Professional Documents

Culture Documents

Wire Line Pressure Control Equipment

Uploaded by

Stan Andrei100%(1)100% found this document useful (1 vote)

2K views39 pagesWire Line Pressure Control Equipment

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWire Line Pressure Control Equipment

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

2K views39 pagesWire Line Pressure Control Equipment

Uploaded by

Stan AndreiWire Line Pressure Control Equipment

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 39

Wireline Pressure Control Equipment

Wireline Pressure Control Equipment

Wireline Operations

Wireline Pressure Control (PECO) Products

- Introduction

- Quality Assurance

- After Sales Service

- Rental Equipment

- Product Information

Quick Union Cross-reference Table

Wellhead Flange Adapters (Xmas Tree Caps)

Single Manual Wireline Valves

Dual Manual Wireline Valves

Single Hydraulic Conventional Wireline Valves

Single Monoblock Wireline Valves

Dual Monoblock Wireline Valves

Triple Monoblock Wireline Valves

Wireline Valves Optional Accessories

Side Entry Fishing Branch Sub

Tool Traps

Conventional Lubricators & Risers

Lightweight Lubricators

Integral Lubricators & Risers

Tool Catchers

Chemical Injection & Liquid Chamber Subs

Manual Stuffing Boxes

Hydraulic Stuffing Boxes

Stuffing Box Accessories

Grease Injection Control Heads

Hydraulic Line Wipers & Swabbing Heads

Pump-in Tees

Quick Union Test Caps & Stumps

Quick Union Lifting Caps & Lifting Test Caps

Quick Union Crossovers & Adapters

In-situ Pressure Test Sub

Slickline Hay Pulleys & Line Wipers

Floor Stands & Rig-up Dollies

Wireline Clamps

Single Hand Pump Assemblies

Dual Hand Pump Assemblies

Ball Valve

API Tubing Table

Casing Data Table

click to exit

Next Item:

After Sales Service

Rental Equipment

Product Information

Section Menu www.cromar.com

Wireline Pressure Control (PECO) Products

Wireline Pressure Control (PECO) Products

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Introduction

Since 1979, Cromars wireline pressure control products

have been operational with major oil and oil service

companies world-wide. During this time we have

established an excellent field service history for

quality, safety and reliability. Our flexible operator

friendly designs have evolved by working closely with

our customers in order to provide engineering solutions

that meet their operational requirements. Our

extensive design, engineering and operational

experience is continually utilised in bringing new

products and ideas to the industry.

Cromar pressure control equipment is available with:

Bore sizes ranging from 2 to 9 ID

3,000 to 15,000psi working pressures

H2S and standard service

Working temperature range from -32C to +190C

Quality Assurance

Cromar recognises the need to meet the high quality

standards expected by our customers. To this end,

we have successfully implemented a quality system

in accordance with European Standard ISO 9001. All

our products are subject to stringent manufacturing

quality procedures which ensure compliance with

customer and industry requirements. Our pressure

control products are manufactured to the exacting

standards of SI 913 and NPD, NACE MR-01-75 (where

applicable) and API specifications as a minimum. All

parts are fully traceable and interchangeable (100%

quality control). All Cromar products are available

with full type approval from a certifying authority.

Next Item:

Quick Union

Cross-reference Table

Section Menu Last Item www.cromar.com

Wireline Pressure Control (PECO) Products

Wireline Pressure Control (PECO) Products

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

After Sales Service

Cromar carries a large inventory of spare parts at our

Aberdeen facilities. Our modern store is only minutes

from Aberdeen Airport and is ideally positioned to

respond to our customers urgent requirements.

General operating spares are also available at our

International bases.

Our trained specialist technicians are available 365

days a year, on a world-wide basis, to assist our clients

with repair and maintenance of their pressure control

equipment

As part of our after sales customer support provision,

Cromar offers a full back-up maintenance service

which includes annual and major re-certification in

accordance with current legislation.

Product Information

This Cromar wireline pressure control sales catalogue

has been compiled to give our clients an indication

of the product range and is not intended to be used

for field service purposes or as a composite catalogue.

In order to allow us to provide a fast and efficient

response, please specify the following information on

your enquiries:

Product type

Product number

Minimum inside diameter (ID)

Working pressure

Service (H2S or Standard) and temperature ratings

Wire or cable size

Rental Equipment

Cromar has a large, modern, fully certified rental

fleet of wireline pressure control equipment and

associated products. Stocked in Aberdeen and available

through our International offices, rental equipment

can be very quickly deployed to anywhere in the

world.

Next Item:

Wellhead Flange Adapters

(Tree Cap)

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Quick Union Cross-reference Table

Quick Union Cross-reference Table

4 3/4"-4 3.750 2.50 10,000 STD

4 3/4"-4 3.750 2.50 5,000 H2S

4 3/4"-4 3.750 3.00 5,000 STD

4 3/4"-4 x 2 3.750 3.00 10,000 H2S

5 1/2"-4 x 2 4.375 3.00 5,000 H2S

5 1/2"-4 x 2 4.375 3.00 10,000 STD

6"-4 x 2 4.875 3.00 5,000 H2S

6 5/16"-4 4.375 2.50/3.00 10,000 H2S

6 5/16"-4 3.750 2.50 15,000 H2S

6 5/16"-4 4.375 3.00 10,000 H2S

7"-5 SA 5.250 4.00 5,000 H2S

8 1/4"-4 x 2 6.000 4.00 10,000 H2S

8 1/4"-4 x 2 6.750 5.00 5,000 H2S

8 7/8"-4 x 2 6.500 5.00 10,000 H2S

9 7/8"-4 x 2 8.000 6.38 5,000 H2S

13"-4 9.500 6.37/7.37 10,000 H2S

13 1/2"-4 10.000 7.37 10,000 H2S

Thread Seal Dia Bore Pressure Service

Type B Acme

5"-4 3.500 2.50/2.92 10,000 STD

5"-4 3.500 2.50/2.92 5,000 H2S

5"-4 3.500 2.50/3.00 10,000 STD

5"-4 3.500 2.50/3.00 5,000 H2S

5"-4 3.500 2.50 15,000 H2S

5 3/4"-4 4.000 3.00 10,000 H2S

6"-4 4.875 4.00 5,000 STD

6 1/4"-4 4.000 2.50 15,000 H2S

6 1/2"-4 4.750 3.00 10,000 H2S

6 1/2"-4 4.750 4.00 5,000 H2S

6 1/2"-4 5.188 4.00 5,000 H2S

6 1/2"-4 5.250 4.00 5,000 H2S

7 1/2"-4 5.500 3.00 15,000 H2S

8 1/4"-4 6.188 5.00 10,000 STD

8 1/4"-4 6.188 5.00 5,000 H2S

8 3/8"-4 5.250 4.00 10,000 H2S

9"-4 6.750 5.00 10,000 H2S

9 1/2"-4 8.000 6.38 5,000 H2S

9 1/2"-4 6.250 4.00 15,000 H2S

11 1/2"-4 8.250 6.38 10,000 H2S

12"-4 10.313 9.00 5,000 H2S

12 1/4"-4 7.000 5.12 15,000 H2S

Thread Seal Dia Bore Pressure Service

Type O Acme

Type B Acme

Type O Acme

Next Item:

