Professional Documents

Culture Documents

Supercritical Uid Extraction of Spent Coffee Grounds - Measurement of Extraction Curves and Economic Analysis

Supercritical Uid Extraction of Spent Coffee Grounds - Measurement of Extraction Curves and Economic Analysis

Uploaded by

Marcelo MeloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supercritical Uid Extraction of Spent Coffee Grounds - Measurement of Extraction Curves and Economic Analysis

Supercritical Uid Extraction of Spent Coffee Grounds - Measurement of Extraction Curves and Economic Analysis

Uploaded by

Marcelo MeloCopyright:

Available Formats

J.

of Supercritical Fluids 86 (2014) 150159

Contents lists available at ScienceDirect

The Journal of Supercritical Fluids

journal homepage: www.elsevier.com/locate/supflu

Supercritical uid extraction of spent coffee grounds: Measurement of extraction curves, oil characterization and economic analysis

Marcelo M.R. de Melo, Hugo M.A. Barbosa, Cludia P. Passos, Carlos M. Silva

Department of Chemistry, CICECO, University of Aveiro, Aveiro 3810-193, Portugal

a r t i c l e

i n f o

a b s t r a c t

This work addresses scientic and techno-economic aspects of supercritical uid extraction (SFE) of spent coffee grounds which are of interest under the biorenery context. Soxhlet experiments were carried out and SFE curves were measured at 190 bar and 40 C/55 C. The extracts were characterized by GC-FID, and the triacylglycerides proles were almost constant along an extraction curve, and similar to the n-hexane Soxhlet results: linoleic and palmitic acids content in both extracts are 44.5 and 37.5% (wt.), respectively. The oil solubility, intraparticle diffusion, convective mass transfer coefcient, and oil removal ux (this one estimated for innite dilution) were calculated and discussed in detail in the ranges of operating conditions under analysis. It was concluded that solubility is the chief parameter behind the distinct cumulative extraction curves, and that all experiments are subjected to equivalent mass transfer resistances. An economic analysis involving cost of manufacturing (COM) and net income calculations were performed for distinct operating conditions and unit arrangements. The optima results were obtained for 1 1 an arrangement of 3 beds of 1 m3 , extraction time of 2.0 h, 300 bar, 50 C and 30 kgCO2 kg h . Under SCG these conditions production can reach 454 ton year1 , a cost of manufacturing (COM) around 2.4 MD , and process net income of 56.6 MD . A sensitivity analysis varying the unit capacity, extraction time and precipitation pressure (extract vessel), showed the process economics to remain viable. 2013 Elsevier B.V. All rights reserved.

Article history: Received 10 July 2013 Received in revised form 14 December 2013 Accepted 16 December 2013 Keywords: Economic analysis Extraction curve Modeling Oil Spent coffee grounds Supercritical uid extraction

1. Introduction According to data from 2011, coffee market in Portugal involves an annual consumption of around 50 kton [1]. Considering what it represents for nal consumer drinking habits, this value implies a large volume of waste being generated by food industry in consequence of processing this raw material. For instance, when considering soluble coffee, 24.5 tons of spent coffee grounds (SCG) are generated per ton of soluble coffee produced [2,3], with a moisture content around 80% [3]. Whether in domestic or industrial contexts, SCG are a waste material that typically undergoes incineration and landll disposal despite its toxicity due to caffeine, tannins and polyphenols content. In view of minimizing the environmental impact of this residue and to increase its market protability, researchers have been studying SCG features and identifying potential applications [2,46]. Furthermore it has been shown that SCG have an oil content up to 23.9% [4], and generates a biocrude oil up to 55% if fast pyrolysis is employed [7]. The SCG material comprising the nonextractable residue can be further used as a fuel source through

Corresponding author. Tel.: +351 234401549; fax: +351 234370084. E-mail address: carlos.manuel@ua.pt (C.M. Silva). 0896-8446/$ see front matter 2013 Elsevier B.V. All rights reserved. http://dx.doi.org/10.1016/j.supu.2013.12.016

pelletizing, as a fertilizer or even as a feedstock for bioethanol production [2,8]. In what concerns the composition of this oil, works may be found in literature aiming at phenolic [9] and diterpenic [10,11] compounds enrichment on its constitution. A very recent publication from Ribeiro et al. communicated the promising potential of SCG for cosmetic industry after a cream formulation containing SCG lipids has conrmed hydration features [6]. The employment of supercritical carbon dioxide (SC-CO2 ) for the extraction of vegetable matrices has been widely studied as a green extraction solution aiming at the replacement of conventional organic solvents. For instance, in recent publications on this extraction technology, different raw materials have been studied, like eucalypt [1216] and grape seed [1719], with attention to aspects such as optimization of working conditions [11,14], extract properties [17] and modeling [12,13,20,21]. In addition, within the last years several works on economic assessments of SFE have been published employing cost of manufacturing (COM) calculations, following a methodology proposed by Turton et al. [22]. It is the case of SFE of jabuticaba skins [23], Amazonian trees [24] and Tabernaemontana catharinensis [25], grape seed [19], Anacardium occidentale L. [26] and rosemary [27]. Coffee was one the rst raw materials to be processed by supercritical uid extraction, mainly for decaffeination purposes. It is thus likely that also SCG become matter of this technology,

