Professional Documents

Culture Documents

SZH

Uploaded by

Mani RichardCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SZH

Uploaded by

Mani RichardCopyright:

Available Formats

Firma Leibrock Maschinenfabrik GmbH, Kettrichhofstr. 34, D-66955 Pirmasens, Geschftsfhrer: P. Albrecht, W. Kiefer, K.-H.

Geiler

Telefon: +49 (6331) 21 43 0 Telefax: +49 (6331) 21 43 29 Email: sales@Leibrock.de Internet: www.Leibrock.de

MASCHINENFABRIK

Hydraulic pulling over, forepart, side and ball-line cement lasting machine

Modell

SZH-9CD

Clearly arranged screen can be operated by TFT Touch Panel.

Hydraulic Pulling-Over-, Toe-, Side- and Ball-Lasting Machine

With PLC-Control Model SZH-9CD

Advantages of Leibrock Lasting Machine:

1st Advantage

The shank wipers can be programmed differently innen and outer ball-point and automatically adapt itself during working process to the

exact size of the shoe. Positioning is very accurate thanks to a motoric- not a hydraulic-movement.

2nd Advantage

Lasting cement (adhesive) will be attached on toe-area by a small extruder

followed by programmable nozzles (tracers) in side and ball-area.

The programming of the tracer-contour will be easily done for a shoe of medium size directly on the screen and all other shoe-sizes will be

graded automatically. If a correction is necessary, this can also be done directly on the screen digitising-point by digitising-point.

3rd Advantage

Upper and lower position of the last support also can be adjusted directly on the screen.

4th Advantage

Pincer-pull can be adjusted each pincer-pair in mm-distance on the screen. By choice, each individual

pincers can be re-adjusted manually via a lever nearby. It goes without saying, that all described adjustments can be stored per style and/or

model of the shoe.

5th Advantage

Hydraulic machines can create problems, if oil-temperature is getting too hot or too cold. Movements of the machine will be more fast or slow

and this can come to the result, that pincers when pulling the upper do not hold same position.

Leibrock Lasting Machines will be protected by adding a heater and a cooler, so that always a steady temperature and perfect working

conditions are guaranteed.

One further advantage can be achieved by having steady temperatures of oil: Only very limited wear of all sealing-elements (gaskets).

The Toe-Laster will be available in the following specifications:

SZH-7C Hydraulic Toe-Lasting-Machine with PLC-Control, Rod-Cement-Supply and Extruder, with Ball-Lasting-Equipment,

programmable, 7 pincers

SZH-9C Hydraulic Toe-Lasting-Machine with PLC-Control, Rod-Cement-Supply and Extruder, with Ball-Lasting-Equipment,

programmable, 9 pincers

SZH-9CD Hydraulic Toe-Lasting-Machine with PLC-Control, Rod-Cement-Supply and small Extruder followed by a programmable nozzle

(tracer)-system, with Ball-Lasting-Equipment, 9 pincers

SZH-9CC Hydraulic Toe-Lasting-Machine with PLC-Control, Rod-Cement-Supply, full nozzle (tracer)-system = without any extruder, with

Ball-Lasting-Equipment, 9 pincers

Technical details:

length, width, hight: 1700x1200x1750

packing dimensions: 1800x1300x2000

electrical supply: 230/400 V 50 Hz

electrical contact: 4,0 KW

pneumatical contact: 3/8

air consump.: 10 NL/Takt

oilfilling: 60 Ltr.

output pair/hour: 160 Paar/Std.

weight net: 1200 Kg

weight gross (crate): 1400 Kg

You might also like

- 11101174-0 MTF1500-320editionS PDFDocument11 pages11101174-0 MTF1500-320editionS PDFAnonymous f3LUQEdFNo ratings yet

- TapelineDocument4 pagesTapelineusmankhawaja100% (1)

- Krishna ElectronicsDocument10 pagesKrishna Electronicsrishi070881100% (1)

