Professional Documents

Culture Documents

Desidn Aop

Uploaded by

David LambertOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Desidn Aop

Uploaded by

David LambertCopyright:

Available Formats

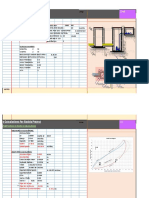

1 DESIGN FLOW OF BAR SCREEN Number of intake: Design flow

1 400 16.6667 0.0046 1.5 0.0069 m3/d m3/h m3/s m3/s

Hydraulic coefficient for the hydraulic elements: Design flow: 2 FUNCTION OF BAR SCREEN To remove floating debris 3 DIMENSIONS BAR SCREEN HWL = LWL = Elevation of the river bed: Number of bar screen: Width Length Area of each = Flow of each bar screen: Velocity at the bar screen v = 1.25 x q x k / A Where: q = Design flow k=2 Velocity at the bar screen: Note: Note: 0.1 0.3 m/s is the practical guideline 4 DESIGN FLOW OF FINE SCREEN Number of intake: Design flow

0.806 0.558 0.248 1 0.31 0.558 0.17 0.0069

m m m unit m m m2 m3/s

2 0.1004 m/s

1 400 16.6667 0.0046 1.5 0.0069 m3/d m3/h m3/s m3/s

Hydraulic coefficient for the hydraulic elements: Design flow: 5 FUNCTION OF FINE SCREEN To remove small floating objects 6 DIMENSIONS FINE SCREEN Number of bar screen: Width Length Area of each = Flow of each bar screen: Velocity at the bar screen v = 1.25 x q x k / A Where: q = Design flow k = 1.69 Velocity at the bar screen:

1 0.24 0.288 0.0691 0.0069

unit m m m2 m3/s

1.69 0.2122 m/s

Note: Note: 0.1 0.3 m/s is the practical guideline

Q operation time det Vol W L H

4.2 24 100.8 20 1.4 0.3 0.65 0.1

m3/jam jam/hari m3/hari menit m3

30 mm 0.03 m jumlah #REF! panjang plat dibutuhkan #REF! dibuthkan #REF! dipilih Tebal plat Lebar plat Panjang Plat 2 6000 1/4 inch inch mm bar m plat strip

harga plat strip ukuran di atas SS 304

Rp

3,000,000

Biaya pembelian plat Accessories Grand tot

#REF! #REF! #REF!

1.116 0.248

0.833333

#REF! #REF!

m m

1/8 1/8 1/8 1/8 1/8 1/8 3/16

3.18 3.18 3.18 3.18 3.18 3.18 4.76

5/8 3/4 1 1 2 1 1/4 1/2 3/4

1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 5/16 5/16 5/16 3/8 3/8 3/8 3/8 3/8 3/8

6.35 6.35 6.35 6.35 6.35 6.35 6.35 6.35 6.35 6.35 6.35 6.35 6.35 6.35 7.94 7.94 7.94 9.53 9.53 9.53 9.53 9.53 9.53

5/8 1 1 1 2 3/4 1 1 1 1 2 2 3 4 1 1 2 3/4 1 1 1 2 2 1/4 1/2 1/2 1/2 1/2 1/4 1/2 3/4 1/4 1/2

3/8 3/8 1/2 1/2 1/2 1/2 5/8

9.53 9.53 12.70 12.70 12.70 12.70 15.88

3 4 1 1/2

3 4

7.86E-06 kg/mm3

15.88 19.05 25.40 31.75 50.80 38.10 19.05

besi (weight) SS 304 2.26 2.7 3.6 4.5 7 5.37 4.5

PLATE STREEP 2.4 kg 2.9 3.8 4.8 7.6 5.7 4.3

Plat streep atau sering disebut juga plat bar merupakan profi Untuk anda yang memerlukan dimensi dan berat, anda bisa m

PLATE STREEP (PLAT BAR)

No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 Ukuran T x W mm inch 3 x 16 3 x 19 3 x 25 3 x 30 3 x 38 4.5 x 19 4.5 x 25 4.5 x 32 4.5 x 38 4.5 x 50 6 x 19 6 x25 6 x 32 6 x 38 6 x 50 6 x 65 6 x 75 6 x 85 6 x 100 6 x 125 6 x 150 9 x25 1/8 x 5/8 1/8 x 3/4 1/8 x 1 1/8 x 1 1/4 1/8 x 1 1/2 3/16 x 3/4 3/16 x 1 3/16 x 1 1/4 3/16 x 1 1/2 3/16 x 2 3/16 x 3/4 3/16 x 1 3/16 x 1 1/4 3/16 x 1 1/2 3/16 x 2 3/16 x 2 1/2 3/16 x 3 3/16 x 3 1/2 3/16 x 4 3/16 x 5 3/16 x 6 3/8 x 1

15.88 25.40 31.75 38.10 50.80 19.05 25.40 31.75 38.10 44.45 50.80 63.50 76.20 101.60 38.10 25.40 50.80 19.05 25.40 31.75 38.10 50.80 63.50

3.8 5.9 7.5 9 11.8 5.37 7.08 9.08 10.8 12.7 14.4 18.4 22 28.2 14.3 9.5 18.9 8 10.6 13.6 16 21.2 27.6

4.8 7.6 9.5 11.4 15.2 5.7 7.6 9.5 11.4 13.3 15.2 19.0 22.8 30.4 14.3 9.5 19.0 8.6 11.4 14.3 17.1 22.8 28.5

