Professional Documents

Culture Documents

AVL MicroIFEM PiezoModule

Uploaded by

scribd695Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AVL MicroIFEM PiezoModule

Uploaded by

scribd695Copyright:

Available Formats

MICROIFEM

PIEZO MODULE 4P3E/F/G/H

Application Software IndiSignal from v2.8 Product Guide

June 2008 AT2626E, Rev. 01

DIN EN 62079: 11.2001 Certificate n. Z2D 06 12 10049 007

Copyright 2008 by AVL List GmbH, Graz - Austria The contents of this document may not be reproduced in any form or communicated to any third party without the prior written consent of AVL. While every effort is made to ensure its correctness, AVL assumes no responsibility neither for errors and omissions which may occur in this document nor for damage caused by them. All mentioned trademarks or registered trademarks are owned by their respective owners. Printed in Austria at AVL. All rights reserved.

Warnings and Safety Instructions

Warnings and Safety Instructions

This manual contains important warnings and safety instructions, which must be observed by the user. The device is intended only for an exactly defined use which is described in the manual. The manual also explains the essential prerequisites for the application and operation of the device as well as the safety measures to ensure smooth operation. AVL can offer no warranty nor accept any liability if the device is used in applications other than those described and if the necessary requirements are not met and the safety instructions not followed. The device may only be used and operated by personnel, who, due to their qualifications, are capable of observing the necessary safety measures during use and operation. Any accessories and equipment used with the device must be supplied or approved by AVL. The operating principle of this device is such that the accuracy of the measurement results depends not only on the correct operation and functioning of the device, but also on a variety of peripheral conditions beyond the control of the manufacturer. Therefore, the results obtained from this device must be examined by an expert (e.g. for plausibility) before any action is taken based on those results. Any adjustment and maintenance work necessary on instruments when open and under voltage must be carried out by a professional technician who is aware of the dangers. Repairs to the device may be carried out by the manufacturer or qualified service personnel only. When the device is in use, an expert must ensure that neither the object under test nor the testing equipment is operated under conditions that may lead to damage or injury. List GmbH

Product Guide

Warnings and Safety Instructions

microIFEM Piezo Module 4P3E/F/G/H

Grouped Safety Messages

Grouped Safety Messages

WARNING Danger of explosion and injury This device must not be used in any environment where there is a danger of explosion.

CAUTION Danger of death from electrical voltage Connected equipment that uses voltages equal to or greater than 50 V AC or 75 V DC must comply with the requirements of the 2006/95/EC Low Voltage Directive. To ensure that the risk of electric shock is minimized, the device may only be opened by qualified staff. To prevent the risk of fire and electric shock, the device must not be exposed to rain or permanent humidity or moisture. If a foreign body or liquid gets inside the device, disconnect the device from the power supply and have it checked by an expert before using it again. Make sure that the device is supplied with the correct supply voltage. Only use the supplied power supply cable with protective ground. Only connect the power supply cable to a grounded socket. Disconnect the equipment from the power supply system whenever you change a fuse. NOTICE Only shielded cables may be used with appropriately shielded connectors in order to comply with the 2004/108/EC Electromagnetic Compatibility Directive. Power supply connections with standardized connectors and the exceptions mentioned do not need to be shielded. Always place the device in a position that allows air to circulate freely through the device's venting aperture. Information When disposing of the product or of parts of it, make sure that the legal regulations in force in the country in which the device is operated are observed (e.g. regulations for the disposal of electronic scrap). The device must always be completely emptied of any fuel which might be present.

Product Guide

Grouped Safety Messages

microIFEM Piezo Module 4P3E/F/G/H

Table of Contents

Table of Contents

Warnings and Safety Instructions................................................................................................................ 3 Grouped Safety Messages ............................................................................................................................ 5

1 What You Should Know.................................................................................................... 9

1.1 1.2 1.3 Safety Instructions .................................................................................................................... 9 Intended Purpose of Application............................................................................................... 9 About this Documentation ...................................................................................................... 10 1.3.1 Abbreviations and Glossary Terms................................................................................... 10 1.3.2 Typographic Conventions ................................................................................................. 10 1.3.3 Online Help ....................................................................................................................... 11 1.3.4 We Want to Hear from You............................................................................................... 11

2 General ............................................................................................................................. 13

2.1 2.2 2.3 2.4 Applicability............................................................................................................................. 13 Application .............................................................................................................................. 13 Basic Equipment..................................................................................................................... 14 Options ................................................................................................................................... 14 2.4.1 External Voltage Supply.................................................................................................... 14 2.4.2 Cascading Package .......................................................................................................... 14

3 System Overview............................................................................................................. 15

3.1 3.2 3.3 Front View .............................................................................................................................. 15 Rear View ............................................................................................................................... 16 Cascading............................................................................................................................... 17

4 General Operating Instructions, Input Cable................................................................ 19

4.1 4.2 4.3 4.4 Cable Length, Cable Installation............................................................................................. 19 Insulation ................................................................................................................................ 19 Cable Noise ............................................................................................................................ 19 Electromagnetic Compatibility ................................................................................................ 19

Product Guide

Table of Contents

5 IndiSignal Operating Software ....................................................................................... 21

5.1 5.2 Installation .............................................................................................................................. 21 IndiSignal View ....................................................................................................................... 22 5.2.1 Toolbar ..............................................................................................................................22 5.2.2 Rack View .........................................................................................................................23 5.2.3 Transducers and Calibration .............................................................................................23 5.2.4 Status Bar .........................................................................................................................23 General Information About Calibration ................................................................................... 24 Settings 4P3x ......................................................................................................................... 25 5.4.1 Piezo Amplifier Tab ...........................................................................................................25 5.4.2 Calibration Info Tab ...........................................................................................................30 Functions ................................................................................................................................ 31 5.5.1 Drift Compensation ...........................................................................................................31 5.5.2 Calculation of the Calibration Factor ................................................................................32 5.5.3 Electronic Sensor Data TEDS (SDC) ................................................................................32 5.5.4 Calibration with Dead-Weight Tester (IndiSignal Stand-alone Only).................................35 Measurement.......................................................................................................................... 45 Offline Mode ........................................................................................................................... 45 INDISIGNAL.INI...................................................................................................................... 46 5.8.1 INDISIGNAL.INI Settings ..................................................................................................46 SENSORCAL.TXT.................................................................................................................. 47

5.3 5.4

5.5

5.6 5.7 5.8 5.9

6 Maintenance ..................................................................................................................... 49

7 Technical Data ................................................................................................................. 51

7.1 7.2 7.3 7.4 7.5 7.6 General................................................................................................................................... 51 Signal Input............................................................................................................................. 51 Signal Output.......................................................................................................................... 52 Transmission Data.................................................................................................................. 52 Data of Other Functions ......................................................................................................... 53 Pin Assignment - Rear Panel ................................................................................................. 54 7.6.1 Connector RS232 OUT (X7) / Socket RS232 IN (X8) .......................................................54 7.6.2 Connectors 9.5 ... 36 V DC IN (X1) / 9.5 ... 36 V DC OUT (X2) ........................................55 7.6.3 Connector X9 ....................................................................................................................55 7.6.4 Connector Socket to Connector X9...................................................................................56

8 Appendix .......................................................................................................................... 57

8.1 CE Compliance....................................................................................................................... 57

Index.............................................................................................................................................................. 59

microIFEM Piezo Module 4P3E/F/G/H

What You Should Know

What You Should Know

This documentation describes the functionality of the microIFEM 4P3x Piezo Amplifier family, which includes the following types: Suitable for TEDS with Fischer connector (AVL SDC):

� � � �

4P3E Piezo Amplifier Standard 4P3F Piezo Amplifier Double Range 4P3G Piezo Amplifier with SID Sensor Identification (with SAW print) 4P3H Piezo Amplifier Double Range and SID Sensor Identification (with SAW print)

Double Range SID

If the expected sensor charge exceeds 14400 pC, this version provides the option of using the double range. Using this option and the relevant sensors, the sensitivity values can be determined automatically by the amplifier. This chapter provides general information on the following topics:

� �

important warnings and safety instructions this documentation in general NOTICE

This documentation is not intended to and should not replace adequate training!

1.1

Safety Instructions

This documentation contains a number of important warnings and safety instructions that must be observed by the user. Smooth operation can only be ensured if the requirements are met and the safety instructions are followed.