- Kustner AV YH enDocument2 pagesKustner AV YH enyasser0% (2)

- N.1 Flexographic Printing Press "Stack Type" Mod Sirio S-Plus 8 Colours - 1200 WidthDocument9 pagesN.1 Flexographic Printing Press "Stack Type" Mod Sirio S-Plus 8 Colours - 1200 WidthMahmoud FathiNo ratings yet

- pc290 8Document20 pagespc290 8Bodoman Gyozy100% (1)

- En HSM Vertical Baling Presses 2012-04Document16 pagesEn HSM Vertical Baling Presses 2012-04Rodrigo CerveiraNo ratings yet

- PW160 7Document24 pagesPW160 7Baciu SorinNo ratings yet

- ICOMATEX StenterDocument29 pagesICOMATEX StenterNabeel Ahmed100% (1)

- Manituo Maniscopic Tyre HandlerDocument14 pagesManituo Maniscopic Tyre Handlermohanngp100% (2)

- Komatsu PC160LC 7Document20 pagesKomatsu PC160LC 7Virgil Cenariu100% (3)

- LRB 125 XL Data Sheet en - 9800-0Document12 pagesLRB 125 XL Data Sheet en - 9800-0siva_arNo ratings yet

- PM5xx USERMANUAlDocument23 pagesPM5xx USERMANUAlAntonUvarovNo ratings yet

- COILERS Hand Lei Ding ENG - R2Document34 pagesCOILERS Hand Lei Ding ENG - R2gertvanwijkNo ratings yet

- CNC 3 Index UkDocument2 pagesCNC 3 Index UkHemily RoseNo ratings yet

- 522541Document8 pages522541AmirAmiriNo ratings yet

- Vak Tisch EnglDocument4 pagesVak Tisch EnglNeculai VeninNo ratings yet

- Harish Machines Brochure DesignDocument3 pagesHarish Machines Brochure DesignVamsi RajaNo ratings yet

- MARUTI ENGINEERING Hydraulic Goods Loading PlatformDocument8 pagesMARUTI ENGINEERING Hydraulic Goods Loading PlatformKush ThumarNo ratings yet

- PDFDocument8 pagesPDFomarNo ratings yet

- PW130 7Document24 pagesPW130 7Csongor Molnár100% (1)

- Plasma Arc Cutting System With Automatic Gas Console Product Configuration ManualDocument35 pagesPlasma Arc Cutting System With Automatic Gas Console Product Configuration ManualDiego maerNo ratings yet

- Tablet Press Double RSE Version 9.12Document48 pagesTablet Press Double RSE Version 9.12Kevin WeberNo ratings yet

- Vs 20Document10 pagesVs 20Mari PrunaNo ratings yet

- Buser 11 1 WebDocument12 pagesBuser 11 1 WebpavanuNo ratings yet

- C3003 With Crawler Control Unit CCU186Document38 pagesC3003 With Crawler Control Unit CCU186Felix U Onojeta67% (3)

- Catalogo Bomba Gabbioneta Modelo VBN PDFDocument2 pagesCatalogo Bomba Gabbioneta Modelo VBN PDFPrabha KaranNo ratings yet

- Rotary Screen Printing OfferDocument10 pagesRotary Screen Printing OfferHardik A ShahNo ratings yet

- 31fae81aeef24f52fcbfede5f8db735aDocument10 pages31fae81aeef24f52fcbfede5f8db735aFeni KartikaNo ratings yet

- Installation Instructions for Unisab III on HOWDEN WRV CompressorsDocument18 pagesInstallation Instructions for Unisab III on HOWDEN WRV CompressorsnikvaanNo ratings yet

- Compresores Reciprocantes Sabroe CMODocument2 pagesCompresores Reciprocantes Sabroe CMOJesus N RodriguezNo ratings yet

