Professional Documents

Culture Documents

Spe 93594 MS P

Uploaded by

GustavoMillaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spe 93594 MS P

Uploaded by

GustavoMillaCopyright:

Available Formats

Copyright 2005, Society of Petroleum Engineers Inc.

This paper was prepared for presentation at the 2005 Asia Pacific Oil & Gas Conference and

Exhibition held in Jakarta, Indonesia, 5 7 April 2005.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in a proposal submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to a proposal of not more than 300

words; illustrations may not be copied. The proposal must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

The original Kulin Horizontal well project scope was

to drill two horizontal wells and run Electric Submersible

Progressive Cavity Pumps (ESPCPs). ESPCP is a

combination of Progressive Cavity Pump (PCP) and Electric

Submersible Pump (ESP) motor as a down hole fluid lifting

system and is ideal for use in horizontal wells. With rod less

system, it will eliminate friction loss at tubing and rod. The

PCP has more resistance to sand production and provides high

efficiency production of viscous fluid. The Kulin Horizontal

Drilling project started in early 2002 and ended in February

2003. The first horizontal well was Kulin 082 (KL082) and the

second well was Kulin 083 (KL083). After the wells were

completed using ESPCP as artificial lift, the initial production

for KL082 was 708 BFPD, 531 BOPD, 25% water cut and

KL083 was 518 BFPD, 394 BOPD, 24% water cut. The initial

production was above estimated initial production of 300

BOPD/well.

The ESPCPs in both Kulin horizontal wells are

installed in tangent sections with less than 2

o

/100 ft build rate

inside 9-5/8 production casing. The design threshold for

ESPCPs is up to a maximum of 15

o

/100 ft build rate in the

tangent section. The stator elastomer inside the PCP is

operated at temperatures between 135

o

F and 150

o

F and this is

below the maximum temperature limitation for the elastomer.

The flow rates, head and pump efficiency of the ESPCPs are

controlled using surface mounted Variable Speed Drive

(VSD).

As of June 2004, the ESPCPs that are installed in

both Kulin horizontal wells have been operating for over 450

days and 800 days respectively without any mechanical

problem from pump or ESP failures. Both ESPCPs was down

in period mid of June04 until early August04 when the Kulin

field was shut down due to facility safety issue.

The production rates from these horizontal wells are about 2.5

3.5 times greater than an average vertical producer in the

field.

This paper will discuss ESPCP design, installation

and performance in the Kulin Horizontal wells.

Introduction

The horizontal wells were designed with 9-5/8 production

casing with a 8.5 open hole lateral section containing a 7

pre-perforated completion liner. The well KL082, is producing

from Duri E sand with 1,340 ft TVD sand depth and 393 ft

lateral length. The well KL083 is producing from Duri B

sand with 980 ft TVD sand depth and 1,214 ft lateral length. A

summary of reservoir properties at initial condition is listed in

table 1.

KL082 KL083

Porosity 33% 25%

Permeability 5000 md 2131 md

Sand Thickness 34 ft 18 ft

Reservoir Pressure 220 psi 235 psi

Reservoir Temp 150

o

F 135

o

F

Oil Gravity 20

o

API 16

o

API

Table 1. Reservoir properties

During pre execution phase of the project, the Kulin

Horizontal Well Execution Team did an assessment to identify

appropriate artificial lift methods for the horizontal well

project that would optimize pump operability and well

production. Horizontal wells located in the adjacent Duri field

were used to evaluate tubing pump performance. This analysis

was done to understand the critical factors that affected pump

performance. The Duri field has unconsolidated sand with

high reservoir temperature as result of steam flood process.

Statistically, tubing pump performance at 25 horizontal wells

in Duri is poor. The average of tubing pump efficiency is less

than 30% with 118 days average pump run life.

Table 2 provides the tubing pump efficiency of Duri

Horizontal wells.

Year # of Pump Installed Avg Pump Efficiency (%)

1999 6 20

2000 15 27

2001 19 43

2002 7 29

Table 2. Tubing pump efficiency in Duri Horizontal

wells (25 wells)

Some contributing factors that have caused low tubing pump

SPE 93594

Electrical Submersible Progressive Cavity Pump (ESPCP) Application in Kulin

Horizontal Wells

M. Taufan, SPE, R. Adriansyah, SPE, and D. Satriana, SPE, P.T. Caltex Pacific Indonesia

2 SPE 93594

ROTOR

STATOR

performance in Duri horizontal wells are: high friction losses

that prevent adequate pump travel and excessive sand

production that damages the tubing pump plunger. Although

some modifications had been made to reduce friction loss by

installing roller guides on the rod string, pump failure still

occurred frequently. The roller guides were damaged by

excessive production of sand due to poor sand control in

horizontal wells. Most of Duri Horizontal wells use pre-

perforated liner set in open hole as sand control and this has

failed to reduce sand production.

