Professional Documents

Culture Documents

Compact Piston Air Motors ATEX II-2-GDc-T5 Ex

Uploaded by

taufiqsy0%(1)0% found this document useful (1 vote)

86 views7 pagesThis document provides information on various air motors offered by Globe Airmotors including compact piston air motors, vane air motors, and geared vane air motors. It describes the advantages of compact piston air motors such as high torque at low speeds, reversibility, variable speed control, and explosion proof certification. Applications mentioned include mixing equipment, turntables, winding equipment, and more. Technical details are also provided on speed and torque control methods, gearbox options, and installation best practices.

Original Description:

Compact Air Piston

Original Title

Globe

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information on various air motors offered by Globe Airmotors including compact piston air motors, vane air motors, and geared vane air motors. It describes the advantages of compact piston air motors such as high torque at low speeds, reversibility, variable speed control, and explosion proof certification. Applications mentioned include mixing equipment, turntables, winding equipment, and more. Technical details are also provided on speed and torque control methods, gearbox options, and installation best practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

86 views7 pagesCompact Piston Air Motors ATEX II-2-GDc-T5 Ex

Uploaded by

taufiqsyThis document provides information on various air motors offered by Globe Airmotors including compact piston air motors, vane air motors, and geared vane air motors. It describes the advantages of compact piston air motors such as high torque at low speeds, reversibility, variable speed control, and explosion proof certification. Applications mentioned include mixing equipment, turntables, winding equipment, and more. Technical details are also provided on speed and torque control methods, gearbox options, and installation best practices.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

Globe Airmotors Program

Planetary Geared Vane Air Motor

Reversible and a compact solution. Available with gear

ratios from 3:1 to 1000:1. Power from 0,44 to 5,4 kW.

Vane Air Motor

Reversible, available in flange, foot, or face execution.

Power from 0,44 to 9,5 kW.

Compact Piston Air Motor

High torque at low speed of rotation, very low air

consumption and low noise level.

Power from 110 to 460 W.

Eikenlaan 261E

NL 2404 BP Alphen aan den Rijn

Tel: (+31)-(0)172-426608

Fax: (+31)-(0)172-426607

E-mail: info@globe-benelux.nl

Web: http://www.globe-benelux.nl

Radial Piston Air Motor

Available with proportional hand or remotely controlled

valve, pneumatic brake and all types of gearboxes.

Power from 0,8 to 23 kW.

Vane Air Motor with Gearbox

Available with planetary, coaxial, or worm gearboxes. Also

possible with pneumatic brake.

Compact Air Motor

Reversible, compact, available with a wide range of

incorporated reduction units. Power from 180 to 1000 W.

AIRMOTORS B.V.

DISTRIBUTOR

Your Global Force in Air Power

COMPACT PISTON AIR MOTORS

Air motors offer a unique form of drive and incorporate advantages

not found in other prime movers.

Simple and inexpensive variable speed and torque control with

a flow control valve and/or pressure regulator.

Intrinsically safe for explosion proof environments. The compact

piston air motors are certified according to the European

explosion directive ATEX II cat. 2 G&D T5.

Air motors can be stalled indefinitely under load. They will not

overheat or burn out.

Long lifetime because of low friction and a minimum of parts

that are exposed to wear.

Controllable over a wide speed range.

Instantly reversible, operated with a simple control valve.

Resistant to warm, dirty and damp conditions.

No shock start up which improves the life span of the equipment.

12 pistons for very low speeds and smooth running.

Improved design pistons for longer life time.

Oil free running.

Silicone free so very useful in mixing applications.

Available with front flange, which incorporates an extra bearing.

Small dimensions.

Special version for food and chemical industry.

ATEX approved.

CONTENTS PAGE

ADVANTAGES/WHY CHOOSE A COMPACT

PISTON AIR MOTOR? 3

APPLICATIONS/CONTROLLING AIR MOTORS 4/5

GEARED PISTON AIR MOTORS 5

RM004 CW, CCW 6

MODEL ORDERING CODE S 7

RM012 - SXX, PXX, SXA ATEX 8

RM024 - SFX, IFX, SFA ATEX 10

LOAD DIAGRAMS 11

Photos on the front cover on courtesy of:

BPL, Haelen (NL) Manipulator

Duits Engineering, Zutphen (NL) Turning device

Gritco Equipment BV, Ridderkerk (NL) Sand blasting equipment

Aerofilm Systems BV, Eindhoven (NL) Lifting table

EMCE, Voorhout (NL) Winch

Hydrauvision, Schoondijke (NL) Powerpack

2 3

Compact Piston

Air Motors

ATEX

II-2-GDc-T5 Ex

GLOBE AIR POWER

ADVANTAGES WHY CHOOSE A COMPACT PISTON AIR MOTOR?