76.20 101.60 38.10 0.00 76.20 101.60 0.00

32 42.5 21.5 31.5 42.4 56.6 37.8

34.2 45.6 22.8 0.0 45.6 60.9 0.0

23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

9 x 32 9 x 38 9 x 50 9 x 65 9 x 75 9 x 85 9 x 100 9 x 125 9 x 150 10 x 38 12 x 25 12 x 38 12 x 50 12 x 65 12 x 75 12 x 100 12 x 150 16 x 38 16 x 50 16 x 65 16 x 75 16 x 100 16 x 150 19 x 38 19 x 50 19 x 65 19 x 75 19 x 100 19 x 125 19 x 150

3/8 x 1 1/4 3/8 x 1 1/2 3/8 x 2 3/8 x 2 1/2 3/8 x 3 3/8 x 3 1/2 3/8 x 4 3/8 x 5 3/8 x 6 3/8 x 1 1/2 1/2 x 1 1/2 1/2 x 1 1/2 1/2 x 2 1/2 1/2 x 2 1/2 1/2 x 3 1/2 x 4 1/2 x 6 5/8 x 1 1/2 5/8 x 2 1/2 5/8 x 2 1/2 5/8 x 3 5/8 x 4 5/8 x 6 3/4 x 1 1/2 3/4 x 2 1/2 3/4 x 2 1/2 3/4 x 3 3/4 x 4 3/4 x 5 3/4 x 6

u sering disebut juga plat bar merupakan profil besi yang umum dipakai dalam konstruksi dan fabrikasi mesin, maupun untuk konstruksi sipil. ng memerlukan dimensi dan berat, anda bisa melihat dalam tabel dibawah ini:

ATE STREEP (PLAT BAR)

Panjang L meter 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 Berat Kg 2.3 2.71 3.56 4.28 5.37 4.03 5.4 6.8 8.3 10.6 5.4 7.13 9.2 10.83 14.55 18.53 21.5 25.5 28.51 35.63 44.5 10.7

6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6 6

14 16.25 21.5 27.8 32.1 38.3 42.76 53.45 64.14 18 14.2 21.66 28.5 37.1 42.8 57.01 85 29 38 49 56.5 76 113 34 45 58.5 67.5 89.5 112 134

esin, maupun untuk konstruksi sipil.

Q operation time det Vol W L H Freeboard Ht Tebal plat Panjang Plat Lebar plat Luas harga plat Estimasi Luas Bak diperlukan Biaya coating FRP MS Rp

4.2 24 100.8 40 2.8 1 2.33 1.2 0.3 1.5 4 2400 1200 2880000 2.88 1,000,000.00

m3/jam jam/hari m3/hari menit m3 m m m m m mm mm mm mm2 m2

Rp Rp

18 m2 400,000.00 7,066,666.67 7 buah 7,000,000.00 14,066,666.97 1,406,666.70 15,473,333.66

Jumlah plat diperlukan Biaya pembelian plat Sub Total Accessories Grand Total

Rp Rp Rp Rp

L W H

4 ft 2 ft 7 ft 750 GPM

0 inc 0 inc 2 inc 2839.058

48 inc 24 inc 86 inc LPM

1.2192 m 0.6096 m 2.1844 m

1.623499 m3 428.8831 gallon

0.405875 m3 107.2208 gallon

170.3435 MPH

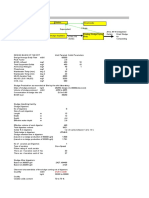

DATA Q Waktu operasi

200 24 8.333333333 0.138888889 0.002314815 Horisontal flow 1 60 1 0.025 0.2 65 0.75 0.45 0.00750 2.65 0.05 0.02

m3/hari jam/hari m3/jam m3/min m3/s grit (channel) dengan proportional weir s 45-90 min m/s 0.25-0.4 mm mesh cm/s 1-1.3 m/min m/s

Type dibuat Detention time Kecepatan horisontal (Vh) Diameter partikel minimal yg diendapkan v= kecepatan pengendapan

Sg grit k f Q channel Luas Penampang (ACross) Luas Permukaan (ASurface) 1. BILANGAN REYNOLD Kedalaman Air, h Lebar Grit Chamber Panjang Grit Chamber R NRe = Check 2. KECEPATAN SCOURING, VSC VSC = Check Direncanakan Debit buangan Kadar (kandungan pasir) per Pengurasan tiap Bentuk Grit Storage DIMENSI Volume Pasir dalam 1 hari Volume Pengurasan Dimensi Grit Storage a Panjang Grit Chamber

3 0.002314815 m /s 2 0.09 m 2 0.31 m

0.45 m 0.2058 m 1.50 m 0.084 0 OKE

20.58

8.05 m/s OKE 0.002314815 m /s 200 m /hari 30 m

3 3 3 3

1,000,000 m Air buangan 6 hari Trapezium

3 0.006 m 3 0.036 m

1.50 m

b Lebar Grit Chamber c panjang dasar trapesium d lebar dasar trapesium Luas Permukaan Luas Dasar Volume Grit Storage tinggi trapesium 3.PROPORTIONAL WEIR Direncanakan Q, debit a 0.1 m y 0.2 m h = tinggi muka air di grit chamber

0.21 m 1.27 m 0.07 m

2 0.3 m

0.1 m

3 0.04 m 0.19 m

0.002314815 0.082 0.33 0.66 0.45 1.47636

m /s ft3/s ft ft m ft

diperoleh nilai b, = Perbandingan, y/a = Dari tabel diperoleh, nilai x/b = shg x

0.02 ft 0.006 m 2 0.392 0.01 ft

Marsono, "Hidrolika Teknik Penyehatan", Hal : II-53)