M.M.R. de Melo et al. / J. of Supercritical Fluids 86 (2014) 150159

151

particularly if one takes into account that SFE is already applied to produce decaffeinated coffee. In this work, SFE curves of SCG oil are measured, and its composition is analyzed. SFE and Soxhlet extraction results are compared with data taken from the literature in Sections 3.1 and 3.2 and a preliminary economic evaluation of the supercritical the process is performed in Section 3.3 in order to determine the most promising operating conditions. Here values for the costs of manufacturing (COM) are estimated as well as net income and production are investigated. Still in Section 2.3, economic results are also assessed upon a sensitivity analysis regarding the impact of extraction time, unit capacity, and separator pressure on the process viability. Final remarks are presented in Section 4. 2. Experimental 2.1. Materials and methods A fatty acids methyl esters (FAME) mix (C8C24) and methyl heptadecanoate ester were purchased from Supelco (Bellefonte, PA, USA). All other reagents used were of analytical grade or higher available purity. Carbon dioxide was supplied with a purity of 99.95% from Praxair (Porto, Portugal) and all the other reagents were of analytical grade or higher available purity. 2.2. Samples and general procedures Espresso spent coffee grounds (SCG) were obtained in a coffee vending machine from a commercial batch of Delta Cafs Platina (Portugal). The SCG samples were dried according to the ISO/DIS 11294-1993, by the method of oven drying at 105 C during 8 h [28]. 2.3. Soxhlet extraction For comparison purposes an extract of spent coffee grounds were rstly obtained by Soxhlet. An amount of 30.4 g of spent coffee grounds was placed inside the Soxhlet apparatus and treated with 300 mL of analytical grade n-hexane for 4 h. At the end the solvent was evaporated to dryness and the extract was weighed and analyzed by GC-FID. The extraction was performed in triplicate. 2.4. Supercritical uid extraction The SFE experiments were carried out with carbon dioxide under semi-continuous operation in an apparatus built/assembled at the University of Aveiro. A detailed description of this equipment may be consulted in a previous work [17]. Briey the CO2 withdrawn from a container is rstly liqueed in a refrigerated bath and then pressurized by an air driven liquid pump to a high-pressure vessel. The solvent is brought to the extraction temperature by means of a long tubing coil placed inside the oven and the pressure is xed in a forward pressure regulator. After percolating the seed bed, the extract stream passes through micrometering valves. The valves and the adjoining line are heated to prevent blocking up due to oil and CO2 freezing, enabling the safe collection of extract in a separator. At the end extract samples were dried and weighed. In each experiment, 60 g of dried raw material was placed inside the extractor, the ow rate used was 12 gCO2 min1 , the temperature varied from 40 to 55 C, and a pressure of 190 bar. The operating conditions are shown in Table 1, along with two runs taken from the literature to enrich the preliminary economic analysis performed below. It was considered acceptable to combine data from different sources because the contents of lipids and fatty acid proles are

comparable. Nevertheless they are distinguished as blocks A1, A2 (this work) and B1 and B2 (data from [29]). 2.5. Triacylglycerides prole The triacylglycerides content was determined by GC-FID by the sum of the amounts of the individual fatty acids methyl esters obtained after transesterication with sodium methoxide according to the methodology described by Passos et al. [17]. The compounds were identied by comparing their retention times with those of a commercial FAME mixture (C8 C24 ). 2.6. Economic analysis In order to accomplish a preliminary economic evaluation of the process viability at industrial scale, lab results were scaled-up based on criteria that take into account the nature of the limitation that governs the extraction process [30]: when solubility limitation prevails, the ratio of mass of solvent to mass of raw material 1 ) shall be kept constant, but if a diffusional mechanism (wCO2 wSCG is dominant the ratio to be held constant is the quotient of solvent ow rate to mass of feed. The economic analysis was based on the methodology of Turton et al. [22] which has been used by other authors for SFE processes [3133]. It sets the cost of manufacturing (COM) as a function of investment cost (FCI), labor cost (COL), utility cost (CUT), waste treatment cost (CWT) and raw material cost (CRM), using the following relation: COM = 0.304 FCI + 2.73 COL + 1.23 (CUT + CWT + CRM) (1)

By specifying a market value for the extracted oil based on current prices of coffee oil, revenue and a net income (annual revenue COM) calculations were also accomplished, which lead to a true disclosure regarding the economy of the SFE process. The list of assumptions that support our economic assessment results are presented in Table 2. All data regarding utilities costs were obtained from simulations of the SFE process in Aspen Plus (version 7.3). 3. Results and discussion This section is divided in three subsections: Section 3.1 presents our Soxhlet extraction results and establishes a comparison with data from literature; Section 3.2 is devoted to the SFE, where the measured curves are also analyzed and compared with results from literature; the third subsection comprises the economic assessment of the most promising results from Section 3.2, followed by a sensitivity analysis. 3.1. Soxhlet extraction Table 3 presents the Soxhlet results obtained in this assay for the extraction of SCG with n-hexane, along with others reported in the literature for the same system. By comparing the obtained values with other equivalent works it is noticeable that the oil yields can suffer some variation depending on the samples employed, ranging from 14% to 18% (wt.). This observation has been also reported by Cruz et al. [4] who analyzed and compared the composition and extraction yield of SCG oil obtained from 13 coffee brands through Soxhlet, using petroleum ether. They showed that, depending on the coffee brand, the total soluble solids could range from 18.2% to 23.9% (wt.). The extraction yield determined in this essay, as an average of three runs, is 15.0% (wt.) and lies within the values found in previous works for this raw material (see Table 3) [29,39,40]. In what

152

M.M.R. de Melo et al. / J. of Supercritical Fluids 86 (2014) 150159

Table 1 Operating conditions of the experiments performed in this work and taken from literature for comparison purposes. wSCG (g) Run A1 Run A2 Run B1 Run B2 60 60 20 20 QCO2 (g min1 ) 12 12 10 10

1 QCO2 wSCG (h1 )

P (bar) 190 190 200 300

T ( C) 40 55 50 50

Ref. This work This work [29] [29]

12 12 30 30

Table 2 List of assumptions of the economic analysis of the SFE of spent coffee grounds (SCG). General - Unit working period: 24 h per day, 330 days per year. - Number of workers per extractor = 1. - Scale-up criterion: solvent ow rate per mass of SCG in the 1 ) extractor (QCO2 wSCG - Minimum pressure in the separator (extract collection vessel) = 45 bar. - Required time to unload, load and pressurize 1 extractor (tprep ): 1 h - Whenever the extraction time is inferior to the preparation time (t < tprep = 1 h), the unit is switched off. - The CO2 losses in each full decompression correspond to the mass of CO2 inside the extractor at 45 bar and 40 C. - SCG bed density = 400 kg m3 . - SCG bed porosity = 0.8. - Exchange ratio D /$US (on May 2013) = 0.766 - Market price of coffee oil = 130 D kg1 [34] (in ref. [35], a large value of 194 D kg1 is reported. We adopted the lower one for a conservative analysis of the process.) - SCG initial moisture = 60.7% (wt) [36] - Dried SCG heat capacity = 1.434 kJ kg1 C1 [37] - Annual depreciation rate = 10% - SFE units prices: (i) 1.5 MD for a unit comprising two 0.4 m3 extractors as presented by Rosa et al. [32]; (ii) 2.3 MD for a three-extractors unit each with 0.4 m3 of capacity, calculated by the expression proposed by Lack et al. [38]; (iii) 3.2 MD for a three-extractors unit each with 1.0 m3 of capacity, calculated by the expression proposed by Lack et al. [38]. - Labor cost = 10 D h1 worker1 - Cost of electricity = 50 D MWh1 - Cost of steam = 1.53 D ton1 - Cost of waste treatment = 0 D