The compact radial piston air motor operates without rod or crank

shaft. The radial arranged pistons travel along a curve and are

controlled by the centre.

The static control shaft supplies the driving pistons with the

necessary air. Air supply and release openings along the static shaft

are periodically opened and closed by the rotation of the rotor to

pressurise or release the pistons in an appropriate sequence.

Six of the twelve driving pistons are actively contributing to the

torque at any moment. Once reaching the highest point on the curve,

the air driving the piston is released by the control unit and the piston

is forced into its lowermost position. This operating principle is

equivalent with the one of a simple cylinder.

The compact piston air motors high torque is due to the power

transmission of the pistons along the large external diameter of the

curve. The friction connected with the travel along the curve is low

due to the installation of rollers at the tip of the pistons. This results

in high lifetime of the drive.

Noise emissions were determined according to the noise measuring

standards ISO 11202 and within the frame of the ISO 11200 stan-

dards. The measured noise levels were below 78 dB for the RM012

and RM024. The pneumatic drive thus fulfils the noise regulations

without requirement for ear protection devices.

We recommend to operate the drive within a speed range of 50 350

R.P.M. shaft dimensions can be adapted according to the specific

requirements of the client. Dimensions in millimetres.

WORKING PRINCIPLE

Within the air motor family the compact piston air motor takes a

special place, because this motor is often used in applications where

other air motors can not be used.

High torque at low speed of rotation. Therefore most of the times

a gearbox is not necessary.

Highest torque at start-up. The compact piston air motor does not

have a variable starting torque. This always guarantees the rated

starting torque.

Possibility to connect up to three units in series if higher torque

or power is required.

Very low air consumption due the use of pistons, low internal

friction and low internal air leakage.

Low noise emission that fulfils the noise regulations without

requiring ear protection.

The compact piston air motors can be supplied directly coupled to

a wide range of gearboxes such as planetary, helical bevel helical

and worm gears.

Due to the low speed of rotation the compact piston air motor

is especially suitable for applications in which the air motor is

constantly in stall.

Compact construction made out of aluminium with steel shaft.

Also available in a plastic housing with a stainless steel shaft.

Integrated brake function. When both the inlet and outlet port are

pressurised, the motor functions as a brake with a torque that is

50% of the starting torque.

Able to run without lubrication. The compact piston air motors

can operate with a minimum of lubrication. Complete oil-less

operation is possible in certain applications. Consult GLOBE

Airmotors BV or your local distributor for more information.

Both RM012 and RM024 have twelve pistons

Speed regulation

Controlling the performance of an air motor is done by regulating

the air supply. This is relatively cheap and simple. The methods to

regulate the air supply are throttling and pressure regulation.

The air flow is controlled by placing a flow control valve at the inlet

port or the outlet port of the air motor. Throttling will reduce the

maximum speed of the motor but will not affect the starting

performance; the air pressure is unaffected at low flow conditions

i.e. starting. Note the difference in the graph between throttling on

the inlet port and outlet port.

Throttling

Air quality

Pressure regulating

CONTROLLING AIR MOTORS

The speed and power can also be reduced by installing a pressure

regulator on the incoming air supply. The pressure regulator reduces

the air pressure to the motor. A pressure regulator is always fitted

on the inlet port. By using a pressure regulator the torque on the

output shaft will be affected, starting torque is best controlled with

this method.

When both the speed and the torque are to be controlled the best

configuration is to use a pressure regulator in the air line to the

motor and a flow control valve on the outlet port. This way every

point in the torque-speed graph can be set accurately.

Inlet throttling,

uni-directional motor.

Pressure regulation, uni-directional motor.

Outlet throttling,

uni-directional motor.

Inlet throttling,

bi-directional motor.

4 5

Compact piston air motors are used in numerous of applications.

Most suitable are light and medium duties at low speed operations.

A combination of a GLOBE compact piston air motor with a large

variety of gearboxes is possible when lower speed operations and/or

higher torques are demanded for the application.