Single Manual

Wireline Valves

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Wellhead Flange Adapters (Tree Cap)

Wellhead Flange Adapters (Tree Cap)

The Cromar wellhead flange adapter (tree cap)

assembly consists of an API flange by quick union box

adapter, a blanking cap with bleed port (larger sizes

can be provided with lifting eyes) and a quick union

collar. Positioned on top of an API wellhead, the

adapter is designed to provide a positive connection

between the wellhead and surface pressure control

equipment during well intervention operations.

Adapter assemblies are available with a choice of:

Material:

Alloy steel, stainless steel and nickel alloys

Inlays and cladding can also be provided

Connection:

Standard API and non standard flanges

Type B, O & C Acme Quick Union connections

Working Pressure Rating:

Up to 15,000psi

Size:

From 2 1/16 ID upwards

Service:

H2S, Standard

Please refer to relevant section for blanking cap

and lift test cap information.

Cromar flange by quick union adapters are available

in all combinations for deployment of pressure control

equipment, including quick union pin and collar

connections besides those specified above.

Product code: 243

API Flange by Quick Union Box Adapter

Flanged Lift Test Cap Assembly

API Flange by Quick Union Pin Adapter

Wellhead Adapter Assembly

Next Item:

Dual Manual

Wireline Valves

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Single Manual Wireline Valves

Single Manual Wireline Valves

Product code: 510

The Cromar single manual wireline valve is positioned on top of the wellhead; it is designed to provide a

positive seal and contain well pressure around stationary wireline or braided cable during well intervention

operations.

Manually operated stems are used to actuate rams into the bore of the valve and seal around the wireline or

braided cable. The ram bodies are fitted with guides to align the wire/cable into the inner seals. Guides and

inner seals are dressed to suit the wire or cable being deployed. Ram bodies also include outer seals which

seal between the ram body and the bore above. Grease and well pressure behind the rams, acting on these

seals, assist in keeping the rams shut against the wire/cable. When the rams are positively closed, pressure

is bled off above them, allowing safe access to the wire above for fishing operations or to carry out repairs

to the pressure control equipment above the valve. After the task has been completed and the integrity of

the pressure control equipment has been confirmed, an equaliser valve, situated in the wireline valve body,

is used to equalise the pressure across the rams allowing them to be opened manually.

Manual wireline valves are recommended for well pressures of 5,000psi or less, and are not recommended

for H2S or high temperature applications.

Cromar single manual wireline valve assemblies are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 5,000psi

Size:

From 2.5 ID upwards

Service:

Standard

Single Manual Wireline Valve

Next Item:

Single Hydraulic

Conventional

Wireline Valves

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Dual Manual Wireline Valves

Dual Manual Wireline Valves

Product code: 510

The Cromar dual manual wireline valve is positioned on top of the wellhead; it is designed to provide a positive

seal and contain well pressure around stationary wireline or braided cable during well intervention operations.

Manually operated stems are used to actuate the rams into the bore of the valve and seal around the wireline

or braided cable. The ram bodies are fitted with guides to align the wire/cable into the inner seals. Guides

and inner seals are dressed to suit the wire or cable being deployed. The ram bodies also include outer seals,

which seal between the ram body and the bore above or below (when the lower ram set is inverted). A grease

injection port is provided in the cavity between the ram bodies. Grease is injected into this volume to achieve

a seal around a braided cable. Grease and well pressure behind the rams, acting on these seals, assist in

keeping the rams shut against the wire/cable. When the rams have been positively closed, well pressure is

bled off above them. This procedure allows safe access to the wire/cable for fishing operations or to carry

out repairs to the pressure control equipment above the valve. After the task has been completed and the

integrity of the pressure control equipment has been confirmed, equaliser valves, situated in the wireline

valve body, are used to equalise the pressure across both sets of rams.

Manual valves are recommended for well pressures of 5,000psi or less, and are not recommended for H2S or

high temperature applications.

Cromar dual manual wireline valve assemblies are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

5,000psi

Size:

From 2.5" ID upwards

Service:

Standard

Dual Manual Wireline Valve

Next Item:

Single Monoblock

Wireline Valves

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Single Hydraulic Conventional Wireline Valves

Single Hydraulic Conventional Wireline Valves

Product code: 511

The Cromar single hydraulic conventional wireline valve is positioned on top of the wellhead; it is designed

to provide a positive seal and contain well pressure around a stationary wireline or braided cable during well

intervention operations.

Hydraulically operated cylinder pistons with manual back up are used to actuate the rams into the bore of

the valve and seal around the wireline or braided cable. The ram bodies are fitted with guides to align the

wire/cable into the inner seals. Guides and inner seals are dressed to suit the wireline or cable being deployed.

The ram bodies also include outer seals which seal between the ram body and the bore above. Well pressure

behind the rams, acting on these seals, assists in keeping the rams shut against the wire/cable. When the rams

have been positively closed and the manual back-up stems functioned, pressure is bled off above them, allowing

safe access to the wire above for fishing operations or to carry out repairs to the pressure control equipment

above the valve. After the task has been completed and the integrity of the pressure control equipment has

been confirmed, an equaliser valve, situated in the wireline valve body, is used is used to equalise the pressure

across the rams. The manual back-up stems are then retracted, allowing the rams to be opened hydraulically.