1 - Cost of spent coffee grounds drying = 0.016 D kg SCG - Cost of CO2 = 800 D ton1

FCI

cumulative curves from Couto et al. [29] are also represented for comparison. In general all curves exhibit the typical trend found in the SFE of edible oils, i.e. a constant period of extraction followed by a second diffusional period. In this work, the registered curvatures evidence kinetic limitations to mass transfer, particularly in Runs A1, A2, B1. Considering that pressure, ow rate, and mass of SCG bed remained constant in our experiments (Runs A1 and A2), the different performances are due to the inuence of temperature (40 C vs. 55 C). It is known that this variable is usually important in SFE processes owing to its impact on the solubility and diffusivity of compounds. Any increase in temperature generates two thermodynamic opposing effects the positive inuence upon solute vapor pressure and negative impact on CO2 density and also an effective diffusivity enhancement inside the particle. The external diffusion in the lm may evidence a more complex dependence. The solute uxes result obviously from the combination of these factors as it is analyzed in detail in the following. The oil solubility (kg m3 ) can be estimated by the correlation of del Valle and Aguilera [41] as function of temperature (K) and SC-CO2 density (kg m3 ) by: ys =

10.724

exp

18708 2186840 + 40.361 + T T2

(2)

COL CUT CWT CRM

where density can be computed by the accurate equation of Pitzer and Schreiber [42]. The increment (over the same reference) of the convective mass transfer coefcient (kf ) can be estimated by the correlation of Wakao and Funazkri [43]: Sh = 2.0 + 1.1Re0.6 Sc 1/3 (3)

Here the viscosity of SC-CO2 was obtained by the equation of Altunin and Sakhabetdinov [44], and the diffusion coefcient (cm2 s1 ) of triolein (taken as model molecule) was estimated by the very simple and accurate model of Magalhes et al. [45]: D12 = t a

1

concerns fatty acids proles, the obtained results fall below the values published by Couto et al. [29], particularly for palmitic acid, 37.37% against 46.22% (wt.) (Table 3). For this reason, the most abundant fatty acid found in our SCG samples is linoleic acid, with a share of 44.67% (wt.), while in the case of the referred authors palmitic acid was the most representative. 3.2. Supercritical uid extraction Fig. 1 presents the SFE curves measured at 190 bar/40 C and 190 bar/55 C plotted against time. The results are normalized by the Soxhlet extraction yield and graphed as function of time. The

Table 3 Fatty acids prole of the extracted oil obtained by Soxhlet with n-hexane. Fatty acid Palmitic Stearic Oleic Linoleic -Linoleic Arachidic

1 ) Total extraction yield (kgSCG oil 100 kg SCG

+b

(4)

where T is in K, viscosity in cP, and triolein constants are a = 6.34288 109 and b = 4.89262 108 . The effective diffusivities inside the biomass particles may be estimated taking into account their porosity () and tortuosity ( ) by Deff = D12 / . Finally, the oil ux from the matrix to the supercritical bulk can be predicted as a rst approximation by its value at innite dilution, i.e.:

Noil = kf CO2 (ys

0)

(5)

This work C16:0 (wt. %) C18:0 (wt. %) C18:1 (wt. %) C18:2 (wt. %) C18:3 (wt. %) C20:0 (wt. %) 37.37 7.07 8.31 44.67 1.42 1.16 15.0

Couto et al. [29] 46.22 6.87 8.63 34.36 1.39 2.53 18.3

Calixto et al. [39]

Al-Hamamre et al. [40]

14.0

15.3

M.M.R. de Melo et al. / J. of Supercritical Fluids 86 (2014) 150159

153

Fig. 1. SFE curves of spent coffee grounds (SCG) oil at different pressures and temperatures (see Table 1).

Fig. 2. Normalized (a) oil solubility computed by the expression proposed by del Valle and Aguilera [41], and (b) intraparticle effective diffusivities calculated by the correlation of Magalhes et al. [45], as functions of temperature and pressure.

In Figs. 2 and 3 the calculated results for the oil solubility, effective intraparticle diffusivity, convective mass transfer coefcient, and oil ux at innite dilution are plotted. In order to evaluate the inuence of the operating conditions upon each dependent variable, they are represented normalized by the same quantity at 190 bar/55 C (Run A2), giving readers the opportunity to capture the enhancements over the reference values. In the case of Fig. 2, the quantities corresponding to the experimental runs under analysis in this essay are superimposed. From Fig. 2a it is evident that solubility favors largely Run B2 in comparison to Runs A1, A2 and B1, due to the chief effect of pressure; the ys values increase like Run A2 < Run B1 < Run A1 Run B2 (global variation = 3.43). On the other hand, the kinetics inside the particles disclosed in Fig. 2b emphasize that the internal limitations to mass transfer are equally important in all experiments, since there is not any major diffusivity jump (global variation = 0.08); however the increasing sequence of normalized Deff is: Run A1 < Run B2 < Run B1 < Run A2. In terms of the normalized convective mass transfer coefcient, Fig. 3a points out the following behavior: Run A1 < Run A2 Run B2 < Run B1, though the global variation is 0.25. Finally, the oil uxes at innite dilution plotted in Fig. 3b detach once again the importance of the pressure, since Run A2 < Run A1 Run B1 Run B2 (global variation = 2.96). As a result, the distinguishing factor behind the four experiments is the solubility enhancement observed which affects signicantly the uxes. Moreover all runs are equally affected by internal and/or external limitations to mass transfer. The experimental results of Fig. 1 will be now analyzed on the light of these principles. Coming back to Fig. 1, a temperature increase from 40 C (Run A1) to 55 C (Run A2) at 190 bar penalized the performance of the process, since the rate of extraction at 55 C was delayed in comparison to the results at 40 C. While Run A1 yields increased progressively until reaching 73% of Soxhlet value, within the 7.2 h of the extraction curve at 190 bar/55 C (Run A2), the highest yield attained was 61%. These two assays denote a counterproductive effect of temperature for the process at this pressure, which is in great agreement with the indicative Ni results for the two runs shown in Fig. 3b. In this case, the solubility increment compensates the negative effects of the internal and external mass transfer (confront Fig. 2a with Figs. 2b and 3a). The nal yield achieved on Run A1 (190 bar/40 C) is comparable to the value obtained by Couto et al. [29] on Run B1, at 200 bar/50 C. On the other hand the extraction velocity from these authors is 60% higher (measured by the slopes at short times), which apparently disagrees with the Ni trend suggested in Fig. 3b. However taking into account that the space time of Run B1 is 40% of Run A1, we are farther from the innite dilute conditions, which means that the