Dimensi Proportional weir : a 0.328 ft b 0.021 ft x 0.008 ft y 0.656 ft

0.21 m

300

L H Freeboard Ht Tebal plat Panjang Plat Lebar plat Luas harga plat Jumlah Luas Bak Biaya coating FRP MS Rp

1.50 0.45 0.3 0.75 4 2400 1200 2880000 2.88 1,000,000.00

m m m m mm mm mm mm2 m2

1,500 450 300 800

Rp

#REF! m2 400,000.00 #REF! #REF! #REF! #REF! #REF! #REF! buah

Jumlah plat diperlukan Biaya pembelian plat Sub Total Accessories Grand Total

(channel) dengan proportional weir

0.082021 ft/s

W L H Freeboard Ht

1.50 m a

b 0.21 m 0.19 t

d c 1.27 m 0.07 m

mm

#REF!

mm mm mm mm

#REF!

#REF!

Input PUMP Description Nos reqd Project -1 Eq Length Size ID

2 m

Plant SCHEME

Puskesmas

2 in

Drum Pressure 0.5 BarA P1

1.9 m

1.2 m 1.3 m Length Size ID 2m 1 in

0.10 m

OTHER LOSSES SUCTION FE / Orifice 0.0 Strainer 0.1 Nozzle 0.0 FLUID FLOW AND PROPERTY

Other1 Other2 Total

0.0 0.0 0.1

Bar

DISCHARGE FE/Orifice Rotametr Nozzle

0.0 0.5 0.0

Fluid Flow Temp Density Viscosity Vap Press SUCTION SIDE Suc vessel press Min liq level above Pump center line Line length Suc line (ID) Line loss Other loss (Inst, str, equip etc)

M3/hr C kg/m3 cP Bara

Water 0.50 30 1000 0.8 0.10

BarA mt mt in Bar

0.5 1.2 2 1 0.001 0.1

Min suc press NPSH A 85% / NPSHA -0.6 mt NPSH A for datasheet DISCHARGE SIDE Terminal pressure Max static ht above pump center line Line length Dis line (ID) Line loss (x chk with simulator) Other loss (Inst, Nozz, CV,equip etc) Dis Press reqd PUMP CALCULATION Calculated difference pressure Calculated difference head Calcuated hydraulic power (100% eff) REMARKS Rev 2 1 0 Date Prepared

BarA mt mt mt

0.52 4.3 3.6 3.6

Bara mt mt in Bar Bar Bara

2.0 1.9 2.0 2 0.00 1.5 3.7

Bar m kW

3.2 32 0.0

Checked

Pompa Inlet Type Kapasitas Power Jumlah Harga

Sentrifugal 50 Liter/menit 0.2 - 0.7 kW/220V/50 Hz 2 unit

3 m3/hr

5,000,000.00

Centrifugal XYZ 2 Terminal Pressure 2.0 BarA P2

M g F=W= A P

500 9.8 4900 0.25 19,600 0.20

kg m/s^2 N m2 N/m2 bar

2.84

2.00 m

Elevation

Filter Margin Total

0.5 0.5 1.5

Bar

FE/Orifice Rotametr Nozzle

0.5 0.5 0.0

Filter Margin Total

0.1 0.5 1.6

Velocity in suction line 0.3 m/s

3.7

Velocity in Discharge line 0.1 m/s

Approved

psi

Input PUMP Description Nos reqd Project -1 Eq Length Size ID

1 m

Plant SCHEME

Puskesmas

2 in

Drum Pressure 0.0 BarA P1

2.4 m

-1.1 m -1.0 m Length Size ID 2m 1 in

0.10 m

OTHER LOSSES SUCTION FE / Orifice 0.0 Strainer 0.1 Nozzle 0.0 FLUID FLOW AND PROPERTY

Other1 Other2 Total

0.0 0.0 0.1

Bar

DISCHARGE FE/Orifice Rotametr Nozzle

0.0 0.5 0.0

Fluid Flow Temp Density Viscosity Vap Press SUCTION SIDE Suc vessel press Min liq level above Pump center line Line length Suc line (ID) Line loss Other loss (Inst, str, equip etc)

M3/hr C kg/m3 cP Bara

Water 1 30 1000 0.8 0.10

BarA mt mt in Bar

0.0 -1.1 2 1 0.001 0.1

Min suc press NPSH A 85% / NPSHA -0.6 mt NPSH A for datasheet DISCHARGE SIDE Terminal pressure Max static ht above pump center line Line length Dis line (ID) Line loss (x chk with simulator) Other loss (Inst, Nozz, CV,equip etc) Dis Press reqd PUMP CALCULATION Calculated difference pressure Calculated difference head Calcuated hydraulic power (100% eff) REMARKS Rev 2 1 0 Date Prepared

BarA mt mt mt

-0.21 -3.1 -2.7 -3.7

Bara mt mt in Bar Bar Bara

0.5 2.4 1.0 2 0.00 1.0 1.7

Bar m kW

1.9 20 0.0

Checked

Pompa Sirkulasi Type Kapasitas Power Jumlah Harga

Sentrifugal 30 Liter/menit 0.2 - 0.7 kW/220V/50 Hz 2 unit

1.8 m3/hr

5,000,000

Centrifugal XYZ 2 Terminal Pressure 0.5 BarA P2

2.50 m

Elevation

Filter Margin Total

0.0 0.5 1.0

Bar

FE/Orifice Rotametr Nozzle

0.5 0.5 0.0

Filter Margin Total

0.1 0.5 1.6

Velocity in suction line 0.3 m/s

-3.7

Velocity in Discharge line 0.1 m/s

Approved

Input PUMP Description Nos reqd Project -1 Eq Length Size ID

2 m

Plant SCHEME

Puskesmas

2 in

Drum Pressure 0.5 BarA P1

1.9 m

1.2 m 1.3 m Length Size ID 2m 1 in

0.10 m

OTHER LOSSES SUCTION FE / Orifice 0.0 Strainer 0.1 Nozzle 0.0 FLUID FLOW AND PROPERTY