Cromar hydraulic single conventional wireline valve assemblies are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 5,000psi

Size:

From 2.5 ID upwards

Service:

H2S, Standard

Options include:

Shear/seal rams for cutting wire and cable

Single Hydraulic Conventional Wireline Valve

Next Item:

Dual Monoblock

Wireline Valves

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Single Monoblock Wireline Valves

Single Monoblock Wireline Valves

Product code: 512

The Cromar hydraulic single monoblock wireline valves is positioned on top of the wellhead; it is designed to

provide a positive seal and contain well pressure around a stationary wireline or braided cable during well

intervention operations.

Hydraulically operated cylinder pistons with manual back-up stems are used to actuate the rams into the bore

of the valve and seal around the wireline or braided cable. The ram bodies are fitted with guides to align the

wire/cable into the inner seals. Guides and Inner seals are dressed to suit the wire or cable being deployed.

The ram bodies also include outer seals, which seal between the ram body and the bore above. Well pressure

behind the rams, acting on these seals, assist in keeping the rams shut against the wire/cable. When the rams

have been positively closed and the manual back-up stems functioned, well pressure is bled off above them,

allowing safe access to the wire above for fishing operations or to carry out repairs to the pressure control

equipment above the valve. After the task has been completed and the integrity of the pressure control

equipment has been confirmed, an equaliser valve, situated in the wireline valve body, is used to equalise

the pressure across the rams. The manual back-up stems are then retracted, allowing the rams to be opened

hydraulically.

Cromar single hydraulic monoblock wireline valve assemblies are available with

a choice of:

Connection:

Type B, O & C Acme Quick Union and standard API Bolt through flanges

Working Pressure Rating:

Up to 15,000psi

Size:

From 2.5 ID upwards

Service:

H2S, Standard

Special Features Include:-

Monoblock construction

Quick release hydraulic cylinders

Hydraulic cylinder support rods

Non-rising manual stems

Hydraulic piston position indicators

Keyless ram bodies

Integral equalisation valve

Options include:

Galvanised steel hollow section

crash frames with fold down

stabbing platforms

Shear/seal rams for cutting wireline and braided cable

Equalising Valve Detail

Single Monoblock Wireline Valve

Next Item:

Triple Monoblock

Wireline Valves

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Dual Monoblock Wireline Valves

Dual Monoblock Wireline Valves

Product code: 514

The Cromar dual hydraulic monoblock wireline valve is positioned on top of the wellhead; it is designed to provide

a positive seal and contain well pressure around wireline or braided cable during well intervention operations.

Hydraulically operated cylinder pistons with manual back-up stems are used to actuate the rams into the bore

of the valve and seal around the wireline or braided cable. The ram bodies are fitted with guides to align the

wire/cable into the inner seals. Guides and Inner seals are dressed to suit the wire or cable being deployed.

The ram bodies also include outer seals, which seal between the ram body and the bore above or below (when

the lower ram set is inverted). A grease injection port is provided in the cavity between the ram bodies. Grease

is injected into this area to achieve a seal around a braided cable. Grease and well pressure behind the rams,

acting on these seals, assist in keeping the rams shut against the wire/cable. When the rams have been positively

closed and the manual back-up stems functioned, well pressure is bled off above them. This procedure allows

safe access to the wire/cable for fishing operations or to carry out repairs to the pressure control equipment

above the valve. After the task has been completed and the integrity of the pressure control equipment has

been confirmed, equaliser valves, situated in the wireline valve body, are used to equalise the pressure across

both sets of rams. The manual back-up stems are then retracted, allowing the rams to be opened hydraulically.

Cromar dual hydraulic monoblock wireline valve assemblies are available with a

choice of:

Connection:

Type B, O & C Acme Quick Union and standard API bolt through flanges

Working Pressure Rating:

Up to 15,000psi

Size:

From 2.5" ID upwards

Service:

H2S, Standard

Special Features Include:-

Monoblock construction

Quick release hydraulic cylinders

Hydraulic cylinder support rods

Non-rising manual stems

Hydraulic piston position indicators

Keyless ram bodies

Integral equalisation valves

Integral grease injection port

Options include:

Galvanised steel hollow section crash frames

with fold down stabbing platforms

Shear/seal rams for cutting wire and cable

Equalising Valve Detail

Dual Monoblock Wireline Valve

Next Item:

Wireline Valves

Optional Accessories

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Triple Monoblock Wireline Valves

Triple Monoblock Wireline Valves

Product code: 516

The Cromar triple hydraulic monoblock wireline valve is positioned on top of the wellhead; it is designed to

provide a positive seal and contain well pressure around stationary wireline or braided cable during well

intervention operations. Triple valves are predominately used during high pressure operations or during fishing

operations where a set of shear and seal rams are installed.

Hydraulically operated cylinder pistons with manual back-up stems are used to actuate the rams into the bore

of the valve and seal around the wireline or braided cable. The ram bodies are fitted with guides to align the

wire/cable into the inner seals. Guides and Inner seals are dressed to suit the wire or cable being deployed.

The ram bodies also include outer seals, which seal between the ram body and the bore above or below (when

the lower ram set is inverted). Grease injection ports are provided in the cavities between the ram bodies.

Grease is injected into these volumes to achieve a seal around a braided cable. Grease and well pressure

behind the rams, acting on these seals, assist in keeping the rams shut against the wire/cable. When the rams

have been positively closed and the manual back-up stems functioned, well pressure is bled off above them.

This procedure allows safe access to the wire/cable for fishing operations or to carry out repairs to the pressure

control equipment above the valve. After the task has been completed and the integrity of the pressure control

equipment has been confirmed, equaliser valves, situated in the wireline valve body, are used to equalise the

pressure across the three sets of rams. The manual back-up stems are then retracted, allowing the rams to

be opened hydraulically.

Cromar triple hydraulic monoblock wireline valve assemblies

are available with a choice of:

Connection:

Type B, O & C Acme Quick Union and standard API

bolt through flanges

Working Pressure Rating:

Up to 15,000psi

Size:

From 2.5" ID upwards

Service:

H2S, Standard

Special features include:

Monoblock construction

Quick release hydraulic cylinders

Hydraulic cylinder

support rods

Non-rising manual stems

Hydraulic piston position indicators

Keyless ram bodies

Integral equalisation

valves

Integral grease

injection ports

Options include:

Galvanised steel

hollow section crash frames

with fold down stabbing platforms

Shear/seal rams for cutting wire and cable

Equalising Valve Detail

Triple Monoblock Wireline Valve

Next Item:

Side Entry

Fishing Branch Sub

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Wireline Valves Optional Accessories

Wireline Valves Optional Accessories

Product code: 601

Wireline Valve Stabbing Frame

Equalising Manifold

Wireline Shear and Seal Rams

Next Item:

Tool Traps

Section Menu Last Item

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

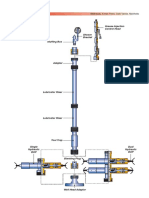

Side Entry Fishing Branch Sub

Side Entry Fishing Branch Sub

Product code: 564

The Cromar side entry fishing branch sub is positioned between the wireline valve and

the lowest lubricator section. It is designed to allow a second fishing tool string to be

deployed into the well on wireline in the event that the original tool string should

become stuck or jar action should be lost.