Realizing that Kulin has unconsolidated sand and the

horizontal wells were designed using a similar completion

with pre-perforated liner in open hole; the team took the

initiative to identify other artificial lift alternatives to tubing

pumps. The desired characteristics of the new system were a

rodless system with more resistance to sand production. The

team has considered both ESP and PCP separately but the ESP

is not designed to handle sand production, and the PCP is

using a rod system that is prone to failure in horizontal well.

The team then decided to utilize ESPCP as solution.

ESPCP Design

ESPCP is PCP (Progressive Cavity Pump) driving with an

ESP (Electric Submersible Pump) motor as a downhole drive

system. This configuration is a rodless system which

eliminates friction loss at tubing and rod. PCP is a single

helical (rotor) which rotates eccentric inside double helical

(stator). The PCP is a positive displacement pump. As the

rotor rotates inside the stator, fluid moves through the pump

from cavity to cavity.

As one cavity closes, its opposing cavity opens at exactly the

same rate. This results in a constant non-pulsating flow. The

PCP can handle viscous fluids and solids laden fluid. The

standard rotor is made from stainless steel, and hard chrome

plated for abrasion protection. The stator elastomer is made

from a mixture of compounds designed to handle variety of

produced fluids, solids and gases.

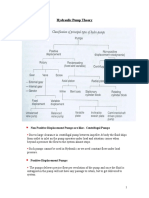

Figure 1 is Progressive Cavity Pump with 2 main component,

rotor and stator.

Fig 1. Progressive Cavity Pump

Various types of stator elastomers are available from vendors.

The stator elastomer generally has a heat limitation associated

with bottom hole temperature. Some available products have

variety of temperature resistance to a maximum of 95

o

C (203

o

F), 105

o

C (221

o

F), 135

o

C (275

o

F) and 150

o

C (302

o

F).

Because the BHT of the producing sand was about 65.6

o

C

(150

o

F), we chose an elastomer with a temperature resistance

of 95

o

C (203

o

F).

Another consideration when designing a PCP installation is

determining whether the elastomer will be compatible with the

aromatics in the produced fluids. The ESPCP system

configuration is provided at figure 2.

Flex Shaft &

Cavity Pump

ESP Motor

Gear Reducer

Seal Section

Intake

Progressing

Fig 2. Electric Submersible Progressive Cavity Pump (ESPCP)

ESP Motor

ESP motor sizing is determined by the power required to start

and operate the PCP, the size of the casing and the downhole

temperature. Standard for the ESPCP system is two pole

motor with a 50Hz speed at 2,917 rpm and a 60Hz speed of

3,500 rpm.

Gear Reducer

The primary function of the gear reducer is to provide a speed

that is acceptable to PCP. The normal range of the PCP is 100

to 500 rpm.

The second function of gear reducer is to increase the torque

available to the PCP.

Gear ratio are varying depend on each product. Example of

gear ratio: 9:1 and 11:1

Seal Section

The main function is to prevent well fluids entering the gear

reducer and motor, isolating the specially formulated motor oil

from the well bore fluids. This isolation allows the motor oil

to expand or contract as downhole temperatures and pressure

vary.

Flex Shaft and Intake

The flex shaft assembly is designed to convert the concentric

rotation of the seal section shaft to the eccentric rotation

required by PCP. Design for high torque load. Utilize standard

SPE 93594 3

ESP intake base. Maximum intake flow is 9,000 bpd

(1,430m

3

/d).

To control the flow rates, head and pump efficiency, the

ESPCP was run using Variable Speed Drive (VSD), which is

operated at the surface. By adjusting the frequency, the VSD

system offers potential for controlling production and reduces

down time.

ESPCP Installation

ESPCP installation at horizontal wells KL082 and KL083 has

considered the maximum allowable inclination for the pump

placement. The ESPCP is capable to be operated in horizontal

wells with less than 15

o

/100 ft tangent section. ESPCP in

KL082 was installed at 64

o

inclination with 1.6

o

/100 ft build

rate inside 9-5/8 casing. Depth installation is 1,440 ft MD or

1,267 ft TVD. ESPCP in KL083 was installed at 58

o

inclination with 1.5

o

/100 ft build rate. The pump depth is

1,014 ft MD or 891 ft TVD.

The pumps were installed using 3-1/2 tubing and equipped

with 3-1/2 check valve and bleeder valve 90 ft above the

pump. To prevent motor cable friction with casing, a cable

guard was installed along the pump and tubing.