- Cfx700 EcoDocument19 pagesCfx700 Eco6b98pgb4v8No ratings yet

- MF 750 CS - enDocument18 pagesMF 750 CS - ensteph_4458No ratings yet

- GyratoryDocument4 pagesGyratoryFrancisco M. RamosNo ratings yet

- FinkbeinerDocument38 pagesFinkbeinermordidomiNo ratings yet

- PC210 8M0Document8 pagesPC210 8M0Vamshidhar Reddy KundurNo ratings yet

- Levelling, Lining and Tamping MachinesDocument6 pagesLevelling, Lining and Tamping MachinesAnonymous Byopfd100% (2)

- Flour Siever / Flour Sifter: SpecificationDocument9 pagesFlour Siever / Flour Sifter: SpecificationJustine AbanadorNo ratings yet

- KYMC Coating and Laminating Presses Offer Fully Automatic OperationDocument6 pagesKYMC Coating and Laminating Presses Offer Fully Automatic OperationValli MuthuNo ratings yet

- EX Extruders Data SheetDocument2 pagesEX Extruders Data SheetNordson Adhesive Dispensing SystemsNo ratings yet

- 450-4000 Ton Two-Platen Injection Molding MachinesDocument8 pages450-4000 Ton Two-Platen Injection Molding MachinesDenny BayuajiNo ratings yet

- ProfilDocument18 pagesProfilAnonymous 6EW2MsFbkNo ratings yet

- Original May Vary From Picture: Info@paus - de WWW - Paus.deDocument7 pagesOriginal May Vary From Picture: Info@paus - de WWW - Paus.deSANTANDER GARCIANo ratings yet

- Ambulift - Low Cabin - Specs - V2Document5 pagesAmbulift - Low Cabin - Specs - V2gueusquinNo ratings yet

- PSR FM24000Document28 pagesPSR FM24000RHoskaNo ratings yet

- Manual Controls C807Document40 pagesManual Controls C807Felipe Aguilar Rivera100% (1)

- Bombas Estacionarias SP 2800Document2 pagesBombas Estacionarias SP 2800SchwingLatinoamerica100% (1)

- Operation ManualDocument10 pagesOperation ManualBaeMoonSeobNo ratings yet

- Mfd500e Product NewsDocument2 pagesMfd500e Product Newsapi-232189763No ratings yet

- PSM 8Document5 pagesPSM 8Salvatore MirandaNo ratings yet

- Hydraulic Press SpectsDocument11 pagesHydraulic Press SpectszNo ratings yet

- Surface-Mounted Hair Dryer: Technical DataDocument2 pagesSurface-Mounted Hair Dryer: Technical Datachinni1658No ratings yet

- PC200LC 8M0 - Cen00489 01Document8 pagesPC200LC 8M0 - Cen00489 01cosminNo ratings yet

- Specification of PCL ProductsDocument2 pagesSpecification of PCL ProductstharezNo ratings yet

- Titan 325 EPM: Robust Paver with Proportional Screed ControlDocument12 pagesTitan 325 EPM: Robust Paver with Proportional Screed ControlGabriel Cizmarita50% (2)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Motor CatalogueDocument48 pagesMotor CatalogueMani RichardNo ratings yet

- Super Nu SeriesDocument36 pagesSuper Nu Serieshalder_kalyan9216No ratings yet

- Atom Clicker Press SE20, SE8, SE20C, SE22, SE24, SE25 - Die Cutting Machine, Die Cutting Press Machinery Manufacturer For SaleDocument5 pagesAtom Clicker Press SE20, SE8, SE20C, SE22, SE24, SE25 - Die Cutting Machine, Die Cutting Press Machinery Manufacturer For SaleMani RichardNo ratings yet

- MUL1-R1 Installation Instructions: ACS150, ACS310, ACS320, ACS350 and ACS355Document4 pagesMUL1-R1 Installation Instructions: ACS150, ACS310, ACS320, ACS350 and ACS355Mani RichardNo ratings yet