The side entry sub consists of a forged steel body sized to the well completion, complete

with pin and collar down by box up quick union connections. An offset 3 ID branch

bore is positioned adjacent to the main bore and fitted with a nominal 3 quick union

box connection. Internally, the branch bore is fitted with a 0.5 NPT bleed port, wireline

roller positioned at the intersection with the main bore and a quick union box complete

with an integral ball safety check valve.

When the tool string becomes stuck or jar action is lost, thus preventing normal retrieval,

the side entry sub offers a controlled method of wire/tool removal. This is achieved

by closing the wireline valve on the stuck wire, bleeding down the pressure above the

valve and clamping the wire, as per normal operational procedures. Thirty to forty

metres of line are spooled-off the winch and cut. The end of the line is re-routed back

up through the side entry subs branch bore, exiting via a conventional stuffing box.

The line is then attached to another winch unit or similar spooling device. A fishing

tool string is rigged-up within the lubricator complete with a special wire cutter that

is designed to ride on the stuck wire while being deployed into the well. A controlled

cut at the rope socket of the stuck wire is performed as per normal fishing procedures.

Then the fishing tool string and cut wire are both retrieved from the well in the

conventional way.

These techniques may also be applied to similar problems encountered during braided

line operations.

Cromar can provide a complete range of specialised fishing tools for use with the side

entry fishing branch sub.

Cromar side entry sub assemblies are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 15,000psi

Size:

From 2.5 ID upwards

Service:

H2S, Standard

Typical Rig-up

Side Entry Sub

Next Item:

Conventional

Lubricators & Risers

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Tool Traps

Tool Traps

The Cromar tool trap is positioned between the

wireline valve and lower lubricator section; it is

designed to trap wireline tools within the surface

pressure control equipment in the event of the tool

string becoming detached from the wireline at surface,

and so prevent the string from falling back into the

well.

Manual and hydraulic tool trap assemblies are available

with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 15,000psi

Sizes:

From 2.5 ID upwards

Service:

H2S, Standard

Manual Tool Trap

Hydraulic Tool Trap

Manual Tool Trap

When deploying tools into the well, the single

flapper is opened manually to allow the tool

string to pass, then it is closed. As the tool

string is retrieved, the flapper opens to allow

it to pass through. The counter balance weight

of the handle closes the flapper after the tool

string has passed. This action also provides the

operator with a positive visual indication that

the tool string is in the surface pressure control

equipment.

Hydraulic Tool Trap

When deploying tools into the well, two flappers

are opened hydraulically to allow the tool string

to pass, then they are hydraulically closed. As

the tool string is retrieved, the flappers open

to allow it to pass through. Return springs close

the flappers after the tool string has passed.

Product code:

Manual-523 / Hydraulic-524

Next Item:

Lightweight Lubricators

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Conventional Lubricators & Risers

Conventional Lubricators & Risers

Cromar lubricator and riser sections are designed to

contain well pressure and act as a manifold for tool

deployment. When coupled together to the desired

length, they form an effective operating height to

accommodate the tool string and sub-surface flow

control being deployed into the well. Longer sections

are referred to as riser sections as they are used on

platforms to rise the working well containment

manifold from the Christmas tree to the rig floor.

Conventional lubricators and riser sections typically

consist of a lubricator tube with quick union

connections: box on top and pin on the bottom. Where

appropriate, a double box collar is used between the

tube and pin connection to accommodate a bleed

port. These component parts are fitted together by

means of a Cromar S-Type acme thread which

incorporates a primary O ring seal and a back-up

secondary metal-to-metal seal.

During slickline operations three sections are normally

used. The lowest section is sized to the well completion

or hanger plug and the middle and upper sections are

sized for the tool string. For electric line operations

the lubricators would typically have the same ID.

Lubricator and riser sections are available with a

choice of:

Connection:

Type B, O & C Acme Quick Union

Inside Diameter:

From 2.5 ID upwards

Length:

From 3ft to 20ft

Pressure Rating:

Up to 15,000psi

Service:

H2S, Standard

Product code:

Ported-526

Non Ported-527

Conventional Lubricator/Riser Section

Next Item:

Integral Lubricators & Risers

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Lightweight Lubricators

Lightweight Lubricators

Product code: 534

The Cromar lightweight lubricator offers an alternative

to conventional threaded and integral lubricator

sections. This design uses a special high strength

material which provides a significant weight saving,

making this type of lubricator easier and safer to

manhandle.

The Cromar lightweight lubricator consists of a

lightweight, high yield strength tube with a quick

union pin connection on top and a box connection at

the bottom. The quick union connections are assembled

to the tube by means of a specially designed threaded

connection which incorporates both a primary 'O' ring

seal and a secondary (back up) metal-to-metal seal.

Lock rings are used to secure the unions to the tube.

All parts are treated with a special coating to prevent

wire cutting.

Cromar lightweight lubricator sections are not normally

supplied with bleed off ports. They are therefore used

as upper lubricator sections or with wireline valves

that incorporate a bleed off port.

Lightweight lubricator sections are available with a

choice of:

Connection:

Type B, O & C Acme Quick Union

Inside Diameter:

3", 4" ID

Length:

3ft to 20ft

Working Pressure Rating:

5000psi, 10,000psi

Service:

H2S

Lightweight Lubricator Section

Next Item:

Integral Lubricators & Risers

(continued)

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Integral Lubricators & Risers

Integral Lubricators & Risers

Cromar lubricator and riser sections are designed to

contain well pressure and act as a manifold for tool

deployment. When coupled together to the desired

length, they form an effective operating height to

accommodate the tool string and sub-surface flow

control being deployed into the well. Longer sections

are often referred to as riser sections, as they are

used on platforms to rise the working well

containment manifold from the Christmas tree to the

rig floor.