154

M.M.R. de Melo et al. / J. of Supercritical Fluids 86 (2014) 150159

Fig. 3. (a) Normalized convective mass transfer coefcient calculated by the correlation of Puiggen et al. [46], and (b) normalized oil removal uxes in the limit of innite dilute solutions.

real ux in our case is inferior. This fact justies the slit of curves A1 and B1 in Fig. 1. When considering the extraction curve 4 obtained at a harder pressure condition (300 bar) but same temperature (50 C) of Run 3, the oil removal rate is visibly increased (3.6 times). In fact after 1 h of extraction the curve has already achieved a nearly at region in the yield ratios range of 7882%. Such evidence unveils the great inuence of pressure upon this SFE process, which is conrmed by the higher oil uxes estimated by Ni (see Fig. 3b): 1.62 versus 3.96. Once again the milestone effect is the solubility (see Fig. 2a) since the transport limitations are similar (see Figs. 2b and 3a).

in the literature for SCG [4,29] (see Table 4). In this work, both Soxhlet and supercritical experiments were performed using the same amount of SCG, which explains the high correlation between the data. In general, literature results show that the fatty acids prole is independent of the raw material treatment (green vs. roasted), method of preparation (coffee brew vs. ltration), and also extraction method (Soxhlet vs. supercritical CO2 ). The maximum

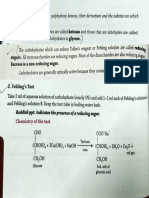

3.3. Triacylglycerides prole The fatty acids prole along time of the SCG oil obtained by supercritical extraction in Run A2 (190 bar/55 C) has been determined and is represented in Fig. 4. The main fatty acids present in all the samples are linoleic acid (C18:2) and palmitic acid (C16:0), followed by oleic acid (C18:1) and stearic acid (C18:0). Other minor acids present in the extracts are linolenic (C18:3), and arachidic (C20:0) acids. Furthermore, Fig. 4 shows that there is a small variation between the composition of individual supercritical extracts and that of Soxhlet. The global oil obtained by joining all SC extracts is also in good agreement with our Soxhlet and those reported

Fig. 4. Fatty acids prole of Soxhlet extracted SCG oil, and of the individual supercritical extracts E1E5 obtained at 190 bar/55 C (Run A2 of Table 1 and Fig. 1).

M.M.R. de Melo et al. / J. of Supercritical Fluids 86 (2014) 150159 Table 4 Extraction yields and fatty acids proles obtained in this work and taken from literature. Data for SFE and Soxhlet extraction. Composition This work Soxhlet (n-hexane) C16:0 C18:0 C18:1 C18:2 C18:3 C20:0 (%) 37.37 7.07 8.31 44.67 1.42 1.16 15.0 SFE (Run A2) 37.48 6.02 9.53 44.52 0.99 1.46 Couto et al. [29] Soxhlet (n-hexane) 46.22 6.87 8.63 34.36 1.39 2.53 18.3 SFE (Run B1) 36.19 7.59 11.24 41.45 0.86 2.68 Cruz et al. [4]

155

Soxhlet (petroleum ether) 32.8 7.1 10.3 44.2 1.5 2.6 12.5

yield of SCG oil obtained was 15.0% of the SCG (dry weight) which is slightly lower when compared to Couto et al. [29] but higher when compared to Cruz et al. [4], all within an acceptable range. 3.4. Economic analysis 3.4.1. Selection of extraction curves and extraction times In view of the objective to perform an economic evaluation of this SFE process, the selection of the operating conditions was based on the normalized cumulative curves of Fig. 1. Runs A1 and B2 were chosen for this purpose: 190 bar/40 C and 300 bar/50 C (see Table 1 and Fig. 1). To perform the comparative economic evaluation, the extraction time should be held constant in each case. The specication of this variable is very important because it denes the moment when an extracted bed should be replaced by a virgin one, and through this denition aspect like utilities, SCG processed or energy costs are also affected. In this essay it corresponds to the transition from the period when process is being mostly controlled by external mass transfer limitations and the period when intraparticle diffusion starts to be dominant, which can be determined by the intersection of the straight lines tting both regimes (see Fig. 5). The times obtained are 0.7 h and 3.8 h for 300 bar/50 C and 190 bar/40 C runs, respectively. 3.4.2. Economic evaluation The economic assessment of the SFE of the SCG oil based on the data of Fig. 5, Tables 1 and 2 was accomplished after tting the extraction time. A SFE unit comprising two 0.4 m3 extractors (see Table 2) was chosen to compare the performances of the two SFE conditions considered (Runs A1 and B2). Fig. 6 presents the cost of manufacturing (COM) and the annual SCG oil production expected in each circumstance. In what concerns COM, it may be observed there are signicant differences between the two cases. While the

lower pressure case (190 bar/40 C, Run A1) leads to a COM of 642 kD year1 , at 300 bar and 50 C it reaches 951 kD year1 . To better understand the nature of these very distinct COM values, Fig. 7 provides the partition of COM values in their respective fractions, namely, investment (FCI), labor (COL), utility (CUT), waste treatment (CWT), and raw material (CRM) costs see Eq. (1). While FCI + COL absolute costs are exactly the same in both cases, (the SFE unit and the work load is the same), the CUT + CRM parcels increase signicantly, passing from 25% of COM in Run A1 to 50% of COM in Run B2. Such increase is a direct consequence of the severer conditions of pressure (300 bar) and temperature (50 C), and of the higher number of batches being processed annually in view of the shorter extraction time (0.7 h). The more the batches processed the higher the amount of CO2 that is lost due to full decompression steps which increases of the make-up costs of CO2 . Moreover, shorter extraction cycles also imply higher costs of repressurization (CUT) and, also, a higher cost regarding the drying of the raw material (CUT). If the economic assessment was based only on COM values, one would be tempted to opt toward the situation that leads to lower process costs. This is the drawback of using this methodology as single tool to evaluate the economic attractiveness of a process. Accordingly, if productivities are also taken into account for each case, one may disclose that the differences between the performances of the two cases are even greater than those of the COM values, as shown in Fig. 6. While SFE case with severer condi1 tions (300 bar/50 C/30 kgCO2 kg h1 ) lead to a COM 1.5 times SCG greater, it also leads to an annual production 4.1 times greater, which reects the great impact of the higher extraction rate advantages observed in Fig. 5. As a result, the expected annual production at 300 bar, 50 C and t = 0.7 h is 176 ton of SCG oil, while at 190 bar, 40 C and t = 3.8 h, it is set on 43 ton. Furthermore if the COM and

Fig. 5. SFE curves of spent coffee grounds (SCG) for experiments A1 and B2 of Table 1, and determination of their extraction times.