Other1 Other2 Total

0.0 0.0 0.1

Bar

DISCHARGE FE/Orifice Rotametr Nozzle

0.0 0.5 0.0

Fluid Flow Temp Density Viscosity Vap Press SUCTION SIDE Suc vessel press Min liq level above Pump center line Line length Suc line (ID) Line loss Other loss (Inst, str, equip etc)

M3/hr C kg/m3 cP Bara

Water 0.50 30 1000 0.8 0.10

BarA mt mt in Bar

0.5 1.2 2 1 0.001 0.1

Min suc press NPSH A 85% / NPSHA -0.6 mt NPSH A for datasheet DISCHARGE SIDE Terminal pressure Max static ht above pump center line Line length Dis line (ID) Line loss (x chk with simulator) Other loss (Inst, Nozz, CV,equip etc) Dis Press reqd PUMP CALCULATION Calculated difference pressure Calculated difference head Calcuated hydraulic power (100% eff) REMARKS Rev 2 1 0 Date Prepared

BarA mt mt mt

0.52 4.3 3.6 3.6

Bara mt mt in Bar Bar Bara

2.0 1.9 2.0 2 0.00 1.5 3.7

Bar m kW

3.2 32 0.0

Checked

Pompa Filter Type Kapasitas Power Jumlah Harga

Sentrifugal 50 Liter/menit 0.2 - 0.7 kW/220V/50 Hz 2 unit

3 m3/hr

5,000,000

Centrifugal XYZ 2 Terminal Pressure 2.0 BarA P2

M g F=W= A P

500 9.8 4900 0.25 19,600 0.20

kg m/s^2 N m2 N/m2 bar

2.84

2.00 m

Elevation

Filter Margin Total

0.5 0.5 1.5

Bar

FE/Orifice Rotametr Nozzle

0.5 0.5 0.0

Filter Margin Total

0.1 0.5 1.6

Velocity in suction line 0.3 m/s

3.7

Velocity in Discharge line 0.1 m/s

Approved

psi

Input PUMP Description Nos reqd Project -1 Eq Length Size ID

2 m

Plant SCHEME

Puskesmas

2 in

Drum Pressure 0.5 BarA P1

0.4 m

1.2 m 1.3 m Length Size ID 2m 1 in

0.10 m

OTHER LOSSES SUCTION FE / Orifice 0.0 Strainer 0.1 Nozzle 0.0 FLUID FLOW AND PROPERTY

Other1 Other2 Total

0.0 0.0 0.1

Bar

DISCHARGE FE/Orifice Rotametr Nozzle

0.0 0.5 0.0

Fluid Flow Temp Density Viscosity Vap Press SUCTION SIDE Suc vessel press Min liq level above Pump center line Line length Suc line (ID) Line loss Other loss (Inst, str, equip etc) Min suc press NPSH A 85% / NPSHA -0.6 mt NPSH A for datasheet

M3/hr C kg/m3 cP Bara

Water 0.50 30 1000 0.8 0.10

BarA mt mt in Bar BarA mt mt mt

0.5 1.2 2 1 0.001 0.1 0.52 4.3 3.6 3.6

DISCHARGE SIDE Terminal pressure Max static ht above pump center line Line length Dis line (ID) Line loss (x chk with simulator) Other loss (Inst, Nozz, CV,equip etc) Dis Press reqd PUMP CALCULATION Calculated difference pressure Calculated difference head Calcuated hydraulic power (100% eff) REMARKS Rev 2 1 0 Date Prepared Checked Bara mt mt in Bar Bar Bara 2.5 0.4 2.0 2 0.00 2.0 4.5

Bar m kW

4.0 41 0.1

Pompa Backwash Type Kapasitas Power Jumlah Harga

Sentrifugal 50 Liter/menit 0.2 - 0.7 kW/220V/50 Hz 1 unit

3 m3/hr

5,000,000

Centrifugal XYZ 2 Terminal Pressure 2.5 BarA P2

M g F=W= A P

500 9.8 4900 0.25 19,600 0.20

kg m/s^2 N m2 N/m2 bar

2.84

0.50 m

Elevation

Filter Margin Total

1.0 0.5 2.0

Bar

FE/Orifice Rotametr Nozzle

0.5 0.5 0.0

Filter Margin Total

0.1 0.5 1.6

Velocity in suction line 0.3 m/s

3.7

Velocity in Discharge line 0.1 m/s

Approved

psi

Qlimbah Concentration

ppm O3

0.5 8.33 80 0.667 40.0 37,360.00

m3/hr lpm g/m3 g/menit g/hr ppm O3

500 L/hr seharusnya #DIV/0!

Faktor Konversi : 1 g O3 / m3 = 467 PPM O3 1 PPM O3 = 2.14 mg O3/m3 100 pphm (parts per hundred million) = 1 ppm (parts per million) Sterilisasi 3 m3 = 5 gram O3 Dipilih Ozone generator 40 gram/h Spesifikasi Tabung Reactor Corona : Stenless 304. - Issolator Corona : Glass FIREX - Teflon - Nilon. - Air Compressor : Ressun ACO 007. - Generator Pembangkit HV - Trafo. - Pendingin Fan. - Air Drayer Elektrik , Auto ON - Off / Control Digital Harga Rp 22,000,000

