple With the cutter ring. 8. The cutter assembly as claimed in the claim 6, Wherein the cutter ring comprises plurality of bayonet slots to accom modate the fastening members. 9. The cutter assembly as claimed in the claim 7, Wherein the bayonet slots comprises a hole to pass head portions of the

at least one fastening member therethrough and a hole to

accommodate base portions of the fastening member.

[00 6 1]

10. The cutter assembly as claim 1, Wherein the cutter ring comprises a plurality of tenon slots at predetermined loca

tions to make contact With the drive tenon.

11. A method of assembling a cutter assembly comprising:

fastening a back plate on a machine spindle, Wherein said

Referral numeral

100 1 01 102 103

Description

Cutter assembly Back plate Cutter ring Fastening members

back plate has a stepped portion on its surface, the

stepped portion including a plurality of oblong slots and

locating surfaces at predetermined locations on an outer

circumference of the stepped portion;

inserting a plurality of fastening members into holes pro vided on the back plate for guiding a cutter ring;

US 2012/0257940 A1

Oct. 11, 2012

mounting the cutter ring on the stepped portion of the back plate, Wherein said cutter ring has plurality of bayonet slots for passing the plurality of fastening members

13. The method as claimed in the claim 11, Wherein a drive

therethrough;

rotating the cutter ring in predetermined direction to lock

tenon is provided on the back plate for transmitting torque. 14. The method as claimed in the claim 11, Wherein plu rality of tenon slots are provided in the cutter ring at prede

termined locations to accommodate the drive tenon. 15. The method as claimed in the claim 11, Wherein the cutter ring is rotated in a direction opposite to a direction of

the plurality of fastening members in the bayonet slots;

and tightening the plurality of fastening members to secure the

cutting to lock the fastening members in the bayonet slots.

16. A method of milling using a cutter assembly as claimed in claim 1.

cutter ring against the back plate.

12. The method as claimed in the claim 11, Wherein a gap

is created betWeen the back plate and the cutter ring during mounting/dismounting of the cutter ring on the back plate.

You might also like

- Ci3503crsi - Column Tie ConfigurationsDocument7 pagesCi3503crsi - Column Tie ConfigurationsNono_geotecNo ratings yet

- INA Conrod BearingsDocument17 pagesINA Conrod Bearingsspeed844No ratings yet

- Title - Wood Chipper Disc and Knife MountingDocument5 pagesTitle - Wood Chipper Disc and Knife Mountingمحمد عبدالدايمNo ratings yet

- Improving The Candidate ExperienceDocument6 pagesImproving The Candidate ExperienceSunil PandeyNo ratings yet

- Checklist Co-Branding AgreementDocument6 pagesChecklist Co-Branding AgreementGryswolfNo ratings yet

- TEPZZ - 4 885B - T: European Patent SpecificationDocument10 pagesTEPZZ - 4 885B - T: European Patent SpecificationshamsNo ratings yet

- Title - Wood Chipper ConstructionDocument4 pagesTitle - Wood Chipper Constructionمحمد عبدالدايمNo ratings yet

- TEPZZZ89Z4 - 4B - T: European Patent SpecificationDocument25 pagesTEPZZZ89Z4 - 4B - T: European Patent Specificationzweisteine777No ratings yet

- EP19218347NWA1Document13 pagesEP19218347NWA1ginni koundalNo ratings yet

- European Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorDocument16 pagesEuropean Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorSelvaraji MuthuNo ratings yet

- US20010024927A1Document7 pagesUS20010024927A1MahnooshNo ratings yet

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDocument7 pagesUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinNo ratings yet

- US20110274550A1Document9 pagesUS20110274550A1雷黎明No ratings yet

- Patent Application Publication (10) Pub. No.: US 2003/0192191 A1Document15 pagesPatent Application Publication (10) Pub. No.: US 2003/0192191 A1Luis JJNo ratings yet

- European Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)Document10 pagesEuropean Patent Specification F01D 11/00: Printed by Jouve, 75001 PARIS (FR)shamsNo ratings yet

- US20050231024A1Document8 pagesUS20050231024A1aungkyawzoreNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1Document9 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0170973 A1almedinNo ratings yet

- 01Document4 pages01Santos JustinNo ratings yet

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pages偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongNo ratings yet

- United States Patent (10) Patent No.: US 8,251,371 B2Document4 pagesUnited States Patent (10) Patent No.: US 8,251,371 B2shamsNo ratings yet