The ESP motor that was installed at both wells are two pole

motor with 60 Hz speed of 3,500 rpm, 562 series, 38 HP, 453

volts and 53 ampere. Actual setting is 40 Hz speed of 2,333

rpm. Motor Outside Diameter is 5.62 with 6.98 ft length.

The 562 motor series is suitable for minimum 7-32# casing

size.

Both Kulin Horizontal wells are using 9:1 gear ratio. At 40 Hz

speed of 2,333 rpm results in speed at the pump:

2,333/9 = 259 rpm

Motor Output torque = Motor HP * 5,252/ Motor Speed

= 38 (HP)*5,252/2,333 (rpm)

= 86 ft lbs

Gear reducer output torque = 86 ft lbs * 9

= 774 ft lbs

The PCP model is 054-12-045 with capacity of 340 BFPD/100

rpm.

Pump Rate = Pump Speed * Pump Capacity

= 259 (rpm) * 340 (BFPD/100 rpm)

= 881 BFPD

Pump dimension is 4.25 pump OD with 13.3 ft stator length.

Table 3 summarizes the ESPCP design which was installed at

KL082 and KL083 wells.

Motor Speed (RPM) @ 40 Hz 2,333

Gear Reducer 9:1

Pump Speed (RPM) 259

PCP Capacity (BFPD/100 RPM) 340

Pump Rate (BFPD) 881

Table 3. ESPCP design at KL082 & KL083

Field Result

KULIN 082

Well KL082 started production in April 2002. Initial

production was 708 BFPD, 531 BOPD and 25% water cut.

Average production of the wells is 445 BOPD with 20-30%

water cut range.

Fiq 3 showing production performance at KL082

200

300

400

500

600

700

800

900

A

p

r

-

0

2

M

a

y

-

0

2

J

u

n

-

0

2

J

u

l

-

0

2

A

u

g

-

0

2

S

e

p

-

0

2

O

c

t

-

0

2

N

o

v

-

0

2

D

e

c

-

0

2

J

a

n

-

0

3

F

e

b

-

0

3

M

a

r

-

0

3

A

p

r

-

0

3

M

a

y

-

0

3

J

u

n

-

0

3

J

u

l

-

0

3

A

u

g

-

0

3

S

e

p

-

0

3

O

c

t

-

0

3

N

o

v

-

0

3

D

e

c

-

0

3

J

a

n

-

0

4

F

e

b

-

0

4

M

a

r

-

0

4

A

p

r

-

0

4

M

a

y

-

0

4

J

u

n

-

0

4

B

b

l

/

D

a

y

FLUID_RATE OIL_RATE

Fig 3. Production performance KL082

Since initial production the water cut is stable at level 20-25%

and slightly increase to 27% starting March 2004. Fig 4

showing water cut trend at well KL082.

10

15

20

25

30

35

A

p

r

-

0

2

M

a

y

-

0

2

J

u

n

-

0

2

J

u

l

-

0

2

A

u

g

-

0

2

S

e

p

-

0

2

O

c

t

-

0

2

N

o

v

-

0

2

D

e

c

-

0

2

J

a

n

-

0

3

F

e

b

-

0

3

M

a

r

-

0

3

A

p

r

-

0

3

M

a

y

-

0

3

J

u

n

-

0

3

J

u

l

-

0

3

A

u

g

-

0

3

S

e

p

-

0

3

O

c

t

-

0

3

N

o

v

-

0

3

D

e

c

-

0

3

J

a

n

-

0

4

F

e

b

-

0

4

M

a

r

-

0

4

A

p

r

-

0

4

M

a

y

-

0

4

J

u

n

-

0

4

W

C

(

%

)

Water Cut

Fiq 4. Water Cut trend at KL082

The ESPCP has better pump efficiency compared to tubing

pump efficiency in Duri horizontal wells. Average pump

efficiency at well KL082 since initial production is 66%. After

more than 800 days (2.2 years) producing time, there have

been no indications of pump failures. Fig 5 shows Pump

Efficiency at well KL082.

20%

40%

60%

80%

100%

A

p

r

-

0

2

M

a

y

-

0

2

J

u

n

-

0

2

J

u

l

-

0

2

A

u

g

-

0

2

S

e

p

-

0

2

O

c

t

-

0

2

N

o

v

-

0

2

D

e

c

-

0

2

J

a

n

-

0

3

F

e

b

-

0

3

M

a

r

-

0

3

A

p

r

-

0

3

M

a

y

-

0

3

J

u

n

-

0

3

J

u

l

-

0

3

A

u

g

-

0

3

S

e

p

-

0

3

O

c

t

-

0

3

N

o

v

-

0

3

D

e

c

-

0

3

J

a

n

-

0

4

F

e

b

-

0

4

M

a

r

-

0

4

A

p

r

-

0

4

M

a

y

-

0

4

J

u

n

-

0

4

Pump Eff

Fig 5. Pump Efficiency at KL082

Some operational problems were encountered early in the life

of the wells, when no fluids were produced while the pump

was running. A fluid level survey also indicated a high fluid

level above the pump. The team suspected that something was

plugging the pump intake. The team successfully used the

4 SPE 93594

technique of backflushing the pump by reversing the motor to

return the well to production without pulling the pump. By

reversed the motor rotation in couple minutes and then turn

back to normal motor rotation, the well was successfully

returned to production.