- BeginnerDocument24 pagesBeginnerPriyanka BundhooNo ratings yet

- Wire Net BrochureDocument4 pagesWire Net BrochureMani RichardNo ratings yet

- ATV310 Getting Started Parameters en EAV96136 03Document2 pagesATV310 Getting Started Parameters en EAV96136 03hitesh100% (2)

- Agra Train TicketDocument1 pageAgra Train TicketMani RichardNo ratings yet

- National Association of Container Freight Station.: Matexnet PVT LTDDocument11 pagesNational Association of Container Freight Station.: Matexnet PVT LTDMani RichardNo ratings yet

- Haier Warranty CardDocument2 pagesHaier Warranty CardMani RichardNo ratings yet

- Isf Memebers Shoe Units - 1Document2 pagesIsf Memebers Shoe Units - 1Mani RichardNo ratings yet

- Leather Footwear Components Tech Fair ApplicationDocument1 pageLeather Footwear Components Tech Fair ApplicationMani RichardNo ratings yet

- Swing Arm Hydraulic Clicker PressDocument9 pagesSwing Arm Hydraulic Clicker PressMani Richard100% (1)

- Biodata Format For Marriage Personal DetailsDocument2 pagesBiodata Format For Marriage Personal DetailsMani Richard60% (5)

- Anna University Report FormatDocument7 pagesAnna University Report Formatdilip_66690% (10)

- Required For ExportDocument1 pageRequired For ExportMani RichardNo ratings yet

- Gelo 13: P R E Machines (India) PVT LTD.Document1 pageGelo 13: P R E Machines (India) PVT LTD.Mani RichardNo ratings yet

- (NIIR) Project List For Mechanical, Engineering, Automobile Industries, Metal, Metallurgical, S.S. Utensil, Wire, Aluminum, Brass, Copper Products, LPG Cylinder and ValvesDocument18 pages(NIIR) Project List For Mechanical, Engineering, Automobile Industries, Metal, Metallurgical, S.S. Utensil, Wire, Aluminum, Brass, Copper Products, LPG Cylinder and ValvesDeepankumar AthiyannanNo ratings yet

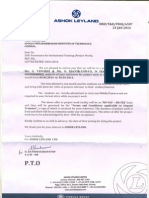

- Ashok Leyland Project ApprovalDocument1 pageAshok Leyland Project ApprovalMani RichardNo ratings yet

- Eeca QB Kce PDFDocument8 pagesEeca QB Kce PDFMichelle HendersonNo ratings yet

- Design of Transmission SystemsDocument6 pagesDesign of Transmission SystemsSelva KumarNo ratings yet

- Declaration Form LetterDocument1 pageDeclaration Form LetterRajasekaran SekaranNo ratings yet

- Applied Hydraulics and Pneumatics NotesDocument92 pagesApplied Hydraulics and Pneumatics NotessbhaleshNo ratings yet

- ME2307 Lab ManualDocument15 pagesME2307 Lab Manualamit4u1984No ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine ElementsGowtham RajNo ratings yet

- 02 CertificateDocument1 page02 CertificateMani RichardNo ratings yet

- Student ScheduledDocument2 pagesStudent ScheduledAbhishek RaneNo ratings yet

- 2484Document72 pages2484Mani RichardNo ratings yet

- PumpxDocument20 pagesPumpxDyego MarkoskiNo ratings yet

- DAV Public School Book ReviewDocument4 pagesDAV Public School Book ReviewHarshvardhan S. KantimahanthiNo ratings yet

- Supplement of Safety Catalog MARCH, 2007: Toyota Ball Joint Stock No. Oe Number Car Name Model Year PositionDocument36 pagesSupplement of Safety Catalog MARCH, 2007: Toyota Ball Joint Stock No. Oe Number Car Name Model Year PositionВалерий ГерасимовNo ratings yet