1.2

Intended Purpose of Application

The product is only intended for the area of application which is described in the documentation. If used contrary to its intended purpose or if the prerequisites and safety instructions mentioned are not observed, no guarantee and/or liability shall be assumed. Due to the operating principle of this product, the accuracy of measurement results which it produces does not only depend upon its correct operation and function, but also upon a variety of boundary conditions beyond the control of the manufacturer. Therefore the results obtained from this product must be subjected to careful examination by an expert (e.g. for plausibility) before action based upon the results is undertaken. It is explicitly stated that use of this product alone will not ensure safety-related monitoring of the operating condition of the combustion engine under test.

Product Guide

10

What You Should Know

1.3

About this Documentation

This documentation has been written for test bed engineers/application engineers who set up and execute indicating measurements. It covers the following topics:

� � �

Setup Parameterization Calibration and Maintenance

For details about working with AVL Indicating Systems, refer to the relevant IndiCom system manual.

1.3.1

Abbreviations and Glossary Terms

SDB SDC SID TEDS Sensor Data Base Sensor Data Connector Sensor Identity Transducer Electronic Data Sheet

1.3.2

Typographic Conventions

Safety messages: WARNING WARNING indicates a hazardous situation which if not avoided could result in death or serious injury.

CAUTION CAUTION indicates a hazardous situation which if not avoided could result in minor or moderate injury. Additional safety symbols: Voltage hazard warning Notes: NOTICE This text indicates situations or operation errors which could result in property damage or data loss. Information This text indicates important information or operating instructions. Not observing these instructions could inhibit or impede you from successfully completing the tasks described in this documentation.

microIFEM Piezo Module 4P3E/F/G/H

What You Should Know

11

Standard text styles: Bold Italics Parameters; control elements in windows and dialog boxes; important text Cross-references; foreign-language or new terms; wildcards for elements that need to be entered by the user, i.e. characters or text. If you read, for example, macro name, you are required to type the name of a macro. Operating states Programming examples, source code Formulas Description of how to select a menu item from a given menu

UPPERCASE LETTERS

Courier

Times New Roman

Menu | Option

Lists: 1. 2.

� �

Step-by-step procedures with a given sequence One-step instructions Unordered series of concepts, items or options

1.3.3

Online Help

This printed manual is also available as online Help. To access online Help:

� �

open the Help menu or press the F1 key for context-sensitive Help.

1.3.4

We Want to Hear from You

Your comments and suggestions help us to improve the quality and practical relevance of our manuals. If you have any suggestions for improvement, please send them to: docu@avl.com We look forward to hearing from you!

Product Guide

12

What You Should Know

microIFEM Piezo Module 4P3E/F/G/H

General

13

2

2.1

General

Applicability

4P3E bis 4P3H, Rev. Level 00

2.2

Application

The microIFEM Piezo Module 4P3x is designed as a compact 4-channel amplifier. Its small size makes it perfectly suitable for use in test cells close to the pressure transducers or in the vehicle. The connections on the microIFEM Piezo Module permit the remote control of the amplfiers as well as the transmission of the output signals. Electrical isolation of each channel's power supply and use of a differential output amplifier ensure that the microIFEM Piezo Module is also suitable for use in environments with severe interference. The high upper cut-off frequency on the other hand permits highly dynamic measurements. AVL Piezo Amplifiers 4P3x are used to measure the electrostatic charges generated by pressure transducers in pressure, force and acceleration measurement systems. The extremely high input resistance makes it possible to carry out quasi-static measurements. The large sensitivity range means that the amplifier can be used in conjunction with most piezoelectric measurement transducers. An integrated drift compensation function ensures drift free measurement results where the isolation conditions are less than ideal. The option of reading sensor data from a sensor data connector or a database (either manually or automatically via SID) is one of the most important new features. This includes both calibration values and sensor runtimes.

�

AVL SDC (Sensor Data Connector) or TEDS (Transducer Electronic Data Sheet) This additional connector contains a memory in which the characteristic data are stored. Type, serial number and sensitivity according to the set input range are read out of this memory.

SDB (Sensor Data Base) Here you can select a sensor type and a serial number via an input field. Sensitivity is then read out automatically from a Sensor Database according to the set input range.

SID (Sensor Identity) If SID is activated, the amplifier identifies the unique sensor ID number which allows to read the type, serial number and sensitivity of the sensor from the Sensor Database. (Requires amplifier with SID detection (4P3G, 4P3H) and piezo transducers provided with SID.)

Product Guide

14

General

2.3

Basic Equipment

� � � � � � �

1 microIFEM Piezo Module 4P3x 1 serial interface cable, 5m 1 power supply cable, 10m 4 BNC connecting cables E109 - 1.5 4 clamp-on ferrites 1 CD-ROM with IndiSignal program 1 Product Guide

2.4

2.4.1

Options

External Voltage Supply

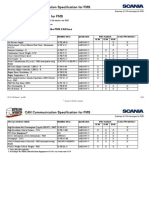

To supply the microIFEM 4FM2, 4P3x, 4C3x. Type Model TR70 =EN0457= IN Maximum no. of Maximum ambient connectable microtemperature IFEM 4xxx 4 3 2 1 6FA1Z01 *) Tab. 1 *) This type is out of production and will be replaced by TR70 =EN0457= 100 - 240 V AC 50 - 60 Hz 1.3 A 3 2 45 C 50 C 55 C 60 C 55 C 60 C

100 - 240 V AC 50 - 60 Hz 1.5 A

2.4.2

Cascading Package

The Cascading Package (TI04FCCSA.01) includes 1 serial interface cable and 1 power supply cable, 30 cm each.

microIFEM Piezo Module 4P3E/F/G/H

System Overview

15

3

3.1

System Overview

Front View

PIEZO

Q1

AVL MICRO IFEM

Q2 Q3 Q4

Fig. 1 microIFEM Piezo Module 4P3E/4P3F/4P3G/4P3H, front view Q1 to Q4 Lefthand sockets Righthand sockets 4 LEDs Connection for pressure transducers BNC sockets for pressure transducers with BNC connector 4-pin FISCHER sockets for pressure transducers with Sensor Data Connector (SDC) Status display of each amplifier channel GREEN: ORANGE: RED flashes: Regular operating state. Acknowledgement of a control signal. The amplifier channel is in saturation.

Product Guide

16

System Overview

3.2

X1 IN

Rear View

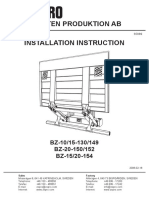

9.5 ... 36 V DC OUT X2 X9 X7 OUT RS232 IN X8

4 FOLLOW THE DIRECTIONS! DONT OPERATE THIS INSTRUMENT IN EXPLOSIVE HAZARDOUS LOCATIONS! 3 2

6 7 8

CH4

X3

CH3

X4

CH2

X5

CH1

X6

UNIT ADDRESS

Fig. 2 microIFEM Piezo Module 4P3x, rear view X1 IN 9.5 ... 36 V DC X2 OUT 9.5 ... 36 V DC

Power supply connection (9.5 to 36 V DC) DC voltage output. If microIFEMs are cascaded, the next microIFEM can be connected to this DC voltage output for power supply. NOTICE For restrictions, see sections Cascading on page 17 and Technical Data on page 51.

X3 to X6 CH4 to CH1 UNIT ADDRESS

BNC output sockets for the analog signal of the respective amplifier. Address switch for cascading: Address must be set to 0 if only one microIFEM is used. If microIFEMs are cascaded, the first microIFEM must be set to address 0. The address must be increased by 1 for each subsequent microIFEM. Serial connection to another microIFEM if microIFEMs are cascaded. Connection to the PC serial port or to the RS232 OUT socket of the previous microIFEM if microIFEMs are cascaded. Connection for Mounting Tray for 4 microIFEMs (TI04F4MTA.02).