KULIN 083

Well KL083 starting producing in March 2003. Initial

production of the well was 518 BFPD, 394 BOPD and 24%

water cut. There were some problems early in the life of this

well. High oil viscosity with 16

o

API gravity and about 2

kilometers of 4 production line generated pressure build up in

production line. When starting the pump during the first 24

hours, the pressure at the well head reached 200 psi and was

continuing to increase. The Operations Team decided to shut-

in the pump while conducting a flushing job on the production

line. The flushing job indicated that there were no materials

plugging the production line. The team then decided to tie-in

KL083 surface production line with production line from

offset well KL073, which has high rate and high water cut,

with average 90% water cut and 900 BFPD. This commingled

production succeeded in reducing the well head pressure at

KL083 to 130 psi. The well was then successfully put on

production with close monitoring.

This well has demonstrated increasing water cut from an

average of 30% to 64% and resulted in lower oil production.

Average oil production in first 6 months was 400 BOPD and

decreased to average 150 BOPD. Fig 6 and 7 provides

production performance and water cut trend of KL083.

0

100

200

300

400

500

600

700

800

M

a

r

-

0

3

A

p

r

-

0

3

M

a

y

-

0

3

J

u

n

-

0

3

J

u

l

-

0

3

A

u

g

-

0

3

S

e

p

-

0

3

O

c

t

-

0

3

N

o

v

-

0

3

D

e

c

-

0

3

J

a

n

-

0

4

F

e

b

-

0

4

M

a

r

-

0

4

A

p

r

-

0

4

M

a

y

-

0

4

J

u

n

-

0

4

B

b

l

/

D

a

y

FLUID_RATE OIL_RATE

Fig 6. Production Performance KL083

0

10

20

30

40

50

60

70

80

M

a

r

-

0

3

A

p

r

-

0

3

M

a

y

-

0

3

J

u

n

-

0

3

J

u

l

-

0

3

A

u

g

-

0

3

S

e

p

-

0

3

O

c

t

-

0

3

N

o

v

-

0

3

D

e

c

-

0

3

J

a

n

-

0

4

F

e

b

-

0

4

M

a

r

-

0

4

A

p

r

-

0

4

M

a

y

-

0

4

J

u

n

-

0

4

W

C

(

%

)

Water Cut

Fig 7. Water cut trend at KL083

As of June 2004, The ESPCP performance at KL083 exceeds

the expectation of the Kulin Horizontal Well Execution team

with running life of the pump is 450 days. There was no pump

recondition or pulling out job during this period. There were

pump down time recorded but not associated with pump

failure. The pump was down due to power outage and

unrelated facility issues with the pump performance. Average

pump efficiency since the well put on production is 56%. Fig

8 showing pump efficiency at KL083.

20%

30%

40%

50%

60%

70%

80%

M

a

r

-

0

3

A

p

r

-

0

3

M

a

y

-

0

3

J

u

n

-

0

3

J

u

l

-

0

3

A

u

g

-

0

3

S

e

p

-

0

3

O

c

t

-

0

3

N

o

v

-

0

3

D

e

c

-

0

3

J

a

n

-

0

4

F

e

b

-

0

4

M

a

r

-

0

4

A

p

r

-

0

4

M

a

y

-

0

4

J

u

n

-

0

4

Pump Eff

Fig 8. Pump Down & Pump Efficiency at KL083

Another advantage of the ESPCP system is that during the

put-on-production operations no oil was spilled at surface.

This was possible because the rodless system of the ESPCP,

eliminated the friction between the rod and stuffing box at the

well head that can contribute to small spills during start-up.

Production from these horizontal wells significantly

contributes to total Kulin field production. Incremental

production from horizontal wells is about 17% of total Kulin

production. Fig 9 illustrates the impact of the development of

horizontal wells on Kulin fields production. Since May 2004,

some wells in Kulin field were shut down due to an unrelated

facility safety issue, resulting in lower field-wide production.