The most typical applications for compact piston air motors are:

Mixing equipment Turntables

Winding equipment Packing machines

Conveyor belts Cap screwing machines

Hose Reels

APPLICATIONS

TORQUE

SPEED

THROTTLING

6 bar

6 bar No throttle

Inlet throttle Exhaust throttle

6 bar

TORQUE

SPEED

PRESSURE REGULATING

7 bar

6 bar

5 bar

4 bar

3 bar

2 bar

Directions of rotation

The GLOBE piston air motors can be used both as a uni-directional

and as a bi-directional air motor. When the air motor is used in a

non-reversible application, it is sufficient to use a 2/2 or a 3/2 valve.

For the reversible motor you can use either a 5/3 or two 3/2 valve to

gain directional control.

To insure optimal working conditions for the GLOBE piston air motors,

the air supply must be dry, filtered and lubricated. A 5 micron filter or

better is recommended. The GLOBE piston air motors should be lubri-

cated sufficiently. Oilless operations are possible in certain applications.

Air line restrictions

Air line restrictions on the inlet side of the motor will result in

performance loss. Therefore it is important to make sure that the

desired air pressure is available at the motor during operation.

The pressure reading at the compressor or pressure regulator may be

different then the pressure available at the motor. Performance loss

can also occur by an exhaust restriction generating back pressure on

the outlet side of the motor. An insufficiently sized silencer, valve

or coupling is usually the cause.

Although air motors can be adjusted over a wide range of speed

and torque, the output characteristics are not always suitable for

the application. To achieve the required output speed and torque

a gearbox can be coupled directly to the air motor.

GLOBE Airmotors BV has a wide range of gear units such as planetary,

helical, beval helical and worm gears in their program. Consult Globe

Airmotors BV or your local distributor for more detailed information.

GEARED VANE AIR MOTORS

AIR SUPPLY

seperator regulator

control unit

control unit

exhaust

silencer

exhaust

silencer

exhaust

silencer

exhaust

silencer

inlet air

choke

inlet air

choke

inlet air

choke

rotational force left rotational force

(seperate direction control are

required to provide a work break

between change in direction)

Compact piston

air motor RM012

Compact piston

air motor RM012

on/off

oiler

(optional)

oiler

(optional)

seperator regulator

right

max. 5 2 8 bar

viscosity: 32

volume: 1 drop / min

mm2

s

max. 5 2 8 bar

viscosity: 32

volume: 1 drop / min

mm2

s

UNI - DIRECTIONAL

THROTTLING METHODS

PRESSURE REGULATING METHOD

BI - DIRECTIONAL

6

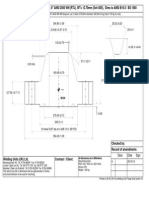

DIMENSIONS RM004 CW, CCW

Type

Rational

Speed

Torque IP Weight

CW = Clockwise

CCW = Counter-Clockwise

When looked upon shaft

inch

lbs.

35.4

31.0

26.6

22.1

17.7

13.3

8.9

4.4

100 300 500

4,0

3,5

3,0

2,5

2,0

1,5

1,0

0,5

160

140

120

100

80

60

40

20

0.21

0.19

0.16

0.13

0.11

0.08

0.05

0.03

NM W hp

RPM

120 psi - 8 B

AR

90 psi - 6 B

AR

120 psi - 8 BAR

90 psi - 6 BAR

60 psi - 4 BAR

60 psi - 4 B

AR

O

p

e

ra

tio

n

o

n

ly

a

fte

r c

o

n

s

u

ltin

g

s

u

p

p

lie

r

25

20

15

10

5

883

706

530

353

177

900 600 300

RPM

m3/hr cu.ft/hr

O

p

e

r

a

tio

n

o

n

ly

a

fte

r

c

o

n

s

u

ltin

g

s

u

p

p

lie

r

1

2

0

p

s

i - 8

B

A

R

9

0

p

si - 6

B

A

R

60 psi - 4 BAR

PERFORMANCE RM004

Front side (F)

Back side (B)

7

RM004 CW

(Clockwise)

60 - 600rpm 0.5 - 3 Nm 2.1 kg

2.1 kg 64

64

0.5 - 3 Nm 60 - 600rpm

DIMENSIONS RM004 - R Reversible

Type

RM004 - R

Reversible

Rational

Speed

Torque

60 - 500rpm 0.5 - 4 Nm

IP Weight

2.1 kg 64

Airsupply

G1/8

anti-clockwise

rotation

Inside pressure

compensation

Do not block

Airsupply

G1/8

clockwise

rotation

2 x air

connections

G1/8

9.5 Deep

Back side (B)

