Professional Documents

Culture Documents

Fretting

Uploaded by

solidwormCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fretting

Uploaded by

solidwormCopyright:

Available Formats

//article 1122.334// Fretting refers to wear and sometimes corrosion damage at t he asperities of contact surfaces.

This damage is induced under load and in the presence of repeated relative surface motion, as induced for example by vibratio n. The ASM Handbook on //article 1122.334// Fatigue and Fracture defines fretting as: "A special wear process that occurs at the contact area between two materials under load and subject to minute relativ e motion by vibration or some other force." //article 1122.334// The amplitude of the relative sliding motion is often in the order from micromet ers to millimeters, but can be as low as 3 to 4 nanometers.[1] //article 1122.334// The contact movement causes mechanical wear and material transfer at the surface , often followed by oxidation of both the metallic debris and the freshly expose d metallic surfaces. Because the oxidized debris is usually much harder than the surfaces from which it came, it often acts as an abrasive agent that increases the rate of both fretting and a mechanical wear called false brinelling. //article 1122.334// Contents [hide] 1 Steel 2 Products affected 3 Fretting fatigue 4 Mitigation 5 See also 6 References 7 External links Steel[edit] Fretting damage in steel can be identified by the presence of a pitted surface a nd fine 'red' iron oxide dust reminiscent of cocoa powder. Strictly this debris is not 'rust' as its production requires no water. The particles are much harder than the steel surfaces in contact, so abrasive wear is inevitable; however, pa rticulates are not required to initiate fret. Products affected[edit] Fretting examples include wear of drive splines on driveshafts, wheels at the lu g bolt interface, and cylinder head gaskets subject to differentials in thermal expansion coefficients. There is a current focus on fretting research in the aerospace industry. The dov etail blade-root connection and the spline coupling of gas turbine aero engines experience fretting. Fretting fatigue[edit] Fretting decreases fatigue strength of materials operating under cycling stress. This can result in fretting fatigue, whereby fatigue cracks can initiate in the fretting zone. Afterwards, the crack propagates into the material. Lap joints, common on airframe surfaces, are a prime location for fretting corrosion. This i s also known as frettage or fretting corrosion.[2] Mitigation[edit] The fundamental way to prevent fretting is to design for no relative motion of t he surfaces at the contact. Surface finish plays an important role as fretting n ormally occurs by the contact of the asperities of the mating surfaces. Lubrican ts are often employed to mitigate fretting because they reduce friction and inhi bit oxidation.

Soft materials often exhibit higher susceptibility to fretting than hard materia ls of a similar type. The hardness ratio of the two sliding materials also has a n effect on fretting wear.[3] However, softer materials such as polymers can sho w the opposite effect when they capture hard debris which becomes embedded in th eir bearing surfaces. They then act as a very effective abrasive agent, wearing down the harder metal with which they are in contact.

You might also like

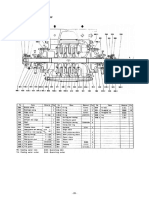

- Size MMK 40, 50, 65 Tuffing Box Housing: Type HW SDocument1 pageSize MMK 40, 50, 65 Tuffing Box Housing: Type HW SsolidwormNo ratings yet

- Sectional Drawings and Lists of Components: Size MMK 40, 50, 65 Stuffing Box Housing: Type NDocument1 pageSectional Drawings and Lists of Components: Size MMK 40, 50, 65 Stuffing Box Housing: Type NsolidwormNo ratings yet

- S Pare PartsDocument1 pageS Pare PartssolidwormNo ratings yet

- Fluid Statics: Manometers and Pressure MeasurementsDocument1 pageFluid Statics: Manometers and Pressure MeasurementssolidwormNo ratings yet

- 4.2.3. Re-Assembly of Pumps With End Suction NozzleDocument2 pages4.2.3. Re-Assembly of Pumps With End Suction NozzlesolidwormNo ratings yet

- Stub Shaft Dimensions, Packing Details, Cooling Water and Oil Requirements, Bearings, Seals, O-Rings and GasketsDocument1 pageStub Shaft Dimensions, Packing Details, Cooling Water and Oil Requirements, Bearings, Seals, O-Rings and GasketssolidwormNo ratings yet

- And Liquid Viscosity: Stress ZDocument1 pageAnd Liquid Viscosity: Stress ZsolidwormNo ratings yet

- Essentials of Turbo Machinery in CFD: Ideen SadrehaghighiDocument9 pagesEssentials of Turbo Machinery in CFD: Ideen SadrehaghighisolidwormNo ratings yet

- Fluid Properties: Density, Specific Volume, Specific Weight, Specific Gravity, and PressureDocument1 pageFluid Properties: Density, Specific Volume, Specific Weight, Specific Gravity, and PressuresolidwormNo ratings yet

- Buoyancy: Basic EquationsDocument1 pageBuoyancy: Basic EquationssolidwormNo ratings yet

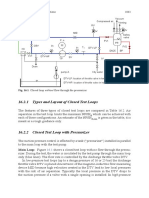

- 16.2.1 Types and Layout of Closed Test LoopsDocument1 page16.2.1 Types and Layout of Closed Test LoopssolidwormNo ratings yet

- Fluid Prope Pipe Flow: Bhabani P Mohanty. PH.D., Development Engineer. Allison Engine Company 2 7Document1 pageFluid Prope Pipe Flow: Bhabani P Mohanty. PH.D., Development Engineer. Allison Engine Company 2 7solidwormNo ratings yet