X7 RS232 OUT X8 RS232 IN X9

microIFEM Piezo Module 4P3E/F/G/H

System Overview

17

3.3

Cascading

1. Up to 9 additional devices of the microIFEM family can be cascaded. Connect the PCs serial interface to the RS232 IN socket on the rear panel of the first microIFEM. Set the UNIT ADDRESS switch on this rack to 0. For cascading, connect the RS232 OUT socket of the first microIFEM to the RS232 IN socket of the second microIFEM. Connect the 9.5 ... 36 V DC OUT socket of the first microIFEM to the 9.5 ... 36 V DC IN socket of the second microIFEM. Set the UNIT ADDRESSswitch on the second microIFEM to 1. Connect additional microIFEMs following the same principle, increasing the address by 1 for each rack added. Information Indimaster Advanced 671 only: If more than 9 devices are cascaded, it is possible to connect these devices to an additional serial interface on your PC. NOTICE Make sure that the maximum continuous current of the supply connector does not exceed 8 A. E.g.: 24 V DC power supply: 15 W/24 V = 0.625 A, i.e. 9 racks can be cascaded. E.g.: 12 V DC power supply: 15 W/12 V = 1.25 A, i.e. 6 racks can be cascaded. Also ensure that the start-up power consumption (22 W per unit) of all microIFEMs does not exceed the maximum power output of the power supply! The optional AVL Power Supply Unit TR70 can supply up to four AVL microIFEMs. The RS232 and power supply connecting cables are 1:1 connecting cables. For the connector pin assignment and cable types, see section Pin Assignment Rear Panel on page 54.

2.

3.

Product Guide

18

System Overview

microIFEM Piezo Module 4P3E/F/G/H

General Operating Instructions, Input Cable

19

4

4.1

General Operating Instructions, Input Cable

Cable Length, Cable Installation

For best signal quality ensure that:

� �

The amplifier input cable is kept short. The amplifier input cable is installed as far away from other cables as possible. The amplifier input cable is not exposed to mechanical stress and vibrations. The connections of the input cable are kept clean and dry.

4.2

Insulation

For quasi-static operation, the cable should have an insulation resistance of >1013 Ohm, otherwise the output voltage of the charge amplifier will drift significantly.

4.3

Cable Noise

Normal coaxial cables generate electrical charges as a result of vibrations due to friction between the shield and dielectric. To prevent this effect, coaxial cables used for piezo electric measurements should have an additional coating of graphite or conductive plastic on the dielectric material.

4.4

Electromagnetic Compatibility

To comply with the Electromagnetic Compatibility (EMC) directive it is necessary to mount a clamp-on ferrite core onto the input signal cable (included in scope of supply, see the figures below) close to the connector:

Ferrit Core Piezo Amplifier

Fig. 3 Position of ferrite core (thick cable)

Ferrit Core Piezo Amplifier

Fig. 4 Position of ferrite core (thin cable)

Product Guide

20

General Operating Instructions, Input Cable

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

21

5

5.1

IndiSignal Operating Software

Installation

The AVL microIFEM system is fully remote controlled via a serial connection. The microIFEMs are parameterized by means of the operating software IndiSignal. Depending on your indicating system, the software is available in different versions. The basic operation is the same with all versions. IndiCom IndiSignal is an integral part of the Graphical Parameter Explorer IndiPar in IndiCom. Not only the the data acquisition hardware, but also the microIFEMs are visualized. In this case, it is not necessary to do a separate IndiSignal installation. Stand-alone Set the relevant COM port in the [IndiSignal] section within the INDICOM.INI file.

For all other systems, install IndiSignal as a separate program, which is provided on the CD that comes with the microIFEM. 1. Insert the CD-ROM into the CD drive. The installation procedure will be started automatically if the Autorun function is enabled. If it does not start automatically after inserting the CD-ROM, double-click the file INSTALL.EXE in the directory Install on your CD-ROM. Follow the instructions on the screen. By default, IndiSignal assumes a connection to the microIFEM via serial connection COM1. however you are free to change this to COM2 to COM8 in file INDISIGNAL.INI (see section INDISIGNAL.INI on page 46). Information Administrator privileges are required for installation.

2.

Product Guide

22

IndiSignal Operating Software

5.2

IndiSignal View

The IndiSignal window is composed of the following areas: 1 2

1 .... Toolbar 2 .... Rack View 3 .... Transducers and Calibration 4 .... Status Bar Fig. 5 IndiSignal main window

5.2.1

Toolbar

Check for new amplifiers Not relevant for microIFEM because the location of the amplifiers is fixed. Properties Displays the Properties dialog of the selected amplifier. Overrange check on When this button is clicked, IndiSignal continuously monitors the overrange state of all amplifiers and displays it via different colors of the LED symbol. The state is checked every 5 seconds. Click the button again to deactivate the mode. Calling up a properties menu and reloading amplifiers or sensors will also deactivate the function. Reset all Piezo Amplifiers When you click this button, the system will reset all installed Piezo Amplifiers in all available racks (i.e. set their output voltage to 0 V or -8 V). Reset Piezo Amplifiers at BDC When you click this button, the system will reset all installed Piezo Amplifiers in all available racks in the correct pressure phase (i.e. to 0 V or 8 V). Overview Displays system information about the microIFEM and its amplifiers. Use the mouse to enlarge the window if you need to! Temperature Displays the current temperature of the amplifiers and the modules in deg. Celsius.

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

23

Help Starts the online Help. Refresh Sensor Data Reloads the sensor data of all connected sensors (SDC, SID) into the relevant amplifier. Auto connect (IndiCom) Calls up a dialog in which the amplifier channels can be connected automatically to an input channel group of a data acquisition unit.

5.2.2

Rack View

This part of the view displays the selected microIFEM. Devices can be selected in the status bar at the bottom of the window. Just click the required microIFEM or the associated option button. Information If you are working with IndiCom, you also see here icons for the connected acquisition units. The corresponding unit is shown when you click the icon. These two views can also be used to define the connection between data acquisition and microIFEM. The selection of the Properties dialog of an amplifier may be done in different ways:

� �

Double-click the relevant amplifier. When you click an amplifier, it will be marked with a red frame. Click the button to call up the Properties dialog.

Right-click an amplifier area to show a context menu. Select Properties from the menu.

For details about amplifier settings, see section Settings 4P3x on page 25.

5.2.3

Transducers and Calibration

This view shows a simplified version of calibration data. You see there sensitivity, type and serial number of the connected sensors and the range of corresponding amplifier. If a connection to an input channel of the data acquisition unit exists, this is also shown. If you double-click into this view, a small input dialog will be opened and you can edit these parameters without having to open the full Properties dialog. Modifications are submitted by pressing RETURN. If the TEDS (SDC), SID or SDB functions are activated for a piezo transducer, the system will read in type, serial number and sensitivity from the data connector or the database. These values are not editable.

5.2.4

Status Bar

The status bar shows all connected microIFEMs and is used to select microIFEMs for parameter setting.

Product Guide

24

IndiSignal Operating Software

5.3

General Information About Calibration

Every amplifier is configured in the associated Properties dialog in IndiSignal. In this dialog, the sensor and measurement parameters are input, and the calibration factor is automatically calculated. It is also possible to input additional information about the sensor (i.e. type of sensor, serial number; etc.) and to set operating parameters of the amplifier. These parameters are then stored in a non-volatile memory in the amplifier. If the TEDS (SDC), SID or SDB functions are activated for a piezo transducer, the system will read in type, serial number and sensitivity from the data connector or the database. These values are not editable. The signal calibration factor, which is shown on the second page of the Properties dialog of every amplifier, has to be used for the signal calibration in the connected indicating system. If you work with IndiCom, it is not necessary to manually transfer this calibration factor. When establishing a connection between an analog input channel in the indicating system and an amplifier in the microIFEM, the calibration factor is automatically transferred to IndiCom. For more information on this subject, see Users Guide IndiPar, chapter IFEM/microIFEM Signal Conditioning.

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

25

5.4

5.4.1

Settings 4P3x

Piezo Amplifier Tab

Fig. 6 Piezo Amplifier Properties This Properties dialog shows all Piezo Amplifier settings, which can be changed if required.

5.4.1.1

Calibration

The calibration area of the dialog is where the gain is defined as a function of the measuring range (Signal Input Range input field) in the corresponding unit (bar, psi, MPa, kPa, Pa, g) and the sensor sensitivity (Transducer Sensitivity input field). The ideal gain is calculated internally with a resolution of 12 bit. The characteristic sensor data can be input in the Transducer Type and Serial Number fields. Information If this amplifier has already been calibrated with a dead weight tester, the calibration parameters are locked for input.

Product Guide

26

IndiSignal Operating Software

5.4.1.2

TEDS (SDC)

Fig. 7 Piezo Amplifier Properties, TEDS Requirements IndiCom version: IndiSignal version: microIFEM: as of 1.6 SPb as of 2.8 4P3E / 4P3F / 4P3G / 4P3H

Selecting the check box TEDS (SDC) activates the reading of the sensor data from a connected TEDS element (TEDS = Transducer Electronic Data Sheet). To call up the Properties dialog of the TEDS, click the button shown below. For details, see section Electronic Sensor Data TEDS (SDC) on page 32.