- Music Math Music MathDocument12 pagesMusic Math Music MathWanda Elissa ZieliñskaNo ratings yet

- Perlis F.A. - WikipediaDocument29 pagesPerlis F.A. - WikipediaMuh Lingga Nur AlimNo ratings yet

- Triptico SpeechDocument2 pagesTriptico SpeechZshoØn KaØzNo ratings yet

- Forces experiment resultsDocument49 pagesForces experiment resultsHoba BobaNo ratings yet

- Powerbuilding BrianDecostaDocument5 pagesPowerbuilding BrianDecostaNayeli ZamarrónNo ratings yet

- Box Codes for Krypt CheatsDocument3 pagesBox Codes for Krypt Cheatssyafri maryonoNo ratings yet

- Atlantis Park Sughad Navratri 2014 EnglishDocument1 pageAtlantis Park Sughad Navratri 2014 EnglishYogendra OzaNo ratings yet

- Periodisation TemplateDocument1 pagePeriodisation TemplateCarla BaraybarNo ratings yet

- Acceleration Speed Time Worksheet PDFDocument3 pagesAcceleration Speed Time Worksheet PDFlheanz22% (9)

- F1 Flash Owner ManualDocument18 pagesF1 Flash Owner ManualholaclaudeNo ratings yet

- Trailer Systems Troubleshooting Guide: How To Use This ChartDocument1 pageTrailer Systems Troubleshooting Guide: How To Use This ChartPototoNo ratings yet

- Free Fitness WeekDocument1 pageFree Fitness WeekCharlotte Eriksen O'DonnellNo ratings yet

- On The Non Player CharacterDocument62 pagesOn The Non Player CharacterCassidy MoonNo ratings yet

- Health Related Fitness: Bunggo National High SchoolDocument19 pagesHealth Related Fitness: Bunggo National High SchoolJeslie Madrigal SagsagatNo ratings yet

- How to Prepare for CAT Quantitative AptitudeDocument10 pagesHow to Prepare for CAT Quantitative AptitudeRishav Khandelwal100% (1)

- Cresselia IV Chart (Level 20)Document1 pageCresselia IV Chart (Level 20)kevin777No ratings yet

- Bruno Mars Grenade LyricsDocument2 pagesBruno Mars Grenade LyricsElsiWestlifers d'MeatballsCeek LoveMark-feehilyNo ratings yet

- D Inton Equip: Sale! Sale! Sale! Sale! Sale! Sale! Sale!Document8 pagesD Inton Equip: Sale! Sale! Sale! Sale! Sale! Sale! Sale!16 Dela Cerna, RonaldNo ratings yet

- Technical Specification PC 3: Atlas Copco PowercrusherDocument4 pagesTechnical Specification PC 3: Atlas Copco PowercrusheralmirNo ratings yet

- LMS Plus V7 Fault Code ManualDocument4 pagesLMS Plus V7 Fault Code ManualElmer Samuel Diaz GarciaNo ratings yet

- Or 2004 ADocument544 pagesOr 2004 AVon Lefos100% (1)

- Cara Flash STOCK ROM - Stock Recovery. SmartFren AndroMax Android Games HD and AppsDocument3 pagesCara Flash STOCK ROM - Stock Recovery. SmartFren AndroMax Android Games HD and AppsSaidAnwarNo ratings yet

- Orphan Persian Empire Richard Coyle Toby Kebbell Ben Kingsley AlamutDocument5 pagesOrphan Persian Empire Richard Coyle Toby Kebbell Ben Kingsley AlamutJessielyn B. SingNo ratings yet

- Road Marking Materials and Application TechniquesDocument9 pagesRoad Marking Materials and Application TechniquesMalith De SilvaNo ratings yet

- Carlson On Athletic IQDocument2 pagesCarlson On Athletic IQJohn O. HarneyNo ratings yet

- VW V12.0 enDocument7 pagesVW V12.0 enwatt tngchaiNo ratings yet