- EjectionDocument32 pagesEjectionsk9145No ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0117282 A1Document11 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0117282 A1Cường Nguyễn QuốcNo ratings yet

- United States Patent: 54 All Purpose SawDocument4 pagesUnited States Patent: 54 All Purpose SawAngeliaNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- TEPZZ 7766 - B - T: European Patent SpecificationDocument15 pagesTEPZZ 7766 - B - T: European Patent Specificationanas aNo ratings yet

- Us 20020182054Document12 pagesUs 20020182054Nemanja StojanovicNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2003/0019100 A1Document10 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2003/0019100 A1amd mhmNo ratings yet

- Us20030075626 PDFDocument28 pagesUs20030075626 PDFprouserdesigner77No ratings yet

- EP1321438B1Document10 pagesEP1321438B1Alessandro PatanèNo ratings yet

- Us 4234275Document6 pagesUs 4234275MahnooshNo ratings yet

- EP21160517NWB1Document16 pagesEP21160517NWB1frank saruhanNo ratings yet

- Metrology M2Document85 pagesMetrology M2sidNo ratings yet

- US20030094838A1Document22 pagesUS20030094838A1Liam SkrooNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- MillingDocument54 pagesMillingVickyVenkataramanNo ratings yet

- taibl1 صورةDocument26 pagestaibl1 صورةAyham MhannaNo ratings yet

- TEPZZ 5649 8B - T: European Patent SpecificationDocument13 pagesTEPZZ 5649 8B - T: European Patent SpecificationneusonNo ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- United States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994Document6 pagesUnited States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994mohammadreza91No ratings yet

- Us 20090020472Document12 pagesUs 20090020472ankitsarvaiyaNo ratings yet

- Us20140196515 PDFDocument23 pagesUs20140196515 PDFnangkarak8201No ratings yet

- Cone Tolerance PDFDocument21 pagesCone Tolerance PDFsosu_sorin3904No ratings yet

- Tandard: Detail A Detail BDocument1 pageTandard: Detail A Detail BAnonymous YgEKXgWNo ratings yet

- TEPZZ Z85967A - T: European Patent ApplicationDocument15 pagesTEPZZ Z85967A - T: European Patent ApplicationJesusNo ratings yet

- TEPZZ Z789 - 5B - T: European Patent SpecificationDocument13 pagesTEPZZ Z789 - 5B - T: European Patent SpecificationСлэйтер Строительная компанияNo ratings yet

- European Patent Specification B64C 27/32: Printed by Jouve, 75001 PARIS (FR)Document12 pagesEuropean Patent Specification B64C 27/32: Printed by Jouve, 75001 PARIS (FR)Amir BahramiNo ratings yet

- MP-Term Work Part - 1Document20 pagesMP-Term Work Part - 1Dhruv DesaiNo ratings yet

- Wave Anchor Soil Reinforcing Connector and MethodsDocument17 pagesWave Anchor Soil Reinforcing Connector and MethodsSoumya Prakash SahooNo ratings yet

- OSHAS 29 CFR Part 1910 Subpart O (Up To Date As of 6-01-2023)Document97 pagesOSHAS 29 CFR Part 1910 Subpart O (Up To Date As of 6-01-2023)ReyVeg'AmhelNo ratings yet

- 06.damper Apparatus and Mounting Clip ToDocument4 pages06.damper Apparatus and Mounting Clip ToRohit BirajdarNo ratings yet

- Machining Process Used To Produce Various ShapesDocument33 pagesMachining Process Used To Produce Various ShapesAamer MohammedNo ratings yet

- Crankshaft AssemblyDocument87 pagesCrankshaft AssemblyGreg HannaNo ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- WO2013072747A1Document64 pagesWO2013072747A1MahnooshNo ratings yet

- Milling Operations and Types of MillingDocument33 pagesMilling Operations and Types of MillingLeo Dev WinsNo ratings yet

- US3883181Document8 pagesUS3883181aungkyawzoreNo ratings yet

- United States Patent (19) : GullettDocument7 pagesUnited States Patent (19) : GullettMaJoy GarciaNo ratings yet

- TEPZZ 66 - 44A - T: European Patent ApplicationDocument22 pagesTEPZZ 66 - 44A - T: European Patent ApplicationFernandoNo ratings yet

- Berco AB 651Document8 pagesBerco AB 651CTN2010No ratings yet

- Seeger RingDocument3 pagesSeeger Ringjprins7No ratings yet

- Frontify-Cabify Case StudyDocument8 pagesFrontify-Cabify Case StudyGlenda MontejoNo ratings yet