Information The system will automatically use the optimal gain, depending on the set signal input range.

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

27

5.4.1.3

SID (Sensor with ID)

Fig. 8 Piezo Amplifier Properties, SID Requirements IndiCom version: IndiSignal version: microIFEM: as of 1.6 SPb as of 2.8 4P3G / 4P3H

If a sensor with SID is used, the sensor identity will be determined if this check box is activated and the Apply button is clicked. For this purpose, the unique ID stored in the sensor is read out and searched for in the database. If a sensor with this ID is found in the database, the fields Transducer Sensitivity, Transducer Type and Serial Number are automatically filled with values. Information The system will automatically use the optimal gain, depending on the set signal input range.

Information A central Sensor Database is required to use this function. For installation and operation of the Sensor Database, please turn to your AVL branch for details.

Product Guide

28

IndiSignal Operating Software

5.4.1.4

SDB (Database)

Fig. 9 Piezo Amplifier Properties, SDB Requirements IndiCom version: as of 1.6 SP b

If you are using a sensor without SID, you can nevertheless utilize the benefits of a database. Activating this check box allows you to select the Transducer Type and Serial Number. The Transducer Sensitivity will be read automatically from the database and input in the relevant field. Information The system will automatically use the optimal gain, depending on the set signal input range.

Information A central Sensor Database is required to use this function. For installation and operation of the Sensor Database, please turn to your AVL branch for details.

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

29

5.4.1.5

Settings

�

-8 V Output Offset If the 8 V Output Offset check box is activated, an offset summing of -8 V ensures better ADC range utilization with cylinder pressure signals. This is effectively the same as shifting the zero line by -8 V.

Isolated Sensor Requirements: IndiCom version: IndiSignal version: microIFEM: as of 1.6 as of 2.8 4P3x

If this check box is activated, the sensor input ground is connected to protective ground. NOTICE Only use with sensors whose housing is isolated from sensor ground! Using this setting with normal sensors (housing connected to sensor ground) may cause strong signal distortion due to ripple voltages.

�

Drift Compensation If this check box is activated, a field will be displayed to the right containing the two options Cyclic and Continuous. Cyclic is the mode used in the past and requires cyclic signals, such as e.g. cylinder pressures or line pressures. Continuous mode has been implemented for offset correction of low-pressure signals, because these signals cannot be corrected appropriately with the cyclic method. NOTICE

Make sure to use the drift compensation appropriate for your signal type! The minimum signal lift for the detection of cyclic signals is approx. 0.7 V. Make sure that the amplitudes of the cylinder pressure signal exceed 0.7 V, even at idle. (Utilize the output offset of -8 V and set the gain in a way that, at full load, the output range is optimally used.) For Cyclic or Continuous drift compensation, the following firmware must be provided in the piezo module: Piezo Amplifier: Mainboard: 03 05

The relevant versions can be shown via the Overview toolbar button in IndiSignal.

�

Reset With the check box Reset you can reset this Piezo Amplifier (0 V or -8 V) permanently. Needed if this channel is not used. If you want to reset the amplifier for a short time and then use it, you have the following possibilities: Right-click the relevant amplifier to open the context menu. Select Reset to reset the amplifier. Click the following button on the toolbar:

All amplifiers of all cascaded microIFEM racks will be reset.

Product Guide

30

IndiSignal Operating Software

If you want to reset the amplifier in the correct pressure phase ("grounding"), click the button

on the toolbar. All amplifiers in all cascaded microIFEM 4P3x racks will be reset in the correct pressure phase. Phase-correct resetting means that the RESET function is activated in the low-pressure portion of the pressure signal. This prevents the pressure curve from being shifted downward in the high-pressure portion when the RESET button is pressed.

5.4.1.6

Drift

The check box that is activated shows the drift compensation method currently selected.

5.4.1.7

Filter

The displayed frequency shows the upper cut-off frequency currently set (-3 dB).

5.4.1.8

Buttons

�

OK Submits the settings and stores them in the Piezo Amplifier. The dialog is then closed.

Cancel The modified settings are not submitted. The amplifier will keep the original settings. The dialog is then closed.

Apply Submits the settings and stores them in the Piezo Amplifier. The dialog is not closed.

5.4.2

Calibration Info Tab

Fig. 10 Piezo Amplifier Calibration Info This tab displays the calibration factor determined by the set measuring range and the transducer sensitivity.

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

31

5.5

5.5.1

Functions

Drift Compensation

Connectable device for compensating zero drift of the output voltage (Uout).

Trigger Signal

S/H

Ucontrol

LONG DRCO

Rhighresist

Ck

Icomp

UOUT

Piezo Transducer

Rinsul

Iinsul

Fig. 11 Block diagram of a drift compensation A charge amplifier with no zero point drift is achieved by feeding a compensation current (Icomp) to the input of the charge amplifier that is of the same magnitude as the leak current (Iinsul) that escapes via the total insulation resistances. A control loop (consisting of input amplifier and sample-hold stage) generates a control voltage (Ucontrol) which feeds a compensation current (Icomp) to the input of the Q/U converter via a high-resistance resistor (Rhigh-resistance) so that the output voltage of the Q/U converter is 0 V/-8 V. As long as no input signal is applied to the charge amplifier or the Drift/Continuous radio button is activated, the S/H stage is switched through and the control loop ensures continuous drift compensation, i.e. the system attempts to maintain the Q/U converter output permanently at 0 V/-8 V. When an input signal is applied and the Drift/Cyclic radio button is activated, a trigger signal has to be delivered to the control loop to mark the point in time at which the output signal should be 0 V/-8 V. These trigger signals are not delivered to the S/H stage until the signal period T <1.2 s (corresponds to 100 min-1 in a four-stroke engine). In other words, for input signals T >1.2 s the control loop is in continuous drift compensation mode and attempts to keep the output at 0 V/-8 V. The trigger signals are generated from the input signal by an internal processor.

Product Guide

32

IndiSignal Operating Software

5.5.2

Calculation of the Calibration Factor

See also section Settings 4P3x on page 25. If you know the sensitivity of the Piezo Transducer (Transducer Sensitivity input field) and the expected maximum pressure (Signal Input Range input field), you can set a fixed relationship between the Piezo Amplifier output voltage and the pressure to be measured, without using external calibration facilities. The error caused by the Piezo Amplifier is then within +0.3% (800 pC/V to 25 pC/V) or +0.5% (25 pC/V to 8 pC/V). Gain A is calculated by sensor sensitivity S and the signal input range pN. When you click the Apply button after entering the parameters, the amplifier is set to the following gain: 4P3E / 4C3G:

8000 ( for 0 V offset ) or 14400 ( for -8 V offset ) [ pC ] ] A --------------------------------------------------------------------------------------------------------------------------------pC ------S p N [ bar ] bar 16000 ( for 0 V offset ) or 28800 ( for -8 V offset ) [ pC ] A --------------------------------------------------------------------------------------------------------------------------------pC - p N [ bar ] S ------bar

4P3F / 4C3H:

This produces a signal calibration factor (SCF) of: 4P3E / 4C3G:

bar 800 [ pF ] - = --------------------------SCF ------V pC - A S ------bar bar 1600 [ pF ]- = --------------------------SCF ------V pC - A S ------bar

4P3F / 4C3H:

Regarding transfer of the signal calibration factor to the connected indicating system see section General Information About Calibration on page 24. If the maximum pressure that occurs during operation is not known, we recommend starting with a high initial value and then reducing it until the Piezo Amplifier goes into saturation (check by means of LED or overrange check; red LED icon). Then increase the value until the overrange check shows a green LED icon.

5.5.3

Electronic Sensor Data TEDS (SDC)

Based on the AVL SDC-TEDS, the following sections show the dialogs with which the data stored in a connected TEDS can be displayed or changed. The contents of these dialogs may differ, depending on TEDS type and sensor manufacturer.

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

33

5.5.3.1

Header

Fig. 12 AVL SDC, Header tab

�

AVL Sensor Type Type of sensor. AVL Serial Number Serial number of sensor. Sensor ID Layout Version Version number of internal memory allocation. Total Operating Time Total operating time of the sensor. When you start IndiCom, the operating time counter in the amplifier is set to 0. As soon the amplifier gets a cylinder pressure signal, this internal counter recognizes the duration. When IndiCom is stopped, the current counter content will be added to the field Total Operating Time. The time unit can be defined in the file INDICOM.INI (sec/h).