Front side (F)

Air Consumption Performance

RM004 CCW

(Counter clockwise)

12 Nm RM012 135 x 6

175 x 80 24 Nm RM024

type of motor ATEX Certificate

no ATEX

ATEX II cat.2 G&D T5

X

A

material of housing

S nickel-plated steel

I Inox (RM024 only)

P plastic (RM012 only, non atex)

IP 50

IP 64

IP 64

flange option

X no flange max. 150 N

F flange max. 2000 N

RM012

S X X

RM024

RM012 AND RM024 ORDERING CODES

RM012/RM024-SXX steel housing

RM012/RM024-SFX steel housing and flange

RM012/RM024-SXA steel housing ATEX

RM012/RM024-SFA steel housing, flange, ATEX

RM012-PXX Plastic housing, water resistant,stainless shaft and covers

RM012-PFX Plastic housing, flange with extra bearing, water resistant,

stainless shaft and covers

RM024-IXX Inox housing, water resistant, stainless shaft and covers

RM024-IFX Inox housing, flange, water resistant, stainless shaft and covers

POSSIBLE TYPES

RM012-PFX

RM024-IFX

8 9

DIMENSIONS RM012 - SFX, PFX, SFA ATEX

Type

RM012 - SFX 50 - 350 rpm 0.5 - 1.4 Nm 4.6 kg

5.8 kg

5.8 kg

50

64

64

1 - 14 Nm

1 - 14 Nm

50 - 350 rpm

50 - 350 rpm

RM012 - PFX

RM012 - SFA

ATEX

Rational

Speed

Torque IP Weight

Inside pressure

compensation

Do not block

Compressed-air

supply 6

Push-in coupling

Front side (F)

Back side (B)

Type

RM012 - SXX 50 - 350 rpm 0.5 - 1.4 Nm 3.8 kg

4.2 kg

4.2 kg

50

50

64

1 - 14 Nm

1 - 14 Nm

50 - 350 rpm

50 - 350 rpm

RM012 - PXX

RM012 - SXA

ATEX

Rational

Speed

Torque IP Weight

DIMENSIONS RM012 - SXX, PXX, SXA ATEX

Back side (B)

Front side (F)

PERFORMANCE RM012

NM

11.8

11.1

10.3

9.6

0.20

0.18

0.16

0.14

0.12

0.04

0.02

0.06

0.08

0.10

0.27

0.24

0.21

0.19

0.16

0.05

0.03

0.08

0.11

0.13

8.8

8.1

7.4

6.6

5.9

5.2

4.4

3.7

3.0

2.2

1.5

0.7

13

14

15

16

12

11

10

9

8

7

6

5

4

3

2

1

lbs ft. hp kW

O

p

e

ra

tio

n

o

n

ly

a

fte

r c

o

n

s

u

ltin

g

s

u

p

p

lie

r

1

2

0

p

s

i =

8

.3

B

A

R

(N

M

/lb

/ft)

RPM

100 200 300 400 500

40 psi = 2.1 BAR (NM/lb/ft)

90 p

si =

6.2 B

A

R

(N

M

/lb

/ft)

60 psi =

4.1 BAR (NM

/lb/ft)

120 psi = 8.3 BAR (kW/hp)

30 psi = 2.1 BAR (kW/hp)

90 psi = 6.2 BAR (kW/hp)

60 psi = 4.1 BAR (kW/hp)

Performance

LOAD DIAGRAM FOR RM012 SFA, SFX, PFX LOAD DIAGRAM FOR RM012 SXX, SXA, PXX

Working point (mm)

Working point (mm)

Maximal axial load Fa = 0.1kN

Maximal axial load Fa = 0.1kN

Rotation speed (1/min) Rotation speed (1/min) Radial load Fr (kN) Radial load Fr (kN)

cu.ft/min l/s

7.6

6.6

5.7

4.7

3.8

2.8

1.9

0.9

16

14

10

12

8

6

4

2

RPM

O

p

e

ra

tio

n

o

n

ly

a

fte

r c

o

n

s

u

ltin

g

s

u

p

p

lie

r

1

2

0

p

si =

8

.3

B

A

R

100 150 200 250 300 350 400 450

90 p

si =

6.2 B

A

R

60 psi =

4.1 BAR

30 psi = 2.1 BAR

Air Consumption

G

1

4 for

compressed-

air

Use min.