1 1 = 30 kgCO2 kg h t = 0.7 h, QCO2 wSCG SCG

Fig. 6. Cost of manufacturing (COM) and oil production for two 0.4 m3 extractors in 1 1 1 = 12 kgCO2 kg h , and 300 bar, 50 C, parallel, at 190 bar, 40 C, t = 3.8 h, QCO2 wSCG SCG

1

, respectively.

156

M.M.R. de Melo et al. / J. of Supercritical Fluids 86 (2014) 150159

1 30 kgCO2 kg SCG

1 1 = 12 kgCO2 kg h Fig. 7. Parcels (%) of the COM values (see Eq. (1)) for the SFE units working at 190 bar, 40 C, t = 3.8 h, QCO2 wSCG SCG

1 and 300 bar, 50 C, t = 0.7 h, QCO2 wSCG =

, respectively. In both cases there are two extractors of 0.4 m working in parallel.

production results are combined in terms of a net income calculation, which is shown in Fig. 8, economic viability can be fully unveiled. Notwithstanding the fact that the two cases lead to a positive economic viability, the choice upon the fastest extraction case (300 bar, 50 C, t = 0.7 h) represents 4.4 times the net income of the less productive case, reaching 21.9 MD year1 . It is worthwhile to stress that in this case the viability of the process is highly supported by the larger productivity in view of the high commercial value of SCG oil, which thus pay the higher costs resulting from the harder extraction conditions implied. 3.4.3. Sensitivity analysis: extraction time and SFE unit capacity It is worthwhile to check how COM, productivity and net income behave when some chief process parameters are changed. Furthermore, if the SFE unit layout is changed, the conjugation of different equipment, raw material, labor and utilities costs with the corresponding variations on productivity and thus product revenues may be meaningfully different. The same is true for extraction time, which largely inuences the overall process net income, as previously discussed. The sensitivity analysis of this section is based on

the best case studied before, namely SFE extraction curve at 300 bar, 1 1 = 30 kgCO2 kg h1 (Run B2). 50 C and QCO2 wSCG SCG Fig. 9 presents COM as a function of extraction time for each of the three SFE unit congurations referred in Table 2. Values for time of extraction equal to zero are provided to disclose the impact of investment (FCI) and operational labor (COL) costs, which represent the process xed costs. The COM values exhibit a similar trend in all cases, namely, they increase up to a maximum and then start to decrease: the maxima are 2 h for 3 extractors and 1 h for 2 extractors. For an arrangement of N extractors in parallel, such maxima correspond to: t (COMmax ) = (N 1) tprep (6)

where tprep is the time required for the preparation of an extractor (unload, load and pressurization). The growing sections of Fig. 9 are due to the increment of utilities cost (CUT) while their diminishing is attributed to the fall of CRM. Without loss of generality, this is clearly illustrated in Fig. 10 for the case of 3 extractors of 1 m3 . In Fig. 11 the SCG oil production is plotted against extraction time. It is evident the differences found for the three arrangements, as their maxima lie between 177 and 454 ton year1 . However, the

1 30 kgCO2 kg SCG

Fig. 8. Net Income for two 0.4 m3 extractors in parallel at 190 bar, 40 C, 1 1 1 1 = 12 kgCO2 kg h , and 300 bar, 50 C, t = 0.7 h, QCO2 wSCG = t = 3.8 h, QCO2 wSCG SCG h

1

, respectively.

Fig. 9. Cost of manufacturing (COM) of spent coffee grounds (SCG) oil as function of 1 1 1 = 30 kgCO2 kg h (Run B2), extraction time per cycle, at 300 bar, 50 C, QCO2 wSCG SCG for different SFE unit congurations.

M.M.R. de Melo et al. / J. of Supercritical Fluids 86 (2014) 150159

157

Fig. 10. Utility (CUT) and raw material (CRM) costs against extraction time for the 1 1 1 = 30 kgCO2 kg h SFE of spent coffee grounds (SCG) oil at 300 bar, 50 C, QCO2 wSCG SCG (Run B2) for unit layout comprising 3 extractors of 1 m3 in parallel.

Fig. 13. Variation of cost of manufacturing (COM) as function of the separator 1 = pressure (reference =45 bar). Data for SFE at 300 bar, 50 C, t = 0.7 h, QCO2 wSCG

1

1 h (Run B2). The corresponding densities are 83.9, 97.8, 113.2, 130.2, 30 kgCO2 kg SCG 149.4 and 171.6 kg m3 .

assumptions of Table 2, the net income is positive for any extraction time and layout considered. The shape of the net income proles is quite similar to the annual production proles (Fig. 11), because the expected revenues from the produced oil are rather high in comparison to the respective costs of manufacturing (COM). The maximum values for each unit are 56 MD for 3 extractors of 1 m3 and t = 2 h, 22 MD for 3 extractors of 0.4 m3 and t = 2 h, and 22 MD for 2 extractors of 0.4 m3 and t = 1 h. Within the interval between t = 0.7 h (time established from extraction curve see Fig. 5) and t (COMmax ), the net income prole slightly increases, while outside it decreases sharply instead. 3.4.4. Sensitivity analysis: minimum pressure of the system Besides time and extractors arrangement, another working parameter that also affects COM is the minimum pressure in the separator where the extract precipitates, by means of the mass of CO2 that is lost in each batch and through the energy needed for heating and cooling. In this respect, a sensitivity analysis is provided in Fig. 13 for an arrangement of 2 extractors with 0.4 m3 , where P, T, 1 conditions were held constant (300 bar, 50 C, 0.7 h t and QCO2 wSCG

Fig. 11. Annual production of spent coffee grounds (SCG) oil as function of extraction 1 1 1 = 30 kgCO2 kg h (Run B2), for different SFE unit time, at 300 bar, 50 C, QCO2 wSCG SCG congurations.