; View SDC Operating Time in seconds or hours (sec/h) ViewTime=h

� �

Total Operating Cycles Total number of engine cycles of the sensor. Edit By clicking Edit you can switch to the Edit mode, which enables you to edit the values in the Property column. At the same time, the button Burn is activated which allows you to save the modifications in the SDC. Close Closes the dialog.

Product Guide

34

IndiSignal Operating Software

5.5.3.2

Calibration

Fig. 13 AVL SDC, Calibration tab This tab displays the calibration data.

�

Calibration Date Date of the calibration. User Name Name of the person who does the calibration. Remark Commentary Operating Time In this field you see the operating time for the current calibration. If you recalibrate the sensor, the current data including the operating time will be moved to the History 1 page and the operating time will be set to 0. Range 1 to 3, Sensitivity 1 to 3 and Linearity 1 to 3 In these fields you can input the calibration values for up to 3 ranges. The calibration factor is selected automatically according to the defined input signal range. The calibration values are taken from the Current page (see list box in upper righthand section of window).

Example Pressure Range (input signal range) = 80 bar Range 1 to 15 bar Range 2 to 50 bar Range 3 to 100 bar Selection of calibration factor from range 3

�

Sensor calibration To calibrate a sensor, first click the button New. The calibration data of the Current page will be moved to the History 1 page. History 1 will become History 2, etc. The pages History 1 to 5 allow you to compare the current calibration with the previous ones and see whether there are any changes. Edit By clicking Edit you can switch to the Edit mode, which enables you to edit the values in the Property column. At the same time, the button Burn is activated which allows you to save the modifications in the SDC. Close Closes the dialog.

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

35

5.5.4

Calibration with Dead-Weight Tester (IndiSignal Stand-alone Only)

Individual pressure transducers or the entire measurement system can be calibrated with a dead weight tester. To do this, right-click the Piezo Amplifier and select the option Dead-Weight Tester from the context menu. The first dialog of the Calibration Wizard is then displayed where you can choose one of three calibration methods: Transducer Calibration Calibration of the Entire Measurement System with Preselected Output Voltage Calibration of the Entire Measurement System with Preselected Maximum Pressure

5.5.4.1

Transducer Calibration

The following example shows how to calibrate a sensor on a dead weight tester, i.e. how to determine the sensitivity in pC/bar. The selected calibration pressure is 120 bar, the voltage at ambient pressure is set to -8 V. 1. If you want to calibrate the transducer with a dead-weight tester, activate the Transducer Calibration check box.

Fig. 14 Transducer Calibration 2. Click Next.

Fig. 15 Calibration parameters for transducer calibration 3. Mount the pressure transducer on the dead weight tester and input the calibration pressure (Calibration Pressure input field) as well as the approximate sensitivity (Estimated Transducer Sensitivity input field).

Product Guide

36

IndiSignal Operating Software

4. 5.

Enter the pressure transducer data. Select 8 V offset voltage for optimum utilization of the measurement range. Enter the user ID (User-ID input field) and click Next.

Fig. 16 Voltages measured during transducer calibration 6. Click Reset to reset the charge amplifier to its original status. Read the output voltage without calibration pressure (e.g. with the DVM function of the indicating instrument) and enter this voltage value in the Without Pressure Weight input field. Apply the calibration pressure. Read the output voltage with calibration pressure and enter this voltage value in the With Pressure Weight field. Click Next.

7. 8.

Fig. 17 Transducer calibration results 9. Read the automatically calculated pressure transducer sensitivity under Transducer Sensitivity. You can print out these data by clicking Print or save it to a text file by clicking Save. It is also possible to save or print out the calibration results. See section SENSORCAL.TXT on page 47. 10. Click Finish to close the Calibration Wizard.

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

37

5.5.4.2

Calibration of the Entire Measurement System with Preselected Output Voltage

The example given below shows the calibration of the entire measurement system with preselected output voltage. The selected calibration pressure is 120 bar, the required voltage difference between calibration pressure and offset is 16 V. The estimated sensitivity is 17 pC/bar. 1. If you want to calibrate the entire measurement system using a dead weight tester with preselected output voltage, activate the Measuring chain calibration check box and click the Output voltage predefined option button.

Fig. 18 Calibration of measurement system with predefined output voltage You can use this to obtain the required output voltage (maximum 10 V) for a specific calibration pressure.

Fig. 19 Calibration parameters with predefined output voltage 2. 3. 4. 5. 6. Mount the pressure transducer on the dead-weight tester. Input the calibration pressure (Calibration Pressure input field) and the approximate sensitivity (Estimated Transducer Sensitivity input field). Enter the pressure transducer data. In the Voltage at calibration pressure input field, enter the required output voltage at the applied calibration pressure (in the example 8 V). Select 8 V offset voltage for optimum utilization of the measurement range. The internal gain will be calculated with the following values: Calibration Pressure (in the example 120 bar) Estimated Transducer Sensitivity (in the example 17 pC/bar), and an Output voltage ~16 V (= voltage difference between calibration pressure and offset).

Product Guide

38

IndiSignal Operating Software

7.

Enter the user ID (User-ID input field) and click Next.

Fig. 20 Measured voltages with predefined output voltage 8. 9. Click Reset to reset the charge amplifier to its original status. Read the output voltage without calibration pressure (e.g. with the DVM function of the indicating instrument) and enter this voltage value in the Without Pressure Weight input field.

10. Apply the calibration pressure. 11. Read the output voltage with calibration pressure and enter this voltage value in the With Pressure Weight field. 12. Click Next.

Fig. 21 Calibration results with predefined output voltage A calibration protocol is shown in a dialog. You can print out these data by clicking Print or save it to a text file by clicking Save. After this calibration, the system can calculate the exact sensitivity of this transducer (in our example 16.81 pC/bar instead of the estimated 17 pC/bar). If you now repeat the calibration (click Repeat calibration), the calculated sensitivity (in the example 16.81 pC/V) will be transferred automatically into the field Estimated Transducer Sensitivity and the Calibration Wizard dialog will be displayed again.

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

39

13. Carry out the calibration again as described.

Fig. 22 Measured voltages (adjusted) with predefined output voltage 14. Enter the measurement values in the corresponding fields and click Next.

Fig. 23 Calibration results (adjusted) with predefined output voltage Based on the correct sensor sensitivity you now get the expected voltage difference of 16 V for 120 bar. It is also possible to save or print out the calibration results. See section SENSORCAL.TXT on page 47. 15. Click Finish to close the Calibration Wizard. The calibration values of the entire measurement system including the pressure transducer are stored in the Piezo Amplifier and can be checked on the Calibration Info tab of the Properties dialog. These calibration values cannot be deleted until the link on the Calibration Info tab of the Properties dialog is canceled. 16. To do this, click Cancel. The password to unlock the calibration values is defined in the INDISIGNAL.INI file (entry CAL PW = ).

Product Guide

40

IndiSignal Operating Software

5.5.4.3

Calibration of the Entire Measurement System with Preselected Maximum Pressure

The example given below shows the calibration of the entire measurement system with preselected maximum pressure. A maximum pressure of 140 bar is assumed. However, calibration is performed using a pressure of 120 bar. The estimated sensitivity is again assumed to be 17 pC/bar. 1. If you want to calibrate the entire measurement system using a dead weight tester with preselected output voltage, activate the Measuring chain calibration check box and click the Maximum pressure predefined option button.

Fig. 24 Measurement system calibration with predefined maximum pressure You can use this if you want to carry out a measurement with a higher operating pressure than the one you use for calibration.

Fig. 25 Calibration parameters with predefined maximum pressure 2. 3. 4. 5. 6. Mount the pressure transducer on the dead-weight tester. Input the calibration pressure (Calibration Pressure input field) and the approximate sensitivity (Estimated Transducer Sensitivity input field). Enter the pressure transducer data. Enter the required maximum operating pressure in the Maximum Pressure input field. Select 8 V offset voltage for optimum utilization of the measurement range. The internal gain will be calculated with the following values: Maximum Pressure Estimated Transducer Sensitivity

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

41

7.

Enter the user ID (User-ID input field) and click Next.

Fig. 26 Measured voltages with predefined maximum pressure 8. 9. Click Reset to reset the charge amplifier to its original status. Read the output voltage without calibration pressure (e.g. with the DVM function of the indicating instrument) and enter this voltage value in the Without Pressure Weight input field.