Integral lubricators and riser sections consist of a one

piece lubricator tube with integral quick union

connections: box on top and pin on the bottom. Where

appropriate, an upset is provided to accommodate a

bleed port.

During slickline operations three sections are normally

used. The lowest section is sized to the well completion

or hanger plug and the middle and upper sections are

sized for the tool string. For electric line operations

the lubricators usually have the same ID.

Lubricator and riser sections are available with a

choice of:

Connection:

Type B, O & C Acme Quick Union

Inside Diameter:

From 2.5 ID upwards

Length:

From 3ft to 12ft

Pressure Rating:

Up to 15,000psi

Service:

H2S, Standard

Product code:

Ported-528

Non Ported-529

Integral One Piece Lubricator/Riser Section

Next Item:

Tool Catchers

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Integral Lubricators & Risers

Integral Lubricators & Risers

Product code: 217

Aluminium and Steel Protectors available on request

4 3/4" - 4 THD 217-0475-001 217-0475-002

4 3/4" - 4 THD x 2 217-0475-003 217-0475-004

5 1/2" - 4 THD x 2 217-0550-001 217-0550-002

6" - 4 THD 217-0600-001 217-0600-002

6 5/16" - 4 THD 217-0631-001 217-0631-002

7" - 5 THD SA 217-0700-001 217-0700-002

8 1/4" - 4 THD x 2 10K 217-0825-001 217-0825-002

8 1/4" - 4 THD x 2 5K 217-0825-001 217-0825-002

8 7/8" - 4 THD x 2 217-0888-001 217-0888-002

9 7/8" - 4 THD x 2 217-0988-001 217-0988-002

13" - 4 THD 217-1300-001 217-1300-002

13 1/2" - 4 THD 217-1350-001 217-1350-002

Connection Size Pin Protector Box Protector

Type B Acme (Rubber)

5" - 4 THD 217-0500-001 217-0500-002

5 3/4" - 4 THD x 2 217-5750-001 217-5750-002

6 1/2" - 4 THD x 2 217-0650-001 217-0650-002

6 1/2" - 4 THD 5.18 217-0650-001 217-0650-002

8 1/4" - 4 THD 217-0825-003 217-0825-004

8 3/8" - 4 THD 217-0838-001 217-0838-001

8 3/4" - 4 THD 217-0875-001 217-0875-002

9" - 4 THD 217-0900-001 217-0900-002

9 1/2" - 4 THD 217-0950-001 217-0950-002

11 1/2" - 4 THD 217-1150-001 217-1150-002

12" - 4 THD 217-1200-001 217-1200-002

12 1/4" - 4 THD 217-1225-001 217-1225-002

Connection Size Pin Protector Box Protector

Type O Acme (Rubber)

Next Item:

Chemical Injection

& Liquid Chamber Subs

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Tool Catchers

Tool Catchers

The Cromar hydraulic tool catcher assembly is

positioned between the upper lubricator and the

grease injection head or wireline stuffing box. When

retrieving a tool string from the well, in the event

that the wireline should become detached due to

slamming the tool head into the stuffing box or grease

head, this failsafe design will automatically engage

the rope socket or cable head fishing neck and prevent

the tool string from falling back into the well.

Once the rope socket or cable head has been engaged,

hydraulic pressure can then be applied to cycle the

internal collet to the release position and so release

the tool.

Cromar hydraulic tool catcher assemblies are available

with a choice of:

Connection:

Type B, O & C Acme Quick Union

Flow Tube Acme Box with an

integral ball check valve

Working Pressure Rating:

Up to 15,000psi

Fishing Neck Collet Size:

1.00", 1.187", 1.375", 1.750", 2.313"

Service:

H2S and Standard.

Multi-Latch Hydraulic Tool Catchers

The standard type of tool catcher requires a sized

collet set for each size of fishing neck. Cromar's Multi

Latch hydraulic tool catcher is designed to engage all

sizes of fishing neck from 1.00" through 1.50" without

modification.

Product code:

Multi Latch-542 / Quick Union-540

Flow Tube Box - 541

Hydraulic Tool Catcher

Tool Catcher with Flow Tube Carrier Acme Box Connection C/W

Integral Ball Safety Check Valve

Next Item:

Manual Stuffing Boxes

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Chemical Injection & Liquid Chamber Subs

Chemical Injection & Liquid Chamber Subs

Product code: 537

Cromar chemical injection and liquid chamber

assemblies (subs) are positioned between the upper

lubricator section and the stuffing box. They are

designed to allow the operator to inject inhibitor

chemicals and de-icing agents onto the wireline during

routine operations. Liquid chamber subs also act as

a fluid barrier between the well and the stuffing box

thus preventing hydrates from forming and icing up

the stuffing box.

Chemical injection and liquid chamber assemblies are

available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 15,000psi

Service:

H2S, Standard

Wire Sizes:-

Up to 0.125

Chemical Injection Subs

Internally, the chemical injection sub is equipped

with a brass packing sub dressed with felt packing

and located at the injection port. Inhibitor or de-icing

agent is pumped into the packing sub coating the

wireline as it passes through the sub. The injection

port is equipped with an integral ball safety check

valve.

Liquid Chamber Subs

Internally, the liquid chamber sub is equipped with

a two-pint chamber. Felt packing at the lower end of

the chamber retains the inhibitor or de-icing agent,

coating the wireline as it passes through the vessel.

The injection port is equipped with an integral ball

safety check valve.

Liquid Chamber Sub

Chemical Injection Sub

Next Item:

Hydraulic Stuffing Boxes

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Manual Stuffing Boxes

Manual Stuffing Boxes

Product code: 549

The Cromar manual stuffing box is positioned on top of the lubricator stack. Its purpose is to seal and contain

well pressure around a stationary or moving wireline. The wireline is passed over the sheave wheel and down

through a series of packings in the body of the stuffing box. Upper and lower bushings are provided to guide

the wireline through the stack. To contain well pressure, the packing is tightened against the wireline by

means of a manually operated packing nut. The stuffing box also contains an integral blow out plunger which

is designed to seal the well automatically in the event of the wireline breaking and being forced out of the

packings.

Unless otherwise specified by the client, all Cromar stuffing boxes are supplied with brass internal components.

The use of brass materials has been proven to extend the field life of all types of wireline.