10mm air

supply

Inside pressure

compensation

Do not block

Type

RM024 - SXX 50 - 350 rpm 1 - 28 Nm 7.6 kg

10.9 kg

10.9 kg

50

64

64

1 - 28 Nm

1 - 28 Nm

50 - 350 rpm

50 - 350 rpm

RM024 - IXX

RM024 - SXA

ATEX

Rational

Speed

Torque IP Weight

DIMENSIONS RM024 - SXX, IXX, SXA ATEX

Front side (F)

Back side (B)

10

At 8

bar

Speed

(RPM)

10-350

10-350

A

mm

72

102

Max

Power

(W)

160

320

Starting

Torque

(Nm)

15

30

Weight

(kg)

4,0

5,5

DIMENSIONS RM024 - SFX, IFX, SFA ATEX

Type

RM024 - SFX 50 - 350 rpm

50 - 350 rpm

50 - 350 rpm

8.2kg

12kg

12kg

50

64

64

1 - 28 Nm

1 - 28 Nm

1 - 28 Nm

RM024 - IFX

RM024 - SFA

ATEX

Rational

Speed

Torque Weight

G

1

4 for

compressed-

air

Use min.

10mm air

supply

Inside pressure

compensation

Do not block

Front side (F)

Back side (B)

11

PERFORMANCE RM024

cu.ft/min l/s

16.5

14.2

11.8

9.4

7.1

4.7

2.4

35

30

20

25

15

10

5

RPM

O

p

e

ra

tio

n

o

n

ly

a

fte

r c

o

n

s

u

ltin

g

s

u

p

p

lie

r

1

2

0

p

si =

8

.4

B

A

R

100 150 200 250 300 350 400 450

9

0

p

si =

6

.2

B

A

R

60 psi =

4.1 B

AR

30 psi =

2.1 BAR

Air Consumption

PERFORMANCE RM024

1

2

0

p

s

i =

8

.3

B

A

R

(N

M

/lb

/ft)

NM

22.1

20.7

19.2

17.7

16.2

14.8

13.3

11.8

10.3

8.9

7.4

5.9

4.4

3.0

1.5

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0.47

0.40

0.34

0.27

0.20

0.13

0.07

lbs ft. hp kW

RPM

100 200 300 400 500

O

p

e

ra

tio

n

o

n

ly

a

fte

r c

o

n

s

u

ltin

g

s

u

p

p

lie

r 9

0

p

si =

6

.2

B

A

R

(N

M

/lb

/ft)

60 psi =

4.1 B

A

R

(N

M

/lb/ft)

30 psi = 2.1 BAR (NM/lb/ft)

120 psi = 8.3 (kW/hp)

90 psi = 6.2 (kW/hp)

60 psi = 4.1 (kW/hp)

30 psi = 2.1 (kW/hp)

Performance

LOAD DIAGRAM FOR RM024 SFA, SFA, IFX LOAD DIAGRAM FOR RM024 SXX, IXX, SXA

Working point (mm) Working point (mm)

Working axial load Fa

= 0.4kN

Maximal axial load Fa = 0.13kN

Rotation speed (1/min) Radial load Fr (kN) Rotation speed (1/min) Radial load Fr (kN)

IP

Globe Airmotors Program

Planetary Geared Vane Air Motor

Reversible and a compact solution. Available with gear

ratios from 3:1 to 1000:1. Power from 0,44 to 5,4 kW.

Vane Air Motor

Reversible, available in flange, foot, or face execution.

Power from 0,44 to 9,5 kW.

Compact Piston Air Motor

High torque at low speed of rotation, very low air

consumption and low noise level.

Power from 110 to 460 W.

Eikenlaan 261E

NL 2404 BP Alphen aan den Rijn

Tel: (+31)-(0)172-426608

Fax: (+31)-(0)172-426607

E-mail: info@globe-benelux.nl

Web: http://www.globe-benelux.nl

Radial Piston Air Motor

Available with proportional hand or remotely controlled

valve, pneumatic brake and all types of gearboxes.

Power from 0,8 to 23 kW.

Vane Air Motor with Gearbox

Available with planetary, coaxial, or worm gearboxes. Also

possible with pneumatic brake.