High Capacity Ozone Generator 10 gram/h Spesifikasi: - Tabung Reactor Corona : Stenless 304. - Issolator Corona : Glass FIREX - Teflon - Nilon. - Air Compressor : Ressun ACO 003. - Generator Pembangkit HV - Trafo. - Pendingin Fan. - Air Drayer Elektrik , Auto ON - Off / Control Digital. Asesories : - Volt Meter Digital. - Ampere Meter Digital. - Air Drayer Temperatur Control Digital. - Hour Meter Analog. - ampu Indicator Mesin. - Box Pannel Powder Couting : 40 x 60 x 25 cm. - Berat 40 kg. - 220 Volt - 80 Watt

g/hr

0 L/hr

0.5 m3/hr 500 L/hr 8.33 lpm

Kebutuhan oksigen 35 m3 Jumlah tabung oksigen diperlukan 6.00 tabung harga per tabung Rp 1,600,000 Total harga Rp 9,600,000

http://umpgas.com/product/0/1/OXYGEN-O2#/image-product/img1-1329029207.jpg OXYGEN (O2) atau zat asam adalah unsur kimia yang tidak berbau, tidak berwarna, tidak berasa, tidak terbakar tapi dapat me

OXYGEN (O2) dihasilkan dari air menggunakan cyanobacteria, ganggang, dan tanaman saat melakukan fotosintesa, digunakan Kemasan

OXYGEN (O2) gas dikemas dalam cylinder baja dengan kapasitas 6,7,10 m3 dan tekanan 50-200 atm. OXYGEN (O2)cair dikemas dalam tangki PGS/VGL 45 gallon atau dalam tangki stationer kapasitas 300-11000 galon atau lebih. http://distributor-kursi-roda.blogspot.com/2011/06/tabung-oksigen-regulator.html

A. TABUNG OKSIGEN

Dimensi Tabung Oxygen Keliling Diameter (Perimete Tabung r) Tabung Berat Isi 7 cm 23 cm 2,5 kg 11 cm 35 cm 5 kg 14 cm 45 cm 10 kg 14 cm 45 cm 15 kg 14 cm 45 cm 20 kg 24 cm 75 cm 60 kg

Tabung Ukuran 500 mL 0,5 m3 1 m3 1,5 m3 2 m3 6 m3

Tinggi Tabung 26 cm 40 cm 69 cm 97 cm 120 cm 148 cm

Harga tabung oksigen saja : (harga sewaktu-waktu dapat berubah berdasarkan harga pasar ) - Tabung oksigen 0,5 m3 = Rp. 950.000,- Tabung oksigen 1 m3 = Rp. 600.000,- Tabung oksigen 1,5 m3 = Rp. 750.000,- Tabung oksigen 2 m3 = Rp. 850.000,- Tabung oksigen 6 m3 = Rp. 1.400.000,-

- Tabung oksigen lebih besar dari 6m3 = Rp. CALL - Tabung Oxygen Portable (500 mL) : silahkan klik gambar di bawah ini

Dimensi Tabung Oxygen Keliling Diameter (Perimete Tabung r) Tabung Berat Isi 7 cm 23 cm 2,5 kg 11 cm 35 cm 5 kg 14 cm 45 cm 10 kg 14 cm 45 cm 15 kg 14 cm 45 cm 20 kg 24 cm 75 cm 60 kg

Tabung Ukuran 500 mL 0,5 m3 1 m3 1,5 m3 2 m3 6 m3

Tinggi Tabung 26 cm 40 cm 69 cm 97 cm 120 cm 148 cm

Harga tabung oksigen saja : (harga sewaktu-waktu dapat berubah berdasarkan harga pasar ) - Tabung oksigen 0,5 m3 = Rp. 950.000,- Tabung oksigen 1 m3 = Rp. 600.000,- Tabung oksigen 1,5 m3 = Rp. 750.000,- Tabung oksigen 2 m3 = Rp. 850.000,- Tabung oksigen 6 m3 = Rp. 1.400.000,- Tabung oksigen lebih besar dari 6m3 = Rp. CALL - Tabung Oxygen Portable (500 mL) : silahkan klik gambar di bawah ini

DESKRIPSI

a, tidak terbakar tapi dapat membantu pembakaran (Oksidator), sangat diperlukan makhluk hidup. OXYGEN (O2) dalam udara sebagian b

akukan fotosintesa, digunakan untuk pernafasan sel semua makhluk hidup di dunia.

as 300-11000 galon atau lebih.

GEN (O2) dalam udara sebagian besar diproduksi dengan cara destilasi udara pada suhu rendah dan menggunakan mesin produksi dan ala

nggunakan mesin produksi dan alat control yang handal untuk memperoleh oksigen dengan kemurniaan tinggi (>99,6%), atau dengan syst

tinggi (>99,6%), atau dengan system PSA (Pressure Swing Adsorbtion) , atau dengan sistem VPSA ( Vaccum Pressure S

VPSA ( Vaccum Pressure Swing Adsorbtion) , atau dengan sistem membran. Dalam atmosfir kandungan OXYGEN

mosfir kandungan OXYGEN (O2) sekitar 20,9%.