Cromar manual stuffing box assemblies are supplied with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 5,000psi

Service:

H2S, Standard

Wireline Size:

All sizes up to and including 0.125"

Sheave & Bracket Sub Assemblies:

14" & 16" heavy duty sheave and bracket

assemblies complete with load test certificates

Trim:

Brass, bronze or steel internal parts

Various packing elements for all types of service

Blow-out plunger or ball option

Manual Stuffing Box with Blow-out Plunger

Next Item:

Stuffing Box Accessories

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Hydraulic Stuffing Boxes

Hydraulic Stuffing Boxes

The Cromar hydraulic stuffing box is positioned on top of the lubricator stack; its purpose is to seal and contain

well pressure around a stationary or moving wireline.

The wireline is passed over the sheave wheel and down through a series of packings in the stuffing box body.

Upper and lower bushings are provided to guide the wireline through the stack. To contain well pressure, the

packing is tightened against the wireline by means of a hydraulically operated packing nut. The stuffing box

also contains an integral blow out plunger which is designed to seal the well automatically in the event of

the wireline breaking and being forced out of the packings.

Unless otherwise specified, all Cromar stuffing boxes are supplied with brass internal components. The use

of brass materials has been proven to extend the field life of all types of wireline.

Hydraulic stuffing box assemblies

are supplied with a choice of:

Connection:

Type B, O & C Acme

Quick Union

Working Pressure Rating:

Up to 15,000psi

Service:

H2S and Standard

Wireline Size:

All sizes up to and including 0.125

Sheave & Bracket Sub Assembly:

14 & 16 heavy-duty sheave and

bracket assemblies complete

with load test certificates

Trim:

Brass, bronze or steel internal parts

Various packing elements for all types of service

Blow-out plunger or ball check valve option

Product code:

Hydraulic-550 / Modular-552

Hydraulic (with ball check valve)-551

Hydraulic Stuffing Box with Ball Check Valve

Modular Stuffing Box with Chemical Injection

Next Item:

Grease Injection

Control Heads

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Stuffing Box Accessories

Stuffing Box Accessories

Sheaves & Brackets

Cromar stuffing boxes are fitted with heavy duty

aluminium alloy sheave and bracket sub-assemblies.

They are designed to endure the increased pulling

capability of the new generation of wirelines.

All sheave and bracket assemblies are load tested and

supplied to the client complete with appropriate

documentation.

Sheave and bracket assemblies are available in two

sizes:

14 diameter for wire sizes up to 0.108

16 diameter for wire sizes up to 0.125

Product code:

Packing Nuts-244

Stuffing Box Bracket Assembly-300

Stuffing Box Sheave Bracket Assembly

Hydraulic Packing Nuts

Cromar hydraulic stuffing boxes are fitted with

hydraulic packing nut sub-assemblies which replace

the existing manual packing nut and upper packing

gland.

They consist of a body, lower connection, piston,

packing gland (to suit wire size), return spring and

hydraulic manifold.

Unless requested otherwise, all Cromar hydraulic

packing nuts are normally supplied with brass internal

components. Brass materials have been proven to

significantly extend the field life of all types of

wireline.

Hydraulic Packing Nut

Next Item:

Hydraulic Line Wipers

& Swabbing Heads

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Grease Injection Control Heads

Grease Injection Control Heads

The Cromar grease injection control head is positioned

on top of the lubricator stack and designed to seal and

contain well pressure around stationary or moving

braided cable.

A grease injection control head consists of quick union

pin and collar with a ball safety check valve, flow tube

carriers, connectors and flow tubes, grease injection

and return manifolds and a hydraulic pack-off.

Flow tubes are available for all cable sizes. When ordering

flow tubes it is recommended that a clearance of .003

to .008 be added to the actual line size.

A seal is attained by pumping grease through the annular

space between the flow tube and the cable: this action

causes a pressure drop to occur across each tube prior

to the grease exiting through the return manifold. The

injection port is fitted with an integral ball check valve

as a safety precaution, in case grease seal is lost.

The operational effectiveness of the grease injection

control head depends on: well pressure, flow tube

clearance, number of tubes, temperature and type of

grease used. For operations below 5,000psi, three tubes

are usually adequate. For well pressures at and above

5,000psi, a minimum of four tubes is recommended.

Grease injection control heads are available with a

choice of:

Connection:

Type B, O & C Acme Quick Union

Adapter back to tool catcher

Working Pressure Rating:

Up to 15,000psi

Service:

H2S, Standard

Cable Size:

All sizes up to and including 15/32

Optional Extras:

Free standing sheave & bracket assemblies

Product code:

W/Union Pin & Collar-544

W/Flowhead Pin-545

W/Dual Pack-off(15K)-546

Conventional Greasehead C/W

Safety Check Valve

15K Grease Injection Head

with Dual Pack-off

Next Item:

Pump-in Tees

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Hydraulic Line Wipers & Swabbing Heads

Hydraulic Line Wipers & Swabbing Heads

Product code:

Swabbing Head-547

Linewiper-548

Hydraulic Line Wiper

The Cromar hydraulic line wiper is positioned on top

of the grease injection control head; it is designed to

remove excess grease from braided cable when

retrieving tools from the well. Hydraulic line wipers

are not pressure retaining. They are available for all

cable sizes.

The assembly consists of a main body with a cable

protector funnel on top and a quick union or line pipe

bottom connection, a hydraulic

piston, upper and lower bushings

and wiper seal. When retrieving

tools from the well, the wiper seal

is hydraulically tightened against

the cable by the piston. This action

removes excess grease from the

cable into a chamber below the seal.

A port is provided on the side to

allow the grease to drain, via a hose,

to a waste oil tank.

Cromar hydraulic line wipers are

available with a choice of:

Connection:

Type B, O & C Acme Quick Union

2 Line Pipe

Cable sizes:

All sizes up to and

including 15/32

The Cromar hydraulic swabbing

head is designed to provide a

fluid seal around a braided cable

during a swabbing operation.

Cromar swabbing heads are rated

for 5,000psi working pressure.

The assembly consists of a main

body with a top sub and a quick

uni on bottom connecti on;

hydraulic piston(s), upper and

lower bushings, and pack-off

seal(s). The pack-off seal is

tightened against the wire by the

hydraulic piston(s), in order to

contain well fluid under pressure.