Compact Air Motor

Reversible, compact, available with a wide range of

incorporated reduction units. Power from 180 to 1000 W.

AIRMOTORS B.V.

DISTRIBUTOR

Your Global Force in Air Power

COMPACT PISTON AIR MOTORS

You might also like

- Onan RV GenSet Service ManualDocument136 pagesOnan RV GenSet Service ManualAlbert A Ghazaleh100% (2)

- GD755 5R - Cen00449 02 PDFDocument16 pagesGD755 5R - Cen00449 02 PDFlesantiago100% (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- PW130 7Document24 pagesPW130 7Csongor Molnár100% (1)

- PC1250-8 PC1250SP-8Document20 pagesPC1250-8 PC1250SP-8Banu Agus Hartoyo100% (1)

- EWM Certification Syllabus (9.5) Topic Areas Topic Details, Courses, Books WeightingDocument2 pagesEWM Certification Syllabus (9.5) Topic Areas Topic Details, Courses, Books Weightingguru_3112No ratings yet

- Csa Rotordryer PDFDocument8 pagesCsa Rotordryer PDFpeterpunk75No ratings yet

- Twin Lobe Compressor Instruction ManualDocument14 pagesTwin Lobe Compressor Instruction Manualpbs9890271109100% (1)

- Komatsu WA470-5 Wheel Loader Productivity & ReliabilityDocument7 pagesKomatsu WA470-5 Wheel Loader Productivity & ReliabilityPhilip Chandra100% (2)

- Wa480-5 PDFDocument12 pagesWa480-5 PDFMhd Hanafi LubisNo ratings yet

- ABAC Formula 5 5 22kWDocument6 pagesABAC Formula 5 5 22kWsebastianNo ratings yet

- Wa320 7Document16 pagesWa320 7Carlos Felipe Orjuela Ramírez100% (1)

- Mhi Integrally Geared CompressorsDocument6 pagesMhi Integrally Geared CompressorscandhareNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Boge Oil-Free Screw Compressors - SO SeriesDocument16 pagesBoge Oil-Free Screw Compressors - SO SeriesAir Repair, LLCNo ratings yet

- Boge Screw UsaDocument40 pagesBoge Screw UsaAir Repair, LLC100% (1)

- Doosan 340Document16 pagesDoosan 340Victor VillarrealNo ratings yet

- Principle of Economics Consolidated Assignements-2 - 10th February 22Document27 pagesPrinciple of Economics Consolidated Assignements-2 - 10th February 22Mani Bhushan SinghNo ratings yet

- w50df DsDocument4 pagesw50df DssestoubosNo ratings yet

- Boge Air Compressors - Screw Compressors BrochureDocument52 pagesBoge Air Compressors - Screw Compressors BrochureAir Repair, LLC100% (5)

- ROTARY SCREW COMPRESSORS ENCAPSULATED HP 7,5 - 10 - 15 20 - 25 - 30Document6 pagesROTARY SCREW COMPRESSORS ENCAPSULATED HP 7,5 - 10 - 15 20 - 25 - 30Daniel Arbeláez0% (1)

- Boge Screw CompressorDocument16 pagesBoge Screw CompressorarjmandquestNo ratings yet

- MAN 946 E - 72dpi Precommissing Compressor ScrewDocument16 pagesMAN 946 E - 72dpi Precommissing Compressor ScrewBalu Venkatesa PerumalNo ratings yet

- Komatsu Gd555-5 eDocument8 pagesKomatsu Gd555-5 eRobert Lowe100% (2)

- Volvo Crawler Excavators: More Care. Built inDocument12 pagesVolvo Crawler Excavators: More Care. Built inAnonymous 0PuvmpoNo ratings yet

- Steam TurbineDocument10 pagesSteam TurbineAmeya Ranade100% (1)

- Heavy Oil's Production ProblemsDocument22 pagesHeavy Oil's Production Problemsalfredo moran100% (1)

- Komatsu WA320 5Document7 pagesKomatsu WA320 5cristi_ama100% (2)

- Ingersoll Rand Large Rotary Screw Single & Two-Stage Compressors 100-500HPDocument14 pagesIngersoll Rand Large Rotary Screw Single & Two-Stage Compressors 100-500HPMarco Antonio LópezNo ratings yet

- Pet Brochure EnglishDocument12 pagesPet Brochure EnglishCelso FernandesNo ratings yet