2000

3000

4000

5000

6000

7000

8000

9000

J

a

n

-

0

1

M

a

r

-

0

1

M

a

y

-

0

1

J

u

l

-

0

1

S

e

p

-

0

1

N

o

v

-

0

1

J

a

n

-

0

2

M

a

r

-

0

2

M

a

y

-

0

2

J

u

l

-

0

2

S

e

p

-

0

2

N

o

v

-

0

2

J

a

n

-

0

3

M

a

r

-

0

3

M

a

y

-

0

3

J

u

l

-

0

3

S

e

p

-

0

3

N

o

v

-

0

3

J

a

n

-

0

4

M

a

r

-

0

4

M

a

y

-

0

4

O

i

l

(

B

O

P

D

)

Without Hz Wells KL082 KL083

Fig 9. Illustrated the impact of the development of horizontal wells

in Kulin field.

Conclusion

1. ESPCP which is a combination between PCP and ESP

motor has some advantages to be implemented at

Horizontal well:

a. High production efficiency even for viscous fluid and

high solid content.

b. Rodless system will eliminate friction loss.

c. Without stuffing box, avoid oil spill at surface.

SPE 93594 5

d. High torque capabilities

e. Allows back flush capability by reversing motor.

2. ESPCP application at Kulin horizontal wells results in

higher pump efficiency with average 56 66 % compared

to tubing pump efficiency at Duri Horizontal wells which

has less than 30% efficiency.

3. ESPCP offers longer pump run life, proven at KL082 &

KL083 horizontal wells that never have pump problems

or pulling out job. As of June 2004, ESPCP KL082 has

been operating over than 800 days and ESPCP KL083

over 450 days.

References

1. Centrilift Product Catalog, Electric Submersible Pumps &

Equipment

2. Lee, Zabel., Electric Submersible Progressing Cavity Pump

(ESPCP): An Alternative Lift Method for Problem Applications

, Centrilift

3. Taufan, Mochamad., Horizontal Well KL082 Evaluation,

Internal Report, PT.CPI, 2002

You might also like

- DDocument15 pagesDJuan Lopez100% (2)

- SPE-149944-MS - Aplicación Exitosa de Metal PCP Rechnology para Maximizar La Recuperación de Petróleo en El Proceso SAGDDocument6 pagesSPE-149944-MS - Aplicación Exitosa de Metal PCP Rechnology para Maximizar La Recuperación de Petróleo en El Proceso SAGDBreyner Villegas VelezNo ratings yet

- All Metal PCP Field Trial Update: A. Damnjanovic, S. Jahn, G. Mitskopoulos, L. SeinceDocument7 pagesAll Metal PCP Field Trial Update: A. Damnjanovic, S. Jahn, G. Mitskopoulos, L. SeinceVenus DobosNo ratings yet

- Spe 131758 Ms - GL and EspDocument11 pagesSpe 131758 Ms - GL and EspSamuel VmNo ratings yet

- Kal War 2017Document10 pagesKal War 2017khusnul9No ratings yet

- Levant Amien ToDocument8 pagesLevant Amien ToCharles CarreraNo ratings yet

- Peng 2016Document11 pagesPeng 2016NileshgordeNo ratings yet

- SPE-184215 - Hybrid System - ESP and GL - Aplication From Conceptual To Pilot TestDocument13 pagesSPE-184215 - Hybrid System - ESP and GL - Aplication From Conceptual To Pilot TestDede PratamaNo ratings yet

- PETE 300 5660300 Summer Practice I: TH THDocument7 pagesPETE 300 5660300 Summer Practice I: TH THEmir MazlumNo ratings yet

- PCP VenezuelaDocument6 pagesPCP VenezuelakurtbkNo ratings yet

- Novel Idea of Optimizationof PCP System at Different Stages of CBM Well LifeDocument14 pagesNovel Idea of Optimizationof PCP System at Different Stages of CBM Well Lifemohit narayan100% (1)

- SPE 136817 The Special Successful PCP Applications in Heavy OilfieldDocument10 pagesSPE 136817 The Special Successful PCP Applications in Heavy Oilfieldatilio martinezNo ratings yet

- Supervisión Tremendo - PCPDocument17 pagesSupervisión Tremendo - PCPmanuel cabarcasNo ratings yet

- Design of Sucker Rod Pump for Offshore Oil WellDocument13 pagesDesign of Sucker Rod Pump for Offshore Oil Wellpramod_prasad_3No ratings yet

- Design of Progressive Cavity Pump WellsDocument12 pagesDesign of Progressive Cavity Pump WellsIndra Bayu100% (2)

- Zhang - The Application of High T Elastomers in PCP in CSS Wells, 2009Document4 pagesZhang - The Application of High T Elastomers in PCP in CSS Wells, 2009oreamigNo ratings yet

- Impeller DesignDocument6 pagesImpeller Design19MECH052 SYED YOUNUS100% (1)