10. Apply the calibration pressure. 11. Read the output voltage with calibration pressure and enter this voltage value in the With Pressure Weight field. 12. Click Next.

Fig. 27 Calibration results with predefined maximum pressure A calibration protocol is shown in a dialog. You can print out these data by clicking Print or save it to a text file by clicking Save. After this calibration, the system can calculate the exact sensitivity of this transducer (in our example 16.81 pC/bar instead of the estimated 17 pC/bar). If you now repeat the calibration (click Repeat calibration), the calculated sensitivity (in the example 16.81 pC/V) will be transferred automatically into the field Estimated Transducer Sensitivity and the Calibration Wizard dialog will be displayed again.

Product Guide

42

IndiSignal Operating Software

13. Carry out the calibration again as described.

Fig. 28 Measured voltages (adjusted) with predefined maximum pressure 14. Enter the measurement values in V and click Next.

Fig. 29 Calibration results (adjusted) with predefined maximum pressure Based on the correct transducer sensitivity you now get a maximum pressure range of 140.1 bar. It is also possible to save or print out the calibration results. See section SENSORCAL.TXT on page 47. 15. Click Finish to close the Calibration Wizard. The calibration values of the entire measurement system including the pressure transducer are stored in the Piezo Amplifier of the microIFEM and can be checked on the Calibration Info tab of the Properties dialog. The password to unlock the calibration values is defined in the INDISIGNAL.INI file (entry CAL PW =).

5.5.4.4

Deleting the Saved Calibration Data

If you want to enter parameters directly or use a new calibration method, you first have to unlock the calibration data. To do this, click the Unlink button on the Calibration Info tab of the Properties dialog. The password to unlock the calibration values is defined in the INDISIGNAL.INI file (entry CAL PW =).

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

43

5.5.4.5

Calibration of the Entire Measurement System with Preselected Output Voltage for all Piezo Amplifiers

The example given below also demonstrates how to calibrate the entire measurement chain with preselected output voltage, but for multiple sensors. 1. If you want to calibrate more sensors at the same time, activate the check box All Piezo Amplifiers.

Fig. 30 Calibration of measurement system with predefined output voltage for all Piezo Amplifiers The calibrating parameters are valid for all sensors, the sensor parameters have to be defined individually.

Fig. 31 Calibration parameters with predefined output voltage for all Piezo Amplifiers 2. After the pressure drop at the dead-weight tester, fill in the displayed voltage values for every amplifier.

Fig. 32 Measured voltages with predefined output voltage for all Piezo Amplifiers

Product Guide

44

IndiSignal Operating Software

Finally, the system calculates the calibrating factors and writes them into each amplifier.

Fig. 33 Calibration results with predefined output voltage for all Piezo Amplifiers 3. 4. Carry out the calibration again as described. Enter the measured values in the relevant fields and click Next.

Fig. 34 Measured voltages (adjusted) with predefined output voltage for all Piezo Amplifiers

Fig. 35 Calibration results (adjusted) with predefined output voltage for all Piezo Amplifiers Based on the correct sensor sensitivity you now get the expected voltage difference of 16 V for 120 bar. It is also possible to save or print out the calibration results. See section SENSORCAL.TXT on page 47. 5. Click Finish to close the Calibration Wizard.

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

45

5.6

Measurement

A measurement can only be carried out when a pressure transducer is connected and the calibration has been performed. You have a choice of three modes - LONG (with no drift compensation) and DRCO (with drift compensation) Cyclic or Continuous: LONG For quasi-static measurements. The Drift Compensation check box is deactivated (e.g. dead weight calibration). Advantage Amplitude and phase of the measurement signal are not affected. Disadvantage Zero point drift; reset required prior to each measurement. DRCO Continuous For signals with no distinctive pressure maximum. The Drift Compensation check box is activated (e.g. low-pressure signals, such as e.g. intake manifold pressure). In this mode, the device attempts to keep the output permanently at 0 V or -8 V and, thus, also influences the wanted signal. For this reason, this mode is not suitable for cylinder pressure signals (IMEP errors might occur). Advantage No zero point drift; no reset required prior to each measurement. Disadvantage Amplitude and phase of the measurement signal might be affected. DRCO Cyclic For periodical signals, such as e.g. cylinder pressure. Advantage No zero point drift, no effect on amplitude and phase, no reset necessary prior to each measurement. With signal periods T <1.2 s, Continuous mode is automatically selected. You can choose between 0 V and -8 V offset voltage. 0V To be used for:

� �

Positive input voltage range of the evaluation device Input signal with significant negative range (e.g. intake manifold pressure) 18 V input voltage range of the evaluation device Charge amplifier input signal with low negative signal range (e.g. cylinder pressure) NOTICE

-8 V

To be used for:

� �

If the LED on the microIFEM flashes red, this indicates a brief or longer saturation of the amplifier. If necessary, reduce the sensitivity by entering a higher value in the Signal Input Range input field. Also check cable connections.

5.7

Offline Mode

IndiCom Offline also contains an offline version of IndiSignal. The microIFEM contained in the test environment file (which may be copied from the test bed to an office PC) is displayed. Via context menu it is, however, also possible to add or remove microIFEMs. This allows you to set the amplifiers to the required signal input range and input the sensor sensitivities in the office. These values are saved in the IndiCom parameter file and can then be used directly on the test bed.

Product Guide

46

IndiSignal Operating Software

5.8

INDISIGNAL.INI

The software can be adjusted to your system configuration by changing several INI file entries.

�

For IndiCom, you find these settings in the [IndiSignal] section of the INDICOM.INI file. For the stand-alone version, edit the file INDISIGNAL.INI.

Example

[IndiSignal] ;===Language (ENG,GER)=== Language = GER ;===ComPort 1,2...or OFFLINE, OFF=== ;===IFEM COMPORT or GLOBAL OFFLINE ComPort=1 ;===PreLoad Amplifier-Properties, Off=0, On=1 ;PreLoad=0 ;===Password for removing Amplifier / Transducer Link=== CalPW=AVL ;Password for SDC Editor TEDSEditPW=AVL ;View SDC OperatingTime in seconds or hours (sec/h)

ViewTime=sec

5.8.1

INDISIGNAL.INI Settings

Entry Language= Input Options GER ENG 1, 2 OFFLINE, OFF AVL (factory setting) or any password 0 1 0 = NO 1 = YES TEDSEditPW= AVL (factory setting) or any password sec h Description Dialog language German Dialog language English (IndiSignal only) Serial interface 1 or 2 Offline mode Password to unlock the calibration values after dead-weight tester calibration This parameter defines whether or not the settings of the amplifiers come from the IndiCom parameter file. The system makes a configuration check of racks and amplifiers. (Only if used with IndiCom.) Password which is requested if you want to change the settings of the SDC connector. Defines whether the operating time of the SDC connector is displayed in seconds or hours.

ComPort= CalPW=

PreLoad=

ViewTime=

Tab. 2

microIFEM Piezo Module 4P3E/F/G/H

IndiSignal Operating Software

47

5.9

SENSORCAL.TXT

Calibration Results: -------------------Transducer Type: QH33D Serialnumber: N199 Maximum Pressure Range: 120.1 bar Calibration Pressure: 120 bar Sensitivity: 16.84 pC/bar Signal Calibration Factor: 6.67162 bar/V User: WG Date: 07-25-2005 ******************** Calibration Results: -------------------Transducer Type: QH33D Serialnumber: N120 Maximum Pressure Range: 120.2 bar Calibration Pressure: 120 bar Sensitivity: 15.92 pC/bar Signal Calibration Factor: 6.67539 bar/V User: WG Date: 07-25-2005 ******************** Calibration Results: -------------------Transducer Type: QH33D Serialnumber: 1745 Maximum Pressure Range: 120.1 bar Calibration Pressure: 120 bar Sensitivity: 15.90 pC/bar Signal Calibration Factor: 6.67484 bar/V User: WG Date: 07-25-2005 ******************** Calibration Results: -------------------Transducer Type: QH33D Serialnumber: A188 Maximum Pressure Range: 120.0 bar Calibration Pressure: 120 bar Sensitivity: 16.02 pC/bar Signal Calibration Factor: 6.66929 bar/V User: WG Date: 07-25-2005 ********************

Product Guide

48

IndiSignal Operating Software

microIFEM Piezo Module 4P3E/F/G/H

Maintenance

49

Maintenance

General The AVL microIFEM 4P3x needs no routine maintenance. However, every charge amplifier that works on a quasi-static principle requires an extremely high insulation resistance at the input to prevent the tendency to drift (i.e. its output voltage gradually changes even without an input signal). The high insulation resistance of Piezo Amplifiers at the time of delivery can only be maintained if the devices are always kept dry and clean. If the Piezo Amplifier is in perfect condition, the drift is <0.03 pC/s, which corresponds to an input current of 0.03 pA. Significant Drift The drift is too large when it exceeds a value of 36 mV/min at gain = 16. This gain is set internally when e.g. the following values are input:

� �

Transducer Sensitivity = 20 pC/bar Signal Input Range = 25 bar.