most signicant feature is the overlapping of the 3 0.4 m3 and 2 0.4 m3 arrangements for extraction times lower than 1 h, since in this period the process is controlled by the preparation time, tprep = 1 h. The net income values are presented in Fig. 12 as function of extraction time for the different SFE unit arrangement. Given all the

1 and 30 kgCO2 kg h1 , respectively) while the separator pressure SCG was varied from 40 to 65 bar. The effect upon COM is very important with variations between 3.4 to +18.2% and it reects the nonlinear variation of CO2 density with pressure. Furthermore, if the pressure in the separator is decreased to 40 bar, COM value is reduced 3.4%, a substantial saving. The implication of this result relies in the balance between the less CO2 that is lost in every full decompression to atmospheric pressure, and utilities necessary to pressurize the unit to 300 bar. Considering the increasing trend observable in Fig. 13, results show that the impact of losing more CO2 penalizes more the COM value than the corresponding energy savings reduce its value. In addition, if 65 bar rather than 45 bar are used in the separator, the system will lead to a COM value that is 18.2% higher. If one takes into account that 25 bar in a process that operates at 300 bar may seem inoffensive, results reveal that such variable is in fact quite inuential in the nal costs.

4. Conclusions The supercritical uid extraction of spent coffee grounds (SCG) oil was studied in this work by measuring extraction curves at different conditions, followed by oil characterization, modeling and economic analysis. Results were deeply compared with data from the literature. Under the range of experimental conditions covered,

Fig. 12. Net income of spent coffee grounds (SCG) oil as function of extraction 1 1 1 = 30 kgCO2 kg h (Run B2), for different SFE unit time, at 300 bar, 50 C, QCO2 wSCG SCG congurations.

158

M.M.R. de Melo et al. / J. of Supercritical Fluids 86 (2014) 150159 [16] D.J.S. Patinha, R.M.A. Domingues, J.J. Villaverde, A.M.S. Silva, C.M. Silva, C.S.R. Freire, C.P. Neto, A.J.D. Silvestre, Lipophilic extractives from the bark of Eucalyptus grandis globulus, a rich source of methyl morolate: selective extraction with supercritical CO2 , Industrial Crops and Products 43 (2013) 340348. [17] C.P. Passos, R.M. Silva, F.A. Da Silva, M.A. Coimbra, C.M. Silva, Supercritical uid extraction of grape seed (Vitis vinifera L.) oil. Effect of the operating conditions upon oil composition and antioxidant capacity, Chemical Engineering Journal 160 (2010) 634640. [18] C.P. Passos, M.A. Coimbra, F.A. Da Silva, C.M. Silva, Modelling the supercritical uid extraction of edible oils and analysis of the effect of enzymatic pretreatments of seed upon model parameters, Chemical Engineering Research and Design 89 (2011) 11181125. [19] J.M. Prado, I. Dalmolin, N.D.D. Carareto, R.C. Basso, A.J.A. Meirelles, J. Vladimir Oliveira, E.A.C. Batista, M.A.A. Meireles, Supercritical uid extraction of grape seed: process scale-up, extract chemical composition and economic evaluation, Journal of Food Engineering 109 (2012) 249257. [20] E.L.G. Oliveira, A.J.D. Silvestre, C.M. Silva, Review of kinetic models for supercritical uid extraction, Chemical Engineering Research and Design 89 (2011) 11041117. [21] C.M. Silva, C.P. Passos, M.A. Coimbra, F.A. Da Silva, Numerical simulation of supercritical extraction processes, Chemical Product and Process Modeling 4 (2009) (Article 9). [22] R. Turton, R.C. Bailie, W.B. Whiting, J.A. Shaeiwitz, Analysis, Synthesis and Design of Chemical Processes, 2nd ed., Prentice Hall, Westford, 2003. [23] D.T. Santos, P.C. Veggi, M.A.A. Meireles, Optimization and economic evaluation of pressurized liquid extraction of phenolic compounds from jabuticaba skins, Journal of Food Engineering 108 (2012) 444452. [24] J.M. Prado, A.R. Assis, M.R. Marostica-Junior, M.A.A. Meireles, Manufacturing cost of supercritical-extracted oils and carotenoids from amazonian plants, Journal of Food Process Engineering 33 (2010) 348369. [25] C.G. Pereira, P.T.V. Rosa, M.A.A. Meireles, Extraction and isolation of indole alkaloids from Tabernaemontana catharinensis A.DC: technical and economical analysis, Journal of Supercritical Fluids 40 (2007) 232238. [26] N.C.M.C.S. Leito, G.H.C. Prado, P.C. Veggi, M.A.A. Meireles, C.G. Pereira, Anacardium occidentale L. leaves extraction via SFE: global yields, extraction kinetics, mathematical modeling and economic evaluation, Journal of Supercritical Fluids 78 (2013) 114123. [27] R.N. Carvalho Jr., L.S. Moura, P.T.V. Rosa, M.A.A. Meireles, Supercritical uid extraction from rosemary (Rosmarinus ofcinalis): kinetic data, extracts global yield, composition, and antioxidant activity, Journal of Supercritical Fluids 35 (2005) 197204. [28] A. Illy, R. Viani, Espresso Coffee: The Chemistry of Quality, 2nd ed., Elsevier Academic Press, Italy, 2005. [29] R.M. Couto, J. Fernandes, M.D.R. Gomes da Silva, P.C. Simoes, Supercritical uid extraction of lipids from spent coffee grounds, Journal of Supercritical Fluids 51 (2009) 159166. [30] J.-Y. Clavier, M. Perrut, Scale-up issues for supercritical uid processing in compliance with GMP, in: P. York, U.B. Kompella, B.Y. Shekunov (Eds.), Supercritical Fluid Technology for Drug Product Development, Informa Healthcare, Champigneulles, France, 2004. [31] A.C. Aguiar, J.V. Visentainer, J. Martnez, Extraction from striped weaksh (Cynoscion striatus) wastes with pressurized CO2 : global yield, composition, kinetics and cost estimation, Journal of Supercritical Fluids 71 (2012) 110. [32] P.T.V. Rosa, M.A.A. Meireles, Rapid estimation of the manufacturing cost of extracts obtained by supercritical uid extraction, Journal of Food Engineering 67 (2005) 235240. [33] P.F. Leal, N.B. Maia, Q.A.C. Carmello, R.R. Catharino, M.N. Eberlin, M.A.A. Meireles, Sweet basil (Ocimum basilicum) extracts obtained by supercritical uid extraction (SFE): global yields, chemical composition, antioxidant activity, and estimation of the cost of manufacturing, Food and Bioprocess Technology 1 (2008) 326338. [34] N.D. Aromatics, Coffee Essential Oil, December 2013, Available from: http://www.newdirectionsaromatics.ca [35] L. Natural Sourcing, Roasted Coffee Oil, December 2013, Available from: http:// www.fromnaturewithlove.com/product.asp?product id=OILCOFFEEROASTED [36] C.P. Passos, M.A. Coimbra, Microwave superheated water extraction of polysaccharides from spent coffee grounds, Carbohydrate Polymers 94 (2013) 626633. [37] Home-Barista.com, 14 December. Available from: http://www.home-barista. com [38] E. Lack, T. Gamse, R. Marr, Separation operations and equipment, in: A. Bertucco, G. Vetter (Eds.), High Pressure Process Technology, Elsevier, Amsterdam, 2001. [39] F. Calixto, J. Fernandes, R. Couto, E.J. Hernandez, V. Najdanovic-Visak, P.C. Simoes, Synthesis of fatty acid methyl esters via direct transesterication with methanol/carbon dioxide mixtures from spent coffee grounds feedstock, Green Chemistry 13 (2011) 11961202. [40] Z. Al-Hamamre, S. Foerster, F. Hartmann, M. Krger, M. Kaltschmitt, Oil extracted from spent coffee grounds as a renewable source for fatty acid methyl ester manufacturing, Fuel 96 (2012) 7076. [41] J.M. del Valle, J.M. Aguilera, An improved equation for predicting the solubility of vegetable oils in supercritical CO2 , Industrial and Engineering Chemistry Research 27 (1988) 15511553. [42] K.S. Pitzer, D.R. Schreiber, Improving equation-of-state accuracy in the critical region equations for carbon-dioxide and neopentane examples, Fluid Phase Equilibria 41 (1988) 117.