- SPE-177272-MS Replacement of ESP With Long Stroke Pumping Units in Heavy and High Viscous Oil in Maranta Block WellsDocument16 pagesSPE-177272-MS Replacement of ESP With Long Stroke Pumping Units in Heavy and High Viscous Oil in Maranta Block WellsFajar Putra NugrahaNo ratings yet

- Dewatering Coalbed Methane Wells Using Espcps: Petroleum SocietyDocument3 pagesDewatering Coalbed Methane Wells Using Espcps: Petroleum SocietyMukul DixitNo ratings yet

- zaini2012Document16 pageszaini2012rahulNo ratings yet

- Abdel Bak y 2018Document9 pagesAbdel Bak y 2018arispriyatmonoNo ratings yet

- A Compact Cryogenic Pump DesignDocument5 pagesA Compact Cryogenic Pump DesignKOWSHIK 4310No ratings yet

- Steam Turbine UpgradesDocument3 pagesSteam Turbine UpgradesYugandhara Chakravarthy Kancherla100% (1)

- Cavitation Performance Improvement of An Industrial Cryogenic Centrifugal Pump by Implementing Variable Pitch InducerDocument12 pagesCavitation Performance Improvement of An Industrial Cryogenic Centrifugal Pump by Implementing Variable Pitch InducerKOWSHIK 4310No ratings yet

- Artificial Lift: Technology FocusDocument10 pagesArtificial Lift: Technology FocuseuderfilhoNo ratings yet

- SPE-64466-Combined ESP-Auto Gas Lift Completions in High GOR WellsDocument6 pagesSPE-64466-Combined ESP-Auto Gas Lift Completions in High GOR WellsDede PratamaNo ratings yet

- SOMC, Vizag Paper Presentation For NTPC-IPS-2018Document6 pagesSOMC, Vizag Paper Presentation For NTPC-IPS-2018Sooraj Surendran SugathaNo ratings yet

- High Volume Insert PCP TechnologyDocument9 pagesHigh Volume Insert PCP TechnologyLind D. QuiNo ratings yet

- Artificial Lift in The Montrose Field, North Sea: E.G. Jacobs, SPE, Amoco (UK) Exploration CoDocument8 pagesArtificial Lift in The Montrose Field, North Sea: E.G. Jacobs, SPE, Amoco (UK) Exploration Comoh kadNo ratings yet

- IPTC 10032 The Successful Application of 2000 PCP Wells in Daqing OilfieldDocument11 pagesIPTC 10032 The Successful Application of 2000 PCP Wells in Daqing OilfieldJosé TimanáNo ratings yet

- Control ThrusterDocument11 pagesControl ThrusterBhayu alfianNo ratings yet

- SPE-196323-MS Improving Horizontal Well Performance With Bottom Feeder Intake On Electric Submersible Pump in Gassy Wells, Offshore North West JavaDocument9 pagesSPE-196323-MS Improving Horizontal Well Performance With Bottom Feeder Intake On Electric Submersible Pump in Gassy Wells, Offshore North West Javaimam zulkipliNo ratings yet

- SPE-177990-MS Electric Submersible Pump Installation and Commissioning - Challenges and Lesson Learned From Field DevelopmentDocument17 pagesSPE-177990-MS Electric Submersible Pump Installation and Commissioning - Challenges and Lesson Learned From Field Developmentmahmoud korieshNo ratings yet

- Propane Gas System Scope of WorkDocument10 pagesPropane Gas System Scope of WorkaeliusmanoNo ratings yet

- Otc 20340Document13 pagesOtc 20340Rasheed YusufNo ratings yet

- Technical Report on Design and Execution of Desalination Plants in Lakshadweep IslandsDocument21 pagesTechnical Report on Design and Execution of Desalination Plants in Lakshadweep IslandsZainal Hashim100% (1)

- Screw PumpDocument12 pagesScrew Pumpemilliomud100% (1)

- Experiences Innovations and Best Practices of Hydraulic Jet Pump (VEntajas y Mejores Prácticas) IPTC-16953-MSDocument10 pagesExperiences Innovations and Best Practices of Hydraulic Jet Pump (VEntajas y Mejores Prácticas) IPTC-16953-MSrudo212No ratings yet

- SLB Premium ReshearchDocument13 pagesSLB Premium ReshearchJay PatelNo ratings yet

- SPE168279 - Optimizing Frac Plug Mill Outs in Horizontal Wells Using Coiled Tubing - TTSDocument10 pagesSPE168279 - Optimizing Frac Plug Mill Outs in Horizontal Wells Using Coiled Tubing - TTSfkong16688No ratings yet