- Sany Excavators SY75CDocument8 pagesSany Excavators SY75Ccsbersama100% (3)

- 3,000-7,000 IC Pneumatic Forklift Trucks PDFDocument26 pages3,000-7,000 IC Pneumatic Forklift Trucks PDFForklift Systems IncorporatedNo ratings yet

- Compresor Dossan 100 Psi c185t2Document4 pagesCompresor Dossan 100 Psi c185t2Edson RicardoNo ratings yet

- Beverage Brochure EnglishDocument16 pagesBeverage Brochure Englishsalicurri0% (1)

- Aerzen Usa TB Series Turbo BrochureDocument4 pagesAerzen Usa TB Series Turbo BrochureFelix LopezNo ratings yet

- ENERGY SAVING STAR, LEADING THE INDUSTRYDocument9 pagesENERGY SAVING STAR, LEADING THE INDUSTRYpiteng1945100% (2)

- Turblex - Bulletin 2000Document16 pagesTurblex - Bulletin 2000Don Ing Marcos León0% (1)

- Sany Excavators SY75C Tier 3Document8 pagesSany Excavators SY75C Tier 3csbersama0% (1)

- Tier 4 Interim Engine: Operating Weight Net Horsepower Bucket CapacityDocument16 pagesTier 4 Interim Engine: Operating Weight Net Horsepower Bucket CapacityCarlos Alfredo LauraNo ratings yet

- Inlets and NozzlesDocument63 pagesInlets and NozzlesMokshanandNo ratings yet

- Brochure 302 en ScrewDocument48 pagesBrochure 302 en ScrewMayur ChauhanNo ratings yet

- ABAC Formula 5.5 22kWDocument6 pagesABAC Formula 5.5 22kW1976gt500No ratings yet

- PC200-220 Brochure Feb15 V1Document9 pagesPC200-220 Brochure Feb15 V1Lusitania HsrNo ratings yet

- Cargador Frontal WA430-6 Komatsu, FolletoDocument6 pagesCargador Frontal WA430-6 Komatsu, FolletoRoman Roa MachucaNo ratings yet

- Wa250 5Document7 pagesWa250 5Ronny Lukmana Putera100% (1)

- Wa200 5Document7 pagesWa200 5Richi Munez100% (2)

- PVI Aerzen Screw Compressors (Old) (En)Document32 pagesPVI Aerzen Screw Compressors (Old) (En)pitichai_pNo ratings yet

- Turbo-Air 3000Document6 pagesTurbo-Air 3000SISOYDANNYNo ratings yet

- PC88MR-8 EnglishDocument12 pagesPC88MR-8 EnglishSiegfried Lara0% (1)

- Highly efficient two-stage rotary screw compressor specificationDocument9 pagesHighly efficient two-stage rotary screw compressor specificationbiberiusNo ratings yet

- Plant Air BrochureDocument20 pagesPlant Air Brochure陳0鴻No ratings yet

- PC220 PC220LC: Gross: 129 KW 173 HP / 2000 Min Net: 123 KW 164 HP / 2000 MinDocument8 pagesPC220 PC220LC: Gross: 129 KW 173 HP / 2000 Min Net: 123 KW 164 HP / 2000 MinAnonymous oxXFTMwCodNo ratings yet

- PC200LC 8M0 - Cen00489 01Document8 pagesPC200LC 8M0 - Cen00489 01cosminNo ratings yet

- P1V-S Air MotorsDocument28 pagesP1V-S Air MotorsLakshabir DebnathNo ratings yet

- 2935 0594 10 ZH350+ 12p Litho EN LR 20110919 - tcm795-1706670Document12 pages2935 0594 10 ZH350+ 12p Litho EN LR 20110919 - tcm795-1706670Jozsef MagyariNo ratings yet

- Dx480lca Hd520lca HD enDocument12 pagesDx480lca Hd520lca HD enrahmanNo ratings yet

- Engineering Letter: IntegralmotorsforcentrifugalfansDocument4 pagesEngineering Letter: IntegralmotorsforcentrifugalfansjameeloNo ratings yet

- C210 WML 204Document10 pagesC210 WML 204Efrén SantínNo ratings yet

- Pro 71 pc300Document14 pagesPro 71 pc300PROYECTOMSNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Do Not Scale If in Doubt - Ask: DESCRIPTION: 8" ANSI 2500 WN (RTJ), WT 12.70mm (SCH 80S), Dims To ANSI B16.5 / BS 1560Document1 pageDo Not Scale If in Doubt - Ask: DESCRIPTION: 8" ANSI 2500 WN (RTJ), WT 12.70mm (SCH 80S), Dims To ANSI B16.5 / BS 1560taufiqsyNo ratings yet