the nal extraction yields lie within 0.610.81 of n-hexane Soxhlet values. The obtained SFE oils are rich in linoleic and palmitic acids (44.5 and 37.5%) with proles comparable to Soxhlet results (44.7 and 37.4%) and are in agreement with the values reported in the literature. Moreover the triacylglycerides proles remain uniform along the supercritical extraction. A preliminary economic evaluation involving two assays from the four experiments under analysis revealed that 1 300 bar/50 C/30 kgCO2 kg h1 are the most advantageous SCG operating conditions, independently of the unit arrangement considered. For a set-up of 3 beds of 1 m3 , the production evolves like 0439454311 ton year1 for 00.72.03.0 h of extraction. If extraction time is held in 2 h, the cost of manufacturing (COM) is 2.4 MD year1 and the process net income reaches 56 MD year1 , which is a very promising result. Through a sensitivity analysis, it was shown that an accurate denition of the separator vessel pressure has a signicant impact on COM value, and that a 25 bar difference in this parameter can lead to a COM increase of 18.2%. Acknowledgement Authors acknowledge Associate Laboratory CICECO (PestC/CTM/LA0011/2011). References

[1] International Coffee Organization, Statistics Country Datasheets, December 2013, Available from: http://www.ico.org/proles e.asp?section=Statistics [2] S.I. Mussatto, E.M.S. Machado, S. Martins, J.A. Teixeira, Production, composition, and application of coffee and its industrial residues, Food and Bioprocess Technology 4 (2011) 661672. [3] K.S. Andrade, R.T. Gonc alvez, M. Maraschin, R.M. Ribeiro-do-Valle, J. Martnez, S.R.S. Ferreira, Supercritical uid extraction from spent coffee grounds and coffee husks: antioxidant activity and effect of operational variables on extract composition, Talanta 88 (2012) 544552. [4] R. Cruz, M.M. Cardoso, L. Fernandes, M. Oliveira, E. Mendes, P. Baptista, S. Morais, S. Casal, Espresso coffee residues: a valuable source of unextracted compounds, Journal of Agricultural and Food Chemistry 60 (2012) 77777784. [5] P.S. Murthy, M. Madhava Naidu, Sustainable management of coffee industry byproducts and value additiona review, Resources, Conservation and Recycling 66 (2012) 4558. [6] H. Ribeiro, J. Marto, S. Raposo, M. Agapito, V. Isaac, B.G. Chiari, P.F. Lisboa, A. Paiva, S. Barreiros, P. Simoes, From coffee industry waste materials to skinfriendly products with improved skin fat levels, European Journal of Lipid Science and Technology 115 (2013) 330336. [7] J.P. Bok, H.S. Choi, Y.S. Choi, H.C. Park, S.J. Kim, Fast pyrolysis of coffee grounds: characteristics of product yields and biocrude oil quality, Energy 47 (2012) 1724. [8] N. Kondamudi, S.K. Mohapatra, M. Misra, Spent coffee grounds as a versatile source of green energy, Journal of Agricultural and Food Chemistry 56 (2008) 1175711760. [9] A. Zuorro, R. Lavecchia, Spent coffee grounds as a valuable source of phenolic compounds and bioenergy, Journal of Cleaner Production 34 (2012) 4956. [10] J.M.A. Arajo, D. Sandi, Extraction of coffee diterpenes and coffee oil using supercritical carbon dioxide, Food Chemistry 101 (2007) 10871094. [11] H.M.A. Barbosa, M.M.R. de Melo, M.A. Coimbra, C.P. Passos, C.M. Silva, Optimization of the supercritical uid coextraction of oil and diterpenes from spent coffee grounds using experimental design and response surface methodology, Journal of Supercritical Fluids 85 (2014) 165172. [12] M.M.R. de Melo, E.L.G. Oliveira, A.J.D. Silvestre, C.M. Silva, Supercritical uid extraction of triterpenic acids from Eucalyptus globulus bark, Journal of Supercritical Fluids 70 (2012) 137145. [13] R.M.A. Domingues, M.M.R. de Melo, C.P. Neto, A.J.D. Silvestre, C.M. Silva, Measurement and modeling of supercritical uid extraction curves of Eucalyptus globulus bark: inuence of the operating conditions upon yields and extract composition, Journal of Supercritical Fluids 72 (2012) 176185. [14] R.M.A. Domingues, M.M.R. de Melo, E.L.G. Oliveira, C.P. Neto, A.J.D. Silvestre, C.M. Silva, Optimization of the supercritical uid extraction of triterpenic acids from Eucalyptus globulus bark using experimental design, Journal of Supercritical Fluids 74 (2013) 105114. [15] R.M.A. Domingues, E.L.G. Oliveira, C.S.R. Freire, R.M. Couto, P.C. Simoes, C.P. Neto, A.J.D. Silvestre, C.M. Silva, Supercritical uid extraction of Eucalyptus globulus bark a promising approach for triterpenoid production, International Journal of Molecular Sciences 13 (2012) 76487662.