Concentration

Jumlah

diperlukan 1 jerigen 1 jerigen Rp

Harga H2O2

0.5 500 8.33 50% 5 35 500,000

m3/hr L/hr lpm Liter Liter

$230-350 /ton $ 1,000 BJ Berat Harga Rp

12000 Rp 1.135 kg/Lt 39.725 kg 476,700

12,000 /kg

Q operation time det Vol W L H Freeboard Ht Tebal plat Panjang Plat Lebar plat Luas harga plat Estimasi Luas Bak diperlukan Biaya coating FRP MS Rp

0.5 24 12 60 0.5 1 0.42 1.2 0.3 1.5 4 2400 1200 2880000 2.88 1,000,000.00

m3/jam jam/hari m3/hari menit m3 m m m m m mm mm mm mm2 m2

Rp Rp

8 m2 400,000.00 3,233,333.33 3 buah 3,000,000.00 6,233,333.63 623,333.36 6,856,667.00

Jumlah plat diperlukan Biaya pembelian plat Sub Total Accessories Grand Total

Rp Rp Rp Rp

Tank Design Basis Design

Pressure Design Temp DO S/S Ambient

3 psig 0.204081633 barg 0.629921264 inch 84 inch 1/8 in 3.175 mm

Material

Shell Section STAINLESS STEEL S 17500 C/A 3.175 Joint Eff 0.8 Thickness 6.75E-05 Thickness+ DO 0.125067

psi mm Double butt spot examined inch inch

3.176714 mm

M g F=W= A P

500 9.8 4900 0.42 11,760 0.12

kg m/s^2 N m2 N/m2 bar

Q operation time det Vol H/D D H Freeboard Ht Tebal plat Panjang Plat Lebar plat Luas harga plat Estimasi Luas Bak diperlukan Biaya coating FRP SS Rp

0.5 24 12 60 0.5 2 0.68 1.37 0.2 1.6 4 2400 1200 2880000 2.88 4,000,000.00

m3/jam jam/hari m3/hari menit m3 m m m m m mm mm mm mm2 m2

Rp Rp

3.72 m2 400,000.00 1,489,735.05 2 buah 8,000,000.00

Jumlah plat diperlukan Biaya pembelian plat Unit oxydator pompa

Rp

10 lpm 0.6 m3/hr 600 Liter/hr

Rp

Tangki Chemical

Sub Total Accessories Grand Total

Rp Rp Rp

9,489,735.25 948,973.53 10,438,708.78

Tank Design Basis Design

Pressure Design Temp DO S/S

2 0.136054 Ambient 26.88 84

psig barg inch inch

Material

Shell Section STAINLESS STEEL S 18750 C/A 3.175 Joint Eff 0.8 Thickness 0.001792 Thickness+ DO 0.126792

psi mm Double butt spot examined inch inch

3.220517 mm

M g F=W= A P

500 9.8 4900 0.37 13,383 0.13

kg m/s^2 N m2 N/m2 bar

1.94 psi

Q operation time det Vol W L H Freeboard Ht Tebal plat Panjang Plat Lebar plat Luas harga plat Estimasi Luas Bak diperlukan Biaya coating FRP MS Rp

0.5 24 12 30 0.25 1 0.25 1 0.3 1.3 4 2400 1200 2880000 2.88 1,000,000.00

m3/jam jam/hari m3/hari menit m3 m m m m m mm mm mm mm2 m2

Rp Rp

6 m2 400,000.00 2,540,000.00 3 buah 3,000,000.00 5,540,000.30 554,000.03 6,094,000.33

Jumlah plat diperlukan Biaya pembelian plat Sub Total Accessories Grand Total

Rp Rp Rp Rp

Q operation time det Vol W L H Freeboard Ht Tebal plat Panjang Plat Lebar plat Luas harga plat SS 304 Rp

0.5 24 12 120 1 1 0.83 1.2 0.3 1.5 4 2400 1200 2880000 2.88 4,000,000

m3/jam jam/hari m3/hari menit m3 m m m m m mm mm mm mm2 m2

Estimasi Luas Bak diperlukan Biaya coating FRP

Rp Rp

9 m2 400,000.00 3,733,333.33 4 buah 16,000,000.00 150,000.00 1.00 unit 150,000.00

Jumlah plat diperlukan Biaya pembelian plat Harga tube settler jumlah

Rp Rp Rp Rp

Sub Total Accessories Grand Total

Rp Rp Rp

19,883,333.63 1,988,333.36 21,871,667.00

cara hitung berat : harga per kg

23.6 x tebal plat 94.4 kg 38000 Rp 3,587,200.00

Fungsi : Bentuk Bahan konstruksi

Untuk menyaring suspended solid yang keluar dari Silinder tegak dengan alas dan tutup elipsoidal CS/SA-53, Grade B Kondisi penyimpanan Temperatur 30 Tekanan 1 Densitas Air 995.68 kg/m3 62.15827 Laju alir fluida (F) 0.5 m3/hr Faktor keamanan 30% Dirancang untuk penampungan 0.124 Volume air, Va Volume tangki, Vt Direncanakan perbandingan diameter dengan silinder tangki, D/H 1: V = 1/4 D2H Diameter tangki Tinggi tangki

clarifier

oC atm lbm/ft3

jam operasi

3

7.44

0.06 m

3 0.08 m

80.60 Liter

2 0.37 m 0.74 m Plate steel SA-167 304 18750 0.8 1/8 3 20% 52.92 psi inch atm psi 3.83 mm 3.81 mm 1.22 ft 2.44 ft

maka Direncanakan menggunakan bahan konstruksi type Dari Brownell & young, item 4, appendix D, diperoleh : Allowable working stress (S) Effisiensi sambungan (E) Faktor korosi Tekanan hidrostatik, Po Faktor keamanan tekanan Tekanan desain, P Tebal dinding silinder tangki : t = PD/(2SE-1.2P) + CA Dari Brownell & young, tabel 54, dipilih tebal tangki :