- Oëp P LZÑG .I 2I¡'7Ug - Yqzg.3 ÑP L (. 2mì7 3 M'Qil6 #!"Document2 pagesOëp P LZÑG .I 2I¡'7Ug - Yqzg.3 ÑP L (. 2mì7 3 M'Qil6 #!"Sudipta GhoshNo ratings yet

- Lexhawk Summer Internship - 2020: Contract Management Outsourcing ServicesDocument3 pagesLexhawk Summer Internship - 2020: Contract Management Outsourcing ServicesSri MuganNo ratings yet

- CONFERENCE Checklist Date: Location: Status Complete by Who Category Item Comments 9 Months OutDocument8 pagesCONFERENCE Checklist Date: Location: Status Complete by Who Category Item Comments 9 Months OutHeather Bird CorbettNo ratings yet

- CMM CompanyDocument640 pagesCMM CompanyKarthi KeyanNo ratings yet

- Source Document-WPS OfficeDocument2 pagesSource Document-WPS OfficeTeofel John Alvizo PantaleonNo ratings yet

- GCC Patent LawDocument11 pagesGCC Patent LawSamar HijaziNo ratings yet

- AcknowledgementDocument7 pagesAcknowledgementforwasteNo ratings yet

- Business To Business Marketing ManagementDocument1 pageBusiness To Business Marketing ManagementLara Michelle Sanday BinudinNo ratings yet

- Gapps Change Management PDFDocument120 pagesGapps Change Management PDFRommel GonzalezNo ratings yet

- Auditing and Assurance ServicesDocument12 pagesAuditing and Assurance ServicesAlysha Harvey EANo ratings yet

- 2VAA001810 en S Control SPCIS22 SPQRS22 Control I O Module and Quick Response I O ModuleDocument55 pages2VAA001810 en S Control SPCIS22 SPQRS22 Control I O Module and Quick Response I O Moduleanbarasan100% (2)

- Events After Reporting DATE - FSDocument5 pagesEvents After Reporting DATE - FSAngela MartiresNo ratings yet

- Logistics Leverage For Sustainable Competitive AdvantagesDocument57 pagesLogistics Leverage For Sustainable Competitive AdvantagesragatausNo ratings yet

- ECOM6008 12 Project GuidelineDocument4 pagesECOM6008 12 Project GuidelinerierunaruNo ratings yet

- How Are McKinsey, BCG, Bain, at Kearney and The Likes Playing The Game in India - Page 2 - Timesofindia-EconomictimesDocument3 pagesHow Are McKinsey, BCG, Bain, at Kearney and The Likes Playing The Game in India - Page 2 - Timesofindia-EconomictimesHarrish MurugesanNo ratings yet

- Vendor Briefing OverviewDocument15 pagesVendor Briefing OverviewNarendra PatankarNo ratings yet

- Ramy Anthony Marasigan ResumeDocument2 pagesRamy Anthony Marasigan Resumeam01maraNo ratings yet

- United States Bankruptcy Court District of Nevada: 73203-001/DOCS - SF:67913.2Document21 pagesUnited States Bankruptcy Court District of Nevada: 73203-001/DOCS - SF:67913.2Chapter 11 DocketsNo ratings yet

- Sotreq Condition Monitoring PDFDocument50 pagesSotreq Condition Monitoring PDFAbner VillanuevaNo ratings yet

- RBA Diary Ver1.2Document39 pagesRBA Diary Ver1.2rableenkhuranaNo ratings yet

- Sealway 16801Document2 pagesSealway 16801klecio silvaNo ratings yet

- HP Channel Management - Kashif Ahmed Saeed FinalDocument20 pagesHP Channel Management - Kashif Ahmed Saeed FinalKashif Ahmed SaeedNo ratings yet

- BP CRM Master DataDocument5 pagesBP CRM Master DatajoheleduNo ratings yet

- Sample of Mystery Shopping ReportingDocument42 pagesSample of Mystery Shopping Reportinglieny lestariNo ratings yet

- Ice CreamDocument29 pagesIce CreamRocky Singh0% (1)

- Ten2949 27jan2017Document208 pagesTen2949 27jan2017Cassandra StapelbergNo ratings yet

- Title: Analytical Term Paper of Chapter 10: Fraud and Forensic Auditing Part 1: General ObjectivesDocument2 pagesTitle: Analytical Term Paper of Chapter 10: Fraud and Forensic Auditing Part 1: General ObjectivesAndy ANo ratings yet