Drift should be checked 10 minutes after power-up. Too much drift in the measurement system: 1. Disconnect the pressure transducer and the cable from the amplifier input. If the drift is then less than with the pressure transducer connected, the drift is caused by the cable and/or the pressure transducer. If there is still too much drift, carefully clean the insulation element in the input socket contact first using a clean, dry cloth. If that does not reduce the drift, then clean it with pure diethylether or trichlorethylene and dry it with a clean cloth. If there is still too much drift, dry the amplifier for 6 hours at +70 C.

2.

3.

If none of these measures solves the problem, the amplifier needs cleaning inside as well. This should only be done by the manufacturer. WARNING Danger of chemical burns and injury Always heed the relevant warnings and safety instructions when using caustic or highly flammable cleaning agents.

Product Guide

50

Maintenance

microIFEM Piezo Module 4P3E/F/G/H

Technical Data

51

7

7.1

Technical Data

General

Pollution degree 2 Power supply Input voltage range 9.5 V to 36 V DC Max. continuous current load of supply connector 8A Power consumption 22 W start-up power, 15 W continuous power Dimensions 218 x 42 x 230 mm (width x height x depth), depth including cable connections: 250 mm Weight 1 microIFEM = 1.5 kg 19" trough including 2 pieces microIFEM = 4 kg Ambient temperature -40 C ... +60 C (see also section External Voltage Supply on page 14) Storage temperature 0 C ... +80 C Maximum relative humidity 80% for temperatures up to 31 C, with a linear decrease to 50% relative humidity at 40 C, non-condensing.

7.2

Signal Input

Type Asymmetric, highly insulated for connecting piezoelectric measurement transducers. Connection BNC socket or FISCHER sockets Q1 to Q4 on the front panel. Insulation resistance >1013 Ohm Overload capacity Input protected against electrostatic voltages and charges occurring during operation and handling.

Product Guide

52

Technical Data

7.3

Signal Output

Type Asymmetric, output ground connected to protective ground and decoupled from the input ground by means of a differential amplifier. Connection BNC socket on the rear panel of the microIFEM. Voltage -11 V ... +11 V at load >333 Ohm Current +30 mA max. Output offset 0 V or 8 V selectable Temperature drift <0.5 mV/ C (DRCO, 50 pC/V)

7.4

Transmission Data

Polarity Inverting, negative input charge produces positive output voltage. Sensitivity 4P3E / 4P3G: adjustable from 800 pC/V to 8 pC/V 4P3F / 4P3H: adjustable from 1600pc/V to 16 pc/V Measurement range

�

Offset 0 V 4P3E / 4P3G: For +10 V at output: 4P3F /4P3H: For +10 V at output: 4P3E / 4P3G: For 18 V at output: 4P3F /4P3H: For 18 V at output: 8000 pC max., 80 pC min. 16000 pC max., 160 pC min.

Offset -8 V 14400 pC max., 144 pC min. 28800 pC max., 288 pC min.

Error Output voltage / input charge

� �

Linearity error<0.01% F.S. Gain error 4P3E / 4P3G: 800 pC/V... 25 pC/V:+0.3% 25 pC/V ... 8 pC/V: +0.5% 4P3F /4P3H: 1600 pC/V... 50 pC/V:+0.3% 50 pC/V ... 16 pC/V: +0.5%

Temperature sensitivity of gain <250 ppm/ C Gain resolution 12 bit

microIFEM Piezo Module 4P3E/F/G/H

Technical Data

53

Frequency Response

Upper cut-off frequency(-3 dB) Adjustable: 100 kHz / 50 kHz / 12 kHz Lower cut-off frequency

�

DRCO OFF Quasi-static measurements possible. The time constant depends mainly on the degree of soiling and humidity of the highly insulated elements, the connected cable and the measurement transducer. DRCO ON Zero point drift-free, depending on the measurement signal period: Measurement signal period T <1.2 s: Amplitude and phase not affected. Measurement signal period T >1.2 s: Continuous drift compensation (i.e. amplitude and phase are affected)

Drift (due to leakage current) +0.03 pC/s (at 25 C, DRCO OFF) Hum and noise <1 mVRMS or <10 mVss (0 to 50 MHz) (50 pC/V, DRCO)

7.5

Data of Other Functions

Overload Display When the control range is exceeded (approx. +11 V), the LED flashes red (or LED icon lights up red) if the range monitoring function has been activated in IndiSignal. Signal period

�

Drift Compensation DRCO

T <1.2 s (corresponds to 100 min-1 in 4-stroke engines): Drift-free measurement without any effect on amplitude and phase. T >1.2 s: Continuous drift compensation.

Output signal lift Uout min = 0.7 Vss Minimum output signal lift for drift compensation to function properly.

Product Guide

54

Technical Data

7.6

7.6.1

Pin Assignment - Rear Panel

Connector RS232 OUT (X7) / Socket RS232 IN (X8)

Assignment Pin 1 Pin 2 Pin 3 Pin 4 Pin 5 Pin 6 Pin 7 Pin 8 Pin 9 Socket housing Tab. 3 Signal Not used. TXD RXD Not used. Ground Not used. Not used. Not used. Not used. Cable shield (protective ground)

Fig. 36 9-pin Sub-D connector RS232 OUT (X7)

Fig. 37 9-pin Sub-D socket RS232 IN (X8)

microIFEM Piezo Module 4P3E/F/G/H

Technical Data

55

7.6.2

Connectors 9.5 ... 36 V DC IN (X1) / 9.5 ... 36 V DC OUT (X2)

Assignment Pin 1 Pin 2 Pin 3 Socket housing Tab. 4 Signal Ground Protective ground +24V Cable shield (protective ground)

2 1

Fig. 38 3-pin Sub-D connectors 9.5 ... 36 V DC IN (X1) / 9.5 ... 36 V DC OUT (X2)

7.6.3

Connector X9

Assignment for 25-pin SUB-D connector Pin 13 Pin 16 Pin 17 Pin 18 Pin 19 Socket housing Tab. 5 Signal Ground RESET CH1 RESET CH2 RESET CH3 RESET CH4 Cable shield (protective ground)

Fig. 39 25-pin Sub-D connector X9

Product Guide

56

Technical Data

7.6.4

Connector Socket to Connector X9

Assignment for 37-pin SUB-D socket Pin 16 Pin 25 Pin 26 Pin 27 Pin 28 Socket housing Tab. 6 Signal Ground RESET CH1 RESET CH2 RESET CH3 RESET CH4 Cable shield (protective ground)

Fig. 40 37-pin Sub-D socket to connector X9

microIFEM Piezo Module 4P3E/F/G/H

Appendix

57

8

8.1

Appendix

CE Compliance

The microIFEM complies with the following Directives and Standards: 2004/108/EC Directive on Electromagnetic Compatibility met by complying with the following standards:

�

EN 61326-1:06 Electrical Equipment for Measurement, Control and Laboratory Use EMC Requirements

Area of application: Class A equipment: Equipment suitable for use in establishments other than domestic and those directly connected to a low voltage power supply network which supplies buildings used for domestic purposes. Piezo Amplifier 4P3x The charge inputs Q1 to Q4 are not EMC-protected. Because:

�

The inputs must have high external impedance (>1013 Ohm) so that no EMC filters can be used. The main sources of interference on the test bed are ground loop problems. To suppress such interference, the shields of input cables at the amplifier end must not be connected to protective ground because the sensors are connected to the engine ground at the engine end. In this way, no effective HF shielding can be achieved.

The CE test was therefore carried out with no measurement cables and pressure transducers connected.