Cromar hydraulic swabbing heads

are available with a choice of:

Connection:

Type B, O & C

Acme Quick Union

Cable sizes:-

All sizes up to and

including 15/32

Hydraulic Swabbing Head

Hydraulic Line Wiper

Hydraulic Swabbing Heads

Next Item:

Quick Union Test Caps

& Stumps

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Pump-in Tees

Pump-in Tees

Product code: 504

Cromar pump-in tee assemblies are normally situated

below the wireline valve. They are designed to provide

a large flow fluid entry path into the pressure control

equipment for hydrostatic testing or for pumping fluid

into the well.

Unless otherwise specified by the client, Cromar

pump-in tees are supplied with single or dual 2

FIG1502 thread-half side outlet connection(s). The

connections can be either integral to the body or

screwed on via a line pipe or Acme connection,

mounted on a standard API flange or special Cromar

four bolt flange.

Pump-in Tee with API Studded Side Outlet Flange

Cromar pump-in tee assemblies are available with a

choice of:

Connection (top & bottom):

Type B, O & C Acme Quick Union

Standard API pipe connections

Connection (side):

Standard 1 & 2 FIG **02 Thread Half

Working Pressure Rating:

Up to 15,000psi

Size:

From 2 ID upwards

Service:

H2S, Standard

Low Torque Plug Valves:

Cromar offers a range of industry standard

plug valves

Pump-in Tee with Cromar Four Bolt Side Outlet Flange

Next Item:

Quick Union Lifting Caps

& Lifting Test Caps

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Quick Union Test Caps & Stumps

Quick Union Test Caps & Stumps

Product code:

Blanking Cap & Collar-703

Test Cap-560

Test Stump-561

Quick Union Test Caps

Cromar quick union test cap sets are designed for

testing pressure control equipment and consist of:

a blanking cap and collar for testing box connections

and a test cap for testing pin connections. Blanking

and test caps come with bleed ports. The 0.5 NPT

connection is standard on 10,000psi MWP equipment,

while the 0.56(9/16) AutoClave connection is

standard on 15,000psi MWP equipment.

Blanking cap and collar sub-assemblies are also used

on wellhead adapter assemblies.

Cromar test cap sets are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 15,000psi

Service:

H2S, Standard

Quick Union Test Stumps

Cromar quick union test stumps are used to mount

and test items of pressure control equipment such as

wireline valves within transportation frames. The

stumps also retain inhibitor fluids within the item,

while it is stored on the frame. Cromar test stumps

are fitted with lock-down studs on the bottom and a

bleed port mounted on the side.

The 0.5 NPT port connection is standard on 10,000psi

MWP equipment, while the 0.56(9/16) AutoClave

port connection is standard on 15,000psi MWP

equipment.

Cromar test stumps are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 15,000psi

Service:

H2S, Standard

Blanking Cap & Collar

Test Cap

Test Stump

Next Item:

Quick Union Crossovers

& Adapters

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Quick Union Lifting Caps & Lifting Test Caps Quick Union Lifting Caps & Lifting Test Caps

Quick Union Lifting Caps

Cromar quick union lifting caps are designed for safe

lifting of heavy items of pressure control equipment

such as wireline valves, riser sections, etc. The lifting

cap comes with an integral lifting eye or screwed and

pinned eyebolt and is attached to a quick union box

connection like a regular collar.

Quick union lifting caps are designed to comply with

current regulations and are supplied with a full

documentation package.

Cromar lifting caps are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Lifting Capacity:

3t, 5t and 10t SWL

Lifting Cap

Product code:

Lift/Test Cap-562

Lifting Cap-563

Quick Union LiftTest Caps

Cromar quick union lift-test cap assemblies incorporate

the design features of a blanking cap and collar as

well as a lifting cap. They allow items of pressure

control equipment to be lifted and pressure tested

without having to change out caps. The assembly

consists of a blanking cap complete with O ring seal,

a bleed port, a lifting eye and a quick union collar.

Quick union lift-test caps are designed to comply with

current lifting and surface equipment regulations and

are supplied with full documentation.

Cromar lift-test caps are available with a choice of:

Connection:

Type B, O & C Acme Quick Union

Working Pressure Rating:

Up to 15,000psi

Lifting Capacity:

3t, 5t and 10t SWL

Lift-test Cap

Next Item:

In-situ Pressure Test Sub

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Quick Union Crossovers & Adapters

Quick Union Crossovers & Adapters

Product code: 507

Quick union crossovers and adapters are designed to

provide a transition between dissimilar connections

and so allow the operator greater flexibility in utilising

existing equipment. These components are always

rated, in terms of pressure and service, with the lower

rated connection.

Cromar quick union crossovers and adapters are

available with a choice of:

Connection:

Standard API and Non Standard pipe connections

Type B, O & C Acme Quick Union connections

Working Pressure Rating:

Up to 15,000psi

Size:

IDs and lengths to suit requirements

Service:

H2S, Standard

Quick Union Crossover

Quick Union Crossovers

Cromar quick union crossovers are designed with a

pin and collar connection down by box connection

up. With minor exceptions, Cromar crossovers are

supplied with a one-piece integral body complete

with a quick union collar.

Tubing Adapters

Cromar tubing thread adapters are designed with

premium or API pin thread down by quick union box

up. Generally, these crossovers are rated for lower

working pressures and rely on a make-up torque to

establish a seal. Cromar can provide any adapter of

this type, including premium threaded connections.

Variations can be provided within the guidelines of

current API Specifications.

Tubing Adapter

Next Item:

Slickline Hay Pulleys

& Line Wipers

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

In-situ Pressure Test Sub

In-situ Pressure Test Sub

Product code: 522

During Wireline operations it is necessary to break the

quick union between the lower lubricator and the BOP,

to remove the tools within. When this joint is

reconnected it is normal practice to fill and pressure

test the entire lubricator system prior to opening the

wellhead valve.

The Cromar In-Situ Pressure Test Sub allows for only

the joint that was broken to be tested, without filling

the whole lubricator system, saving a substantial

amount of time and large volumes of expensive test

fluid, as well as alleviating the problems associated

with dumping test fluids into the well.

As an added advantage, the Cromar In-Situ Pressure

Test Sub allows for the lubricator system to be pressure

tested whilst pressure sensitive equipment (such as

perforating guns) are in the lubricator.

Design

The Cromar In-Situ Test Sub is fitted between the

lower lubricator and the BOP, and becomes the joint

that is broken out between wireline runs. It looks and

operates like any other quick union, but has two O

ring seals instead of one. The pressure testing takes

place between these two seals and effectively confirms

the integrity of both. The upper-most of the two seals

is of slightly larger diameter than the lower, facilitating

easy make/break of the connection.