44.1 psi

0.15 in 1/7 in

menit

14.63 in 29.26 in

You might also like

- Design of Welded Steel Storage Tanks in Accordance With API650 Job DataDocument4 pagesDesign of Welded Steel Storage Tanks in Accordance With API650 Job DatamirzacogoNo ratings yet

- Pumpstation Input Data: Sewer Pumpstation Design Calculations For Alqibla ProjectDocument18 pagesPumpstation Input Data: Sewer Pumpstation Design Calculations For Alqibla ProjectTahirJabbar50% (2)

- Drilling FormulasDocument87 pagesDrilling FormulasVeCoMo100% (1)

- Digester Design2Document16 pagesDigester Design2Pragathees WaranNo ratings yet

- CETP Calculation r02Document3 pagesCETP Calculation r02kaushalNo ratings yet

- WTP Cost Estimate PDFDocument13 pagesWTP Cost Estimate PDFSurangaGNo ratings yet

- Design of Notch and WeirDocument24 pagesDesign of Notch and WeirSparsh Shukal100% (1)

- Revised Material Balance of Waste Water Treatment PlantDocument28 pagesRevised Material Balance of Waste Water Treatment Plantjobya_4100% (1)

- Plate efficiency η = 100%: Sg. Siput-Design Calculation.xlsx/Sedi (4) Sg. Siput-Design Calculation.xlsx/SediDocument2 pagesPlate efficiency η = 100%: Sg. Siput-Design Calculation.xlsx/Sedi (4) Sg. Siput-Design Calculation.xlsx/SediAnonymous O404LiV4CNo ratings yet

- Preliminar Calculo BlowerDocument3 pagesPreliminar Calculo BlowerAlejo BaronNo ratings yet

- Clarifier Torque CalculationDocument4 pagesClarifier Torque CalculationDavid Lambert100% (4)

- Design of Sand FilterDocument5 pagesDesign of Sand FilterAbhay Thakur100% (1)

- Technical Form WWTPDocument35 pagesTechnical Form WWTPDavid LambertNo ratings yet

- 7 FiltrationDocument25 pages7 FiltrationJonelou CusipagNo ratings yet

- Hydraulic Design of Sewage Treatment PlantDocument9 pagesHydraulic Design of Sewage Treatment PlantSCR_010101No ratings yet

- ASME - Shell Thickenss Calculation MAIN SHELLDocument4 pagesASME - Shell Thickenss Calculation MAIN SHELLCoralPT WorldwideNo ratings yet

- Boq For Abb Flow MeterDocument166 pagesBoq For Abb Flow MeterDeepak RajanNo ratings yet

- ETP Design CalculationDocument6 pagesETP Design Calculationmanuel.hernandez100% (2)

- ETP Design ReportsDocument10 pagesETP Design ReportsMuhammad Ashraful ArifinNo ratings yet

- Tool For Master Plan Formulation - Water Supply With Surface Water SourceDocument25 pagesTool For Master Plan Formulation - Water Supply With Surface Water SourceaneeshmeloottuNo ratings yet

- Techno Feasibility Report LAIL 1 PDFDocument28 pagesTechno Feasibility Report LAIL 1 PDFGarad MadhukarNo ratings yet

- Evap Pond - Calculations-MauritaniaDocument9 pagesEvap Pond - Calculations-MauritaniaLandon MitchellNo ratings yet

- Design of Flocculator PaddlesDocument1 pageDesign of Flocculator Paddlessumitanurag100% (1)

- Pressure Drop CalculationDocument8 pagesPressure Drop CalculationDavid Lambert100% (1)

- Design of Rapid Gravity Filter Design Criteria: (Rapid Sand Filter)Document4 pagesDesign of Rapid Gravity Filter Design Criteria: (Rapid Sand Filter)dpkNo ratings yet

- Pump Head and Drive Calculations: General Data Crude OilDocument1 pagePump Head and Drive Calculations: General Data Crude OilyusefriNo ratings yet

- Calculation V-Notch For Sedimentation TankDocument34 pagesCalculation V-Notch For Sedimentation TankDavid LambertNo ratings yet

- Grease Trap SizingDocument9 pagesGrease Trap SizingEngFaisal Alrai67% (3)

- Sludge Treatment: Total Solid in Raw Water 600 Kg/dayDocument12 pagesSludge Treatment: Total Solid in Raw Water 600 Kg/dayThava ThavaNo ratings yet

- STP EvaluationDocument12 pagesSTP EvaluationPatrick Mana-ayNo ratings yet

- Water Treatment DegasifierDocument6 pagesWater Treatment DegasifierEDUARDONo ratings yet

- Aerobic Sludge DigesterDocument5 pagesAerobic Sludge DigesterDavid LambertNo ratings yet

- STP Design CalculationDocument8 pagesSTP Design CalculationRajasekaran Gunasekaran0% (1)

- Commissioning Procedure Air Pre HeaterDocument15 pagesCommissioning Procedure Air Pre HeaterDavid LambertNo ratings yet

- Water HammerDocument3 pagesWater HammerSrinivas ReddyNo ratings yet

- Belt Filter Press TBEDocument2 pagesBelt Filter Press TBEmayukhguha1988No ratings yet