M.M.R. de Melo et al. / J. of Supercritical Fluids 86 (2014) 150159 [43] N. Wakao, T. Funazkri, Effect of uid dispersion coefcients on particle-to-uid mass transfer coefcients in packed beds: correlation of Sherwood numbers, Chemical Engineering Science 33 (1978) 13751384. [44] V.V. Altunin, M. Sakhabetdinov, Viscosity of liquid and gaseous carbon-dioxide at temperatures of 2201300 K and pressures up to 1200 bar, Teploenergetika 8 (1972) 8589.

159

[45] A.L. Magalhes, P.F. Lito, F.A. Da Silva, C.M. Silva, Simple and accurate correlations for diffusion coefcients of solutes in liquids and supercritical uids over wide ranges of temperature and density, Journal of Supercritical Fluids 76 (2013) 94114. [46] J. Puiggen, M.A. Larrayoz, F. Recasens, Free liquid-to-supercritical uid mass transfer in packed beds, Chemical Engineering Science 52 (1997) 195212.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Ketamine HCL Solubility and CutsDocument11 pagesKetamine HCL Solubility and CutsHector QuezadaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fundamentals of MasstransferandkineticshydrogenationDocument14 pagesFundamentals of MasstransferandkineticshydrogenationRamandhaPrasetyaAdibrataNo ratings yet

- Therminol 55Document5 pagesTherminol 55Dinesh KumarNo ratings yet

- XII Carbohydrate, Fats and Protein TestDocument9 pagesXII Carbohydrate, Fats and Protein TestNirmalya Chowdhury Roll 36 XI BNo ratings yet

- Factors Affecting Solubility LabDocument2 pagesFactors Affecting Solubility Lab799800No ratings yet

- Take Test: Quiz 08 & Quiz 09 - Solutions and Solids and Their PropertiesDocument8 pagesTake Test: Quiz 08 & Quiz 09 - Solutions and Solids and Their PropertiesNguyễn ThiệnNo ratings yet

- Instant Coffee 9997 1323 020 PDFDocument12 pagesInstant Coffee 9997 1323 020 PDFAmlan BanerjeeNo ratings yet

- Material Balances of CrystallizerDocument2 pagesMaterial Balances of Crystallizermahesh0% (1)

- IGCSE Chemistry SET - X (Calculation From Equations)Document10 pagesIGCSE Chemistry SET - X (Calculation From Equations)Fatema KhatunNo ratings yet

- Original PDF Fundamentals of General Organic and Biological Chemistry 8th Edition PDFDocument41 pagesOriginal PDF Fundamentals of General Organic and Biological Chemistry 8th Edition PDFgwen.garcia161100% (36)

- Enklo HLP 46Document4 pagesEnklo HLP 46Randax BhosdaxNo ratings yet

- Foaming in A Mine SystemsDocument16 pagesFoaming in A Mine SystemsAhmad FarooqNo ratings yet

- Gas Liquid Mass Transfer Data in A StirrDocument3 pagesGas Liquid Mass Transfer Data in A StirrDiego MamaniNo ratings yet

- Formulation and Evaluation of Thymoquinone NiosomesDocument25 pagesFormulation and Evaluation of Thymoquinone NiosomesHuỳnh NgânNo ratings yet

- An Improved Process For The Purification of Phosphogypsum (Singh-Garg-Verma-Handa-Kumar)Document4 pagesAn Improved Process For The Purification of Phosphogypsum (Singh-Garg-Verma-Handa-Kumar)oriettaNo ratings yet

- Water Quality Characteristics: Nik Azlin Nik AriffinDocument92 pagesWater Quality Characteristics: Nik Azlin Nik AriffinRomaldo ManuelNo ratings yet

- Physical and Chemical ChangesDocument24 pagesPhysical and Chemical ChangesTanesha JohnsonNo ratings yet

- CO2 Acquittal by Jeffrey A. Glassman, PHDDocument428 pagesCO2 Acquittal by Jeffrey A. Glassman, PHDPRMurphy100% (1)

- Topic2.7-Equilibrium, Ions, Solutions, SolubilityDocument88 pagesTopic2.7-Equilibrium, Ions, Solutions, SolubilityTenielleNo ratings yet

- CH Soln 4Document2 pagesCH Soln 4Mariane Every DayNo ratings yet

- Group 1, 2,3 AnalysisDocument19 pagesGroup 1, 2,3 AnalysisLaila ChoudaryNo ratings yet

- Solubility of Stearic Acid in Various Organic Solvents PDFDocument4 pagesSolubility of Stearic Acid in Various Organic Solvents PDFNestor Armando Marin SolanoNo ratings yet

- International Journal of Toxicology 1985 Articles 65 121Document58 pagesInternational Journal of Toxicology 1985 Articles 65 121Holman SanabriaNo ratings yet

- Experiment 1: Preparation of Tris-EDTA Buffer (PH 8) AimDocument2 pagesExperiment 1: Preparation of Tris-EDTA Buffer (PH 8) AimShahina LimaNo ratings yet

- Chemistry Notes Chapter No 2 Experimental Techniques in ChemistryDocument4 pagesChemistry Notes Chapter No 2 Experimental Techniques in ChemistryUmar Zahid67% (3)

- Extraction of Fennel (Foeniculum Vulgare) Seeds: Process Optimization and Antioxidant Capacity of The ExtractsDocument9 pagesExtraction of Fennel (Foeniculum Vulgare) Seeds: Process Optimization and Antioxidant Capacity of The ExtractsruriNo ratings yet

- Art 6Document6 pagesArt 6Adelina AddNo ratings yet

- Liquid Ammonia As A Solvent: Andrew R. BarronDocument3 pagesLiquid Ammonia As A Solvent: Andrew R. Barronibro4khadNo ratings yet

- 4232 AeroWhip Whip Optimized SolutionsDocument2 pages4232 AeroWhip Whip Optimized SolutionspedrazasNo ratings yet