Product Guide

58

Appendix

microIFEM Piezo Module 4P3E/F/G/H

Index

59

Index

A

Ambient temperature 51 AVL SDC 13

N

Noise 53

C

Calibration factor 32 Calibration with dead-weight tester 35 Cascading 16 Cascading Package 14 CE Conformity 57 Coaxial cable 19 Connector Rear panel 54 Continuous current load 51 Current 52

O

Offset voltage 45 Output signal lift 53 voltage selection 37, 43 Output offset 52 Overload display 53

P

Password 46 Polarity 52 Power consumption 51 Preselected maximum pressure 40 Pressure drop 43 Pressure transducer 15

D

Dimensions 51 Double Range 9 DRCO 52-53 Continuous 45 Cyclic 45 Drift 49, 53 Drift compensation 31, 53

R

Rear View 16

S

SDB 13 SDC 15 Sensitivity 52 Sensor Calibration 35 Data Connector 13 Database 13 Identification 13 SDC data 32 SID 9, 13 Signal input 51 Input range 25 Output 52 period 53 Storage temperature 51

E

Electronic sensor data 32 Error 52

F

Frequency Response 53 Front View 15

G

Gain

error 52 factor 52

General information about calibration 24

T

Temperature drift 52 sensitivity 52 Total Operating Cycles 33 Time 33 Transmission Data 52

H

Hum 53

I

INDISIGNAL.INI 46 Installation 21 Insulation resistance 19, 51 Isolated sensor 29

U

UNIT ADDRESS 16 Upper cut-off frequency 53

L

Leakage current 53 Linearity error 52 LONG 45 Lower cut-off frequency 53

V

Voltage 52 Output 16 Supply 16, 51

M

Measurement range 52

W

Weight 51

Product Guide

60

Index

microIFEM Piezo Module 4P3E/F/G/H

AVL List GmbH Hans-List-Platz 1, A-8020 Graz, Austria Phone: +43 316 787-0, Fax: +43 316 787-400 http://www.avl.com

You might also like

- BWM 0000866 99 PDFDocument37 pagesBWM 0000866 99 PDFjose breno vieira silvaNo ratings yet

- Mercedes Actross BS Pin AssignmentDocument2 pagesMercedes Actross BS Pin AssignmentIslam MustafaNo ratings yet

- Ecas AbsDocument124 pagesEcas AbsHenriqueNo ratings yet

- Fundamental of HDD Technology (3) : OutlineDocument8 pagesFundamental of HDD Technology (3) : OutlineJoseMNo ratings yet

- Man Tga 2.Document5 pagesMan Tga 2.Aigars MulisNo ratings yet

- AdBlue Cleaning Kit User ManualDocument199 pagesAdBlue Cleaning Kit User ManualLuispinedaNo ratings yet

- Davie Xdcii 530 Eng DafDocument8 pagesDavie Xdcii 530 Eng Dafjose breno vieira silvaNo ratings yet

- MC 10208811 0001Document49 pagesMC 10208811 0001Luis HernándezNo ratings yet

- Ecomat 2 4139-758-103 Operating InstructionDocument38 pagesEcomat 2 4139-758-103 Operating InstructionjeremyNo ratings yet

- Proyecto: Sitp - NQR - p10 - 00.02 Entradas K30 Nodo 1Document3 pagesProyecto: Sitp - NQR - p10 - 00.02 Entradas K30 Nodo 1Wilber Castell Jr.100% (1)

- Manual Instalare MP 48Document64 pagesManual Instalare MP 48Horga georgeNo ratings yet

- Checking Data, I-CANDocument3 pagesChecking Data, I-CANWaldek KozlowskiNo ratings yet

- Repair Manual: Transmission Actuator and Clutch ActuatorDocument6 pagesRepair Manual: Transmission Actuator and Clutch Actuatorمصطفى بهاءالدين محمد امين خدا كرمNo ratings yet

- 2AC 150.00845811en 2017 06 20 DIWA.6 THBDocument209 pages2AC 150.00845811en 2017 06 20 DIWA.6 THBAdrien De FariaNo ratings yet

- Frame Sensor and Actuator Module (SCH), Component Description PDFDocument1 pageFrame Sensor and Actuator Module (SCH), Component Description PDFrudiNo ratings yet

- 01A-2 Power Supply Before Contact XLRTEH4300G038443Document6 pages01A-2 Power Supply Before Contact XLRTEH4300G038443НиколайNo ratings yet

- Lear MKR MKS Plus System1Document41 pagesLear MKR MKS Plus System1Sebas CorvalánNo ratings yet

- BB Connector - Euro6 - 1Document41 pagesBB Connector - Euro6 - 1Elisabet Sanmarti MuntadaNo ratings yet

- FMS Connector StandardDocument4 pagesFMS Connector StandardmapedmlgNo ratings yet

- 2021 1208 Marine Commercial Pleasure NEF EDC7C1 CAN Spec Mar 2021Document50 pages2021 1208 Marine Commercial Pleasure NEF EDC7C1 CAN Spec Mar 2021KornNo ratings yet

- Voith Service X-Change Manual 06-26-2020Document17 pagesVoith Service X-Change Manual 06-26-2020Mohamed MohamedNo ratings yet

- Trakker E4Document74 pagesTrakker E4EVCYNo ratings yet

- Volvo 7900 HybridDocument4 pagesVolvo 7900 HybridFernando García100% (2)

- 89208694-Wiring Diagram, FLDocument246 pages89208694-Wiring Diagram, FLTaivar PindNo ratings yet

- 01A-3 Power Supply After Contact XLRTEH4300G038443Document5 pages01A-3 Power Supply After Contact XLRTEH4300G038443НиколайNo ratings yet

- LP700 RepairkitDocument6 pagesLP700 RepairkitDaniel Alex Sánchez0% (1)

- Iveco Adblue EmulatorDocument1 pageIveco Adblue EmulatorAleksandar NikolovskiNo ratings yet

- Mid 185 - Psid 2 - Fmi 7Document3 pagesMid 185 - Psid 2 - Fmi 7AkbarNo ratings yet

- Vehicle Technology Division: Vehicle Approval and InformationDocument9 pagesVehicle Technology Division: Vehicle Approval and InformationautocomtrucksNo ratings yet

- Autoclima Ducato MinibusDocument30 pagesAutoclima Ducato MinibusBeltran MartinNo ratings yet

- 74584TL - EN - User Manual 191119Document68 pages74584TL - EN - User Manual 191119Gonzalo SastoqueNo ratings yet

- KWP2000 Manual PDFDocument20 pagesKWP2000 Manual PDFPljjkjNo ratings yet

- Dodge Nitro KA - 2007 - Heated MirrorsDocument2 pagesDodge Nitro KA - 2007 - Heated MirrorseephantomNo ratings yet

- En FM-Tco4 HCV Ruptela Tachograph SolutionDocument20 pagesEn FM-Tco4 HCV Ruptela Tachograph Solutionhusan shahNo ratings yet

- S CS Mega Configurator GBDocument14 pagesS CS Mega Configurator GBtonychavez3No ratings yet

- Electric EGR Valves (Renault, Opel)Document3 pagesElectric EGR Valves (Renault, Opel)audiovox_ro8872No ratings yet

- Руководство по эксплуатации PT6260-800RDocument67 pagesРуководство по эксплуатации PT6260-800Rpavel100% (1)

- Wiring Diagram Index: Released ReleasedDocument83 pagesWiring Diagram Index: Released ReleasedMc NanoNo ratings yet

- 3.3 SAMTEC - Introduction and Configuration: DICV-DM-M053Document6 pages3.3 SAMTEC - Introduction and Configuration: DICV-DM-M053abishekNo ratings yet

- Installation Guide: EB+ Generation 2Document52 pagesInstallation Guide: EB+ Generation 2The fountain of knowledgeNo ratings yet

- dw23271602 PDFDocument443 pagesdw23271602 PDFP GlNo ratings yet

- Twin DiscDocument42 pagesTwin DiscMf LuiNo ratings yet

- 014 ManDocument40 pages014 ManFilipposNo ratings yet

- Daf Ix Custom Par Pmci2Document12 pagesDaf Ix Custom Par Pmci2Mircea GilcaNo ratings yet

- CNH Industrial: FPT Industrial AND IvecoDocument8 pagesCNH Industrial: FPT Industrial AND IvecoCLAUDIA MASININo ratings yet

- RTH2610B - RT3210HV Carrier Catalogue PDFDocument16 pagesRTH2610B - RT3210HV Carrier Catalogue PDFasdNo ratings yet

- Meritor Reman Caliper Catalogue - Web - 1Document234 pagesMeritor Reman Caliper Catalogue - Web - 1SERVICIO AUTOMOTRIZNo ratings yet