- General Requirements:: 1062 16 Pump TestingDocument1 pageGeneral Requirements:: 1062 16 Pump TestingsolidwormNo ratings yet

- Near Net ShapeDocument30 pagesNear Net ShapesolidwormNo ratings yet

- 669 IndexDocument1 page669 IndexsolidwormNo ratings yet

- 1 5736Document2 pages1 5736solidwormNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagessolidwormNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Using Electronic Detonators To Improve All-Round Blasting PerformancesDocument8 pagesUsing Electronic Detonators To Improve All-Round Blasting Performancesangel baez contrerasNo ratings yet

- TOC - Table of Compliance Arsitek SimDocument40 pagesTOC - Table of Compliance Arsitek SimImran nasution0% (1)

- Mineralogy 100A Syllabus 2016-EditDocument4 pagesMineralogy 100A Syllabus 2016-Editnot realNo ratings yet

- Industrial Slab Flooring ReportDocument31 pagesIndustrial Slab Flooring ReportChirag Chikmagalur VenkateshNo ratings yet

- Pulpling of Wood EditedDocument6 pagesPulpling of Wood EditedMuhammad Omar Khan GhouriNo ratings yet

- Shell Diala S2 Zx-A: Performance, Features & Benefits Main ApplicationsDocument3 pagesShell Diala S2 Zx-A: Performance, Features & Benefits Main ApplicationsDaniel Orlando Carballo FernándezNo ratings yet

- CH 4 PE PipeDocument22 pagesCH 4 PE Pipeanon_104613317No ratings yet

- JET - 36 - Coiled Tubing Downhole Tools UpdateDocument144 pagesJET - 36 - Coiled Tubing Downhole Tools UpdateMohamedIbrahim75% (4)

- Pinnacle Flo, InC.Document16 pagesPinnacle Flo, InC.r_chulinNo ratings yet

- Steel Connections Show Final Version 20-6-2008 ModifiedDocument76 pagesSteel Connections Show Final Version 20-6-2008 ModifiedyahNo ratings yet

- Seismic Code Evaluation Trinidad and TobagoDocument7 pagesSeismic Code Evaluation Trinidad and TobagodeniscoteingNo ratings yet

- The Effects of Mechanical Stress On Semiconductor DevicesDocument3 pagesThe Effects of Mechanical Stress On Semiconductor Devicesvishnu vardhanNo ratings yet

- Oil Refinary Dr Adndn 2016-مهمةDocument234 pagesOil Refinary Dr Adndn 2016-مهمةHmid AljbreNo ratings yet

- Atomic Absorption & EmissionDocument80 pagesAtomic Absorption & EmissionAkshay Patil100% (1)

- Ion Exchange Resins Selectivity - 45-D01458-EnDocument4 pagesIon Exchange Resins Selectivity - 45-D01458-EnDFMNo ratings yet

- Weldwell Spectrum July Dec 2019Document20 pagesWeldwell Spectrum July Dec 2019Mahesh DeshmukhNo ratings yet

- Fivc PN16 Vodrv DN65 600Document9 pagesFivc PN16 Vodrv DN65 600Rabea EzzatNo ratings yet

- (Lec6) Phase EquilibriaDocument52 pages(Lec6) Phase EquilibriadinurjNo ratings yet

- Remote Earth Cathodic ProtectionDocument2 pagesRemote Earth Cathodic ProtectionankiNo ratings yet

- Sucker Rod Pump BasicsDocument76 pagesSucker Rod Pump BasicsDumitrescu GabrielNo ratings yet

- 50031161662011fa PDFDocument88 pages50031161662011fa PDFAgung Pramu AjiNo ratings yet

- Plastic InjectionDocument39 pagesPlastic InjectionRishav KumarNo ratings yet

- The Effect of Different Vegetable Peelings and Additives/Chemicals Added To The Quality and Characteristics of BioplasticsDocument55 pagesThe Effect of Different Vegetable Peelings and Additives/Chemicals Added To The Quality and Characteristics of BioplasticsAirielle MiotenNo ratings yet

- Tech AlloyDocument2 pagesTech AlloyDave MulvihillNo ratings yet

- Technical Bulletin: Valdisk TX3 Triple Offset Butterfly Control ValveDocument20 pagesTechnical Bulletin: Valdisk TX3 Triple Offset Butterfly Control ValveAhmed KhairiNo ratings yet

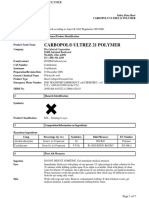

- Carbopol® Ultrez 21 Polymer: The Lubrizol Corporation 29400 Lakeland Boulevard Wickliffe, Ohio 44092 Tel: (440) 943-4200Document7 pagesCarbopol® Ultrez 21 Polymer: The Lubrizol Corporation 29400 Lakeland Boulevard Wickliffe, Ohio 44092 Tel: (440) 943-4200Ana Paula JimenezNo ratings yet

- Misumi OilFreeBushing p281 282Document1 pageMisumi OilFreeBushing p281 282Lutfi ArdiansyahNo ratings yet

- Indrakanty Surya ShashankDocument10 pagesIndrakanty Surya ShashankINDRAKANTY SURYA SHASHANKNo ratings yet

- Drug Product DevelopmentDocument20 pagesDrug Product Developmentducluong28No ratings yet

- SolutionDocument13 pagesSolutionTare Er KshitijNo ratings yet