As a safety precaution, the Cromar In-Situ Pressure

Test Sub's connection is designed so that it cannot be

inadvertently connected to any other known quick

union.

Testing would normally be done to the working pressure

of the lubricator system, but each sub is designed so

that it can be tested to the full test pressure of the

system, as per API-6A. Both Lloyds and Bureau Veritas

have independently verified the design.

Application

The Cromar In-Situ Pressure Test Sub is available for

all diameters, pressure ratings and service with suitable

quick unions for wireline operations, or flanged for

coiled tubing and geothermal applications. The In-

Situ Test Sub may be used as a stand-alone unit, which

is inserted into lubricator riser assembly, or as an

integral part of the BOP where reduced height is

advantageous.

The pressure integrity test is carried out by means of

a hand operated hydraulic pump fitted with a certified

pressure-monitoring gauge. If required the hand pump

can be supplied with a programmable electronic

pressure/time recording gauge assembly for test result

verification. Data is acquired via an RS232

communications port.

Filling of the test chamber, with a volume of

approximately 5 cubic inches, and achieving the

required test pressure normally takes less than a

minute. It is recommended that test pressure be held

for 10 minutes to ensure that no losses have occurred.

Bleed down of the test fluid/pressure is compulsory

and can be carried out at the bleed down valve on

the electronic pressure recorder or hydraulic

hand pump.

Certification

All Cromar supplied items of wireline pressure control

equipment are fully certified in accordance with SI-

913, manufactured and tested in accordance

with API-6A.

Test Chamber

Test Sub

Next Item:

Floor Stands

& Rig-up Dollies

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Slickline Hay Pulleys & Line Wipers

Slickline Hay Pulleys & Line Wipers

Product code:

Pulley-301

Wiper-302

Slickline Hay Pulleys

Cromar lightweight Hay pulleys are manufactured

from heavy duty aluminium alloy material. They are

designed to endure the increased pulling capacity of

the new generation of wirelines. Hay pulleys consist

of a swivel eye, a body frame with wire loading gate

and line wiper mounting point and a sheave wheel

with durable bearings and hollow axle to accept a

floor stand.

All Cromar Hay pulley assemblies are fully load tested

and supplied to the client complete with the

appropriate documentation.

Cromar Hay pulley assemblies are available in two

sheave sizes:

14 diameter, for wire sizes up to 0.108

16 diameter, for wire sizes up to 0.125

SlickLine Wipers

Cromar slickline wipers are designed to remove

corrosive well completion fluids from the wire when

retrieving tools from the well. This function increases

the field life of the wire by preventing the corrosive

substances from attacking it after the job, when it is

stored on the drum.

Cromar slickline wipers are suitable for all wire sizes.

Before retrieving tools from the well, the wiper is

quickly locked into the Hay pulley and the rubber

wiper installed around the wire. A manual nut is

provided to compress the rubber seal around the wire.

The Cromar slickline wiper has the added advantage,

when used in the vertical position, of preventing the

pulley from tilting sideways when tension is

momentarily lost, preventing potential wire damage.

Slickline Hay Pulley

Slickline Wiper

Next Item:

Wireline Clamps

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Floor Stands & Rig-up Dollies

Floor Stands & Rig-up Dollies

Product code: 298

Floor Stands

Cromar lightweight floor stands are designed to support

Hay pulleys or floor blocks in the vertical position

when tension is momentarily lost. In that case, the

floor stand will prevent the sheave from falling over

and snagging the wire.

The stand consists of a lightweight steel frame with

a support axle complete with retaining locks.

Rig-up Dollies

Cromar quick union rig-up dollies are designed to

assist wireline crews safely manhandle surface pressure

control equipment both ways, i.e. horizontal to vertical

and vice-versa, when rigging-up or down from a well.

Similar in design to a blanking cap, the quick union

dolly has a steel axle and two heavy-duty wheels.

The dolly is installed into the lower lubricator quick

union connection. As the hoist is raised or lowered,

the surface equipment weight is distributed through

the wheels and the optimum lifting angle is safely

maintained.

Dolly assemblies are available with a choice of:

Connections:

Type B, O & C Acme Quick Union

Wheels:

Solid wheels or pneumatic tyres

Rig-up Dolly

Floor Stand

Next Item:

Single Hand Pump

Assemblies

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Wireline Clamps

Wireline Clamps

Wireline Clamps

Wireline Chicago clamps are designed to clamp

around wire/cable in order to hold toolstrings stationary

within lubricators while rigging-up or down from a

well. Clamps are used in conjunction with a small

chain or steel wire rope sling which is located around

the up-set on the bottom lubricator double box collar.

The jaws are lined in bronze to prevent damage to

the wire/cable when engaged.

Wireline clamp assemblies are load-tested and supplied

to the client complete with the appropriate

documentation.

Clamp assemblies are available with a choice of:

Slick line and braided line models

With chain or steel wire rope clamp retainers

Product code:

Wireline Clamp-299

Rig-up Dolly-563

Wireline Clamps

Next Item:

Dual Hand Pump

Assemblies

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r

e

C

o

n

t

r

o

l

E

q

u

i

p

m

e

n

t

W

i

r

e

l

i

n

e

O

p

e

r

a

t

i

o

n

s

Wireline Operations

Single Hand Pump Assemblies

Single Hand Pump Assemblies

Product code: 207

Single Acting Hand Pump

Cromar single acting hand pump assemblies are fitted with a two way valve and pressure gauge. They are normally

supplied with a single function/test hose complete with quick connectors.

Single hand pumps are used for pressure testing or for functioning hydraulic items of pressure control equipment,

such as line wipers, swab heads, pack offs, stuffing boxes and tool catchers. They are used for pressure testing

purposes in conjunction with in-situ pressure test subs.

Single acting hand pump assemblies are available

with a choice of:

Maximum Operating Pressure:

3,000psI

5,000psi

10,000psi

Hose Type:

Chemical, test or hydraulic service

Hose Nominal Bore Size:

1/4 NB and 3/8 NB

Hose Length:

25ft, 50ft, 75ft, 100ft

Quick Release Coupling:

1/4 and 3/8 proprietary connection

Please refer to

the wireline mechanical plant section,

for a range of Cromar air / hydro pump units.

Single Acting Hand Pump

Next Item:

Ball Valve

Section Menu Last Item www.cromar.com

W

i

r

e

l

i

n

e

P

r

e

s

s

u

r