- Electrohydrolic Technology For Two ActuatorsDocument21 pagesElectrohydrolic Technology For Two ActuatorstaufiqsyNo ratings yet

- A6 Wear Parts CatalogueDocument3 pagesA6 Wear Parts Cataloguetaufiqsy100% (1)

- Piping ScheduleDocument3 pagesPiping Scheduletaufiqsy100% (1)

- MONO POWER AMPLIFIER SERVICE MANUALDocument34 pagesMONO POWER AMPLIFIER SERVICE MANUALAlexey OnishenkoNo ratings yet

- PN15CS1S01Document4 pagesPN15CS1S01joadNo ratings yet

- Physical ExaminationDocument7 pagesPhysical ExaminationCha CulveraNo ratings yet

- Standardized Recipes - Doc2Document130 pagesStandardized Recipes - Doc2epic failNo ratings yet

- Nichita Stanescu - The Poet of Loneliness and LossDocument28 pagesNichita Stanescu - The Poet of Loneliness and LossEmanuelaCiocanNo ratings yet

- Format Bahasa Inggeris UPSR 2016 ENGLISH (013) Section ADocument33 pagesFormat Bahasa Inggeris UPSR 2016 ENGLISH (013) Section AVINOTININo ratings yet

- Chapter 6Document2 pagesChapter 6Zhane CruzNo ratings yet

- Specification for Child MUAC Tape Quality ChecksDocument4 pagesSpecification for Child MUAC Tape Quality ChecksM HussainNo ratings yet

- FT-IR Analysis of Hock ProcessDocument4 pagesFT-IR Analysis of Hock ProcessmohsengolestanzadehNo ratings yet

- Lifting Plan ProcedureDocument4 pagesLifting Plan ProcedureNath YauNo ratings yet

- Transformer Protection Techniques for Fault DetectionDocument32 pagesTransformer Protection Techniques for Fault DetectionshashankaumNo ratings yet

- ActinobacillosisDocument16 pagesActinobacillosisMd Shamim AhasanNo ratings yet

- Case Study in Competency Appraisal II - ABC and EDNDocument5 pagesCase Study in Competency Appraisal II - ABC and EDNRogelio Saupan Jr100% (1)

- Sibling RivalryDocument2 pagesSibling Rivalrycarlokim14No ratings yet

- Pradhan Mantri Gram Sadak Yojana Pradhan Mantri Gram Sadak YojanaDocument19 pagesPradhan Mantri Gram Sadak Yojana Pradhan Mantri Gram Sadak Yojanapriyajaiswal428No ratings yet

- 2) VT Report Test FormatDocument3 pages2) VT Report Test FormatMoin KhanNo ratings yet

- Etymology: StructureDocument2 pagesEtymology: StructureNaga VNo ratings yet

- 8.1 - Production and Diagnostic Use of UltrasoundDocument3 pages8.1 - Production and Diagnostic Use of UltrasoundTakudzwa Antony MasendekeNo ratings yet

- Eells Chap 5 6Document24 pagesEells Chap 5 6Joaquín OlivaresNo ratings yet

- SOP of Gram StainDocument5 pagesSOP of Gram Stainzalam55100% (1)

- Solution Manual For Chemistry For Today General Organic and Biochemistry 8th EditionDocument37 pagesSolution Manual For Chemistry For Today General Organic and Biochemistry 8th Editionrepastgraffitie17pv100% (14)

- Museum functional areas guideDocument8 pagesMuseum functional areas guideChelle CruzNo ratings yet

- Optimized Die Steel Reference GuideDocument16 pagesOptimized Die Steel Reference GuideKeattikhun ChaichanaNo ratings yet

- 2017 Aso Security TrainingDocument60 pages2017 Aso Security TrainingTanzila SiddiquiNo ratings yet

- Criminalsocio2022ratio Malindan RcrimDocument42 pagesCriminalsocio2022ratio Malindan RcrimWenilyn SmanNo ratings yet

- Chromosomal Basis of Inheritance - Final PDF-1Document3 pagesChromosomal Basis of Inheritance - Final PDF-1Aishwarya ShuklaNo ratings yet