- Spe 27893 New Packer Design Offers Completion Flexibility in Thermal Completions, Esp, Downhole Monitoring Systems, and Annular Safety Systems: Case HistoriesDocument8 pagesSpe 27893 New Packer Design Offers Completion Flexibility in Thermal Completions, Esp, Downhole Monitoring Systems, and Annular Safety Systems: Case HistoriesJhon Harvey Carreño HernandezNo ratings yet

- PCP PresentationDocument38 pagesPCP PresentationAkol MajookNo ratings yet

- Mahbes 2017Document11 pagesMahbes 2017sayidNo ratings yet

- ESP Design Changes For High GLR and High Sand ProductionDocument3 pagesESP Design Changes For High GLR and High Sand ProductionKardusNo ratings yet

- Shrimp Farming ETECDocument4 pagesShrimp Farming ETECGerardo RodriguezNo ratings yet

- Cuproplex Cleaning of GeneratorDocument20 pagesCuproplex Cleaning of GeneratorJayanath Nuwan SameeraNo ratings yet

- Artificial Lift: Technology FocusDocument8 pagesArtificial Lift: Technology FocusPeiwen LimNo ratings yet

- 00087173Document15 pages00087173JohnSmithNo ratings yet

- Spe163887 PDFDocument11 pagesSpe163887 PDFCarlos Ulises LeonidasNo ratings yet

- Appendix: 1 Dr. Alpheus Igbokoyi PTT Well PerformanceDocument25 pagesAppendix: 1 Dr. Alpheus Igbokoyi PTT Well PerformanceCharles Adefemi OmowoleNo ratings yet

- SPE-182251-MS Field Trial Analyzing of Rodless PCP Technology: Problems, Improvements and ResultsDocument7 pagesSPE-182251-MS Field Trial Analyzing of Rodless PCP Technology: Problems, Improvements and ResultsSanobyNo ratings yet

- Case Study of Co2 Removal SystemDocument21 pagesCase Study of Co2 Removal Systemgurdeepsarora8738100% (2)

- IS14220Document36 pagesIS14220Ansons DownloadNo ratings yet

- Engineering News, ECP SlurryDocument3 pagesEngineering News, ECP SlurryRonald Llerena GalanNo ratings yet

- SPE 165669 PCP Sand Handling TechnologiesDocument15 pagesSPE 165669 PCP Sand Handling TechnologiesJosé TimanáNo ratings yet

- ESP Operation, Optimization, and Performance ReviewDocument10 pagesESP Operation, Optimization, and Performance ReviewJoseph IRANZINo ratings yet

- Lab Manual: Mine Machinery-2Document22 pagesLab Manual: Mine Machinery-2Karan Jat (Mr.K J)No ratings yet

- W Anderson, SPE, A I Buchanan, SPE, and A. Susanto P.T BJ Services IndonesiaDocument10 pagesW Anderson, SPE, A I Buchanan, SPE, and A. Susanto P.T BJ Services IndonesiaSebastian Pinilla PradillaNo ratings yet

- SPE 950073-G Determining Friction Factors For Measuring Productivity of Gas WellsDocument10 pagesSPE 950073-G Determining Friction Factors For Measuring Productivity of Gas WellsGustavoMillaNo ratings yet

- Well Completion and Hydraulic Fracturing Methodology Explained1Document9 pagesWell Completion and Hydraulic Fracturing Methodology Explained1GustavoMillaNo ratings yet

- ViscosityDocument2 pagesViscosityworkover5No ratings yet

- SPE 2198 Analysis and Prediction of Minimum Flow Rate For The Continuous Removal of Liquids From Gas WellsDocument8 pagesSPE 2198 Analysis and Prediction of Minimum Flow Rate For The Continuous Removal of Liquids From Gas WellsGustavoMillaNo ratings yet

- Flat Cable Balance - Brief29Document2 pagesFlat Cable Balance - Brief29Lud Wing RamNo ratings yet

- Oil Flow DiagramDocument19 pagesOil Flow DiagramGustavoMillaNo ratings yet

- 15140-PA Study of Multiphase Critical Flow Through WellheadDocument5 pages15140-PA Study of Multiphase Critical Flow Through WellheadGustavoMillaNo ratings yet

- Spe 8025Document36 pagesSpe 8025GustavoMillaNo ratings yet

- Decline Curves - by Gustavo Milla Flores - English Intermediate Two - Final VersionDocument14 pagesDecline Curves - by Gustavo Milla Flores - English Intermediate Two - Final VersionGustavoMillaNo ratings yet

- Reviewing the Ashford and Pierce Relationship for Estimating Multiphase Flow ParametersDocument7 pagesReviewing the Ashford and Pierce Relationship for Estimating Multiphase Flow ParametersGustavoMillaNo ratings yet