- Sewer Pump Calculation ReportDocument4 pagesSewer Pump Calculation Reportarguteconsultants0% (1)

- Al Ain Sludge Status - BwiDocument1 pageAl Ain Sludge Status - BwiHRK65No ratings yet

- Fire Tank Recirculation Pump SizingDocument1 pageFire Tank Recirculation Pump SizingAkhil VijaiNo ratings yet

- Acf DesignDocument21 pagesAcf DesignCapri Akvotech100% (1)

- Slow Sand Filter Design DBPDocument2 pagesSlow Sand Filter Design DBPlordsethdarknessNo ratings yet

- STP Technical SpecificationDocument26 pagesSTP Technical Specificationgnbuildtech Pvt ltdNo ratings yet

- 2SBR REACTOR - 1MLD - BOD Only PDFDocument7 pages2SBR REACTOR - 1MLD - BOD Only PDFHRK65No ratings yet

- Process Calculations 1 MLD SBRDocument168 pagesProcess Calculations 1 MLD SBRAngelo EndozoNo ratings yet

- CO2 and Lime Dosage Sea WaterDocument11 pagesCO2 and Lime Dosage Sea WaterNoureddine Merah100% (2)

- Ipal WikaDocument3 pagesIpal WikaDavid LambertNo ratings yet

- Calculation For Activated Sludge Process PDFDocument6 pagesCalculation For Activated Sludge Process PDFvinoohmNo ratings yet

- Process Design CalcDocument9 pagesProcess Design Calckiran raghukiranNo ratings yet

- Design of Ammonia StripperDocument1 pageDesign of Ammonia StripperthirumuruganNo ratings yet

- Design ETP PDFDocument11 pagesDesign ETP PDFDiky HermawanNo ratings yet

- Qaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secDocument7 pagesQaverage Phase-1 Phase-2 Qpeak Phase-1 Phase-2 m3/d m3/d m3/hr m3/hr M3/sec M3/secHemantk8731100% (1)

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationAnonymous QiMB2lBCJLNo ratings yet

- ATFD PiparDocument10 pagesATFD Piparrajesh kothariNo ratings yet

- Peak Flow Calculations XYZ Dec 16,2003Document7 pagesPeak Flow Calculations XYZ Dec 16,2003Amit BhamreNo ratings yet

- New Microsoft Word DocumentDocument77 pagesNew Microsoft Word Documenthamza A.laftaNo ratings yet

- Grit Removal Mechanism: (Detritor and Classifier Mechanism)Document2 pagesGrit Removal Mechanism: (Detritor and Classifier Mechanism)Kaustav Patnaik100% (1)

- NorsonDocument11 pagesNorsonPiyush A Joshi0% (1)

- 14-Lime Soda Ash Treatment PDFDocument43 pages14-Lime Soda Ash Treatment PDFRaj BisenNo ratings yet

- Pre-Draft MBR StandardsDocument14 pagesPre-Draft MBR StandardsAudrius100% (2)

- Clarifier Settling Tank PDFDocument25 pagesClarifier Settling Tank PDFvenustasiaNo ratings yet

- Orifice CalculationDocument3 pagesOrifice Calculationchandramohan muruganNo ratings yet

- AtfdDocument4 pagesAtfdDarshan PatelNo ratings yet

- Air Requirement For SBR STPDocument2 pagesAir Requirement For SBR STPBS supportNo ratings yet

- WN ARGU KU Pumps-Calculation en USDocument5 pagesWN ARGU KU Pumps-Calculation en USsalamakotbNo ratings yet

- Pumps Calculation Example:: The Following Variables Are GivenDocument5 pagesPumps Calculation Example:: The Following Variables Are GivensukirajNo ratings yet

- Cyclone DesignDocument1 pageCyclone DesignDavid LambertNo ratings yet

- Pekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDocument34 pagesPekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDavid LambertNo ratings yet

- Pekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDocument34 pagesPekerjaan Plumbing Main Equipment: Bill No 3 Project: Coca-Cola Bulan Baru, Surabaya Services: PlumbingDavid LambertNo ratings yet

- Load FactorDocument4 pagesLoad FactorDavid LambertNo ratings yet

- Booster Pump RequiredDocument6 pagesBooster Pump RequiredDavid LambertNo ratings yet

- Venting DesignDocument1 pageVenting DesignDavid LambertNo ratings yet

- Price List With Breakdown & Unit PriceDocument1 pagePrice List With Breakdown & Unit PriceDavid LambertNo ratings yet

- Konversi Besi Tulangan Ke Wire MeshDocument1 pageKonversi Besi Tulangan Ke Wire MeshDavid LambertNo ratings yet

- PFD WTP PDFDocument1 pagePFD WTP PDFDavid LambertNo ratings yet

- Bleaching Tank PT. Gurita Mandala No. Deskripsi KeteranganDocument1 pageBleaching Tank PT. Gurita Mandala No. Deskripsi KeteranganDavid LambertNo ratings yet

- Neraca PanasDocument3 pagesNeraca PanasDavid LambertNo ratings yet

- Wiring Diagram DC IIDocument2 pagesWiring Diagram DC IIDavid LambertNo ratings yet

- Besi Wide Flange (W.F) : Ukuran BeratDocument1 pageBesi Wide Flange (W.F) : Ukuran BeratDavid LambertNo ratings yet

- Pipa Baja Carbon For Pressure Schedule 40: Ukuran OD ID Tebal KG/M Kg/6MDocument1 pagePipa Baja Carbon For Pressure Schedule 40: Ukuran OD ID Tebal KG/M Kg/6MDavid LambertNo ratings yet