- 479 Page Document CollectionDocument480 pages479 Page Document CollectionGustavoMilla100% (3)

- Diccionario Ingles-Espanol PDFDocument295 pagesDiccionario Ingles-Espanol PDFJose Daniel ChamorroNo ratings yet

- Depliant Brochure Marine en PDFDocument9 pagesDepliant Brochure Marine en PDFFadzil NorNo ratings yet

- CCNY LabManualDocument29 pagesCCNY LabManualShady HegazyNo ratings yet

- High Leverage Spring-Loaded Ball Float Type Drain TrapsDocument2 pagesHigh Leverage Spring-Loaded Ball Float Type Drain TrapsmanishNo ratings yet

- Edexcel Higher Fluid Mechanics H1 Unit 8 NQF Level 4 Outcome 2 Viscosity Tutorial 2 - The Viscous Nature of FluidsDocument10 pagesEdexcel Higher Fluid Mechanics H1 Unit 8 NQF Level 4 Outcome 2 Viscosity Tutorial 2 - The Viscous Nature of FluidsTejas PatelNo ratings yet

- Swabbing Equipments Mod 2Document5 pagesSwabbing Equipments Mod 2Anonymous Vb1Tsv106No ratings yet

- Flash Point TutorialDocument8 pagesFlash Point TutorialS. GreenNo ratings yet

- DearatorDocument3 pagesDearatorEDUARDONo ratings yet

- Automatic Return ValveDocument4 pagesAutomatic Return ValvekapsarcNo ratings yet

- Avoiding Pressure SurgeDocument33 pagesAvoiding Pressure SurgeManas KarnureNo ratings yet

- Various Valves Arrangement For Machinery Spaces Piping SystemDocument10 pagesVarious Valves Arrangement For Machinery Spaces Piping SystemRaj GraffitiNo ratings yet

- Operation and Maintenance Manual - SFFECO Fire Pumps - 2012Document44 pagesOperation and Maintenance Manual - SFFECO Fire Pumps - 2012mukhtarahmadaNo ratings yet

- Boiler 2Document25 pagesBoiler 2Aashid PsNo ratings yet

- Shahjalal University of Science and Technology, Sylhet: Lab ReportDocument4 pagesShahjalal University of Science and Technology, Sylhet: Lab ReportatikulNo ratings yet

- Department of Chemical Engineering: (An Autonomous Institution Affiliated To JNTUK, AP)Document6 pagesDepartment of Chemical Engineering: (An Autonomous Institution Affiliated To JNTUK, AP)sagarNo ratings yet

- Santosh G Kelshekar - AssortedDocument10 pagesSantosh G Kelshekar - AssortedscemanjuNo ratings yet

- Centrifugal PumpsDocument5 pagesCentrifugal PumpsWaleed NasirNo ratings yet

- Accurately Calculate Nitrogen RequirementDocument6 pagesAccurately Calculate Nitrogen RequirementRachel BaileyNo ratings yet

- Case Studies PDFDocument12 pagesCase Studies PDFDhruv BajpaiNo ratings yet

- Compressor Station (Specification 98A)Document2 pagesCompressor Station (Specification 98A)Gloria HamiltonNo ratings yet

- Hydro Test ProcedureDocument10 pagesHydro Test Proceduresamer8saifNo ratings yet

- Relief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsDocument1 pageRelief Valves For Centrifugal Pumps According To NFPA 20 - Fire Protection SpecialistsMohamed Abou El hassanNo ratings yet

- Ata 35Document38 pagesAta 35Geovanni Riquelme LooNo ratings yet

- Food Processing - Evaporation Elevates Boiling PointsDocument2 pagesFood Processing - Evaporation Elevates Boiling PointsharshitNo ratings yet

- IB Phys6tr 3 Resources Prac5Document3 pagesIB Phys6tr 3 Resources Prac5Vincent TiaraNo ratings yet

- Steering System: Systems OperationDocument7 pagesSteering System: Systems Operationallan lariosaNo ratings yet

- Final - District Cooling System Design MENA - July2021Document220 pagesFinal - District Cooling System Design MENA - July2021Mubashir KhanNo ratings yet

- BB831 Xa04xen E1 PDFDocument68 pagesBB831 Xa04xen E1 PDFDaniel RamirezNo ratings yet

- Ultima XL XTDocument4 pagesUltima XL XTRICHINo ratings yet

- Pump Primer 2 AssDocument33 pagesPump Primer 2 AssGkou DojkuNo ratings yet

- LMI Series AA-B-C-E-J-P Metering Pumps ManualDocument44 pagesLMI Series AA-B-C-E-J-P Metering Pumps ManualShesharam ChouhanNo ratings yet